Temspec VUD Series Manual

Operation & Maintenance Manual

VUD, VUF, VDF & HCD Series

Unit Ventilator

© 2006 TEMSPEC INCORPORATED

IMPORTANT: Read and save this manual for future reference.

This manual is to be left with the equipment owner

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[1]

Table of Contents

INTRODUCTION

About the Unit Ventilator ….……………………………………………………………………2

Nomenclature for non-compressorized Unit Ventilators ………….……………………2

TYPICAL UNIT LAYOUT

Model VUD 1200 ……………………………………………………….………………………3

Model VUD 1600 ……………………………………………………….………………………4

Model VUD 2000 ……………………………………….………………………………………5

Model VUF 1200 ……………………………………………………….………………………6

Model VUF 1500 ……………………………………………………….………………………7

Model VDF 1200 ……………………………………………………….………………………8

Model HCD 1200 ……………………………………………………….………………………9

Model HCD 1600 ……………………………………………………….………………………10

OPERATION

Sequence Of Operation .………………………………………………………………………11

Hot Water Circuit .……………………………………………………………………………...12

Refrigeration Circuit………....……………………………………………………………….……13

Electrical Circuit ……….….…………………………………………………………………..14

Dampers ……….………….…………………………………………………………………..14

Filtration ……….………….………………………………………………………………......14

MAINTENANCE

Servicing the Unit ………….………….………………………………………………………..15

Maintenance Schedule ….………….……………………………………………………..…15

Changing the Filters………….………….……………………………………………………..…16

Cleaning the Evaporator Coil …….………………………………………………………...16

Motors ………………………….…………………………………………………………...16

TROUBLESHOOTING

Basic Troubleshooting Guidelines…..…………………………………………………………..17

REPLACEMENT PARTS

Limited Warranty ..……………………...………………………………………………………18

Parts Sales …………..………………………..…….…………………………………………....18

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[2]

INTRODUCTION

The Temspec unit ventilator is designed as means for providing heating, cooling and

ventilation to the classroom. Our goal is to help create an enhanced learning environment

by focusing on the following points when designing our equipment:

•COOLING, HEATING, HUMIDITY AND VENTILATION

CONTROL

•AIR DISTRIBUTION

•SOUND ATTENUATION

By installing the vertical unit ventilator into the classroom, superior control can be obtained

for each room. Because the unit can be ducted, an even distribution of air can be achieved

throughout the room. The unit ventilator is constructed with heavy gauge metal and sound

absorbing insulation for optimal sound attenuation.

By applying sound engineering principles and thorough testing, we ensure the highest

quality of performance in our unit ventilators.

ABOUT THE UNIT VENTILATOR

NOMENCLATURE FOR NON-COMPRESSORIZED UNIT VENTILATORS

V=Vertical Unit

H=Horizontal

UD = Upflow Ducted Unit Ventilator

UF = Upflow Freeblow (direct discharge) Unit Ventilator

CD= Horizontally Ducted Unit Ventilator

DF= Downflow Unit Ventilator

1200 = up to 1200 cfm

1500 = up to 1500 cfm

1600 = up to 1600 cfm

2000 = up to 2000 cfm

1200

UD

V

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[3]

TYPICAL LAYOUT

CW

O.A. Outdoor Air

1. Supply air fan.

2. Hot water coil. Optional electric or steam

coil available.

3. DX cooling coil.

4. Drain pan.

5. Outdoor air damper.

6. Spring return mixed air damper actuator.

7. Filters.

SIDE SECTION

(Hot Water /

Chilled Water)

SIDE SECTION

(Split System DX)

6

S.A. Supply Air

21.5"

R.A.

8

21.5"

O.A.

5

4

3

2

1

7O.A.

9

HW

S.A.

8. Return air damper.

9. 2 pipe or 4 pipe (hot water coil can be

in the reheat position).

10. Ceiling tile.

11. Top extension (optional).

12. Coil access panel.

13. Hinged filter access panel.

14. Heavy duty return air grille.

FRONT ELEVATION

14

R.A.

R.A. Return Air

28"

Duct By

Others

10

11

12

13

4

S.A.

93"

H

NOTE: The component arrangement shown above may vary slightly from that in the unit ventilator supplied.

Model VUD 1200 (Upflow, Ducted Configuration)

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[4]

TYPICAL LAYOUT

CW

O.A. Outdoor Air

1. Supply air fan.

2. Hot water coil. Optional electric or steam

coil available.

3. DX cooling coil.

4. Drain pan.

5. Outdoor air damper.

6. Spring return mixed air damper actuator.

7. Filters.

SIDE SECTION

(Hot Water /

Chilled Water)

SIDE SECTION

(Split System DX)

6

S.A. Supply Air

23"

R.A.

8

23"

O.A.

5

4

3

2

1

7O.A.

9

HW

S.A.

8. Return air damper.

9. 2 pipe or 4 pipe (hot water coil can be

in the reheat position).

10. Ceiling tile.

11. Top extension (optional).

12. Coil access panel.

13. Hinged filter access panel.

14. Heavy duty return air grille.

FRONT ELEVATION

14

R.A.

R.A. Return Air

33"

Duct By

Others

10

11

12

13

4

S.A.

93"

H

NOTE: The component arrangement shown above may vary slightly from that in the unit ventilator supplied.

Model VUD 1600 (Upflow, Ducted Configuration)

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[5]

TYPICAL LAYOUT

O.A. Outdoor Air

S.A.

8

5

S.A. Supply Air

1. Dual supply air fans.

2. DX cooling coil.

3. Filters.

4. Spring return mixed air damper actuator.

5. Outdoor air damper.

6. Hot water coil. Optional electric or steam

coil available.

7. Drain pan.

SIDE SECTION

(Split System DX)

O.A.

23"

O.A.

R.A.

SIDE SECTION

(Hot Water /

Chilled Water)

23"

4

1

2

3

9

7

6CW

HW

S.A.

R.A. Return Air

8. Return air damper.

9. 2 pipe or 4 pipe (hot water coil can be

in the reheat position).

10. Ceiling tile.

11. Top extension (optional).

12. Coil access panel.

13. Hinged filter access panel.

14. Heavy duty return air grille.

FRONT ELEVATION

R.A. 14

44"

13

12

11

10

Duct By

Others

93"

H

NOTE: The component arrangement shown above may vary slightly from that in the unit ventilator supplied.

Model VUD 2000 (Upflow, Ducted Configuration)

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[6]

TYPICAL LAYOUT

O.A. Outdoor Air

SIDE SECTION

(Hot Water /

Chilled Water)

S.A. Supply Air

1. Hot water coil. Optional electric or steam

coil available.

2. DX cooling coil.

3. Drain pan.

4. Supply air fan.

5. Outdoor air damper.

6. Spring return mixed air damper actuator.

7. Filters.

SIDE SECTION

(Split System DX)

21.5"

R.A.

21.5"

3

5

6

O.A.

4

1

2

O.A.

7

8

S.A.

9

HW

CW

R.A. Return Air

8. Return air damper.

9. 2 pipe or 4 pipe (hot water coil can be

in the reheat position).

10. Double deflection supply air grille.

11. Coil access panel.

12. Hinged filter access panel.

13. Heavy duty return air grille.

FRONT ELEVATION

13

R.A.

28"

10

11

12

3

S.A. S.A.

93"

S.A.

NOTE: The component arrangement shown above may vary slightly from that in the unit ventilator supplied.

Model VUF 1200 (Upflow, Freeblow Configuration)

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[7]

TYPICAL LAYOUT

S.A.

O.A. Outdoor Air

R.A.

S.A. Supply Air

1. DX cooling coil.

2. Dual supply air fans.

3. Filters.

4. Spring return mixed air damper actuator.

5. Outdoor air damper.

6. Hot water coil. Optional electric or steam

coil available.

7. Drain pan.

SIDE SECTION

(Split System DX)

O.A.

23"

O.A.

R.A.

SIDE SECTION

(Hot Water /

Chilled Water)

23"

4

2

1

3

58

7

6

S.A.

9

HW

CW

R.A. Return Air

8. Return air damper.

9. 2 pipe or 4 pipe (hot water coil can be

in the reheat position).

10. Double deflection grilles.

11. Coil access panel.

12. Hinged filter access panel.

13. Heavy duty return air grille.

FRONT ELEVATION

13

44"

12

11

10

S.A.

93"

S.A.

NOTE: The component arrangement shown above may vary slightly from that in the unit ventilator supplied.

Model VUF 1500 (Upflow, Freeblow Configuration)

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[8]

TYPICAL LAYOUT

HW

O.A. Outdoor Air

SIDE SECTION

(Hot Water /

Chilled Water)

CW

SIDE SECTION

(Split System DX)

1. Return Air damper.

2. Outdoor air damper.

3. Supply air fan.

4. Hot water coil. Optional electric or

steam coil available.

5. Spring return mixed air damper actuator.

6. Filters.

7. Slab type DX cooling coil.

S.A. Supply Air

21.5"

8

7

21.5"

4

3

2

O.A.

1

6

5

R.A.

9

O.A.

8. Drain pan.

9. 2 pipe or 4 pipe (hot water coil can be

in the reheat position).

10. Heavy duty return air grille.

11. Hinged filter access panel.

12. Coil access panel.

FRONT ELEVATION

8

R.A. Return Air

S.A.

28"

S.A.

11

12

10

R.A.

93"

NOTE: The component arrangement shown above may vary slightly from that in the unit ventilator supplied.

Model VDF 1200 (Downflow Configuration)

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[9]

TYPICAL LAYOUT

SIDE SECTION

O.A.

O.A. Outdoor Air

93"

Duct By

Others

OPTIONAL TOP O.A.

INTAKE DETAIL

1. Outdoor air damper.

2. Spring return mixed air damper actuator.

3. Return air damper.

4. Filters.

5. Heavy duty return air grille or duct collar.

6. Split DX or hot water/chilled water coil

(2 pipe or 4 pipe).

7. Drain pan. Drain pan is removable when

option for bottom access panels is selected.

R.A.

S.A. Supply Air

3

Duct By

Others

O.A.

31

1O.A.

5

R.A.

42

10" x 12"

Supply Air

Opening

ISOMETRIC VIEW

(shown with left side access panel)

8. Hot water coil for spilt system DX or heating

only units. Optional steam and electric

heater also available.

9. Supply air fan.

10. Mounting brackets (4 per unit).

11. Left or Right side hinged filter access panel.

Bottom hinged access panel also available.

12. Left or Right side hinged coil access panel.

Bottom hinged access panel also available.

R.A.

10

11

R.A. Return Air

12

10

28"

Duct By

Others

7 9

Optional

O.A. intake

location

6 8

Suspension

Rods By

Others

S.A. 21.5"

NOTE: The component arrangement shown above may vary slightly from that in the unit ventilator supplied.

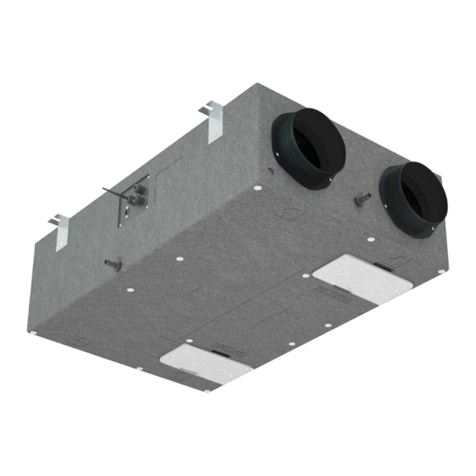

Model HCD 1200 (Horizontal Configuration)

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[10]

TYPICAL LAYOUT

SIDE SECTION

O.A.

O.A. Outdoor Air

93"

Duct By

Others

OPTIONAL TOP O.A.

INTAKE DETAIL

1. Outdoor air damper.

2. Spring return mixed air damper actuator.

3. Return air damper.

4. Filters.

5. Heavy duty return air grille or duct collar.

6. Split DX or hot water/chilled water coil

(2 pipe or 4 pipe).

7. Drain pan. Drain pan is removable when

option for bottom access panels is selected.

R.A.

S.A. Supply Air

3

Duct By

Others

O.A.

3

1

1O.A.

5

R.A.

42

12" x 10"

Supply Air

Opening

ISOMETRIC VIEW

(shown with left side access panel)

8. Hot water coil for spilt system DX or heating

only units. Optional steam and electric

heater also available.

9. Supply air fan.

10. Mounting brackets (4 per unit).

11. Left or Right side hinged filter access panel.

Bottom hinged access panel also available.

12. Left or Right side hinged coil access panel.

Bottom hinged access panel also available.

R.A.

10

11

R.A. Return Air

12

10

33"

S.A.

Duct By

Others

7 9

Optional

O.A. intake

location

6 8

Suspension

Rods By

Others

S.A. 23"

NOTE: The component arrangement shown above may vary slightly from that in the unit ventilator supplied.

Model HCD 1600 (Horizontal Configuration)

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[11]

OPERATION

The following are typical modes of operation for a classroom unit ventilator. Please refer to the

manual provided by the control’s contractor for a more specific controls sequence.

1. Unoccupied Condition

During the “unoccupied heat” mode (night set-back) space temperature is maintained by a

signal from the thermostat/controller to either the modulating control valve, modulating face and

bypass damper actuator or electric coil triac. The powered exhaust damper (if applicable) and

the outdoor air damper are fully closed, and the return air damper is fully open. The supply air

fan operates on call from the thermostat/controller.

2. Occupied Condition

The unit ventilator is switched to “occupied heat” by the thermostat/controller. In this mode a

signal is sent from the thermostat/controller to either the modulating control valve, modulating

face and bypass damper actuator or electric coil triac to maintain room temperature at set point.

The outdoor air damper is held at a minimum position in the heating mode. The supply air fan

runs continuously.

3. Economizer (up to 100% outdoor air)

The first stage of cooling is the “economizer” mode during which all stages of heating are off.

The outdoor air and the return air dampers modulate to maintain the room at the “economizer”

set point. If the mixed air falls to a programmed temperature (usually 52°F) the outdoor air

damper will modulate towards closed until the mixed air temperature rises again (typically to

55°F). in this “free cooling” mode the ability of the unit ventilator to provide sufficient cooling is

limited only by the outdoor air temperature and the total C.F.M. rating of the unit.

4. Cooling

The unit can be equipped with a split system DX evaporator coil that would work in conjunction

with a remote condensing unit (provided by others) or can be equipped with a chilled water coil.

The system maintains the “set temperature plus 5°F” and the cooling is cycled on call from the

thermostat/controller. In this mode the outdoor air damper will return to minimum position.

During night set-back the mechanical cooling and economizer should be locked out.

5. Freeze Protection

For units with a steam or hot water coil, some type of freeze protection is usually implemented.

This can be by either a low limit temperature control (autoreset or manual reset) or by using a

supply air sensor and programming from the controller. When a mixed air temperature is

determined to be too low, then the outdoor air damper will close, and the control valve will fully

open. In some cases, the fan will also shut down until the temperature returns to normal levels.

Typical Modes of Operation

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[12]

The following are typical hot water piping schematics for a unit ventilator. Please refer to the unit

ventilator “shop drawings” for a more specific layout.

Hot Water / Chilled Water with 2-way Control

Manual Air Vent

2-way Control Valve

MIXED

AIR

Strainer

MV

Isolation Valve

Isolation Valve

Balancing Valve

Return

Supply

WATER

COIL

Hot Water / Chilled Water with 3-way Control

MIXED

AIR

C

Strainer

NO

NC

3-way Control Valve

Manual Air Vent

MV

Isolation Valve

Balancing Valve

Isolation Valve

Return

Supply

WATER

COIL

Warning: City water is very corrosive to brass components. Provide water treatment as soon as the

system is charged to avoid premature leaks and/ or failure of internal components.

Hot Water Circuit

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[13]

The following is a typical split system refrigeration circuit.

EVAPORATOR

COIL

MIXED

AIR

Metering Device

Anti-Ice Control

Distributor

Pressure Test Port

Sight Glass, Moisture Indicator

High Limit Cut-Out

Low Limit Cut-Out

CONDENSER

COIL

TEMSPEC UNIT VENTILATOR

REMOTE CONDENSING UNIT

Crankcase Heater

OUTDOOR

AIR

Compressor

Refrigeration Circuit

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[14]

The electrical circuit in the unit ventilator is highly dependent on the controller and

sequence that is being utilized. The unit can be supplied with a 115V, 208V, 277V or 460V

power. Each unit comes standard with an unfused disconnect. A copy of the electrical

schematic can be found folded in a pouch inside of the unit ventilator.

The outdoor air dampers and return air dampers are mechanically linked. As the outdoor

air dampers open, the return air dampers close. A spring return damper actuator is

connected to a linkage that extends to both sets of dampers. The damper actuator

manufacturer can vary. Please refer to the wiring schematic for the damper actuator model

type.

Internal powered exhaust is an optional feature that is provided with our vertical series unit

ventilators. This feature comes with a fan and damper module that is mounted into the

return air section of the unit. Control should be setup by the temperature controls

contractor to operate as an on/off device as the outdoor air damper opens and closes.

Typically, 1” disposable filters are provided in the unit with an extra set shipped loose for

when the unit is ready for start-up. Please refer to the “shop drawings” for specific details

on filter construction and thickness. Below are sizes and quantity per unit for the different

model types.

Model Number Filter Size Quantity Per Unit

VUD, VDF, VUF, HCD 1200 12” x 20”nominal 2

VUD, HCD 1600 12” x 24” nominal 2

VUD 2000, VUF 1500 16” x 21” nominal 2

Electrical Circuit

Dampers

Powered Exhaust (optional)

Filtration

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[15]

MAINTENANCE

Access to the components is gained by removing the front access panels. Typically, the

panels are fastened by heavy duty Phillips head screws. When removing the access panel

(vertical style units), loosen but do not remove the screws. Carefully store the panel in a

place where it will not get damaged. The horizontal style units utilize hinged access

panels.

CAUTION: Disconnect power before servicing the unit.

The filter access panels have a “kill switch” installed that will shut the supply air fan off once

the panel is removed. This will only disconnect the power to the supply air fans. Be sure to

disconnect ALL power by turning the remote disconnect switch to the off position.

Drain Pan Instruction

•Please check the drain pan for proper drainage as part of commissioning.

•Check to make sure the drain pain overflow switch didn’t come loose or shift during

shipping as part of commissioning.

•The unit should be checked to ensure the drain pan is level, free of debris, and the

drain line properly connected to the riser stub-out.

Frequency maintenance greatly depends on the surrounding conditions (inside and outside

of the building). The following is a typical maintenance schedule for a classroom unit

ventilator.

Every 3 months –Change filters

Every 12 months –Vacuum out drain pans

–Clean strainer in hydronic circuit (if applicable)

Every 24 months –Clean evaporator coil

–Vacuum any loose debris from interior of the unit

–Inspect dampers to ensure that there is a proper seal when closed

Servicing the Unit

Maintenance Schedule

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[16]

The outdoor and indoor conditions will determine the frequency of filter changes. Temspec

recommends that the filters be changed every 3 months as a rule-of-thumb. Note that dirty

filters will affect the overall performance of the unit.

To change the filters, open / remove the filter access panel by loosening the Phillips head

screws. Unclip the filters and replace.

To clean the evaporator coil, purchase a suitable evaporator coil cleaning solution such as

those offered by NU-CALGON (www.nucalgon.com). Follow the manufacturers instructions

for use.

Note: Chlorine based or anti-fungal “pucks” or “socks” are acceptable when placed in the

evaporator drain pan. Be sure to vacuum the drain pan during the cleaning process.

If the filters are regularly changed, the heating coils do not require cleaning.

WARNING: Do NOT use chlorine-based cleaners or anti-fungal treatments on the

aluminum fins of coil.

Temspec provides motors that are permanently lubricated. No maintenance is required.

Changing the Filters

Cleaning the Evaporator Coil

Motors

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[17]

TROUBLESHOOTING

Problem Action Required

●Supply fan not running ●Verify that the disconnect is in the on position

●Verify that thermostat / controller is not in

unoccupied mode (night set-back)

●Check the fan relay to see if it energizing and de-

energizing properly

●Check to see if the 24V transformer is defective

●Ensure that wire connections are secured

properly

●Check to see if motor is burned out

●Compressor shot cycles ●Ensure that there are no obstructions which

would cause the unit to cut-out on high head

pressure

●Check refrigerant level. If the level is to low, the

unit will cut-out on low pressure. The Refrigerant

type and the amount is posted on the metallized

CSA label located on the fan housing.

NOTE: Temspec does not recommend the use of a Unit Ventilator during

construction/drywall installation as a space heater or air conditioner.

Motor exposure to drywall dust can reduce motor life and leads to

premature failure

Basic Trouble Shooting Guidelines

Operation and Maint.Manual VUD VUF VDF HCD SeriesRev6.doc

[18]

REPLACEMENT PARTS

TEMSPEC INCORPORATED warrants the equipment from factory defects in material or

workmanship for a period of one year.

For this warranty to be valid, the unit(s) must be installed and maintained in accordance

with the manufacturer’s printed instructions. It does not cover parts damaged by

vandalism, improper installation, maintenance or abuse.

Should any replacement parts be required within the warranty period, they will be supplied

at no charge, freight prepaid to the jobsite. The cost of labor or incidental expenses

incurred in the repair or replacement of parts does not form part of this warranty.

The warranty period commences from the date of shipment, except when otherwise agreed

at the point of sale (see specific warranty terms and conditions for details).

Contact the factory at: 1-888-TEMSPEC or (905) 670-3595

Ask for ‘parts sales’

Be sure to provide the unit serial number, which is located on the metalized CSA label, on

the fan housing, inside the units.

Limited Warranty

Parts Sales

This manual suits for next models

11

Table of contents

Other Temspec Fan manuals

Popular Fan manuals by other brands

mercor

mercor mcr-PROLIGHT C Operation and maintenance manual

Holmes

Holmes HSF1614 owner's guide

Monte Carlo Fan Company

Monte Carlo Fan Company MC5B241 Owner's guide and installation manual

Makita

Makita DCF301Z instruction manual

Xpelair

Xpelair GX6 Installation and maintenance instructions

Tecnosystemi

Tecnosystemi VR180 user manual

DEKON

DEKON B 610 Instructions for use

SAINT-GOBAIN

SAINT-GOBAIN CertainTeed RVG55ML installation instructions

AERMEC

AERMEC Omnia UL C Use and installation

ZyXEL Communications

ZyXEL Communications FAN500 installation guide

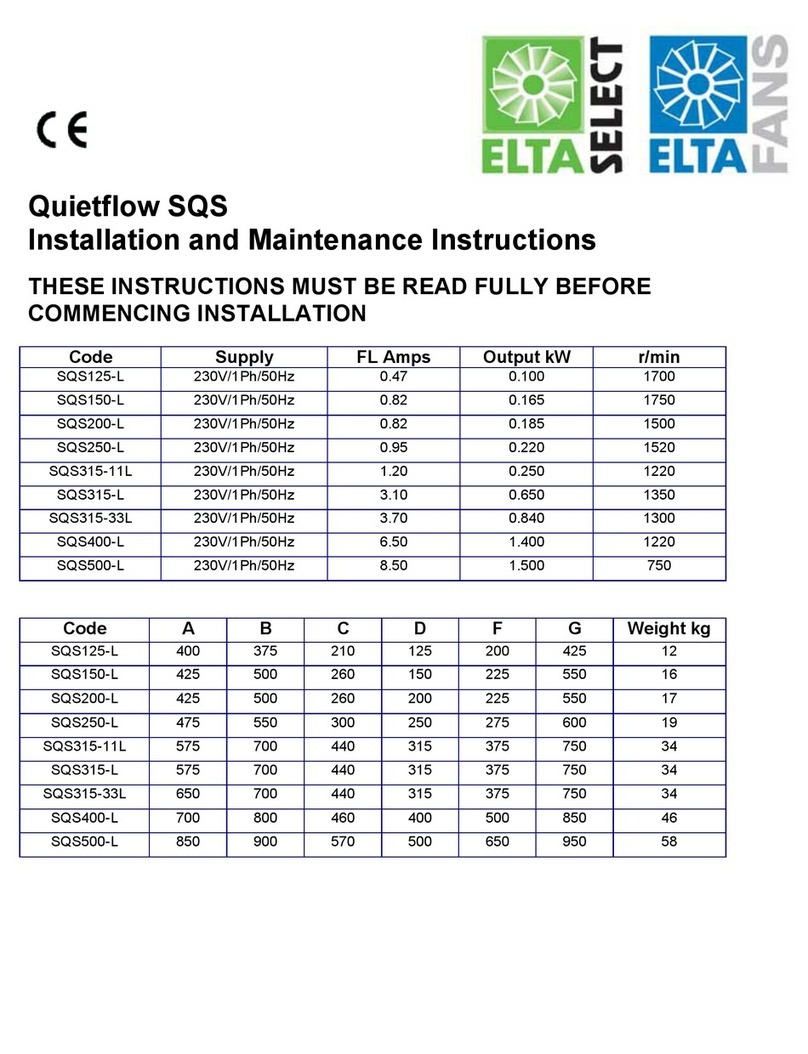

Elta

Elta Quietflow SQS Series Installation and maintenance instructions

Bard

Bard WGCRVS-3C installation instructions