- 2 -

The unit is shipped with plastic wedges installed under the

compressors. Ensure these wedges are removed from the

compressor feet prior to starting the unit

(not required for operation).

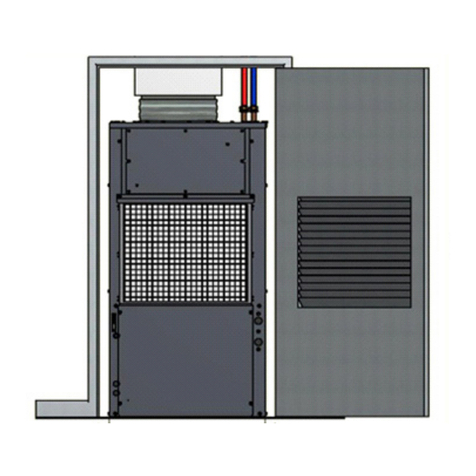

2.4 Economiser/Fresh Air Inlet Option

The Economiser/Fresh Air Inlet cowl is supplied separately

and must be tted to the unit – after the unit is lifted in to

place. Screws and pre-drilled holes are provided. Ensure

the top of the cowl is tucked under the roof lip of the air

conditioner and that all joints are sealed with silicon sealant.

There must be at least 300mm clearance beneath the cowl

once it is tted in place.

2.5 Spill Air Option

Spill Air cowl is supplied separately and must be tted to the

unit – after the unit is lifted in to place. The Spill Air cowl ts

below the Fresh Air cowl. Screws and pre-drilled holes are

provided. There must be at least 300mm clearance beneath

the cowl once it is tted in place.

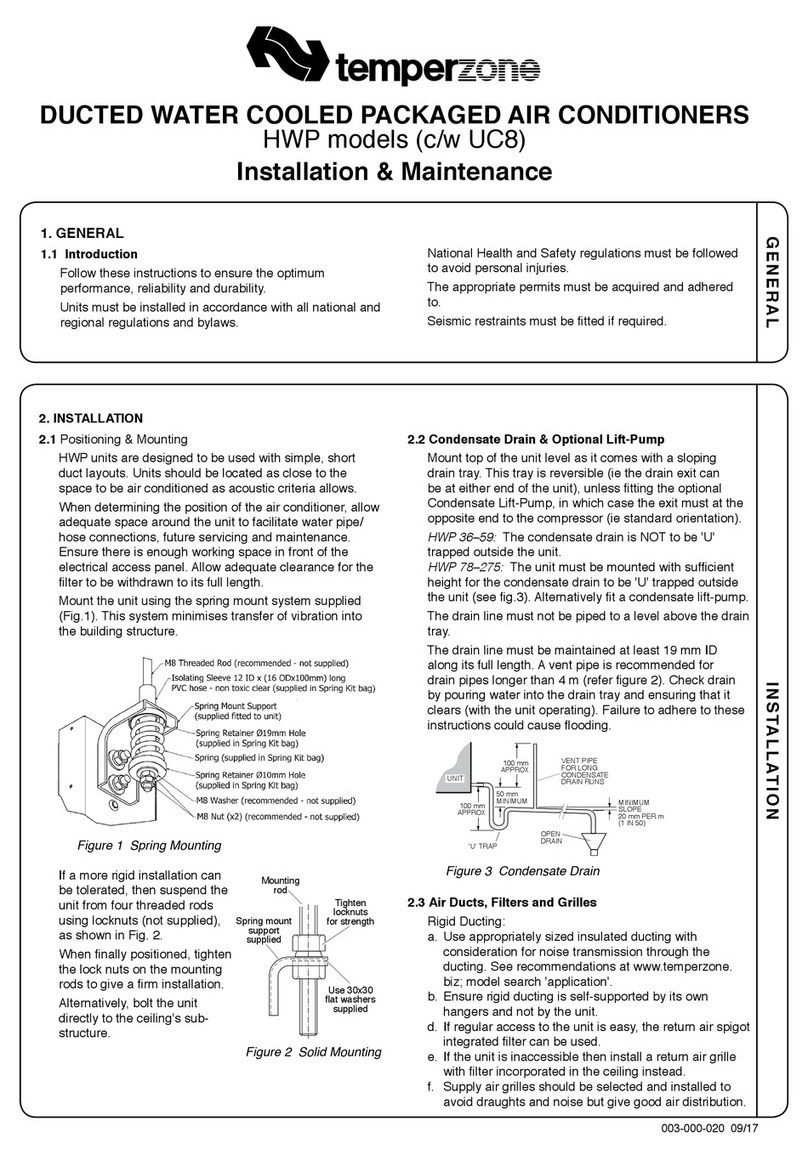

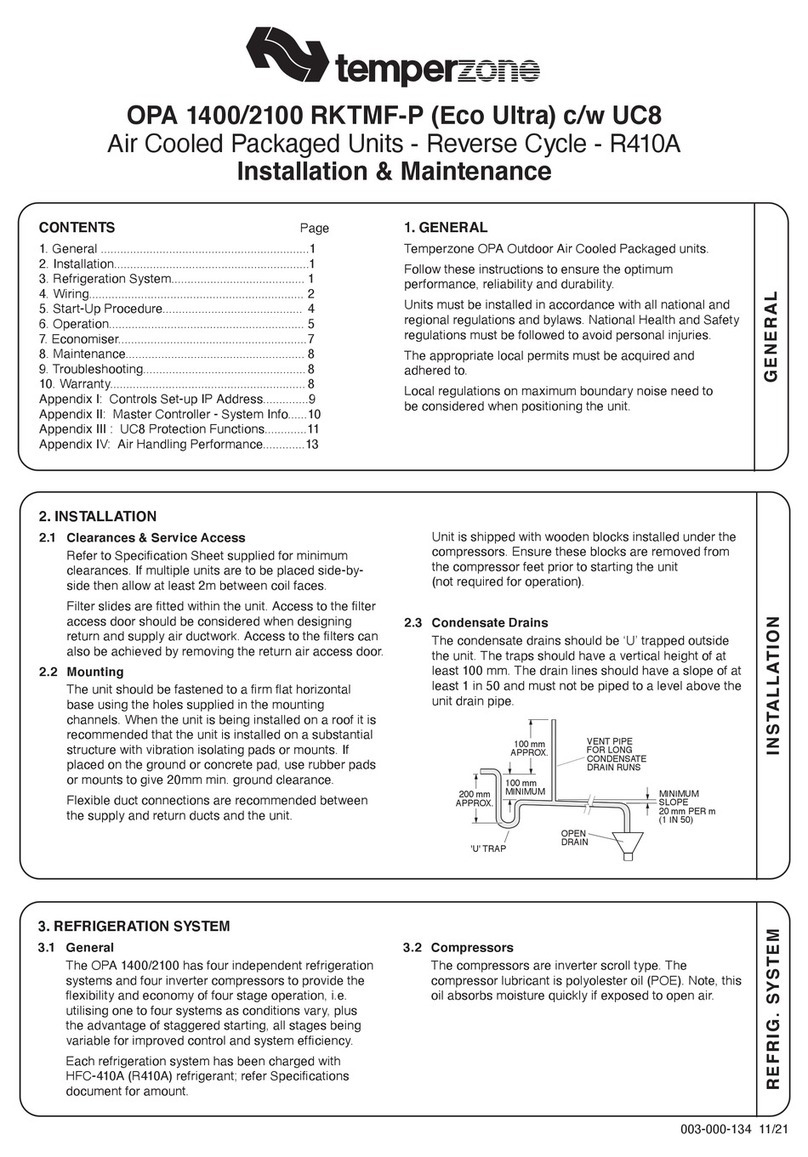

2.6 Condensate Drains

The condensate drains should be ‘U’ trapped outside the

unit. The traps should have a vertical height of at least 100

mm. The drain lines should have a slope of at least 1 in 50

and must not be piped to a level above the unit drain pipe.

OPEN

DRAIN

MINIMUM

SLOPE

20 mm PER m

(1 IN 50)

100 mm

MINIMUM

200 mm

APPROX.

'U' TRAP

100 mm

APPROX.

VENT PIPE

FOR LONG

CONDENSATE

DRAIN RUNS

3. REFRIGERATION SYSTEM

3.1 General

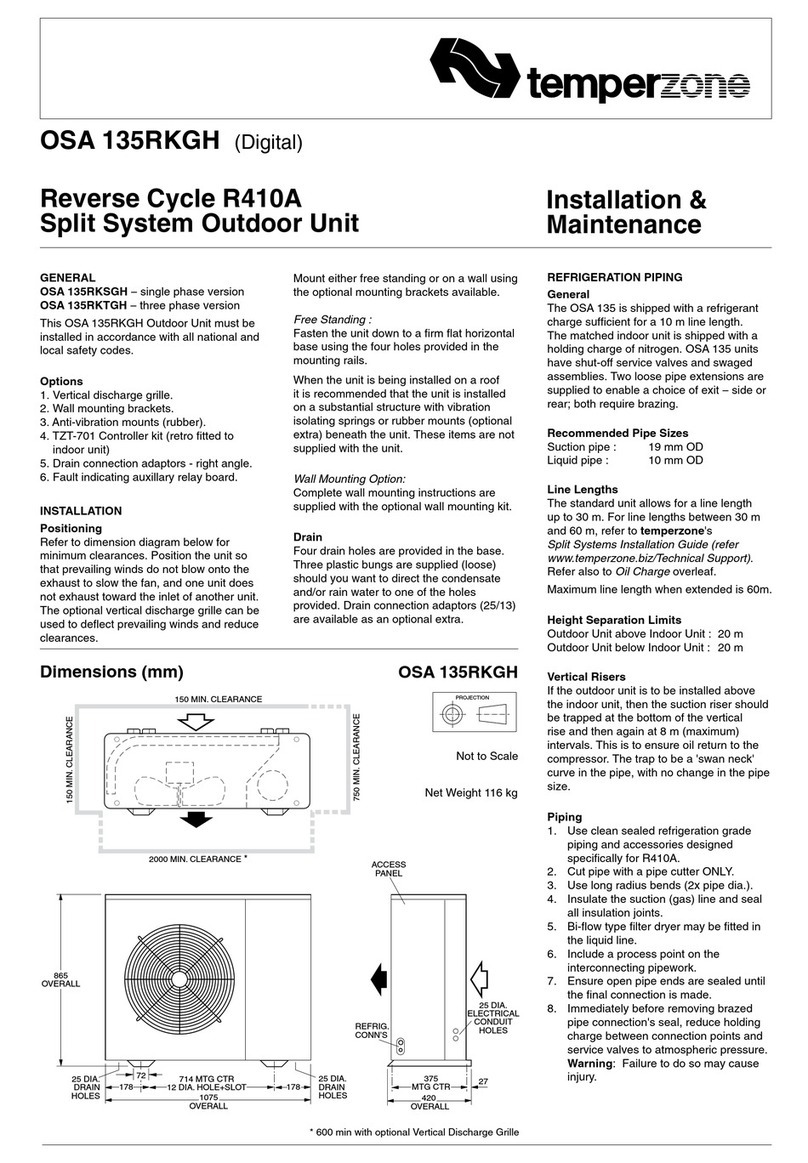

Each OPA 1410/2110 has four refrigeration systems – one

with a variable speed inverter compressor; the remaining

three are xed speed compressors.

Each refrigeration system has been charged with R32

refrigerant; refer Specications document for amount.

3.2 Compressors

The compressors are inverter and xed speed scroll

type. The compressor lubricant is POE-46 (NXG5020

or equivalent). Note, this oil absorbs moisture quickly if

exposed to open air.

4. WIRING

4.1 Electrical Requirements

Electrical work must be done by a qualied electrician

and

meet standard AS/NZS 3000.

!

DANGER! LIVE ELECTRICAL CONNECTIONS. ISOLATE MAINS

POWER BEFORE WORKING ON UNIT. ONLY QUALIFIED PERSONS

WHO ARE COMPETENTLY TRAINED SHOULD PERFORM SERVICE AND

MAINTENANCE TASKS.

The unit must be wired directly from a distribution board

using an appropriately sized circuit breaker. The termination

point for the mains cable is in the electrical compartment. An

isolating switch is required, near but not on the unit.

Refer Appendix III (p.8) for cable entry hole locations and

recommended wiring paths.

4.2 Control options

OPA Econex units can be controlled using any of the

following options:

• TZT-100 wall thermostat

• 24V AC and 0-10V signals from an external controller or

thermostat

• Remote on/off switch and/or time clock

• Modbus RTU serial communications over RS485

connection

• BACnet-IP serial communications over Ethernet

connection (with optional gateway module)

Standard reverse cycle units are suitable for use with

thermostats and controls with manual heating/cooling

selection or automatic change-over.

A unit wiring diagram is supplied alongside the electrical

board and in the Specications document.

4.3 TZT-100 wall thermostat

To connect the thermostat to the unit, use 4 core shielded

twisted pair type cable, suitable for RS485 communications.

(p/n 201-000-399). Signals A & B should form one twisted

pair.

Connect the thermostat as follows:

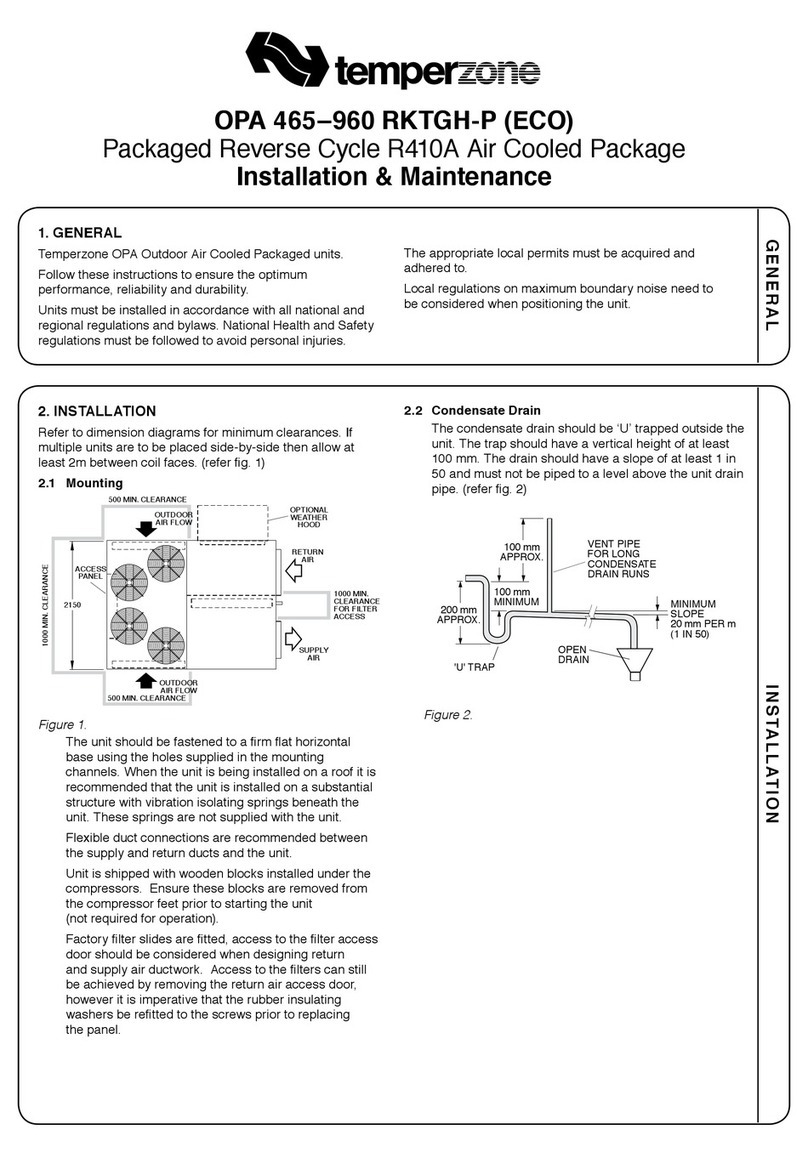

Drawn:

Apprvd:

Title: Drawing No: Rev:

Date:

©temperzone Ltd 2023 DO NOT

SCALE - ASK

Client Wiring

SHEET OF

For Client Wiring to Terminal Blocks & Descriptions, Refer Sheet 5

5

5

A

291-003-468

Wiring Schematic

OPA1410 / 1710 / 2110RLTM1FPQ-S1 R32 UC8

L.C 03-03-22

Sensor(S) / Transducers (T) to UC8

Name Type Colour

DL Discharge SGrey

SL Suction SWhite

AMB Ambient SBlack

DEI Deice SBlue

LPT Suction Pressure T Grey

HPT High Pressure TGrey

IFM

1

IFM

2

IFM

3

IFM

4

System 1

Compressor

System 4

Compressor

System 2

Compressor

System 3

Compressor

Indoor Coil Layout

OD Coil Sys 1 OD Coil Sys 2

OD Coil Sys 4 OD Coil Sys 3

OFM

2

CMM

1

Overall System Layout

OFM

3

CMM

2

CMM

3

CMM

4

OFM

1

OFM

4

TO / FROM CUSTOMER'S

SUPPLY / CONTROL

Client Wiring

Client External Protection and Isolator

Switch

Client Wiring

COMPRESSOR UC8 DIP SWITCHES

ON

SYS 1 INVERTER 1, 4, 6, 7, 10, 14

SYS 2 FIXED CAPACITY 1, 4, 6, 7, 10, 11, 14

SYS 3 FIXED CAPACITY 1, 4, 6, 7, 10, 12, 14

SYS 4 FIXED CAPACITY 1, 4, 6, 7, 10, 11, 12, 14

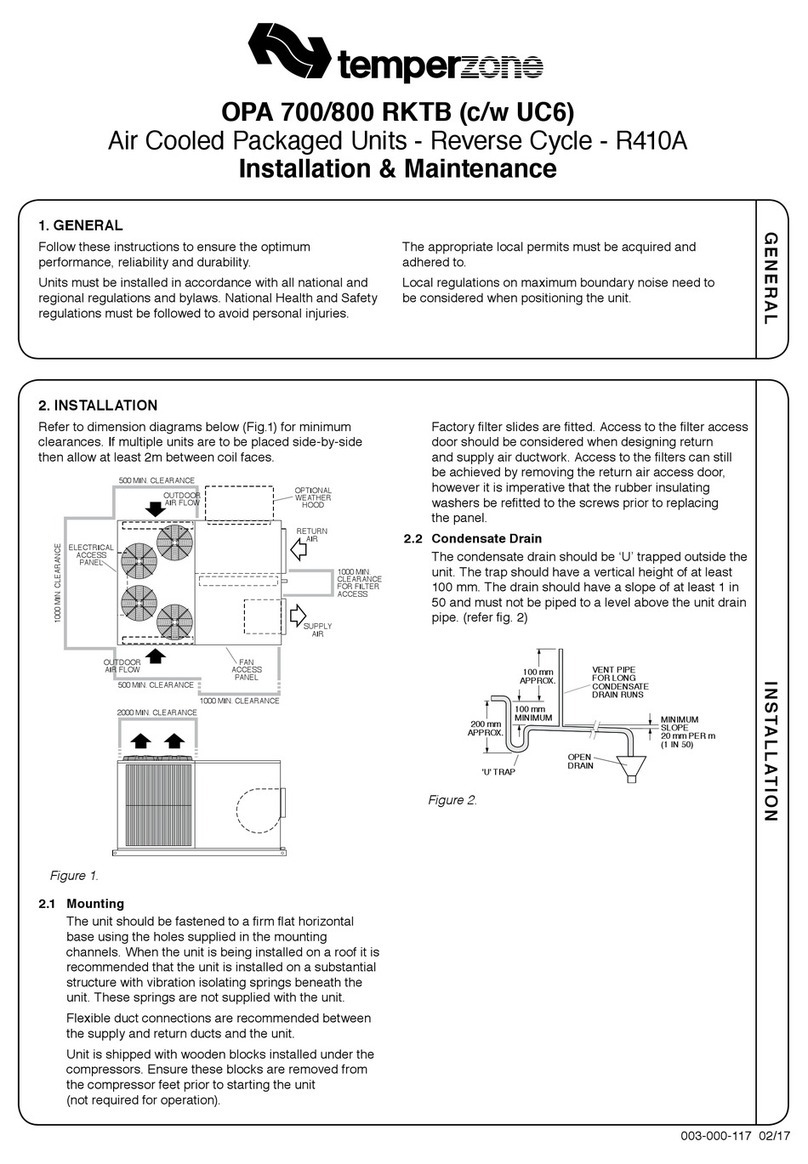

24VCB 24 Volt Circuit Breaker

CBL Cable Marker

CCB Control Circuit Breaker

CCH Crankcase Heater

CMC Compressor Contactor

CMCB Compressor Circuit Breaker

CMM Compressor Motor

CMOL Compressor Overload

CR Control Relay

DMF Damper Motor Fresh Air

DMR Damper Motor Return Air

DMS Damper Motor Spill Air

EEV Electronic Expansion Valve

EMIFB Electromagnetic Interference Filter Board

ETH Earth

FRB Fault Relay Board

HPT High Pressure Transducer

IBB Insulated Bus Bar

IFCB Indoor Fan Circuit Breaker

IFM Indoor Fan Motor

LPT Low Pressure Transducer

MTB Main Terminal Block

OFCB Outdoor Fan Circuit Breaker

OFM Outdoor Fan Motor

PCLP P CLIP

PLR Phase Loss Relay

RV Reversing Valve

SCB Socket Circuit Breaker

SPS Single Phase Socket

TB Terminal Block

TR Transformer

TJ3W Terminal Junction 3 Way

UC8 Unit Controller 8

VSD Variable Speed Drive

VSDCB Variable Speed Drive Circuit Breaker

VSD DIP switch settings

DIP switch On/Off

1,4 On

2,3 Off

MTB

L2

L3

MTB

L1

MTB

N

If Remote On/Off option

fitted remove this link

COMP 1

COMP 2

COMP 3

COMP 4

TB20 DMF

TB19 FLT

C

TB18 FLT

TB22 DMR

TB26 COMP

1

TB33

CAP IN

0-10

TB34

CAP IN

0V

TB27 COMP

2

TB28 COMP

3

TB29 COMP

4

Ferrites

Part Number Frequency Type Number of Turns

A 012-001-074 High 1

Modbus Devices Address

UC8 44, 45, 46, 47

VSD 10

TB35

FAN IN

0-10

TB36

FAN IN

0V

TB31 COM

TB37 ON

TB38 0V

ON

24 Hour power required (on

L1) for control circuit and

crankcase heaters

Important Notes:

Portable RCD shall be used

with single phase socket.

TB24 DMS

TB25 DMS

U

TB32 COM

TB30 HEAT

HEAT

0-10VDC

24VAC /

12VDC

Phase Loss Relay

·PWR (Green) Indicator

lits when power is being

supplied .

·RY (Yellow) Indicator lits

when relay is operating.

0VAC / DC

0VDC

0-10VDC

0-10VDC

0VDC

TB47B

TB47T A1.2

TB47M B1.2

To BMS

Client BMS Input

Connect cable screen

to 'EARTH' terminal

TZT-100

24 24C B A T T

TB47B

TB47T A1.2

TB47M B1.2

TB51T 12V

Connect cable screen

to 'EARTH' terminal

TZT-100 (Optional) Connection

TB39

LOW

IN

TB40

MED

IN

TB41

HIGH

IN

LOW

MED

HIGH

24VAC /

12VDC

A

B

CD

E

+

Start Time = E

A

B

CD

E

+

Initial Voltage = A

Stop Time = E

A

B

CD

E

+

Temperzone Soft Starter

Default Settings

Instructions To Convert To Master-Master Control

1) Turn off power to entire system.

2) Turn off the following dip switches for system 2, system 3 and

system 4 fixed speed UC8 control.

·UC8 System 2 - dip switch 11

·UC8 System 3 - dip switch 12

·UC8 System 4 - dip switch 11 and 12

3) Move the jumper between terminal blocks TB46T and TB47T to

between TB47T and TB48T (refer to sheet 3).

4) Move the jumper between terminal blocks TB46M and TB47M to

between TB47M and TB48M (refer to sheet 3).

5) Turn power back on.

6) Check UC8 System 2 address is set as 45, UC8 System 3 address

is set as 46 and UC8 System 4 address is set as 47. If the address

is wrong, it needs to be changed.

TB53 OFFC

TB52 OFF1

TB58 IFFC

TB57 IFF1

Voltage Free

Contact

Use £ 24V/1A, not 230V

TB21 DMF

U

TB23 DMR

U

Voltage Free

Contact

Use £ 24V/1A, not 230V

Voltage Free

Contact

Use £ 24V/1A, not 230V

REV MODIFICATION DATE ECN APVD

AInitial Release LC

0V UC8 Enable Link Common

12V RS485 12V Supply Output

24V 24VAC Internal Supply

24V COM 24VAC Internal Supply Common

ACT 230VAC Active Supply

Ax.x RS485 A (+) Communication Signal

Bx.x RS485 B (-) Communication Signal

CAP IN 0-10 Compressor Capacity 0-10VDC Analogue Speed Control

CAP IN 0V Compressor Capacity Analogue Speed Control Common

COM UC8 Control Input Signals Common

COMP Compressor ON / OFF Signal

DMF Damper Motor Fresh Air 0-10VDC Command

DMF U Damper Motor Fresh Air 0-10VDC Feedback

DMR Damper Motor Return Air 0-10VDC Command

DMR U Damper Motor Return Air 0-10VDC Feedback

DMS Damper Motor Spill Air 0-10VDC Command

DMS U Damper Motor Spill Air 0-10VDC Feedback

FAN IN 0-10 Indoor Fan 0-10VDC Analogue Speed Control

FAN IN 0V Indoor Fan Analogue Speed Control Common

FLT UC8 Fault Relay Output Normally Closed Contact

FLT C UC8 Fault Relay Output Common Contact

HEAT Cooling / Heating Mode Selection Signal

HIGH IN Indoor Fan Fixed High Speed Control Signal Input

ID FAN 0-10 Indoor Fan 0-10VDC Analogue Speed Control

ID FAN GND Indoor Fan Analogue Speed Control Ground

IFF Indoor Fan Fault Relay Contact Signal

IFFC Indoor Fan Fault Relay Common

LOW IN Indoor Fan Fixed Low Speed Control Signal Input

MED IN Indoor Fan Fixed Medium Speed Control Signal Input

N Neutral

OFF Outdoor Fan Fault Relay Contact Signal

OFFC Outdoor Fan Fault Relay Common

ON UC8 Enable Link Contact

Note: Capacity Staging. A TZT-100 must be congured for

single-stage operation, the default setting.

TZT-100 has its own DIP switches that must be set as

follows:

DIP switch 2 ON Equipment type = Heat Pump

DIP switch 3 OFF Equipment stages = One

DIP switch 4 ON Reverse cycle valve on = Heating

4.4 Communications format for TZT-100

Communications format must be set as per recommended

Modbus RTU:

• Baud rate (bd or br) 19200

• Data bits 8

• Parity Even

• Stop bits (Pa) 1

• TZT-100 address (Ad) 7

The procedure to check and adjust these settings is:

1. Press and hold the O/RIDE button until the display

shows the PIN

2. Use the UP & DOWN buttons to select PIN code 88:21,

then press O/RIDE in installer mode.

3. Use the O/RIDE and PROG buttons to cycle through the

various installer settings.

If necessary, refer TZT-100 User Manual for more detail.

4.5 Remote on/off

The UC8 has an input for a remote on/off function on

terminal ‘On’, signal return is terminal ‘0V’. When used, the

remote on/off terminals should connect to a voltage-free

relay contact. When not used, the remote on/off terminals

should be shorted (‘bridged’).