Tempest Leader SMOKE 3 User manual

1

2

3

Product references

R20.00.113

LEADER Smoke 3 600 m³ per minute-220 v-50/60 Hz

R20.00.114

LEADER Smoke 5 1320 m³ per minute-220 v-50/60 Hz

R20.00.115

LEADER Smoke 3 600 m³ per minute-115 v-50/60 Hz

R20.00.116

LEADER Smoke 5 1320 m³ per minute-115 v-60 Hz

4

1INTRODUCTION ...........................................................................................................................................5

2SAFETY INFORMATION..............................................................................................................................5

3TECHNICAL SPECIFICATIONS ..................................................................................................................8

4PRODUCT DETAILS ...................................................................................................................................10

5QUICK START .............................................................................................................................................11

5.1 Setting up .......................................................................................................................................................11

5.2 Making fog.....................................................................................................................................................11

6INSTALLATION AND SETTING UP.........................................................................................................12

6.1 Location .........................................................................................................................................................12

7AC POWER...................................................................................................................................................12

7.1 Setting up .......................................................................................................................................................13

7.2 Final checks....................................................................................................................................................13

7.3 Turning on the power.....................................................................................................................................13

8CONTROL SETTINGS ...............................................................................................................................14

8.1 Overview........................................................................................................................................................14

8.2 Setting smoke output level...........................................................................................................................14

8.3 Setting continuous operation..........................................................................................................................15

8.4 Setting the Timer............................................................................................................................................15

8.5 Resetting the machine after fluid out.............................................................................................................16

8.6 Auxiliary input...............................................................................................................................................16

9APPROVED FOG FLUID TYPES................................................................................................................17

10 BASIC SERVICE ..........................................................................................................................................18

10.1Cleaning.........................................................................................................................................................18

10.2Fuse replacement............................................................................................................................................18

11 TROUBLESHOOTING.................................................................................................................................19

12 Status messages..............................................................................................................................................19

13 WARRANTY.................................................................................................................................................22

5

1INTRODUCTION

The LEADER Smoke 3 and 5 from LEADER provide a versatile and convenient solution for fire

training. It can produce a variety of effects from and optically translucent haze to a dense ‘white out’

that very effectively simulates dense smoke for realistic firefighter training to a wide range of fog

requirements whether permanently installed or taken on the road.

The units have been designed to cope with the rigors of training with a tough out casing and rugged

water-resistant design.

The units are controlled using an advanced control panel with LCD screen can be operated on

the machine or removed and used as a remote controller. They also have an auxiliary input to allow

remote control

devices to be used with the product for maximum flexibility.

2SAFETY INFORMATION

LEADER Smoke 3 and LEADER SMOKE 5

Read the safety precautions in this manual before installing, operating or servicing

this product.

The following symbols are used to identify important safety information:

Warning! This product is not for household use. It presents risks of injury due to

electric shock, burns, falls and respiratory problems!

Read this manual before operating the machine, follow the safety precautions listed below,

and observe all warnings in this manual and printed on the machine. Use the machine only

as described in this manual and in accordance with local laws and regulations.

If you have questions about how to operate the machine safely, or if you have followed

the instructions in this manual and the machine is malfunctioning, please contact LEADER.

Danger!

Hazardous voltage.

Contact will cause electric

shock.

Danger!

Safety hazard. Risk

of personal injury

Caution!

Burn hazard.

Hot surface.

Do not touch.

Caution!

Fire hazard.

6

Preventing electric shocks

•Always ground (earth) the machine electrically.

•Use only a source of AC power that complies with local building and electrical codes,

and that has both overload and ground-fault protection.

•Before connecting the machine to power, check that the voltage indicated on the

machine’s serial label matches your local AC power

voltage. If your AC power voltage does not match, do not use the machine.

Contact LEADER for assistance.

•Before using the machine, that all power distribution equipment and cables are in

perfect condition and rated for the current requirements of all connected devices.

•If the machine or any cables connected to it are in any way damaged, defective, wet, or

show signs of overheating, stop using the machine and contact LEADER for assistance.

If the supply cord is damaged, it must be replaced by a special cord or assembly

available

from the manufacturer.

•Disconnect the machine from AC power before servicing and when not in use.

•This machine is water-resistant but not totally waterproof. Do not immerse in water or

any other liquid. Do not expose to high-pressure water jets.

•Do not spill fluid over or inside the machine. If fluid is spilled, disconnect AC power

and clean with a damp cloth. If fluid is spilled on to electronic parts, take the machine

out of service and contact LEADER for advice.

•Do not remove the covers or attempt to repair a faulty machine. Refer any service not

described in this manual to LEADER.

•Do not operate the machine if any parts are damaged, defective or missing.

•Moisture and electricity do not mix. Do not aim fog output at electrical connections or

devices.

Preventing burns and fire

•The fog produced by the machine is hot enough to cause burns when it leaves the

nozzle, and very hot droplets of fluid escape occasionally.

Keep people and objects at least 600 mm (24 in.) away from the fog output nozzle.

•Do not touch the fog output nozzle during or after use –it becomes extremely hot and

remains hot for several hours after the machine has been shut down.

•Do not attempt to bypass thermostatic switches, fluid sensors or fuses.

•Replace fuses only with ones of the type and rating specified in this manual for the

machine.

•Provide a minimum free space of 100 mm (4 in.) around the machine.

•Provide a minimum free space of 500 mm (20 in.) around fans and air vents and ensure

free and unobstructed air flow to and around the machine.

•Keep the machine at least 600 mm (24 in.) away from combustible and heat-sensitive

materials.

•Do not operate the machine if the ambient temperature (Ta) is below 5° C (41° F) or

above 40° C (104° F).

•Do not operate the machine if the relative air humidity exceeds 80%.

•Do not recycle dense smoke into the machine.

7

Preventing injuries

•Ensure that any surface on which the machine is installed can safely hold the weight of

the machine.

•Suspending the machine directly over peoples heads is not recommended. Use smoke

ducting instead.

•Do not point the smoke output directly at a person’s face or at face height.

•Do not operate the machine with missing or damaged covers or shields.

•In the event of an operating problem, stop using the machine immediately and

disconnect it from power. Do not attempt to use a machine that is obviously damaged.

•Do not modify the machine in any way not described in this manual or install other than

genuine LEADER parts.

•Refer any service operation not described in this manual to a qualified technician.

•Fog output can cause condensation. Do not point the output at smooth floors. Floors and

surfaces may become slippery. Check these frequently and wipe dry as necessary to

avoid any danger of slipping.

•Fog fluid contains food-grade glycols in solution but may present health risks if

swallowed. Do not drink it. Store it securely. If eye contact occurs, rinse with water.

If fluid is swallowed, give water and obtain medical advice.

•This appliance is not intended for use by persons (including children) with reduced

physical sensory or mental capabilities, or lack of experience and knowledge.

Preventing breathing problems

•A machine can operate safely only with the fog fluid it is designed for.

Use the machine only with fluids specified under “Approved fluid types” on page 16 or

you may cause the release of toxic gases, presenting a severe health hazard. You will

also probably damage the machine.

8

3TECHNICAL SPECIFICATIONS

All dimensions are in millimetres.

▪Robust water resistant design.

▪Integrated digital remote control.

▪Continuous micro-processor controlled output.

▪Two fluid options for different applications.

▪Soft start technology.

▪Fluid sensing system.

▪Easy external fluid hook-up.

▪Optional ducting kits.

Use only an approved LEADER fog fluid as shown on page 16.

Use of other fluid will void warranty.

▪Physical

LEADER Smoke 3

LEADER Smoke 5

Length

485 mm (19.1 in)

602 mm (23.1 in)

Width

335 mm (13.2 in)

395 mm (15.6 in)

Height

242 mm (9.6 in)

306 mm (12.1 in)

Weight.dry

11.2 Kg (24.7 ib)

17.7 Kg (39.1 ib)

Weight.filled

13.5 Kg (30.2 ib)

22.7 Kg (50.0 ib)

9

▪Performance

LEADER Smoke 3

LEADER Smoke 5

Coverage volume

660 m³ per minute

1320 m³ per minute

Fluid consumption (max)

88 ml per minute

176 ml per minute

Continuous effect output Ready time

7 minutes*

10 minutes*

*Please not the 110V units may take approximately 10% longer to reach their ready temperature.

▪Control and programming

LEADER Smoke 3

LEADER Smoke 5

Control options

Integrated digital remote control

Control parameters

Continuous or timer-controlled output

Fog

Variable output control, 0-100%

▪Structure

LEADER Smoke 3

LEADER Smoke 5

Housing

Steel and Aluminium

Colour

Yellow

Heat exchanger

1150w (thermally protected)

2000w (thermally protected)

Fluid pump

Oscillating piston, high pressure

Fluid management

Fluid out sensing, sealed for transportation

Fluid reservoir

2,5 L drop-in reservoir with

quick-connect fitting

5 L drop-in reservoir with

quick-connect fitting

External fluid control

Fluid sensing

Remote control

Integrated digital remote with 3 m cable, 3-pin XLR

▪Installation

LEADER Smoke 3

LEADER Smoke 5

Mounting

Standing

Clearance around machine

100 mm (4 in)

Orientation

Up to +/- 40° from horizontal

▪Connections

LEADER Smoke 3

LEADER Smoke 5

Remote control

3-pin locking XLR

Flimware

AVR socket

▪Electrical

LEADER Smoke 3

LEADER Smoke 5

Ac power

220 v-50/60 Hz

115 v-60 Hz

220 v-50/60 Hz

115 v-60 Hz

Current

5.3 A

8.75 A

9.2 A

15 A

Power

1200 w

1050 w

2100 w

1800 w

Main fuse

6.3 AT (slow-blow)

10 AT (slow-blow)

12.5 AT (slow-blow)

20 AT (slow-blow)

▪Thermal

LEADER Smoke 3

LEADER Smoke 5

Maximum ambient temperature (Ta max)

40° C (104° F)

Exterior surface temperature

Etat stable à 20° C (32° F), température ambiante 30° C (86° F)

Max nozzle temperature

290° C (554° F)

Minimum ambient temperature (Ta min)

5° C (41° F)

10

▪Approvals

EU Model

LEADER Smoke 3

LEADER Smoke 5

EU Safety

EN 60 335-1+A15, EN62233

EU EMC

EN 61000-6-3

EU Immunity

EN 61000-6-1

Australia/NZ (pending)

RCM

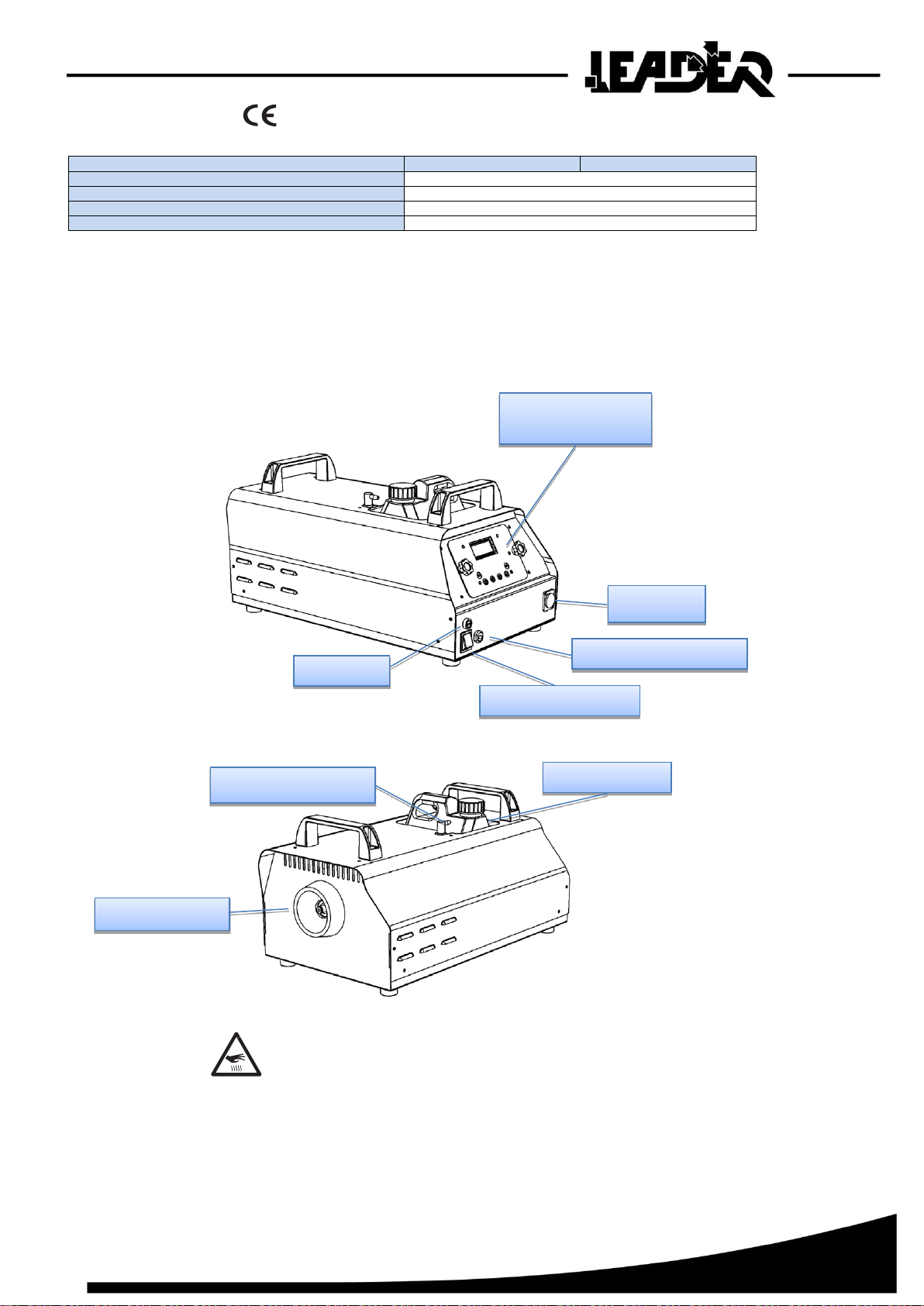

4PRODUCT DETAILS

LEADER Smoke 3 / LEADER Smoke 5

Warning!

High temperature vapour and surfaces

Fluid pipe connection

Fluid container

Integrated digital

remote control

Mains fuse

AUX input

Mains power switch

Mains power connector

Fog output nozzle

11

5QUICK START

If you are familiar with this type of product, this section will help to get you started quickly.

However, please also make the time to read the safety and servicing instructions in the remainder

of this manual.

5.1 Setting up

Locate the machine in a suitable area with nothing in front of the fog output.

Install approved LEADER fog fluid as shown on page 16.

Connect the machine to a suitably rated power source. The power requirements are:

LEADER Smoke 3 1200 W, 5.3 A / 240 V (EU)

1050 W, 8.75 A / 110 V

LEADER Smoke 5 2100 W, 9.2 A / 240 V (EU)

1800 W, 15 A / 110 V

Now set the mains switch on the rear of the unit, to the ‘ON’ (I) position.

The display will show HEAT.

After about 6-8 minutes the display should show READY and the current programmed

output level %.

5.2 Making fog

If you want to adjust the fog output level press the output up/down buttons

until the display shows the desired output level.

Press the Smoke button to begin fog production.

The unit will continue to produce fog until the button is pressed again or the fluid supply is

depleted

(whichever is sooner).

If no fog is produced the first time the unit is fired after a fluid out, it may be necessary to

prime the machine. Program the output to maximum power and fire the machine until fog

is emitted.

HEAT

READY 00%

12

6INSTALLATION AND SETTING UP

DANGER! DO NOT operate the machine until you have read and observed all

the precautions listed under “Safety information” on page 4.

6.1 Location

The Trainer LEADER range of machines are designed to be located on the floor or any

surface suitable to support their weight. The machine can operate in any orientation from 45

degrees upwards to 45 degrees downwards. Steeper tilting may cause fluid leakage.

Ensure that there is at least 100mm (4 in.) clearance all-round the machine and at least

600mm (24 in.) in front of the fog output.

7AC POWER

Before using the machine, ensure that a grounding-type (earthed) power plug that fits the

local power outlets is installed on the power cable provided.

DANGER! Make sure the power plug is correctly rated:

For UE LEADER Smoke 3 and LEADER Smoke 5 models use a plug rated at 10 A

minimum.

When installing the plug, follow the plug manufacturer’s instructions and connect pins

as follows:

Yellow and green wire to ground (earth), blue wire to neutral and brown wire to live.

The table below shows some common pin identification schemes.

Before connecting the machine to power, verify that the AC supply is adequately

dimensioned for the current draw of the machine.

LEADER Smoke 3 1200 W, 5.3 A / 240 V (EU)

1050 W, 8.75 A / 110 V

LEADER Smoke 5 2100 W, 9.2 A / 240 V (EU)

1800 W, 15 A / 110 V

Check that the local AC voltage is appropriate, as indicated on the machine’s serial number

label. If your AC voltage is outside the appropriate range, do not use the machine.

Contact LEADER for assistance.

Wire

Function

Marking

Screw colour

Brown

Live

« L »

Yellow or Brass

Blue

Neutral

« N »

Silver

Green/Yellow

Earth

Green

13

7.1 Setting up

Fill the fluid tank with an approved LEADER fluid as shownon page 16.

7.2 Final checks

Before applying power to the machine, verify the following:

•The machine is safely located or installed and meets the location requirements stated on

page 11.

•The operator is familiar with, and able to comply with, the requirements for safe operation

listed on page 4.

•The fluid is one of the Approved LEADER fluids listed under “Approved fluid types”

on page 16.

•The machine is electrically grounded (earthed).

•The AC power distribution circuits and lines are adequately rated for the current load.

7.3 Turning on the power

Set the mains switch on the rear of the unit, to the ‘ON’ (I) position.

The display will show HEAT.

When the display shows READY the unit is ready to produce smoke.

To obtain maximum output, wait another few minutes after the READY indication

is shown, as the machine continues to heat to full operating temperature and fog output is

reduced while the unit is heating up.

HEAT

READY 00%

READY 00%

14

8CONTROL SETTINGS

8.1 Overview

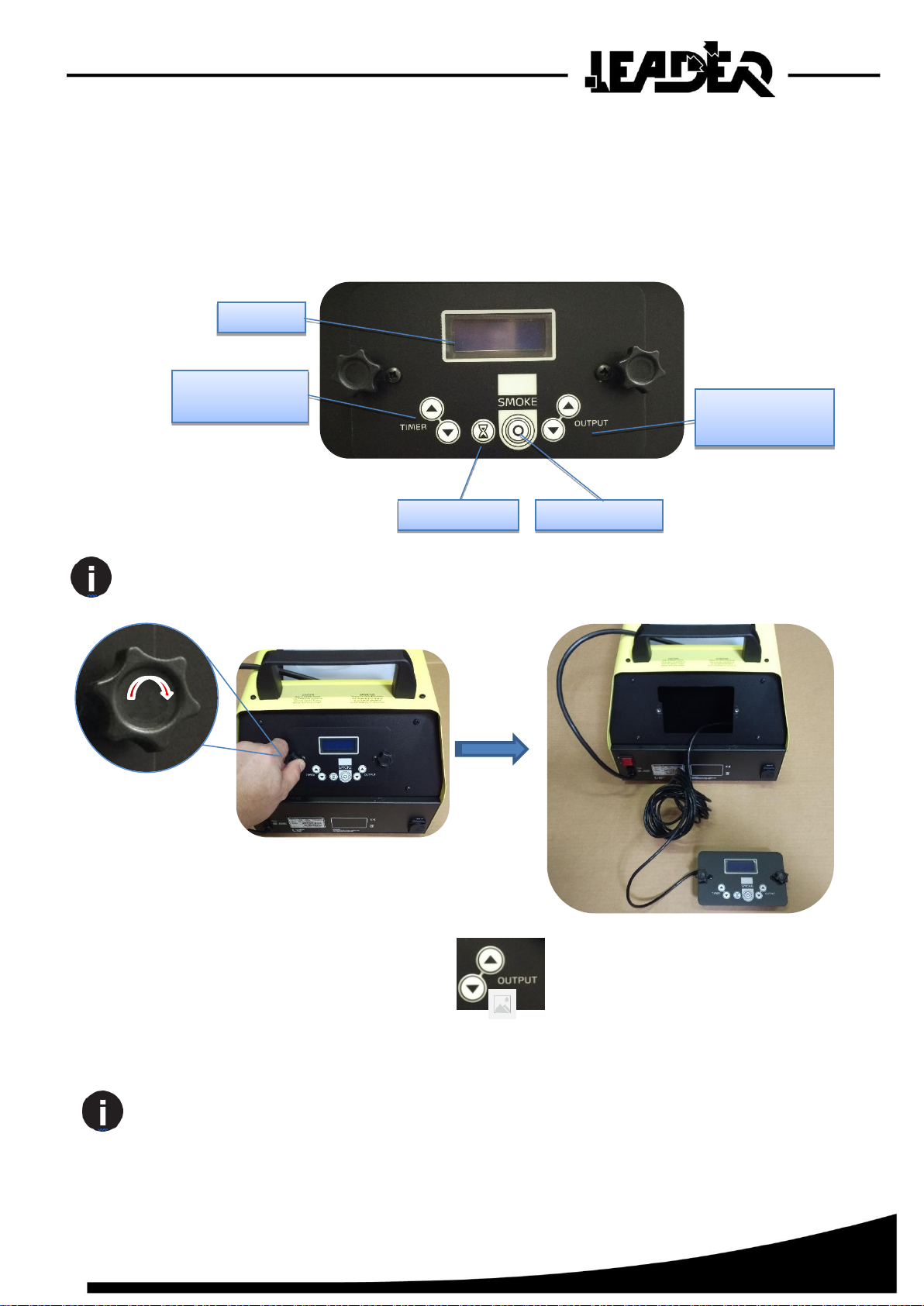

The integrated digital remote control on the rear of the machine allows you to configure it

using option menus.

The integrated digital remote control may be removed from the unit and used as a handheld

remote control by removing the two hand wheel bolts either side of the display.

8.2 Setting smoke output level

Use the output “UP” / “DOWN” buttons to select the desired output

performance. Once the value is selected it is automatically stored.

The machine will automatically default to standby at power up as opposed to resuming any

previous operational state.

Smoke Button

Display

Timer value

Up/Down buttons

Timer button

Output level

Up/Down buttons

15

8.3 Setting continuous operation

At power up the machine will automatically heat to its operating temperature.

When the operating temperature is reached the display will show “READY”.

To set continuous operation, adjust output level to desired value and press “SMOKE”

button.

Whilst the unit is producing smoke the screen will display “Continuous xx%”

to indicate its mode and output level.

The unit will continuously produce smoke until the “SMOKE” button is pressed

again or the fluid supply is exhausted (whichever is sooner).

8.4 Setting the Timer

Use the timer button to toggle between “runtime”

and “offtime”.

To enable the run timer function, set a non-zero value to the runtime using the timer

UP/DOWN buttons.

When runtime is zero the runtime is shown as “OFF” , indicating the

timers will not run.

To Select the off timer value, set a non-zero value to the offtime.

To engage the timer press the “SMOKE” button with a programmed runtime

value.

Whilst the unit is producing smoke the screen will display “Timer xx%”

to indicate its mode and output level.

The machine will begin a cycle of producing fog for the programmed runtime and stopping

production for the programmed offtime until the “SMOKE”

button is pressed again of the fluid supply is depleted (whichever is sooner).

READY 00%

CONTINUOUS 00%

FOG LEVEL 00%

RUN TIME 03

RUN TIME 00

RUN TIME

OFF

16

8.5 Resetting the machine after fluid out

If the machine runs out of fluid, it will automatically shut down and show FLUID OUT

on the display to prevent damage to the pump(s).

To reset this, fault down power the system and refill the fluid reservoir.

Avoid prolonged operation without fluid, since this will damage the pump and prevent

the machine from re-priming.

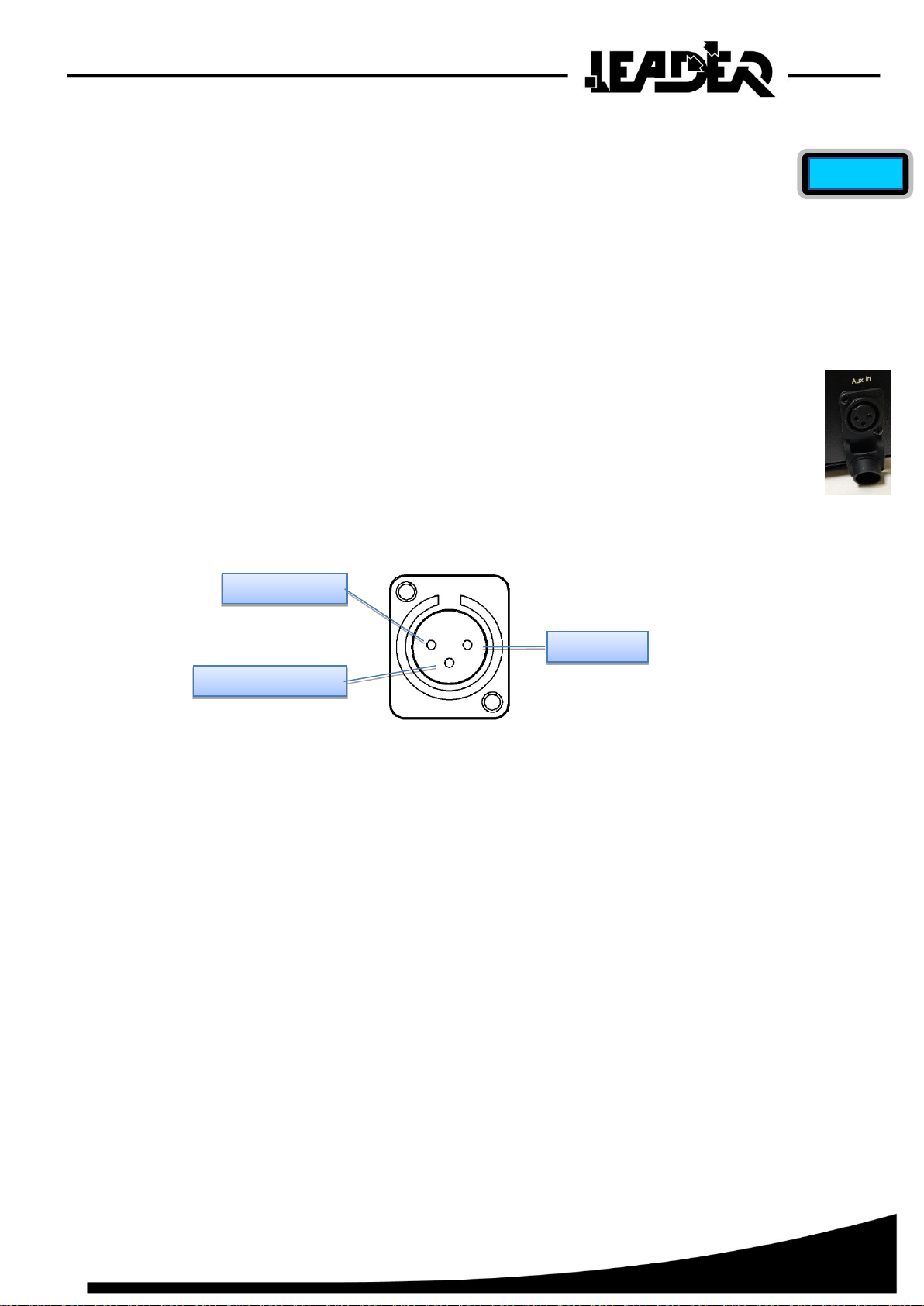

8.6 Auxiliary input

AN auxiliary input is provided for applications requiring an additional means of triggering

the machine other than the remote control.

The rear mounted XLR socket provides 12V DC at 50mA to power an interface device.

This can be used to trigger the machine using a clean contact closure.

The interface may also be used with a common 0-10V signal.

The input signal at pin 3 will trigger the machine operation when it is taken above 2V.

The operating level and mode (continuous or timer) will be taken from the current settings

on the remote, as will the output level.

FLUID OUT

Pin 1 ground

Pin 2 12V

Pin 3 0-10V input

17

9APPROVED FOG FLUID TYPES

The LEADER Smoke machines must only be used with the LEADER

fluids listed below. LEADER supplies high quality fog fluids

that are based on ultra-pure deionized water. No other fluid is suitable

for use.

Trainer Fluid (Medium)

This fluid is used in areas where shorter duration training exercises

occur and faster dispersal of the fog is required.

Trainer fluid (Heavy)

This fluid is used when maximum persistence is required or a very

heavy

density of fog is required to simulate a complete “white out”.

DANGER! The LEADER Smoke range machines can run safely only on the specific

fog fluids they are designed for. Use ONLY the LEADER fog fluids designated in this

manual. NEVER use any other type of fluid, or toxic gas may be produced. You will

probably also cause damage to the machine that will invalidate the product warranty.

Do not dilute fog fluid with water or any other liquid. Discard fog fluid if it becomes

contaminated.

18

10 BASIC SERVICE

Before servicing the Trainer machines, read and observe all the precautions listed in

“Safety information” on page 4. Any service not described in this section must be

carried out by a LEADER technician.

10.1 Cleaning

Excessive dust, fog fluid, and dirt build-up will degrade performance and cause overheating

and damage to the machine that is not covered by the product warranty. To maintain

adequate cooling, dust must be cleaned from the outer casing and air vents of the machine

periodically.

Isolate the machine from power and allow to cool completely before cleaning. The fog

output nozzles remain hot for a period after use.

•Remove dust from the air vents with a soft brush, cotton swab, vacuum, or compressed

air.

•Clean fog fluid residues from the fog output of the machine using a damp cloth.

•Clean the outer casing with a damp cloth only.

10.2 Fuse replacement

The main fuse for the machine is located adjacent to the power inlet on the rear panel.

There is also a T3.15 A fuse located on the electronics board inside the unit which

protects the supply to the pump.

DANGER! Disconnect the power supply before removing any covers orchanging fuses.

Live parts inside!

Rear panel fuse

LEADER Smoke 3: 6.3 AT (slow-blow), 250 V

10 AT (slow-blow), 110 V

LEADER Smoke 5: 12.5 AT (slow-blow), 250 V

20 AT (slow-blow), 110 V

Replace fuse only with one of exactly the same size and rating. Contact LEADER

if the fuse blows repeatedly.

To replace the internal fuse, disconnect the power cord from the supply, unscrew

the screws holding the top cover of the unit and remove the cover. The electronics

board is located in the side compartment.

19

11 TROUBLESHOOTING

12 Status messages

Problem

Probable cause(s)

Suggested remedy

Machine will not produce fog

when control panel set to

CONTINUOUS or fog button

pressed

Machine not at operating temperature

Wait until HEAT message no longer

shown

FOG option set to 0

Increase setting

Fog output is weak

Machine requires priming

Down power the unit, ensure the fluid

bottle is full and the tube is fully

inserted.

Wet, greasy, non-uniform fog

output, fluid drips or spits from

nozzle, or very loud noise when

firing machine

Incompatible fog flui

Use approved fluid!

Machine appears dead

Mains fuse blown

Replace fuse (page 17)

No power at AC cable inlet

Check power cable and circuit breaker

Loss of control from remote

Communication issue between remote and

machine

Check cable connection between

remote and machine

Message

Reason

HEAT

The unit is heating up to operating temperature.

READY

The heater is at operating temperature, but Fog is not turned on (RUN set to STANDBY).

FLUID OUT

Run out of fluid. Refill the fluid tank and then down power the machine to reset the fault.

CALIBRATION ERROR

The machine has detected an error with its calibration settings and will not operate.

Call LEADER for assistance.

SYSTEM ERROR

The machine has detected an error in the temperature sensor and will not

operate. Call LEADER for assistance.

COMM ERROR

Remote has lost communication with the machine and will not operate. Call LEADER for

assistance.

20

Notes

This manual suits for next models

5

Table of contents

Other Tempest Fog Machine manuals