SmokeCloak EASY 2200 User manual

SmokeCloak EASY 2200

INSTALLATION AND OPERATING INSTRUCTION

2 EASY 2200 user manual

Every effort has been made to ensure that the contents of this

manual are correct. MSS Professional A/S does not accept any li-

ability for loss or damage caused or alleged to be caused directly or

indirectly by this manual. The contents of the manual may be subject

to change without notice. MSS Professional A/S makes no warranty

of any kind with regards to this material.

© 2012 MSS Professional

Reproduction in any matter whatsoever without the written permis-

sion of MSS Professional A/S is strictly forbidden.

READ AND SAVE THESE

INSTRUCTIONS

MSS Professional A/S

Agerhatten 25

DK - 5220 Odense SØ

Danmark

Telefon: +45 6473 1407

www.smokecloak.com

3

EASY 2200 user manual

Manual

EASY 2200

Please read this manual carefully before attempting to install an EASY 2200.

4 EASY 2200 user manual

Conventions

The following symbols are used in this manual to help you install the

SmokeCloak system correctly and safely.

Note

Gives useful advice or suggestions to enhance the

performance of the SmokeCloak system.

Important

Indicates important information that is critical for

the correct use of your products and must always be

read carefully.

It is essential that only genuine SmokeCloak uid is

used. Damage to the equipment and possible health

hazard is likely if incorrect uid is used. The warranty

on all of the equipment will also be void.

Under no circumstances should the on board power

supplies of the SmokeCloak “12v output” be linked

to any other 3rd party equipment e.g. alarm panels,

additional power supplies, etc. as this could cause

unexpected faults within the machines.

In areas tted with equipment generating high le

vels of electrical interference, screened alarm cable

may be required to ensure correct operation of the

EASY unit.

5

Contents

Contents

1. IN THE BOX......................................................................... 6

2. QUICK START GUIDE ............................................................ 6

3. SPECIFICATIONS .................................................................. 8

4. MACHINE LAYOUT ............................................................. 10

5. INSTALLATION................................................................... 12

6. DIRECTING THE NOZZLE.................................................... 13

7. FLUID ................................................................................ 15

8. PRIMING THE MACHINE .................................................... 17

9. BATTERIES ........................................................................ 18

10. WIRING UP THE MACHINE ................................................. 21

11. INTERFACE BOARD............................................................ 22

12. CONNECTION DETAILS....................................................... 23

13. CLOAK SENSOR ................................................................. 40

14. SETTING THE ACTIVATIONS TIME ....................................... 42

15. PREPARATION FOR FINAL TEST ......................................... 44

16. MAINTENANCE.................................................................. 45

17. PC-TOOL ........................................................................... 46

18. USING THE SOFTWARE...................................................... 49

19. TIMERS............................................................................. 50

20. ACCESSORIES ................................................................... 56

Fluid FL600 ....................................................................... 56

Cloaksensor CS07A............................................................. 57

LED Strobe......................................................................... 58

Sounder IPA 117 ................................................................ 59

Voice Module...................................................................... 60

Batteries ............................................................................ 61

6 EASY 2200 user manual

1. In The Box

Before attempting to install the machine it is advisable to ensure that you

have all the required components. Upon opening your SmokeCloak EASY

box you should nd:

x1 off EASY 2200 unit

Check serial labels to ensure the correct voltage

x1 off Manual pack

Warning stickers

Mounting template

Quick start guide

CD Rom containing manual

x1 off Accessory Pack

Straight nozzle insert

30 degree nozzle insert

Circlip (x2 off)

Suppressors

x1 off Cloaksensor (CS07A)

In addition to the above items you will also need 2x 1.2 Ah 12 V batteries.

MSS Professional A/S recommends FIAMM or similar quality.

In addition, the following specialist tools will also be required:

Internal Circlip Pliers (20 mm)

2. Quick Start Guide

To quickly prepare and re your unit, the following steps should be taken.

For more detail on anything below, see the full guide provided.

7

98

Test

5

1

Max

2,5 m

Max 3 m

3

7

6

24

8 EASY 2200 user manual

3. Specications

EASY 2200

Dimensions 468 x 382 x 223 mm

Weight (install) 19.15 kg

Weight (shipped) 23 kg

Weight (hanging) 21.15 kg

Performance 764m3in 30 s*

Reaction time 0.2 s

Fluid consumption 260 ml in 30 s

Standard colour White

Mounting Vertical or Horizontal

Fluid Reservoir 1,0 L

Heat up time (Rdy) 9 minutes (230 V)

Heat up time (Full) 15 minutes 45 s (208V)

13 minutes (230V)

Timer Adjustable

Voltage 230V, 208V

Heat Power 208/230V 2 x 950 W

Power consumption at 230V (max) 2.0 KW

Power consumption at 208V (max) 1.65 KW

Standby Power consumption @ full temperature 105 W

Standby Power consumption during power save

mode 72 W

Current Draw at 230 V (max) 8.85 A

Current Draw at 208 V (max) 7.8 A

Pumps x2 24 V solidstate, variable

output

9

EASY 2200 user manual

Weight (Install)

Represents the weight of the machine, without the covers on, and without

the batteries or any uid installed.

Weight (Shipped)

Represents the weight of the machine packed within its box

Weight (Hanging)

Represents the weight of the machine, in its armed state hanging on a

wall. That includes covers, Batteries and a full container of uid.

Heat-up time (rdy)

The gure given is a time to ‘ready’ state at an ambient temperature of 20°C

Heat-up time (full)

The gure given is a time to full temperature at an ambient temperature

of 20°C

10 EASY 2200 user manual

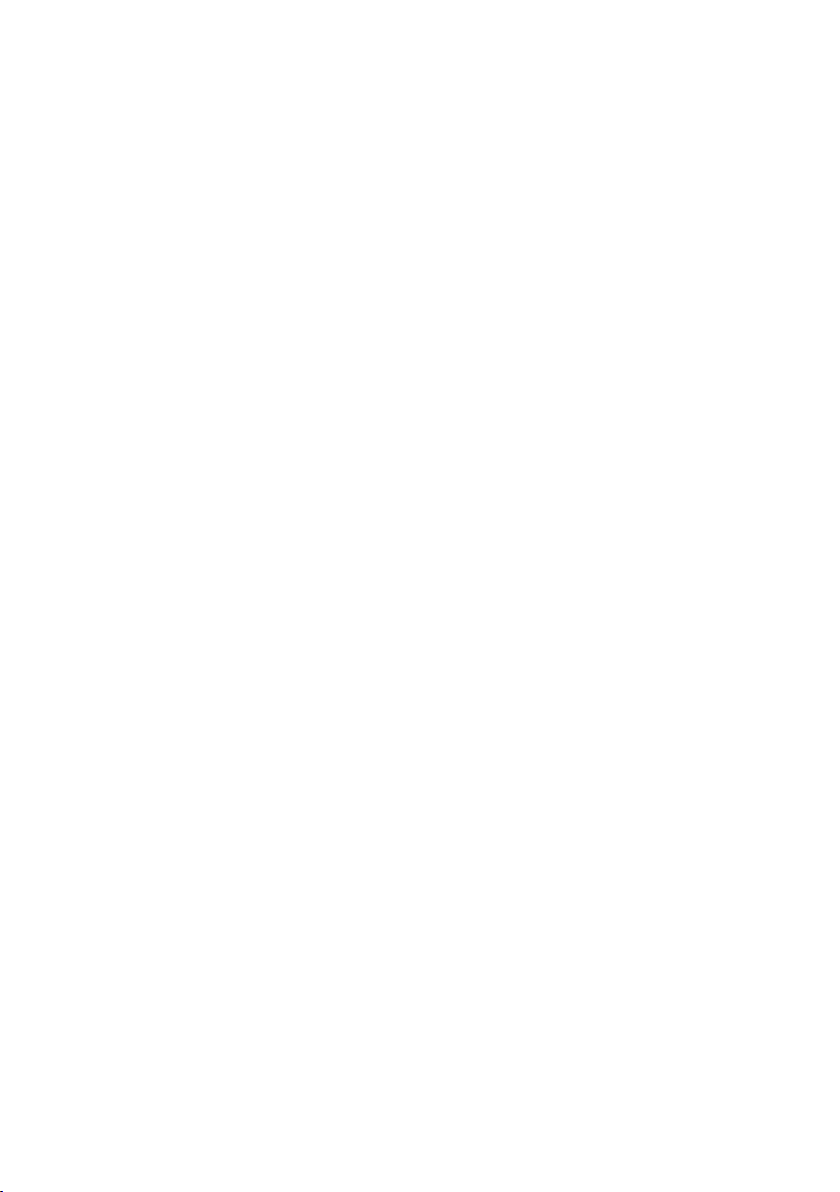

4. Machine Layout

1. Main power PCB

2. Interface PCB

3. Tamper switch

4. Fluid bottle

5. Batteries

5. Pumps

6. Heat exchanger

7. Nozzle output

11

EASY 2200 user manual

Internal isometric

Bottom

L/H side

External front

Top

R/H side

Internal

Rear

Front

12 EASY 2200 user manual

5. Installation

5.1 Position

The SmokeCloak EASY can be installed vertically for wall mounting, or

alternatively mounted horizontally for ceiling installations.

This equipment should only be installed and connected

to the supply by a suitably skilled and competent

person.

This apparatus must be earthed. Connections are

made to a plug-in terminal block. The SmokeCloak

should be connected to a standard 13 amp fused spur.

Flexible mains cables must have a minimum cross-

section area of 1.25 mm2 (and must be BASEC

approved in the UK). Ensure that the protective

earth conductor is made longer than the live and

neutral conductors, and that the cable clamp grips

both the sheath and insulation.

Wall mounting: It is not recommended to install

the machine in excess of 2.5 m high, otherwise the

smoke coverage near the oor may be compromised.

Horizontal mounting: Ensure the machine is no

more than 3 m above the oor, otherwise smoke

dispersal may be compromised.

In areas tted with equipment generating high le

vels of electrical interference, screened alarm cable

may be required to ensure correct operation of the

EASY unit.

13

EASY 2200 user manual

6. Directing the nozzle

EASY 2200 will come as standard with no nozzle installed.

It is the job of the installer to assess, install and test which

of the nozzles supplied should be used in order to ensure

that the machine is best suited to the particular installation.

Straight Nozzle Provides a single powerful burst directed

perpendicular to the front of the

machine.

30-Degree Nozzle Provides a single powerful burst

directed at 30° to the front plane of the

machine.

Note: by changing the orientation of

the nozzle the effect can be projected

in varying directions.

14 EASY 2200 user manual

Installing the correct nozzle

for the rst time:

1. By making a quick assessment of the area to be protected by the

SmokeCloak, decide which of the two available standard nozzles

should be used. You can see examples on the previous page.

2. Take the required nozzle and install it within the nozzle body.

3. Take the circlip provided and using a pair of internal circlip pliers,

engage the circlip into the ridge running around the inside of the

nozzle body. It is crucial this is installed correctly in order to retain the

nozzle safely.

4. Follow the test procedure.

Take great caution when changing the nozzle, it

becomes extremely hot as the machine heats up.

Do not attempt to handle the nozzle once the

machine has heated up to temperature.

Following any installation or changing of the nozzle

– Ensure that a test ring is carried out to ensure

that the new nozzle has been correctly and safely

installed. When performing this rst test ring

insure that the grille plate is installed correctly and

everybody is standing back from the front of the

machine.

15

EASY 2200 user manual

7. Fluid

FL600 uid is used to generate the vapour cloud. This glycol based uid is

made to a special formula, which is designed to produce 40% obscuration

of light at 40 cm with minimum condensation.

The uid should be changed annually and the machine test red after the

uid has been replaced to ush the old uid out of the internal uid lines

in the machine.

Whilst unopened the uid has a 5 year shelf life when stored correctly.

7.1 Installing the Fluid Bottle

Your EASY 2200 product will be supplied with a full uid container

installed. It will arrive with a sealed travel cap installed. The following

steps should be taken in order to correctly install the uid bottle and the

uid sensing unit.

1. Remove the uid bottle from the machine,

2. Slide the uid sensor assembly inside the bottle – screw down the cap

tightly to create a seal.

3. The bottle can then be slid back into position within the machine.

4. It is recommended that following any installation of the bottle a short

test re is carried out to ensure the uid line has been correctly re-

installed and to re-prime the uid feed lines.

16 EASY 2200 user manual

It is essential that only genuine SmokeCloak uid

is used. Damage to the equipment and a possible

health hazard is likely if incorrect uid is used. The

warranty on all of the equipment will also be void

7.2 Changing the Fluid

As part of the maintenance of the SmokeCloak EASY it is essential that

the uid is replaced annually to ensure that the quality of the effect

produced is maintained at the desired level.

In order to change the uid follow the same instructions in the previous

section for installing the uid bottle, once removed.

Discard the empty uid container and replace with a new full bottle of uid.

The uid should be changed (not topped up)

at least once a year. Do not mix batches of uid.

(Batch number is printed on the front of the bottle).

Take care not to overll the bottle

– it could potentially lead to electric shock.

17

EASY 2200 user manual

8. Priming the machine

Following either the initial installation of the uid bottle or following

changing of the bottle it is essential that a short test ring is carried out to

ensure that the uid feed pipes are correctly primed. Failure to follow this

procedure will lead to delayed response time the rst time the machine

is red following the service or, more signicantly, a failure to observe a

connection fault incurred during the installation or re-installation of the

uid bottle.

During the test ring, observe the output to ensure the level is satisfactory

before leaving the machine.

If the level appears to be below what would normally be expected of the

machine, repeat the test process. If after 3 test cycles the output still

appears to be below the ‘regular’ level of effect check the following:

1. The uid cap was correctly re-engaged into the bottle, that the uid

feed pipe wasn’t trapped in any way, and that the cap was rmly

screwed back into position.

2. If there still appears to be a problem contact your supplier.

18 EASY 2200 user manual

9. Batteries

9.1 To install the batteries:

NEW drawing?

19

EASY 2200 user manual

Once the batteries are installed within the bracket provided they must

then be wired together in series and connected to the power board.

Follow the instructions below – The battery loom provided should be

used. It will contain a single blue wire used for linking the batteries in

series and in addition a red and a black wire for connecting the wires back

to the power board.

The red wire should be terminated at PL22 on the power board and the

black wire at PL21. The terminals labeled + with the red wire, and - with

the black wire.

The battery backup system provides power for the control electronics and

pumps when mains electricity is removed.

20 EASY 2200 user manual

The standard backup system does not provide power for the heater. The

insulation is designed to retain sufcient heat in the aluminium heat

exchanger assembly.

The SmokeCloak must have the batteries installed,

even when operating from the mains,

The battery backup system requires 24 V d.c. - it is

necessary to t two 12 V 2.1 Ah batteries in series

in the SmokeCloak. Do not use larger than 2.1 Ah

capacity batteries to prevent fuse failure due to

excessive charging current.

Please note that the temperature inside the SmokeCloak

can exceed 40 degrees depending on the ambient

temperature - the batteries must be able to with-

stand this temperature under charging.

Take care with polarity. The SmokeCloak is protected with an auto-reset

fuse to safeguard against reverse polarity connection of the batteries. The

LEDs on the interface board will give indication of correctly installed uid

and batteries.

PCB damage due to incorrectly tted/sized batteries

is not covered under warranty.

MSS Professional strongly recommends that Fiamm

2.1 Ah batteries or similar quality are tted.

These can be purchased from MSS through your

distributor.

Table of contents

Other SmokeCloak Fog Machine manuals