Tempest Shadow Nightfall User manual

Nightfall

- 1 -

TABLE OF CONTENTS

Introduction .................................................................................................................................................................................2

Important Safeguards...........................................................................................................................................................2-4

Unpacking.....................................................................................................................................................................................5

Controls......................................................................................................................................................................................5-6

Setting Up .....................................................................................................................................................................................7

Fluid Setup ........................................................................................................................................................................7

Power Connections ........................................................................................................................................................7

Operating the Machine..................................................................................................................................................... 8-11

Powering On.....................................................................................................................................................................8

Heating ...............................................................................................................................................................................8

Control Options...............................................................................................................................................................8

Manual Control via the Detachable Remote Control Panel...................................................................8

Multi-Link .................................................................................................................................................................8

Using the Remote Control Panel ...............................................................................................................................8

Using Timers........................................................................................................................................................8-9

Using Multi-Link ..............................................................................................................................................................9

Changing Fluid ................................................................................................................................................................9

Running Dry......................................................................................................................................................... 10

Priming the System ........................................................................................................................................... 10

Powering Down............................................................................................................................................................ 10

Ducting Smoke......................................................................................................................................................................... 10

Troubleshooting ...................................................................................................................................................................... 11

Maintenance ............................................................................................................................................................................. 12

Exterior Cleaning.......................................................................................................................................................... 12

Maintaining the Heat Exchanger ........................................................................................................................... 12

Using the Air-Input Connection.................................................................................................................... 12

Storage and Shipment ............................................................................................................................................... 13

Specifications......................................................................................................................................................................13-14

Warranty ..................................................................................................................................................................................... 15

CE Certificate of Conformity................................................................................................................................................ 16

- 2 -

INTRODUCTION

Congratulations on your purchase of the Shadow Nightfall Smoke Machine. The Nightfall offers the

perfect balance of performance, reliability and affordability.

To ensure efficient and safe operation, please take a few moments to read this manual completely.

The Shadow Nightfall is a thermal aerosol generator designed for continuous, variable smoke output.

This machine is one part of a system, the other component being Rosco’s Smoke Simulation fluid. ALL

ROSCO FOG AND HAZE FLUIDS ARE UNIQUE WATER-BASED FORMULATIONS THAT CONTAIN NO PETRO-

LEUM DISTILLATES AND ARE SAFE WHEN USED ACCORDING TO INSTRUCTIONS.The operating tempera-

ture,pump pressure,and output nozzle of the Nightfall have been specifically designed and engineered

together to maximize the aerosolization of Rosco fog fluids.

Do not use any fluids in the Nightfall other than genuine Rosco Smoke Simulation Fluids as they have not

been tested for optimal performance and safety considerations. Doing so may damage the machine and will

void the warranty.

Note: The terms“fog,”“haze” and“smoke” are used interchangeably throughout this manual.Tempest Shadow

Smoke machines do not produce actual smoke, only a mist or aerosol.

Danger! Hazardous

voltage. Contact will

cause electric shock.

Caution! Safety

hazard. Risk of

personal injury.

Caution! Burn

hazard. Hot surface.

Do not touch

Caution! Fire hazard.

IMPORTANT SAFEGUARDS

READ AND UNDERSTAND THESE SAFETY PRECAUTIONS BEFORE OPERATING THE

MACHINE. FAILURE TO PROPERLY FOLLOW THESE PRECAUTIONS MAY LEAD TO A

FIRE, ELECTRICAL SHOCK, OR BURNS.

The following symbols are used to identify important safety information:

FOG FLUID HEALTH CAUTION:VAPOR FROM THIS FLUID, LIKE ANY OTHER COM-

MON MATERIAL IN A VAPORIZED STATE, MAY BE IRRITATING TO OR CAUSE

ALLERGIC SYMPTOMS IN SOME PERSONS WITH ALLERGENIC SENSITIVITY. DO

NOT EXPOSE AT CLOSE RANGE TO KNOWN ASTHMATICS.

- 3 -

Danger! Hazardous

voltage. Contact will

cause electric shock.

Caution! Safety

hazard. Risk of

personal injury.

Caution! Burn

hazard. Hot surface.

Do not touch

Caution! Fire hazard.

Danger! Hazardous

voltage. Contact will

cause electric shock.

Caution! Safety

hazard. Risk of

personal injury.

Caution! Burn

hazard. Hot surface.

Do not touch

Caution! Fire hazard.

Danger! Hazardous

voltage. Contact will

cause electric shock.

Caution! Safety

hazard. Risk of

personal injury.

Caution! Burn

hazard. Hot surface.

Do not touch

Caution! Fire hazard.

Preventing Electric Shock

• This machine uses electrical power at common commercially available voltages.

When directly contacted, such voltages are hazardous to human life. All precautions

commonly applicable to the use of electric power generally are applicable to the

use of this machine.

• This machine is designed to operate from three-wire power systems where one of the

wires is a safety ground. DO NOT disconnect the safety ground or use extension cords

or“cheater” plugs to connect this machine to a two-wire system. Operation without a

safety ground may result in a hazardous electrical shock.

• Check the current and voltage rating of your machine. Extension cords must be prop-

erly sized and rated for voltage, current and length. Check your local electrical code for

the correct gauge extension cord. If an extension cord shows signs of wear or gets

warm to the touch, discontinue its use and obtain a cord with a higher current rating.

Improper extension cords are not only hazardous, but may result in poor machine

performance due to excessive voltage drop.

• Never use any machine that shows signs of improper use.Even slight damage may be

an indication of a major problem. If the machine looks questionable, use it only under

strict observation. If the machine shows any unusual behavior, disconnect machine

immediately from power and send machine to a Service Center for repair.

• Disconnect unit from power source before servicing and when not in use.

Preventing Burns and Fire

• During the warm-up phase and during operations, people should not stand within

three feet (one meter) of the front of the machine. Flammable material like paper,

fabric, etc., should never be placed directly on or around this equipment, or any other

electrical device with a heating element.

• The fog should be blown into an open space and should not be directed at people

or objects. Never blow fog on hot surfaces, into glowing heating elements or into open

flames. The normally non-flammable and non-toxic fog could react on very hot

surfaces and be burnt or decomposed.

• Do not operate the machine in a tightly confined space where the ambient tempera-

ture might exceed 135° F (57° C). A continuous flow of air is required to maintain

temperature within the machine housing. Sensitive electronic components deterio-

rate rapidly under high heat conditions. Operation of the machine in an enclosure of

less than ten cubic feet (one cubic meter) is dangerous, and automatically voids

the warranty.

• Enclosing any heating device so it is invisible to the operator creates a potential

fire hazard, no matter what the ambient temperature of the enclosure. To do

so with any high-amperage device is to assume substantial risk. Tempest

strongly recommends against it.

- 4 -

• Use of any fluid other than Rosco Smoke Simulation fluid or modification or attempted

unauthorized repair of the machine will immediately invalidate the warranty.

• Machines are designed for continuous use over an 8-hour day, but to protect components, it is wise

to turn off the machine when it is not in use. In permanent installations, it is advisable to equip

the circuit with a night cut-off device.

Additional Precautions: Do’s & Don’ts

• Do Read the entire manual before operating the machine and pay particular attention to all

CAUTIONS AND WARNINGS.

• Do Use an extension cord that is properly rated for voltage, current and length, and is free from

nicks, cuts or other signs of wear.

• Do Check to see that the machine is clean and free of foreign objects before each

operating period.

• Do Ensure that the machine is adequately ventilated.

• Do Use proper caution when handling hot surfaces.

• Do Use the minimum amount of fog required to achieve the desired effect.

• Do Not Use the machine near a person who has asthma or similar inhalation disorder.

• Do Not Use any foreign substances in the machine.

• Do Not Use a machine that is damaged or operating improperly in any way.

• Do Not Use a machine that leaks fluid from the housing.

• Do Not Leave the machine switched on for prolonged periods of time without producing fog.

• Do Not Enclose the machine.

• Do Not Install the machine in such a fashion that the operator cannot see the whole machine,

including the indicator lights.

• Do Not Touch the shielded nozzle of the machine. Allow sufficient cooling time after operation

before attempting to perform maintenance or storage.

• Do Not Direct the fog output continuously against nearby surfaces. This may eventually

cause fluid to re-condense.

Danger! Hazardous

voltage. Contact will

cause electric shock.

Caution! Safety

hazard. Risk of

personal injury.

Caution! Burn

hazard. Hot surface.

Do not touch

Caution! Fire hazard.

Danger! Hazardous

voltage. Contact will

cause electric shock.

Caution! Safety

hazard. Risk of

personal injury.

Caution! Burn

hazard. Hot surface.

Do not touch

Caution! Fire hazard.

Safety Precautions

• In any facility, the fog concentration should be controlled. The fog should never mask

emergency exits, safety signs, staircases or other safety constructions.

• After long use, or if the machine is not properly set, some liquid droplets or wet area

may appear in front of the machine’s outlet. This liquid should be wiped up to prevent

a condition where someone might slip and fall.

Preventing Improper Operation

• Unauthorized repair or alteration of any safety devices can lead to improper operation

and accidents. Repairs should be performed only by an authorized Service Center.

- 5 -

UNPACKING

Your Shadow Nightfall requires no assembly. Note: 230 volt machines are shipped with bare leads at the

end of the power cord. A proper electrical connector must be attached based on the local power require-

ments. Carefully remove the machine from the box. Ensure that no tape or packing materials are stuck

to the machine. Stray packing materials that remain attached to high temperature areas of the ma-

chine could melt or burn during operation. In particular, ensure that the area around the nozzle is free

of any materials or debris.

CONTROLS

Multi-Link Socket

3-Pin XLR socket that allows

for multiple machines to be

daisy chained together and

controlled from a single Remote

Control Panel.

Main Power Switch

Turns unit on or off by con-

trolling the flow of power

to the unit.

Air-Input / Purge Connection

This is a push-to-connect inlet that accepts ¼”OD

tubing and allows compressed air to blow through

the heat exchanger for cleaning

and maintenance.

Heat Indicator

A red indicator light that illuminates

when machine is heating in order to

achieve optimal temperature for

producing smoke.

Fluid Bottle

Ready Indicator

A green indicator light that illuminates when the

minimum temperature for producing smoke has

been achieved. Note: All indicator lights will switch

off if Standby mode is engaged.

Removable Remote

Remote Thumb Screws

Loosen to remove

Power Cable

- 6 -

Fog Button

Press and release to start

making smoke. Press and

release again to stop mak-

ing smoke. The Fog Button is

disabled if Standby mode

is engaged.

Standby Button

Press and release to suspend

heating and operation of the

machine without turning off

the Main Power Switch. The

Power Indicator light on the

Remote Control Panel will go

out when in Standby mode.

Press and release again to

disengage Standby mode.

Once Standby mode is disen-

gaged, the Power Indicator

light on the Remote Control

Panel will come back on.

Timer Button

Press and release to engage the timer

control functions. Timer Indicator

light will come on. Press and release

again to disengage timer functions.

Timer Indicator light will go out. Note:

The Timer Button disabled if Standby

mode is engaged.

Fog Level Knob

Rotate to set the desired

amount of smoke output.

Higher numbers indicate more

smoke. Output is controlled

by pump speed increasing and

sending more smoke fluid into

the heat exchanger.

Fog On Knob

Used only when timer control

is engaged. Rotate to set the

desired time interval that the

machine will produce

smoke

.

During

smoke

production, the

Power Indicator light will flash.

Fog Off Knob

Used only when timer control

is engaged. Rotate to set the

desired time interval that the

machine will wait while NOT

producing smoke.

Timer Indicator

A green indicator light that

illuminates when Timer mode

is engaged by pressing the

Timer Button. Turns off when

Timer mode is disengaged.

Power Indicator

A red indicator light

that illuminates when

the Main Power Switch

is in the“On”position to

indicate the machine is

properly receiving power

and Standby mode is

disengaged. The red

Power Indicator light

flashes while fog is

being produced.

CONTROLS

- 7 -

SETTING UP

The Shadow Nightfall should be located on a secure, solid surface such as the floor. The machine can

operate in any orientation from 45 degrees upwards to 45 degrees downwards. Take precautions to

avoid fluid spills if the machine is oriented at an angle.

Fluid Set Up

OnlyusegenuineRoscoSmokeSimulationfluidinyourNightfallmachine.Theuseofanyotherfluidwillvoidyour

warranty,may damage the equipment,and may cause health hazards.

For convenience, the Nightfall is designed with an integral compartment that will hold a 4-Litre or 5-Litre

bottle of smoke fluid. Place the fluid bottle into the compartment. Feed the fluid inlet hose into the bottle

of smoke fluid, ensuring that the filter, located at the end of the tube is fully submerged in fluid. Slide the

bottle cap along the tube and tighten the cap onto the bottle. Take precautions to avoid fluid spills.

All Shadow machines are primed at the factory with a small amount of fluid. No additional priming

should be necessary for proper smoke output. If smoke output is diminished or intermittent, see the

Priming the System section of this manual for instructions on how to re-prime the fluid path.

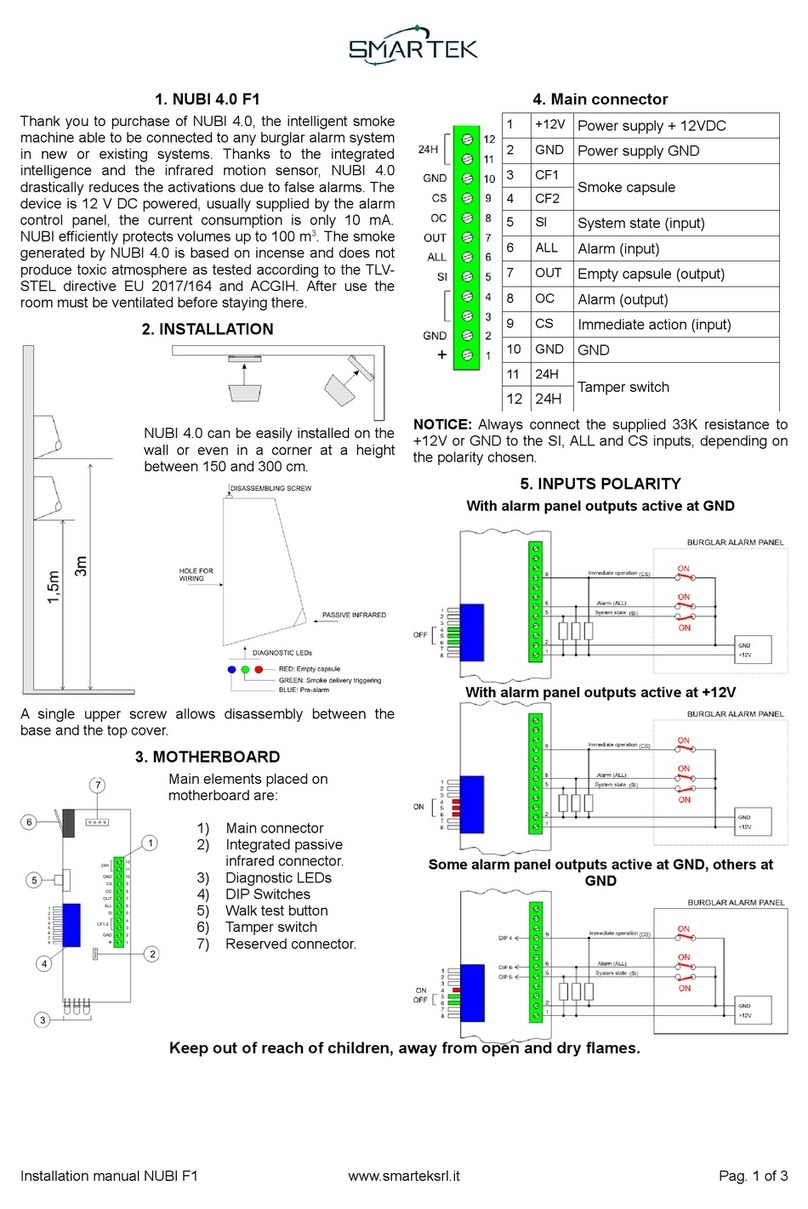

Power Connections

Ensure that the machine is plugged into an outlet rated for the proper voltage and amperage. The

Nightfall is a 1,200 watt device and will draw 5.2A at 230 VAC or 10.9A at 115 VAC. Note:230 volt machines

are shipped with bare leads at the end of the power cord. A proper electrical connector must be attached

based on the local power requirements. If unsure how to do this, please contact Tempest for assistance. An

example of properly wiring a UK 13A connector is shown below.

Earth Wire

Neutral Wire

Outer Insulation

Live Wire

Fuse

Cable grip

- 8 -

OPERATING THE MACHINE

Powering On

Make sure the unit is plugged in. Turn on the Main Power Switch that is located next to the power cord

on the rear of the machine. The red Power Indicator light on the Remote Control Panel will illuminate.

If the Power Indicator light does NOT illuminate, press and release the Standby Button on the Remote

Control Panel.

Heating

When switched on, the red Heat Indicator light will illuminate and the machine will begin to heat up to

its optimal temperature. The initial heating cycle will take 7-10 minutes. When the green Ready Indica-

tor light comes on, the machine is ready to make smoke.

Control Options

There are several methods of controlling the Nightfall, including: Manual Control via the Remote

Control Panel and Multi-Link control that allows multiple machines to be controlled from a single

Remote Control Panel.

Manual Control via the Detachable Remote Control Panel that is included with each machine. An oper-

ator can control the unit at the machine, or from a distance using the included 3-pin cable. The Remote

Control Panel can be used to set smoke output volume, power the machine on and off using Standby

mode, and set a repeating, timed cycle of on/off operation.

Multi-Link allows up to 4 machines to be linked together via 3pin XLR cables (not included) and con-

trolled by a single Remote Control Panel.

Using the Remote Control Panel

The Remote Control Panel can be operated directly on the machine or detached from the unit and used

at a distance. To detach the Remote Control Panel from the unit, loosen the thumb screws and lift the

panel from its recessed mount. A 15 foot (4.5m) cable is provided to allow the machine to be operated

at a distance. If needed, a longer 3-pin XLR cable can be used or joined to the existing cable. Do not

exceed a maximum distance of 165 feet (50 m) from remote to machine.

When the green Ready Indicator light is illuminated, the Nightfall is ready to make smoke. Press and

release the Fog Button to begin producing smoke. The red Power Indicator light will flash to indicate

the machine is operating.To stop making smoke, press and release the Fog Button again. Adjust the Fog

Level knob to increase or decrease the amount of smoke produced.

The Standby Button allows the machine to be“turned off”from the remote without using the Main Pow-

er Switch. In Standby mode,the machine will not reheat or make smoke,the pump remains unpowered

and all indicator lights will switch off. To engage Standby mode, press and release the Standby Button.

The red Power Indicator light will turn off. To disengage Standby mode, press and release the Standby

Button again and the red Power Indicator light will turn back on. Once Standby mode is disengaged,the

machine will immediately start heating in preparation to make smoke. Note: If no remote is connected

and no DMX signal is detected,the machine will not heat.

Using Timers

The timer controls allow you to set the machine to produce smoke in timed intervals without an

operator. To engage the timers,press and release the Timer Button. The green Timer Indicator light will

illuminate and the machine will begin to produce smoke at the level set by the Fog Level Knob, and the

red Power Indicator light will flash to indicate the machine is operating.

- 9 -

Using Multi-Link

In some instances, it may be preferable to control and synchronize multiple machines from a single

Remote Control Panel. This can be quickly and easily accomplished using the Nightfall’s built-in Multi-Link

capabilities. Up to four Shadow Nightfall Machines can be connected and controlled via a single controller.

Connect a 3-pin XLR cable (not included) to the Multi-Link port on the rear of the first machine in the

daisy chain. This unit becomes the “Head Machine” and its Remote Control Panel will control the other

units in the chain.

Remove and detach the Remote Control Panel and its 3-pin XLR cable from the second machine. Con-

nect the plug of the cable from the Head Machine into the remote port of the second machine where the

Remote Control Panel had previously been connected.

Repeat this process to connect a third and/or fourth machine. No additional set-up is required. The

Remote Control Panel attached to the head machine will operate all machines in the Multi-Link as if they

are the same.

Note:The maximum length

of the daisy chain, from

the remote of the Head

Machine to the final

machine is 165 feet (50 m).

Rotate the Fog Off Knob to adjust the period of time that the machine waits before starting to produce

smoke again. The numeric settings on the timer knobs are relative settings and do not correspond to

specific seconds or minutes. See the table below for an approximation of the time duration correspond-

ing to each tic on the knob.

The machine will cycle on and off indefinitely until the Timer Button is turned off. If the Fog Button is pressed

while in Timer mode,this will override any timer settings and the machine will produce smoke. When the Fog

Button is disengaged, the timer settings resume,continuing its On/Off cycle as if not interrupted.

1 - 4 1 to 4 seconds

4 - 5 4 to 16 seconds

KNOB SETTING TIMER SETTING

5 - 7 16 to 64 seconds

7 - 9 64 to 250 seconds

Changing Fluid

The Nightfall consumes 3.6 liters of fluid per hour at its maximum rate. When the fluid in the bottle has

been depleted enough that the tube can no longer stay submerged, it is time to change fluid bottles.

It is recommended that you stop making fog when changing fluid bottles. Once smoke production

has halted, simply unscrew the fluid tube cap from the empty bottle and remove the tube. Take care to

avoid dripping fluid onto the machine case or ground nearby, as it can be slippery. Replace the empty

bottle with a new bottle of Rosco Smoke Simulation fluid, insert the fluid tube insuring that the filter at

the end of the tube is fully submerged, and reattach the fluid cap. Resume making smoke.

- 10 -

Running Dry

Do not allow the machine to run dry of fluid. If the machine does run out of fluid it will stop producing

smoke and the green Ready Indicator light will indicate a Fluid Out condition with a fast double-flash.

In order to reset the Fluid Out condition, power cycle the machine by turning the Main Power Switch

off, wait 5 seconds, and then turn the Main Power Switch back on. After inserting the tube in a new

bottle of smoke fluid, you will need to prime the machine to remove airlocks in the fluid pipework of

the machine.

Priming the System

To prime the machine, turn the Fog Level Knob to Zero, then hold down the Fog Button and turn the

knob to maximum. Keep the button held until the smoke output is strong and steady. Then turn the

Fog Level knob back to the required output level and release the Fog Button.

Powering Down

After use, allow the machine to sit for several minutes before switching the Main Power Switch to off.

Turning off the power switch during smoke production can cause damage to the heat exchanger. Allow

machine to cool completely before packing or storing. Note: The nozzle of the machine may remain hot for

up to 10 hours after power is shut off.

If the machine will be unused for an extended period of time,follow the Storage and Shipment instructions

listed under Maintenance to prepare the machine for long-term storage.

DUCTING SMOKE

It is often desirable to duct smoke from the machine to another location.This can be accomplished using

flexible hose (“dryer hose”) or similar large diameter ducting such as 4in (100mm) PVC. Avoid sharp bends

in the duct, which can create turbulence or back flow.

The duct should be positioned no closer than 2in (50mm) to the nozzle. An open airflow between the

nozzle and opening of the duct is crucial to allow for aerosolization and create proper airflow. Placing

ductwork or tubing directly over the nozzle or nozzle guard will cause damage to the machine and will

void the warranty. Take all precautions to avoid fire hazards as the nozzle is extremely hot.

In some instances, it is desirable to use a fan to accelerate the smoke through the ductwork. Never

run smoke through the blades of a fan as the action of the impeller will cause condensation of fluid

particles. To properly use a fan, create a vent in the ducting system such as a and introduce a fan at the

vent point.This will create a low pressure point that“pulls or pushes”the smoke through the ductwork.

Contact Tempest for more advice on ducting smoke.

Squirrel Cage Fan

Ducting Hose

Hose Adaptor

Fog Machine

- 11 -

TROUBLESHOOTING

Problem Probable Cause(s) Suggested Remedy

Contact nearest Service Center

for repair

Ensure Main Power Switch is on

Press Standby Button on The Remote

Control Panel. Red Power Indicator

light on the Remote Control Panel

will illuminate.

Check to make sure machine is

plugged in properly. Check the cir-

cuit breaker.

Machine will not produce

smoke when Fog Button

is pressed

Smoke output is weak

Machine does not

heat up

Contact nearest Service Center

for repair

Ensure Main Power Switch is on

Wait 7-10 minutes until green

Ready Indicator light illuminates

Rotate Fog Level Knob clockwise

Rotate the Fog Level Knob clockwise

Ensure filter is submerged

See the Priming the System section

of the manual

Contact nearest Service Center

for repair

Machine produces smoke

intermittently when fog

button is not pressed

Turn timers off by pressing Timer

Button. Green Timer Indicator light

should not be illuminated.

Additional help and information can be found contacting Tempest.

Machine has overheated and

internal thermal fuse is blown

Machine is not turned on

Machine is in Standby mode

No power at AC cable inlet

Machine not turned on

Main fuse is blown

Machine not at

operating temperature

Fog level set to zero

Smoke output control is too low

Machine requires priming

Heat exchanger is clogged

Timer is engaged

Fluid filter above fluid line

- 12 -

MAINTENANCE

Before servicing the Shadow Nightfall, read and observe all the precautions listed in the Important

Safeguards section on pages 2-4 of this manual. Note: Any service that is NOT described in the section

below must be carried out by a Rosco service technician. Contact Tempest for more information on your

repair and service needs.

Exterior Cleaning

Excessive dust, fluid residue, and dirt build-up will degrade the performance of the machine and may

cause overheating to occur. To maintain adequate air flow and cooling, the outer casing and air vents

of the machine must be cleaned periodically. Damage caused by lack of cleaning is not covered by the

product warranty.

• Unplug the machine from power and allow the unit to cool completely before cleaning.

Note: The output nozzle may remain hot for up to 10 hours after use.

• Remove dust from the air vents with a soft brush, cotton swab, vacuum or compressed air.

• Clean any fluid residues from the fog output area of the machine using a damp cloth.

• Clean the outer casing with a damp cloth only.

Maintaining the Heat Exchanger

The heat exchanger is the core element in a fog or haze machine that transforms fluid into an aerosol-

ized fog/haze. This component operates under extreme temperatures and pressures and should be

cleaned periodically to ensure optimal performance. The Air-Input Connection was designed to pro-

vide a fast and efficient method of cleaning the heat exchanger by purging it of residual fluid and build

up using compressed air. For lasting performance, Tempest recommends purging the heat exchanger

once a week while in production,and before storing the machine for extended periods of time. Tempest

does not recommend the use of any purified waters, chemicals or fog machine cleaners. Use of these

materials will void the warranty.

Using the Air-Input Connection

You must have a source of compressed air from an air compressor or external air tank available.

Compressed air must be clean and dry.

Allow the machine to heat until the green Ready Indicator light has illuminated.

Using the push-to-connect fitting, connect a ¼”OD tube from your air source by inserting the tube into the

Air-Input Connection located on the rear panel of the machine. Alternately,you can use a blow gun attach-

ment, or similar device with a stepped nozzle, that is held against the orifice of the Air-Input Connection.

Set the air pressure to a maximum of 60 psi. Higher air pressure may damage the internal plumping

components. Blow air into the Air-Input Connection for 30 seconds, or until no additional haze or fluid

exits the nozzle.

CAUTION: Keep people and objects at least 3ft (1m) away from the nozzle of the machine during

air purging.

To release the tubing from the push-to-connect fitting,push back on the fitting collar and pull to release

the air line.

- 13 -

Storage & Shipment

Before storing the machine for an extended period of time, ensure the following:

• Fluid bottle has been removed and securely capped

• Proper cleaning of exterior as described above

• Proper purging of the heat exchanger as described above

• Machine is properly boxed or covered to avoid dust build up on internal components

• If shipping, use original packaging or comparable protection to avoid damaging the machine in transit

SPECIFICATIONS

Physical

Length ...........................................................................22.59”(573.8 mm)

Width ..............................................................................10.94”(278 mm)

Height............................................................................. 9.82” (249.5 mm)

Dry weight..........................................................................24.25 lbs (11 kg)

Performance

Operating time ..........................................................................continuous

Warm up time .........................................................................7-10 minutes

Control and programming

Control options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . timer remote

Fluid system

Capacity ................................................................120v - 4 liters / 240v - 5 litres

Fluid consumption ..................................................................3.6 liters / hour

Connections

Remote / Multi-Link ........................................................................3 pin XLR

AC power ........................................................................Fixed power cable

Electrical

AC voltage ....................................................................120V / 230V, 50/60Hz

Main fuse (120V US version) ....................................................................10AT

Main fuse (230V EU version) .....................................................................5AT

Thermal

Maximum ambient temperature.........................................................40°C (104°F)

Exterior surface temperature, steady state, at 20°C ambient...............................40°C (104°F)

Approvals

European EMC:.....................................EN61000-6-3,EN61000-3-2,EN61000-3-3,EN50366

European safety: ........................................................................EN 60 335-1

Immunity: ..................................................EN61000-6-1, EN61000-4-2,EN61000-4-3

ETL approvals (cETLus) pending ........................................... UL60335-1, CSA-E60335-1

Information in this document is subject to change without notice and does not represent a commitment on

the part of Tempest .

- 14 -

Dimensions

Dimensions are shown in [inches] and millimeters

- 15 -

1 YEAR LIMITED WARRANTY

Rosco Laboratories warrants to the first retail purchaser that this Product will be free from defects in

workmanship and material for a period of twelve (12) months from the date of original purchase. For

warranty service you must be able to provide proof of purchase.

Should this Product prove defective during the warranty period, please contact your local Rosco office

for return authorization. No warranty service will be performed without Return Authorization. At Ros-

co’s sole discretion, covered Products will be repaired or replaced with new or refurbished equipment

or a model of like kind and quality. Exchanged or replaced parts and Products assume the remaining

warranty period of the original Product covered by this limited warranty.

You are responsible for securely packaging the defective Product and returning it to Rosco as per the

instructions on the Return Authorization. Within North America, Rosco will ship the repaired or re-

placed Product to you freight prepaid.Shipments to other locations will be made freight collect. Do not

return fog machines with fog fluid.

This warranty is not transferable and does not extend beyond the first retail purchase of the Product.

This warranty does not cover damage to the Rosco product caused by parts not manufactured, distrib-

uted or certified by Rosco. Rosco is not obligated to provide warranty service should the product fail

to be properly maintained or fail to function properly as a result of misuse, abuse, improper installation,

neglect, improper shipping, damage caused by disasters such as flood, fire and lightning,improper elec-

trical current or connection or service other than by a Rosco Authorized Servicer. If a claimed defect

cannot be identified or reproduced, you will be held responsible for the costs incurred. Unless other-

wise stipulated by state law, all warranties expressed or implied are limited to the twelve (12) month

period of this warranty.

THE WARRANTY AND REMEDY PROVIDED ABOVE ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS

OR IMPLIED WARRANTIES INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANT-

ABILITY, NON-INFRINGEMENT OR FITNESS FOR A PARTICULAR PURPOSE. EXCEPT AS PROVIDED IN

THIS WRITTEN WARRANTY AND UNLESS EXCLUSIONS ARE SPECIFICALLY FORBIDDEN BY STATE LAW,

NEITHER ROSCO NOR ITS AFFILIATES WILL BE LIABLE FOR ANY LOSS, INCONVENIENCE, OR DAMAGE,

INCLUDING DIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING INJURY TO PER-

SONS OR PROPERTY, RESULTING FROM THE USE OR INABILITY TO USE THE ROSCO PRODUCT,WHETHER

RESULTING FROM BREACH OF WARRANTY OR ANY OTHER LEGAL THEORY.

•NOTE: USE OF ANY FLUID OTHER THAN A ROSCO BRAND FLUID WILL VOID THE WARRANTY.

NOTES

NOTES

Tempest Technology Corporation

4708 N. Blythe Avenue, Fresno, CA 93722

www.tempest.us.com

Table of contents

Other Tempest Fog Machine manuals