TERABEAM Gigalink Manual

Terabeam Gigalink

Field Installation and Service Manual

Version 2.1

September, 2002

THIS DEVICE COMPLIES WITH PART 15 OF THEFCC RULES. OPERATION IS SUBJECT

TO THE FOLLOWING TWO CONDITIONS. (1) THIS DEVICE MAY NOT CAUSE HARMFUL

INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE RECEIVED,

INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED OPERATION.

IF THIS PRODUCT IS SUSPECTED OF CAUSING HARMFUL INTERFERENCEWITH

OTHER EQUIPMENT, DISCONTINUE OPERATION IMMEDIATELY AND CONTACT

TERABEAM.

FCCID # O2700001-30-30

Table of Contents iii

Terabeam Gigalink Field Installation and Service Manual

Document Number: 045-1032-0000 / Revision: Draft

Release Date: TBD / Print Date: 12/10/02

Proprietary and Confidential

Table of Contents

Page

1 Introduction 1-1

Gigalink Product Family 1-1

Reliability 1-1

Gigalink Model XXX Description and Specifications 1-2

FCC Compliance Statement 1-4

2 Gigalink Installation Quick Guide 2-1

Unpacking the Kit and Verifying Components 2-2

GigamonSoftware Installation 2-4

System Requirements 2-4

Gigamon Setup and Installation Procedure 2-5

Electrical Services 2-6

Network Interfaces 2-8

Mechanical Installation 2-11

Selecting the Optimum Terminal Mounting Method 2-15

Rough Mechanical (Visual) Alignment 2-16

Final Terminal Alignment 2-16

Radio Terminal Power-Up 2-17

Using Gigamon Software for Precision Alignment 2-18

Verifying Network Operation 2-22

3 Gigamon Software 3-1

Descriptions of Gigamon Components and Their Functions 3-2

Terminology 3-3

Color Convention 3-3

Components of the Main Window 3-3

Triggering Parameters and Threshold Setting Dialog Box Details 3-12

4 Terminal Maintenance and Troubleshooting 4-1

Maintenance 4-1

Troubleshooting 4-1

Recommended Troubleshooting Steps 4-14

5 Terabeam Technical Assistance 5-1

Chapter 1 Introduction 1-1

Terabeam Gigalink Field Installation and Service Manual

Document Number: 045-1032-0000 / Revision: Draft

Release Date: TBD / Print Date: 12/10/02

Proprietary and Confidential

1 Introduction

Gigalink Product Family

The Terabeam®Gigalinkmillimeter wave radio system represents an entirely new

approach to broadband communications. Based on our extensive experience with millimeter

wave systems for military and research applications, we now apply these techniques to a

commercially priced version with our ultra-broadband family of Gigalink radio products.

The Gigalink broadband radio system operatesin the FCC Part 15.255 unlicensed band

covering a frequency range of 57.05 –64.0 GHz. Due to the unlicensed status of this band,

FCC license or special authorization is not required to operate our Gigalink systems. In

addition, the high atmospheric absorption of RF energy at this frequency virtually eliminates

any chance of interference from competing systems or unauthorized interception of the

broadcast signal.

The installation procedures detailed within this guide are similar to those used to install any

wireless system. In fact, certain attributes of the 57.05 –64.0 GHz band actually simplify

deployment. The key to any successful installation project is proper planning and design. The

Gigalink radio product has been designed for ease of installation and trouble-free operation.

We recommend that you read and fully understand this guide prior to initiating the actual

installation work.

As stated above, the key to successful installation is proper system planning and execution.

As with most wireless systems, the Gigalink radio system requires un-obstructed Line of

Sight (LOS) to operate reliably. Because of the extremely high data bandwidth provided by

the Gigalink system (1.25Gbps) it is likely that our radio systems will be utilized as a critical

or primary network connection. This absolute reliance on our systems for connectivity

demands a focused attention to detail in order to assure un-interrupted operation.

Reliability

All Gigalink products are designed to provide a minimum statistical path availability of

99.99% (BER <1 x 10 –9) when operated within the recommended range envelope.

Exceeding the specific model range restrictions will result in unreliable operation particularly

during adverse weather.

Statistical availabilities in excess of 99.99% may be achieved by choosing the next longer

range system for a given path or by co-locating two Gigalink systems. Traditional circuit

redundancy methods utilizing collapsible ring architectures or media diversity may also

increase statistical availability.

1-2Chapter 1 Introduction

Terabeam Gigalink Field Installation and Service Manual

Document Number: 045-1032-0000 / Revision: Draft

Release Date: TBD / Print Date: 12/10/02

Proprietary and Confidential

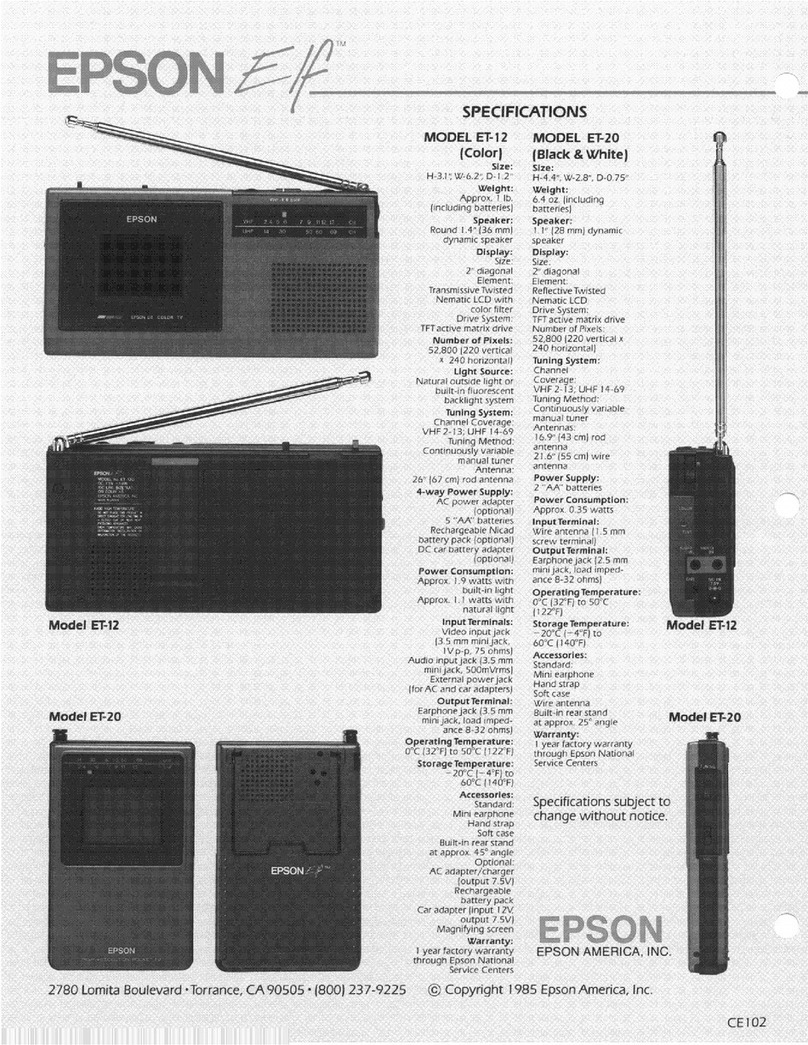

Gialink Model 6451e Specifications

Data Transmission

Bit Rate 1.25Gbps Full Duplex

Protocol Gigabit Ethernet (1000BaseFX)

Interfaces

Data FC Connector (850-nm MMF)

Monitor/Management (Ethernet) RJ-45 Connector and FC Connector (1310nm MMF)

DC Power Proprietary 3 terminal DCReceptacle and Connector Kit

Operational Parameters

Frequency Range 57.05 –64 GHz

Output Power 10mW (antenna injection)

Antenna Type Integral 13” parabolic

Antenna Gain 40dBi, Min.

Beam Width 1.0o, Max.

Regulatory Compliance

Electrical CE –60950 (Pending)

Electromagnetic FCC –Part 15.255, Certification #O2700001-30-30

CE –EMC and R&TTE Directive (Pending)

Power

DC Input Voltage -48 VDC+/-20%

Maximum DC Input Current 1.5 Amperes

DC Power Consumption 75 Watts

Environmental

Operating Temperature -20°C to 50°C (-4°F to 122°F)

Storage Temperature -30°C to 85°C (-22°F to 185°F)

Relative Humidity Up to 95%, Non-Condensing

Mechanical

Transceiver H x W x D 33 x 33 x 20 cm (13.0 x 13.0 x 7.9 in.)

Transceiver Weight 17 lbs (7.7 kg)

FCC Compliance Statement

The Terabeam Gigalink family of products is type-certified for unlicensed operation in

compliance with FCC Part 15.255. Terabeam Gigalink radio products are factory set for

frequency, frequency stability and transmitter power levels. No user-authorized adjustments

are provided. Changes or modifications not expressly approved by the party responsible

for compliance will void the user’s authority to operate this equipment.

For detailed information on Gigalink Part 15.255 type certification and rules governing Part

15 Unlicensed operation, please visit the Federal Communications Commission home page at

http://www.fcc.gov

Chapter 2 Gigalink Installation Quick Guide 2-1

Terabeam Gigalink Field Installation and Service Manual

Document Number: 045-1032-0000 / Revision: Draft

Release Date: TBD / Print Date: 12/10/02

Proprietary and Confidential

2 Gigalink Installation Quick Guide

The Terabeam Gigalink millimeter wave radio system represents an entirely new approach to

broadband communications. Based on our extensive experience with millimeter wave

systems for military and research applications, we now apply these techniques to a

commercially priced version with our ultra-broadband family of Gigalink radio products.

The Gigalink broadband radio system operates in the newly allocated unlicensed band

occupying the frequency range of 57.05 –64.0 GHz. Due to the unlicensed status of this

band, FCC license or special authorization is not required to operate our Gigalink systems.

In addition, the high atmospheric absorption of RF energy at this frequency virtually

eliminates any chance of interference from competing systems or unauthorized interception

of the transmitted signal.

The installation procedures detailed within this guide are similar to those used to install any

wireless system. In fact, certain attributes of the 57.05 –64.0 GHz band actually simplify

deployment. The key to any successful installation project is proper planning and design. The

Gigalink radio product has been designed for ease of installation and trouble-free operation.

We recommend that you read and fully understand this guide prior to initiating the actual

installation work.

Throughout this guide, important topics, instructions or warnings are identified by symbols

notated by the following.

Indicates time saving recommendations

Indicates potential for equipment damage, or unsatisfactory

operation

Identifies areas of safety hazards or potential injury

STOP

!

2-2Chapter 2 Gigalink Installation Quick Guide

Terabeam Gigalink Field Installation and Service Manual

Document Number: 045-1032-0000 / Revision: Draft

Release Date: TBD / Print Date: 12/10/02

Proprietary and Confidential

Unpacking the Kit and Verifying Contents

Your Gigalink system will arrive in two separate boxes, one containing the high band radio

terminal, DC Connector kit, mounting hardware and documentation and one containing the

low band radio terminal, DC Connector kit, mounting hardware and documentation. The

contents of both boxes should be identical with the exception of the fiber optic loop-back

cable, supplied only with one terminal.

Item/Description Qty Supplied Re-Order #

1. Gigalink Radio Transceiver 1 Same as Model #

3. Fiber Loop-Back Jumper 1 SFOFC-01

4. 10BaseT SNMP Adaptor Cable 1 3028

6. Pipe Mount L-Bracket 1 2842-1

7. Terminal Mount Hardware Kit (stainless) 1 2901

8. Gigalink Installation/Operation Manual 1 (not shown)

Chapter 2 Gigalink Installation Quick Guide 2-3

Terabeam Gigalink Field Installation and Service Manual

Document Number: 045-1032-0000 / Revision: Draft

Release Date: TBD / Print Date: 12/10/02

Proprietary and Confidential

With receipt of system delivery, each carton should be inspected to confirm complete

content. If any items are found to be missing, installers should contact the factory to arrange

delivery.

2-4Chapter 2 Gigalink Installation Quick Guide

Terabeam Gigalink Field Installation and Service Manual

Document Number: 045-1032-0000 / Revision: Draft

Release Date: TBD / Print Date: 12/10/02

Proprietary and Confidential

NOTE: During shipping kit inspection, do not remove the contents of Gimbal Mount

#2289 or Hardware kit #2901 in order to avoid mixing-up or loosing the hardware.

Gigamon Software Installation

The SNMP is accessed through the Gigamon™ Graphic User Interface (GUI). The Gigamon

Interface is the primary tool for precision alignment of the Gigalink terminals. Through

Gigamon, the SNMP utility is also used to set terminal configurations and provide ongoing

monitoring of critical radio parameters.

Before proceding with terminal installation the Gigamon GUI application must be installed

on the technician’s laptop computer.

NOTE: Installing the Gigamon monitoring software in two laptop computers will

simplify precision alignment. If two laptops with Ethernet cards are available, it is

recommended that both receive the software.

System Requirements

For proper operation of the Gigamon monitoring utility the following minimum system

requirements must be met.

1. Computer running Windows NT/2000, 2000ME or Windows XP

2. A 10/100 Ethernet Adapter card, installed in the computer.

3. Screen resolution should be 1024x768 or higher. To change screen resolution,

3.1 Click on ‘Start’ menu

3.2 Select ‘Settings’

3.3 Select ‘Control Panel’

3.4 Double click on ‘Display’ icon.

3.5 Click on ‘Settings’, and move the slider in ‘Screen Area’ to adjust the display

Chapter 2 Gigalink Installation Quick Guide 2-5

Terabeam Gigalink Field Installation and Service Manual

Document Number: 045-1032-0000 / Revision: Draft

Release Date: TBD / Print Date: 12/10/02

Proprietary and Confidential

Gigamon Setup and Installation Procedure

1. Insert the resource disc and double click on the “GigaMon Install” icon.

2. Run “setup.exe”. This will install the drivers in Windows System directory, copy main

executable file “GigaMon.exe”to the user’s specified path and add the program name to

program menu.

2.1 Copy W32N50.DLL to the Windows System directory, usually the appropriate

directory will be C:\WINNT\SYSTEM.

2.2 Copy “PCANDIS5.SYS” to the Windows System directory, usually the appropriate

directory will be C:\WINNT\SYSTEM.

2.3 Copy “moncfg.exe”to the preferred path.

At the conclusion of the Installation Session, a Gigamon Icon will be displayed on the

Computer desktop. Double clicking on this Icon will produce the window shown in Figure 3.

If problems are encountered during the Gigamon monitor software installation process, refer

to the more detail description of the Gigalink SNMP utility and Gigamon monitoring

software (sections 3 and 4) of the enclosed “Users Manual”.

Figure 3, Initial Gigamon Screen

2-6Chapter 2 Gigalink Installation Quick Guide

Terabeam Gigalink Field Installation and Service Manual

Document Number: 045-1032-0000 / Revision: Draft

Release Date: TBD / Print Date: 12/10/02

Proprietary and Confidential

Electrical Services

WARNING: The Gigalink Radio Terminal electrical connection at the

radio terminal must be made first in order to avoid arcing and possible

damage to the radio terminal connector. Once the radio connection has

been made, power may be applied to the circuit.

Electrical Power

The Gigalink Model 6451e terminal operates on a single –48VDC supply. Power may be

provided from a regulated power supply or battery plant. The installer must provide a 3

stranded conductor DC power cable of a gauge sufficient for the intended application.

Installers should use the guide below to determine the minimum wire gauge needed based on

the length of the DC power cable run.

Maximum Cable Length vs. Wire Gauge for Pioneer

@ 20 degrees C Wire Temperature

0 100 200 300 400 500 600 700 800

Wire Gauge

Cable Length (feet)

22 Ga.

20 Ga.

18 Ga.

16 Ga.

14 Ga.

12 Ga.

STOP

Chapter 2 Gigalink Installation Quick Guide 2-7

Terabeam Gigalink Field Installation and Service Manual

Document Number: 045-1032-0000 / Revision: Draft

Release Date: TBD / Print Date: 12/10/02

Proprietary and Confidential

Figure 5, DC Power Connections

Network Interfaces

The Gigalink terminals utilize a weatherproof, FC type fiber connector on the radio terminal

and a proprietary 10BaseT interface for SNMP communications. Network Fiber must be

supplied to the radio terminal location and terminated in FC Male. The supplied Gigamon

adapter cable (Figure 1, Item 4) can be permanently installed for the SNMP network

connection by attaching a standard CAT 5 coupler and cable.

The Gigamon adapter cable is wired in a straight configuration to enable communication

directly with the installer’s laptop. For connection to a network switch, a length of cross

connect cable is necessary between the radio terminal and switch.

The IF Monitor port is provided for factory test and diagnostics only and should remain

capped in final installation.

The Network and SNMP interfaces are shown below.

-48VDC

Power

Source

-48VDC Return (Black)

-48VDC Supply (Red)

GigaLink Terminal

Wall or Roof Penetration

Power cable Assembly

Green Power-on

Indicator

Building Ground

Chapter 2 Gigalink Installation Quick Guide 2-1

Terabeam Gigalink Field Installation and Service Manual

Document Number: 045-1032-0000 / Revision: Draft

Release Date: TBD / Print Date: 12/10/02

Proprietary and Confidential

Figure 6, Terminal Power, Network and SNMP Interfaces

TX/RX Type FC

for Data Payload

TX/RX Type FC for

SNMP and Monitor

Proprietary 10BaseT

Copper Monitor Port

Power On/ Fuse status

LED Indicators

50ohm IF Monitor

Port, load and Chain

(3) Conductor

Mil-Style Power

Connector

Location of tapped

hole for terminal

ground lug

Chapter 2 Gigalink Installation Quick Guide 2-1

Terabeam Gigalink Field Installation and Service Manual

Document Number: 045-1032-0000 / Revision: Draft

Release Date: TBD / Print Date: 12/10/02

Proprietary and Confidential

LED Operation Truth Table

LED Condition Terminal Status

Both Lit presence of -48VDC power and internal fuse OK

One Lit -48VDC present but internal fuse blown

None Lit No -48VDC power present

Mechanical Installation

Attaching the Gimbal Mount

Before actual terminal mounting can be accomplished, it is necessary to attach the Pan and

Tilt Gimbal Mount to the Gigalink radio terminal housing. The necessary hardware for this

attachment is provided with the Pan and Tilt Gimbal Mount # 2289-1 and consists of (4) M8

x 1.5cm stainless steel bolts, flat washers and lock washers. Figure 6, details the Gimbal

mounting procedure.

2-2Chapter 2 Gigalink Installation Quick Guide

Terabeam Gigalink Field Installation and Service Manual

Document Number: 045-1032-0000 / Revision: Draft

Release Date: TBD / Print Date: 12/10/02

Proprietary and Confidential

Selecting the Optimum Terminal Mounting Method

The following sections detail available mounting methods and hardware for the Gigalink

product.

Figure 11, Standard Wall Mount

WARNING: It is the responsibility of the installer to assure that the

radio terminal is mounted securely enough to prevent falling.

Particular care must be used when wall mounting the radio terminal

above areas frequented by personnel. In some cases, it may be

advisable to attach a safety chain or lanyard through the gimbal mount

to provide additional security.

Gigalink™ Transceiver

Pan and Tilt C Bracket (#2289)

“L” Bracket (#2842-1)

Stainless Steel Bolts, ½” Minimum O.D.

with wall anchors, or through bolt to

backing plate (specialized wall mount

Hardware not supplied)

!

Chapter 2 Gigalink Installation Quick Guide 2-3

Terabeam Gigalink Field Installation and Service Manual

Document Number: 045-1032-0000 / Revision: Draft

Release Date: TBD / Print Date: 12/10/02

Proprietary and Confidential

Figure 12. Standard Pipe Mount (all hardware included)

Pipe (structural steel) 2.5” –4.5” OD

Rough Mechanical (Visual) Alignment

Once the Gigalink Radio Terminals are securely fastened to the mounting locations, the

installer should visually align the terminals. Visual alignment is accomplished by loosening

both the C Bracket Attachment bolts and L Bracket Mounting bolts slightly. With these (7)

bolts loosened the terminal can be aligned (aimed) toward the other terminal by sighting

along the radio housing body.

Once satisfied that both terminals are aimed at the each other, all seven bolts can be snagged

up enough just to hold the desired position.

Gigalink™ Transceiver

C Bracket (#2289)

Stainless Steel U-Bolts, Washers,

Nuts (hardware kit #2901)

“L” Bracket (#2842-1)

2-4Chapter 2 Gigalink Installation Quick Guide

Terabeam Gigalink Field Installation and Service Manual

Document Number: 045-1032-0000 / Revision: Draft

Release Date: TBD / Print Date: 12/10/02

Proprietary and Confidential

Final Terminal Alignment

NOTE: Although it is possible for a single technician to perform final terminal

alignment. Terabeam recommends that two technicians with monitor-enabled

laptops be dedicated to this task. By dedicating two technicians equipped with

cellular phones or two-way radios, final alignment can be accomplished at both

terminal sites concurrently, eliminating the need to constantly travel between sites.

Radio Terminal Power-Up

Once the Radio terminals have been mechanically mounted in place and visually aligned,

both radio terminals must be powered up, and network services connected.

Terminal Power up

Power-up the Gigalink terminal as follows.

1. Attach DC power cord securely to the radio terminal

2. Attach power leads to –48VDC source Red to –48VDC supply, Black to –48VDC return

and Green to Building Ground.

3. Power up –48VDC circuit.

4. Verify power on condition via Green “Power-on” LED’s located on the bottom of the

terminal housing

Connecting Network Services

Once the power has been applied to the Gigalink terminal, Network services can be

connected and verified. The network Fiber connections to the Gigalink terminal are Type FC

male terminated fiber optic cables. Make these connections by aligning the connector body

index tab, then tightening the outer collar in a clockwise rotation.

In the network switch room, insert the other end of each fiber optic cable into the appropriate

TX and RX switch ports. If done correctly, a link light should be visible. If no link light is

visible, make sure the radio is powered up and swap the fibers.

Table of contents

Other TERABEAM Radio manuals