Teracom TCW242-S User manual

TCW242-S_R1.0 –July 2021 Page 2

1. Introduction

TCW242-S is an industrial IoT (Internet Of Things) module with Ethernet connectivity and data logging

capability. All monitored parameters can be seen as numbers and as graphs.

The device has 4 digital inputs, 4 analog inputs, an RS-485 interface for MODBUS RTU sensors, and 4

relays. The analog inputs can be switched either in a current loop (0 to 20mA) or voltage (0 to 10V)

modes. The relays can be activated remotely (WEB, SNMP, MODBUS TCP/IP, or HTTP API command) or

locally - from the alarm conditions.

TCW242-S supports up to 24 Teracom and third-party MODBUS RTU sensors.

The user can arrange up to 24 independent monitoring channels from the inputs and sensor readings.

Every channel can be set up using up to 2 input parameters and/or constants. There are two types of

channels –discrete (for OPEN/CLOSED outputs monitoring) and general (for general monitoring).

The user can also arrange up to 24 independent alarms with 5 different user-selectable states. Every

alarm can be set up using up to 2 limits and hysteresis. The alarm can be assigned to a specific channel.

In this case, in an alarm state, the assigned channel is colored on the monitoring page and graphs.

The device supports SNMP, HTTP API, and MODBUS TCP/IP protocols for machine-to-machine (M2M)

communication.

2. Features

10/100 Mb Ethernet connectivity with Auto-MDIX;

Password protected, web-based configuration and control;

4 digital (dry contact) inputs;

4 analog inputs with 0/10V and 0/20mA modes;

4 relays with NO and NC contacts;

MODBUS RTU support for up to 24 sensors (registers);

Up to 24 channels for monitoring;

Up to 24 independent alarms;

SNMPv2 and SNMPv3 support;

SNMP traps sending for alert conditions;

HTTP and SNMP port changing;

HTTP API commands;

Periodical HTTP/HTTPS Post of XML/JSON status files for client-server systems;

MODBUS TCP/IP support;

Dynamic DNS with DynDNS, No-IP and DNS-O-Matic support;

NTP protocol support;

Data logger for up to 70000 records;

DIN Rail Mountable;

Wide power supply voltage range;

Backup/restore of settings;

Remote firmware update.

3. Applications

The industrial IоT module is designed to solve a wide range of tasks in the light industry sector, remote

monitoring and control in communication facilities, food and beverage storage, greenhouses, water

stations, etc.

TCW242-S_R1.0 –July 2021 Page 3

4. Specifications

Physical characteristics

Dimensions: 145 x 90 x 40 mm

Weight: 200 g

Environmental limits

Operating temperature range: -20 to 55°C

Storage temperature range: -25 to 60°C

Operating relative humidity range: 10 to 80% (non-condensing)

Warranty

Warranty period: 3 years

Power supply

Operating voltage range (including -15/+20% according to IEC 62368-1): 10 to 28 VDC

Current consumption: 0.35A @ 12VDC (without MODBUS RTU sensors powering)

RS-485 interface for MODNUS RTU sensors

Isolation: Non-isolated

Output voltage (pin 7 of RJ-45): 5.0 ± 0.3 VDC

Maximum output current (pin 7 of RJ-45): 0.2 A

Digital inputs

Isolation: Non-isolated

Mode: OPEN/CLOSED (“Dry contact”) or COUNTER

Maximum input voltage: +5.5VDC

Sampling rate: 1mS

Digital filtering time interval: 5 to 60000mS

Analog inputs

Isolation: Non-isolated

Type: Single-ended

Resolution: 10 bits

Mode: Voltage or current loop

Input Range: 0/10V or 0/20mA

Accuracy: ±1%

Sampling Rate: 600mS per channel (averaged value of 100 samples)

Input Impedance: 1 mega-ohm (min.)

Relay outputs

Type: Form C (N.O. and N.C. contacts)

Contact current rating: 3 A @ 24 VDC, 30 VAC (resistive load)

Initial insulation resistance: 100 mega-ohms (min.) @ 500 VDC

Mechanical endurance: 10 000 000 operations

Electrical endurance: 100 000 operations @ 3 A resistive load

Contact resistance: 50 milli-ohms max. (initial value)

Minimum pulse output: 0.1 Hz at rated load

TCW242-S_R1.0 –July 2021 Page 4

CAUTION: The device does not contain any internal overcurrent protection facilities on the

relays’ contact lines.

External fuses or short circuit current limiting circuit breakers, rated to 3 Amps, are to be

used for overcurrent protection of the connecting lines.

Internal FLASH memory

Settings segment endurance: 100 000 cycles (Every setting change is a memory cycle).

Data logger segment endurance: 100 000 full scrolls (70000 records) of the logger.

Update segment endurance: 100 000 cycles (updates).

Lithium battery

Type: CR1220

Caution! Risk of explosion if the battery is replaced by an incorrect type.

5. LED indicators

The following indicators show the status of the controller:

PWR (red) –in working mode shines, blinks together with STS if there is a hardware error;

STS (yellow) –flashes when the main program of the controller is executed;

NET (orange) –network status - ON when a link is established, blinks if there is an activity.

6. Installation and setup

This device must be installed by qualified personnel.

This device must not be installed directly outdoors.

The installation consists of mounting the device, connecting to an IP network, connecting inputs and

outputs, providing power and configuring via a web browser.

6.1. Mounting

TCW242-S should be mounted in a clean and dry location on a non-flammable surface. Ventilation is

recommended for installations where the ambient air temperature is expected to be high.

Mount the device to a wall by using two plastic dowels 8x60mm (example Würth GmbH 0912

802 002) and two dowel screws 6x70mm (example Würth GmbH 0157 06 70). Attach the screws to

the surface vertically. See Appendix-A, fig. 1 for mechanical details.

Maintain spacing from adjacent equipment. Allow 50 mm of space on all sides, as shown in fig. 2 in

Appendix A, this provides ventilation and electrical isolation

TCW242-S can be mounted to a standard (35mm by 7.55mm) DIN rail. Attach the controller to the

DIN rail by hooking the hook on the back of the enclosure to the DIN rail and then snap the bottom

hook into place.

6.2. Connection

Attention! Disconnect power supply before wiring.

The correct wiring procedure is as follows:

Make sure power is turned off;

Make wiring connections to the terminals;

Apply power.

Make sure that the wires are properly attached to the terminals and that the terminals are

tightened. Not the proper wiring and configuration can cause permanent damage to TCW242-S or

the equipment to which it is connected or both.

TCW242-S_R1.0 –July 2021 Page 5

Connector 1

Ethernet - RJ45

Connector 6

Pin1 –not connected (most left)

Connector 2

Power - 2.1x5.5mm connector,

Pin2 –not connected

central positive

Pin3 –not connected

Connector 3

Pin1 –Power positive

Pin4 –Line B- (D1)

Pin2 –Power negative

Pin5 –Line A+ (D0)

Connector 4

Pin1 –NC Relay4

Pin6 –not connected

Pin2 –COM Relay4

Pin7 –+VDD

Pin3 –NO Relay4

Pin8 –GND

Pin4 –NC Relay3

Connector 7

Pin1 –Digital In 1

Pin5 –COM Relay3

Pin2 –GND

Pin6 –NO Relay3

Pin3 –Digital In 2

Pin7 –NC Relay2

Pin4 –Digital In 3

Pin8 –COM Relay2

Pin5 –GND

Pin9 –NO Relay2

Pin6 –Digital In 4

Pin10 –NC Relay1

Connector 8

Pin1–Analog In 1

Pin11 –COM Relay1

Pin2 –GND

Pin12 –NO Relay1

Pin3 –Analog In 2

Connector 5

Pin1 –Line A+ (D0)

Pin4 –Analog In 3

Pin2 –GND

Pin5 –GND

Pin3 –Line B- (D1)

Pin6 –Analog In 4

6.2.1. Power supply connection

TCW242-S is designed to be supplied by adapter SYS1308(N)-2412-W2E or similar, intended for

use in the conditions of overvoltage category II, and prior assessed for compliance with safety

requirements. The power supply equipment shall be resistant to short circuits and overload in a

secondary circuit.

When in use, do not position the equipment so that it is difficult to disconnect the device from

the power supply.

TCW242-S_R1.0 –July 2021 Page 6

6.2.2. Digital inputs connection

All inputs are non-isolated from the power supply.

The digital inputs of TCW242-S in OPEN/CLOSED mode can be used for monitoring of devices

with “dry contact” outputs – door contact switch, push-button, PIR detector, etc.

The following picture illustrates how a dry contact switch can be connected to the input of

TCW242-S. One side of the contact is connected to “Digital In” and another side is connected to

“GND” terminals.

The digital inputs of TCW242-S in COUNTER mode can be used for monitoring devices with a “dry

contact” pulse output interface.

The maximum cable length should be up to 30 meters.

6.2.3. Analog inputs connection

All inputs are non-isolated from the power supply.

Analog inputs of TCW242-S can be used for monitoring devices with voltage and current loop

outputs. They can be connected directly to analog sensors for temperature, humidity,

current/voltage transducers, etc.

The following picture illustrates how a battery can be connected to the analog input of TCW242-

S in voltage mode. The positive terminal is connected to “Analog In” and the negative terminal to

“GND”.

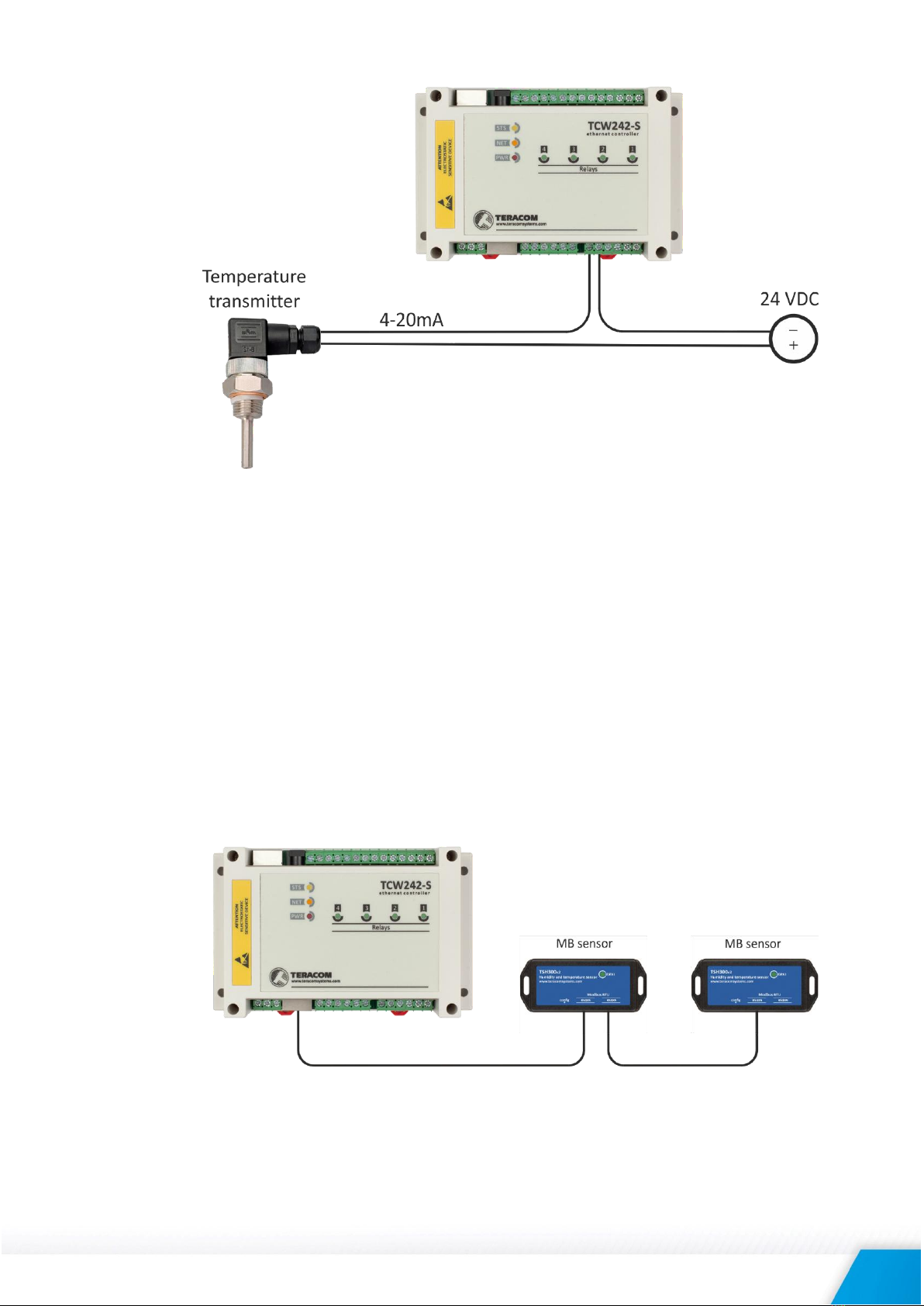

The following picture illustrates how an analog sensor for temperature with current loop output

is connected to the analog input. The active terminal is connected to “Analog In” while the shield

terminal is to “GND”.

TCW242-S_R1.0 –July 2021 Page 7

The maximum cable length should be up to 30 meters.

6.2.4. RS-485 connection

RS-485 interface is non-isolated from the power supply.

Up to 24 MODBUS RTU sensors can be connected to TCW242-S. The device supports Teracom

and third-party sensors.

Connections can be realized by a standard RJ-45 connector. The used pinout is the one

recommended in the document “MODBUS over Serial Line Specification and Implementation

Guide”available on www.modbus.org.

It is mandatory to use 120ohms line terminators at both ends of the bus. TCW242-S incorporates

one of the terminators and should be placed at one end. So the client should only take care of

terminating at the other end of the line.

It is strongly recommended using “daisy-chained” (linear topology) for multiple sensors:

It is recommended to use only UTP/FTP cables and keep the total cable length up to 30 m,

although functionality has been achieved on a longer distance.

TCW242-S_R1.0 –July 2021 Page 8

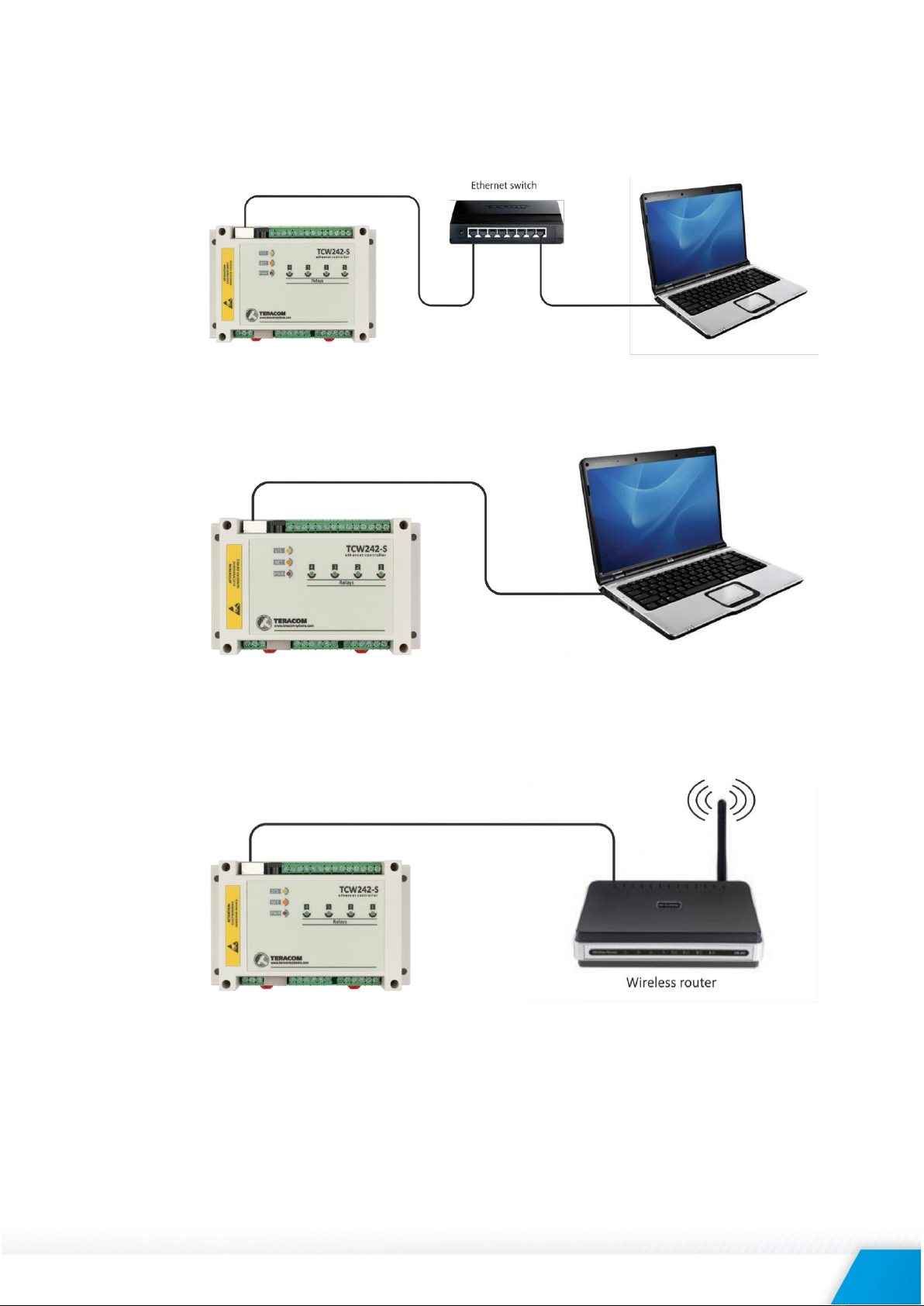

6.2.5. Network connection

The Ethernet port of TCW242-S should be connected to 10/100 Base-T Ethernet hub, switch, or

router.

For configuration, TCW242-S may be connected directly to the Ethernet port on a computer. The

device support Auto-MDIX and it is not necessary to use a “crossover” cable, standard “straight-

through” can be also used.

TCW242-S can be used in a wireless network by connecting through a wireless router.

6.3. Communication setup

By default TCW242-S is delivered with the following network settings:

IP address: 192.168.1.2, Subnet Mask: 255.255.255.0, Default Gateway: 192.168.1.1

TCW242-S_R1.0 –July 2021 Page 9

Communication with TCW242-S can be established by assigning a temporary IP address to the

computer. For computers with Windows OS assigning of IP address is made in “Local area

connection properties”:

This address should be on the same network - for example 192.168.1.3:

To get access to the web interface, you should type http://192.168.1.2 into the browser.

TCW242-S_R1.0 –July 2021 Page 10

If the network settings are correct, the login pop-up window will appear:

Authorization data must be entered (by default username=admin, password=admin).

It is recommended to change the username and password to prevent unauthorized access to the

controller.

All TCW controllers connected to LAN can be easily found by a free tool “TCW discoverer”. It is

available for Win and Mac operating systems and can be downloaded from

www.teracomsystems.com.

7. Concept of setup

The main setup channel of the device is the web interface. It is recommended to use it, even more of

the settings are available through SNMP and HTTP API commands.

The device setup begins with network settings.

Then the so-called primary parameters (MODBUS RTU sensors/registers, analog inputs, and digital

inputs) are set up.

The channels are formed from already set up primary parameters. Every channel can combine up to

two primary parameters and constants with math operations. It is possible that a channel is formed by

only one primary parameter.

Once all channels have been tuned, the alarm can be set up. It is important to remember that alarms

work with channels, not with primary parameters. Each alarm can have up to two conditions. Different

channels may be involved in the conditions. Alarms are independent of the channels but can also be

assigned to a channel.

In other words, the right setup should follow the following order:

Once everything above is set correctly, the wanted services (data logger, SNMP, HTTP API, etc.) can be

turned on.

8. Web interface

The web interface allows configuration and monitoring. All pages are UTF-8 encoded.

The controller supports a few active sessions. For the WEB interface, the device supports HTTP only

(HTTPS is not supported).

8.1. Monitoring

This section displays the status of all channels, relays, and alarms –textually and graphically.

The pages “Data” and “Alarms” are refreshed automatically on at interval of 0 to 253 seconds. Zero

means no automatic refresh. This parameter is set in section “Setup-System- Refresh of channels

and alarms pages”. By default, the refresh interval is 1 second.

TCW242-S_R1.0 –July 2021 Page 11

8.1.1. Channels and relays

This page displays the status of relays and all monitored channels –their values and alarm status.

The information is updated on the refresh interval.

8.1.2. Alarms

This page displays the status of all alarms. The information is updated on the refresh interval.

8.1.3. Graphs

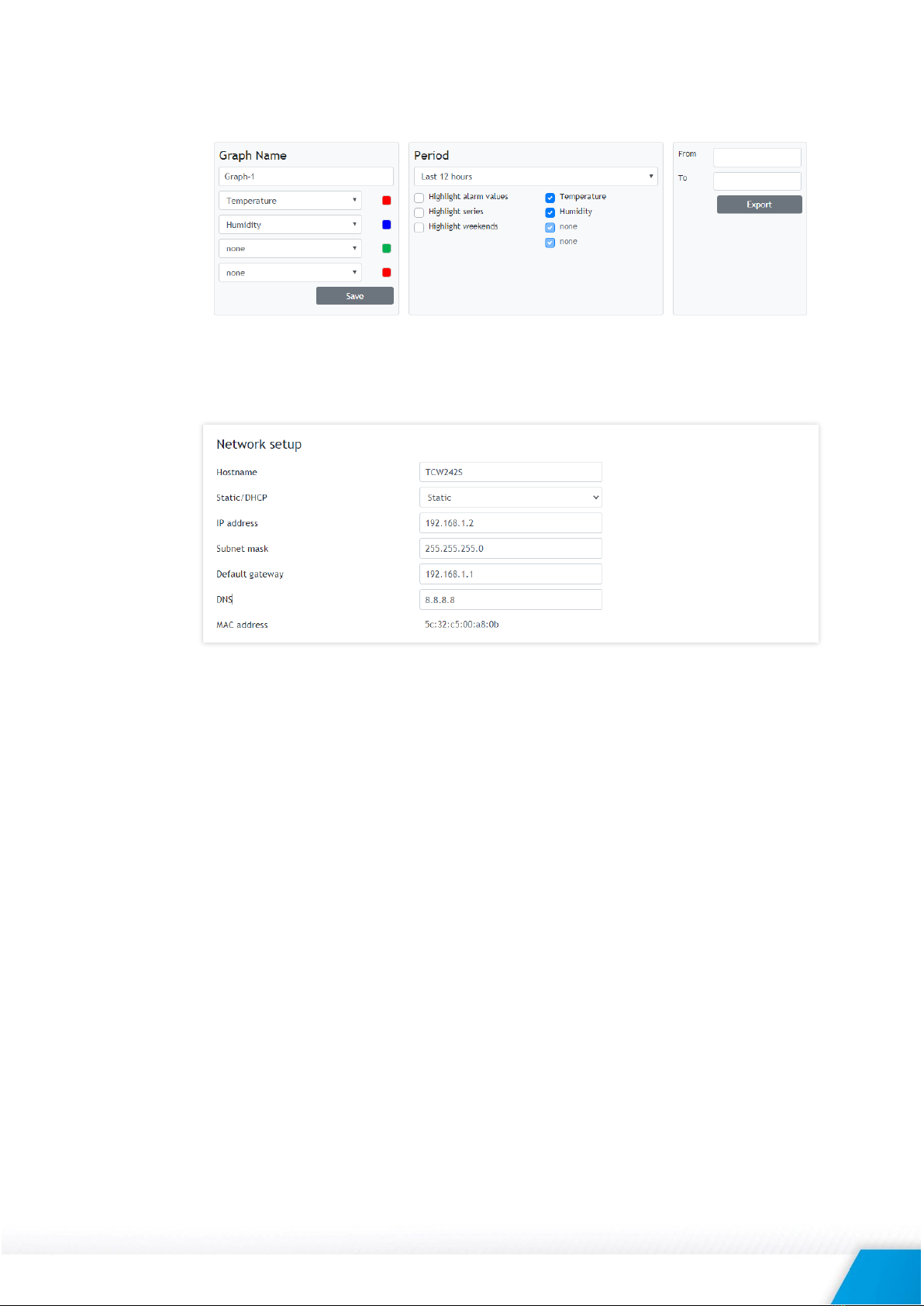

All channels together with their alarm statuses can be monitored graphically in tabs Graph-1 to

Graph-6. Every graph supports up to 4 channels with up to 2 different dimensions. The curve’s

color for every channel is selectable. The alarms status colors are fixed. There are a few

checkboxes for display modification.

Graphs show information from the past, so it is mandatory that the logger is active.

TCW242-S_R1.0 –July 2021 Page 12

It is important to know that the information on graphs is static, it is not updated whit the newest

values. If you want to see the last information, the page should be reloaded. The information can

be exported in a CSV file.

8.2. Setup

8.2.1. Network

The network parameters can be set on this page.

The module supports static and dynamic IP addresses.

It is good practice to change the default IP address of the controller immediately after the first

power-on. This will avoid collisions if many devices are used on the same network.

It may be necessary to clear the arp cache, each time you connect a new device to the network.

This is done by typing arp -d in the command prompt window of the computer.

The “Hostname” is up to 15 characters. It is shown in the search results of the TCW discoverer.

It is recommended to use a public DNS server (8.8.8.8, 8.8.4.4, etc.) rather than the default

gateway.

8.2.2. Modbus sensors

8.2.2.1. Modbus RTU communication setup

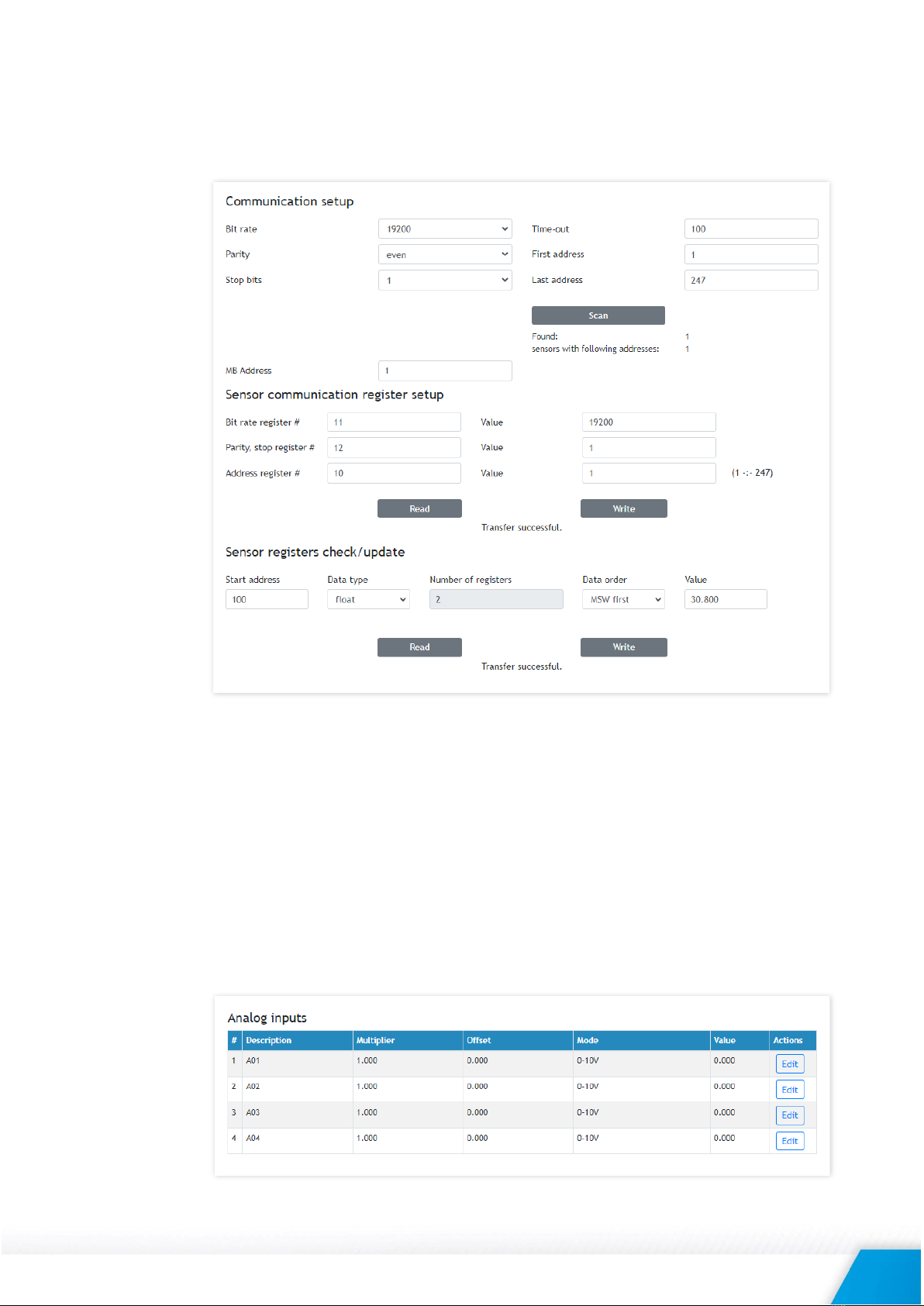

Modbus RTU communication setup

This section allows you to set the communication parameters of the RS-485 interface –bit

rate, parity, and a number of stop bits. By default, the settings are 19200, even parity, and 1

stop bit. It is mandatory that all sensors on the bus use the same bit rate, parity, and number

of stop bits. Before adding any sensor to the interface its parameters should be set up

properly.

In the right part of the section, there is a tool that scans the bus and reports the number of

the found sensor together with their addresses. It is very useful at a time when you add new

sensors. It is recommended to use a small address segment to speed up the scan process.

Playing with “Scan time-out for sensor answer” it is possible to find this parameter for an

unknown sensor. The test starts with a large time-out (for example 500ms) and gradually

TCW242-S_R1.0 –July 2021 Page 13

decreases the time until the sensor stops responding. In order for the operation sustainability,

the found time should be increased with for example 20%.

8.2.2.2. Modbus RTU sensors

This section allows you to add, delete or edit MODBUS RTU sensors/registers. All these are

primary parameters and can be used in forming channels.

It is recommended to add sensors/registers one by one using the scan tool described in

8.2.2.1.

Up to 24 sensors/registers can be added. All they are shown in the table.

According to the MODBUS convention, possible addresses for sensors are in the range of 1 to

247.

The Multiplier and Offset works as follows:

Value = (Raw_Value * Multiplier) + Offset.

If you want to see the raw value of the sensor/register set Multiplier=1 and Offset=0.

During operation, all sensors are polled consecutively. The controller expects an answer in

"response time-out". If the sensor does not respond for that time, the controller addresses

the next sensor. If the same sensor does not respond in series 3 times, the device assumes

that it is not present in the system but continues to polls it.

According to the above paragraph, special attention should be paid to response time-out. On

the one hand, the time-out should be large enough for the sensor to respond, but on the

other hand, the sum of all sensor time-outs forms the "maximum response time-out" of the

whole system. The "maximum response time-out" determines the response of the system.

For the sustainable system operation, polling of every sensor is made at a fixed time - "Polling

time". It is user-selectable and can be 1, 2, 3, or 4 seconds. By default, it is 1 second.

It is recommended that "Polling time" ≥ "Maximum response time-out".

TCW242-S_R1.0 –July 2021 Page 14

8.2.2.3. Sensor setup tool

The device has also a simple but useful tool for configuration and control of MODBUS RTU

sensors. It can change the addresses and communication parameters of sensors from

different manufacturers.

8.2.3. Input/Output

This page is used for the parameterization of relays, analog, and digital inputs.

8.2.3.1. Analog inputs

TCW242-S has 4 analog inputs. All they are isolated from the power supply but use the same

ground. Every analog input can work in voltage (0-10V) or current loop mode (0-20mA).

For every analog input Multiplier and Offset can be set. They work as follows:

Value = (Raw_Value * Multiplier) + Offset.

If you want to see the raw value of the sensor/register set Multiplier=1 and Offset=0.

By default and after “Factory default settings” procedure: Multiplier=1.00, Offset=0.00 and

Mode=0-10V

TCW242-S_R1.0 –July 2021 Page 15

Example:

For humidity sensor HIH-4000-003 the following parameter (coming from datasheet) should

be set for fine work:

Multiplier - 31.74

Offset - 0.826

Mode - 0-10V

Unit - %RH (is set in the channels web page)

The value of the multiplier is inverted of slope parameter (1/0.0315);

If the output voltage of this sensor is 3.198V the value of analog input will be 75.28% RH:

75.28 = (3.198 –0.826) * 31.74

8.2.3.2. Digital inputs

TCW242-S has 4 digital inputs. All they are isolated from the power supply but use the same

ground. Every digital input can work in OPEN/CLOSE or COUNTER mode. In COUNTER mode,

counting can be made on rising, falling, or both edges.

For the counter mode, there is a possibility for setting up the counter initial value.

There are two delays –Open-to Close and Close-to-Open. The delays are in the range of 5 to

60000mS. These delays can be used for additional digital filtering. The delays are applied in

both modes.

In the picture above Open-to Close and Close-to-Open delays are set to 13mS.

8.2.3.3. Relay outputs

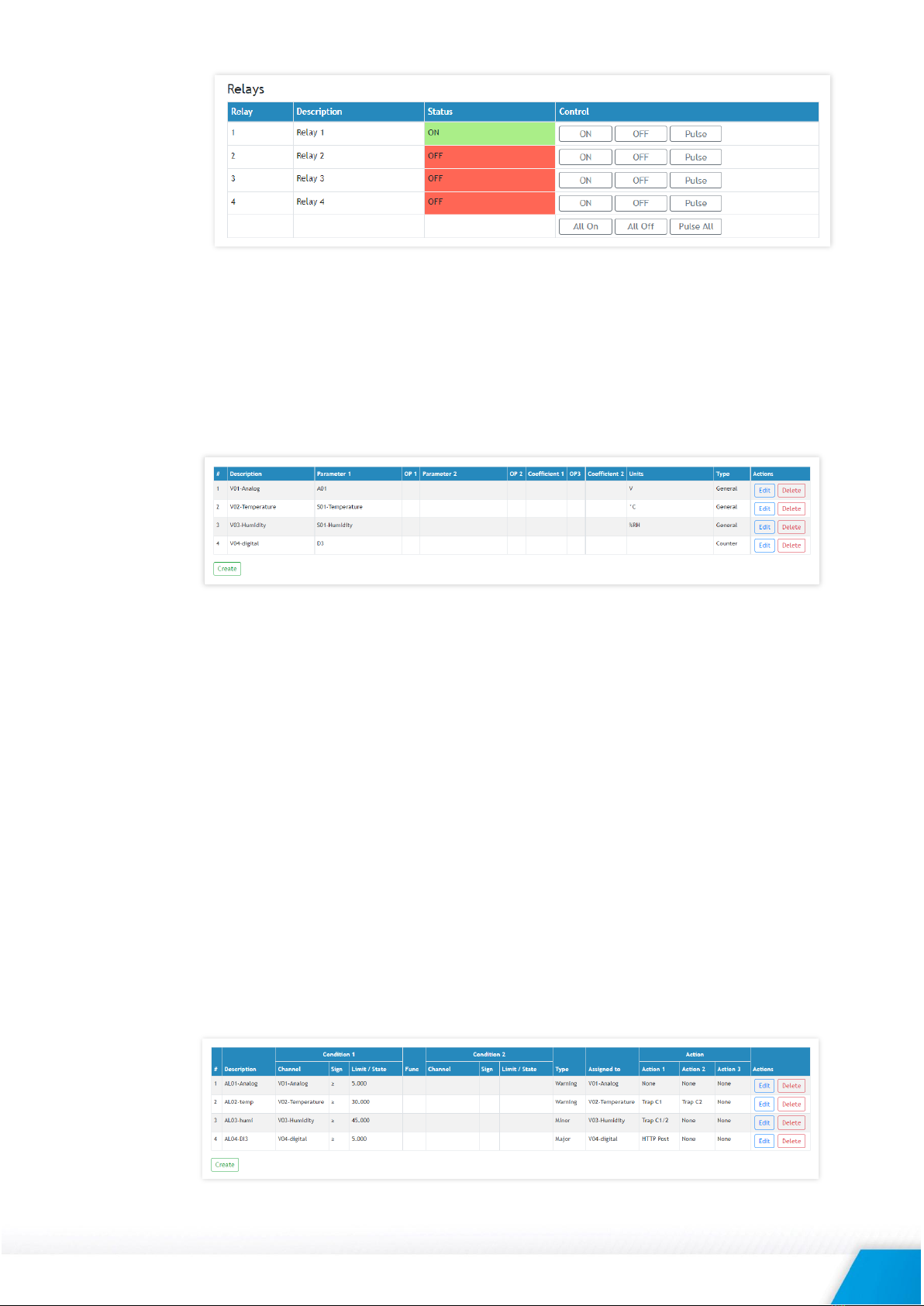

Each relay can be activated either remotely by the WEB interface, HTTP API, and SNMP or locally,

from the alarm conditions.

For WEB control every relay has “On”, “Off” and “Pulse” buttons. There are also “All On”, “All

Off” and “Pulse All” for common control of relays. Pulse duration in seconds can be set

separately for each relay in “Setup-Input/Output-Relay Outputs”.

TCW242-S_R1.0 –July 2021 Page 16

For locally activated relays a text description of the controlling parameter is displayed rather

than buttons. Parameters for local relay activation can be set in “Setup-Input/Output-Relay

Outputs”.

8.2.4. Channels

This section allows you to add, delete or edit channels. All they can be monitored on monitoring

pages and their values can be recorded periodically by the data logger.

Up to 24 channels can be set up.

There are two types of channels –discrete (it forms by one digital input in OPEN/CLOSE mode)

and general (it forms by up to 2 primary parameters and constants)

It is important to know that for general channels, the sequence of operations is OP1, then OP2,

and finally OP3.

It is possible to use a digital input in OPEN/CLOSE mode to form a general channel. In this case,

its values for operations are 0 (for CLOSE) and 1 (for OPEN).

8.2.5. Alarms

This section allows you to add, delete or edit alarms. Up to 24 alarms can be set up.

There are four types of alarms –Warning, Minor, Major and Critical.

Only channels can be used to form the alarms.

The alarms are independent but can be assigned to a channel. There isn’t a restriction to which

channel to assign the alarm.

For every alarm up to 2 conditions can be used. Both conditions can be logically joined using the

logical operators AND and OR.

It is not mandatory to use the same channel in both conditions. In this case, conditions for two

different channels can be combined in one alarm.

TCW242-S_R1.0 –July 2021 Page 17

The “Limit” indicates the border of the working range for the observed channel.

A trigger condition occurs when the value goes higher (“Sign” is “≥”) and lower (“Sign” is “<”)

than the limit. In both cases, the monitored parameter goes out of range.

Coming back in range for the observed channel is considered when the value goes higher than

Limit + Hysteresis (“Sign” is “<”) or lower than Limit – Hysteresis (“Sign” is “≥”).

The hysteresis is used to prevent excessive triggering when the value vacillates around the

trigger point.

It is strongly recommended not to use Hysteresis=0.0.

For every alarm “Return notification” option is available. If this option is chosen there will be a

notification also when the parameter returns in range.

For every alarm, there is a “Notification delay” parameter. It is very useful as a filter for short

alarm conditions.

TCW242-S_R1.0 –July 2021 Page 18

8.2.6. System

On this page, some general system parameters can be set up.

System name, system location, and system contact are used for device identification. They are

presented in SNMP three and XML/JSON status files.

WEB access authentication by default is active with admin/admin details.

HTTP port for WEB access by default is 80 but it can be changed. This is useful for some routers

which don’t support different outside/inside ports for port forwarding.

HTTP API access authentication by default is active. Authentication details are the same as WEB

access. The controller support two types of authentication –see the explanation for HTTP API

below.

The refresh interval can be set between 0 and 253 seconds. Zero means no automatic refresh.

Alarms colors are fixed and are presented here just for information.

TCW242-S_R1.0 –July 2021 Page 19

8.3. Services

8.3.1. NTP

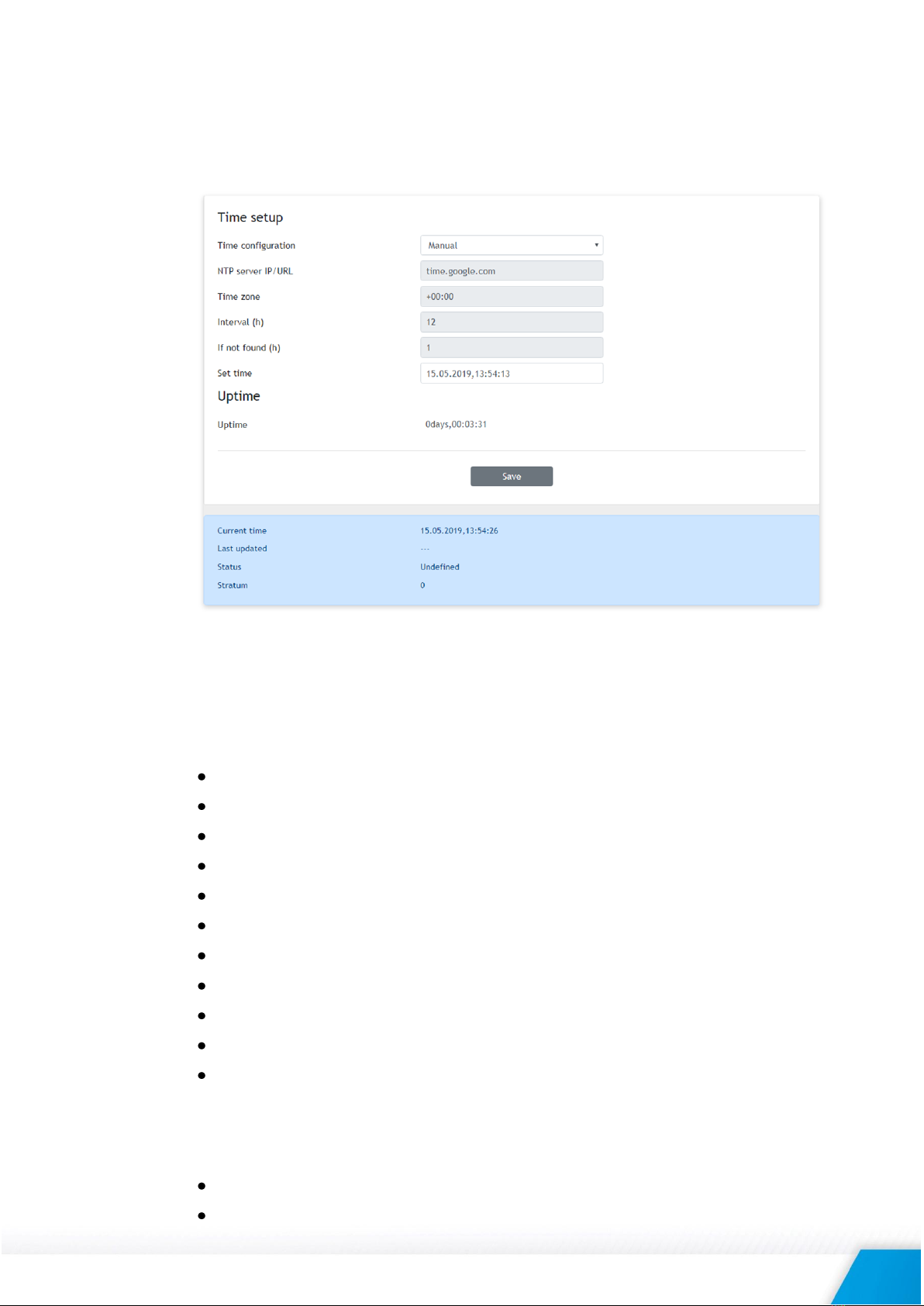

The internal real-time clock of the controller can be set either manually or automatically.

For automatic clock synchronization, the controller supports NTP (Network Time Protocol).

By default NTP synchronization is disabled, server –time.google.com, Time zone +00:00, and

interval of 12 hours.

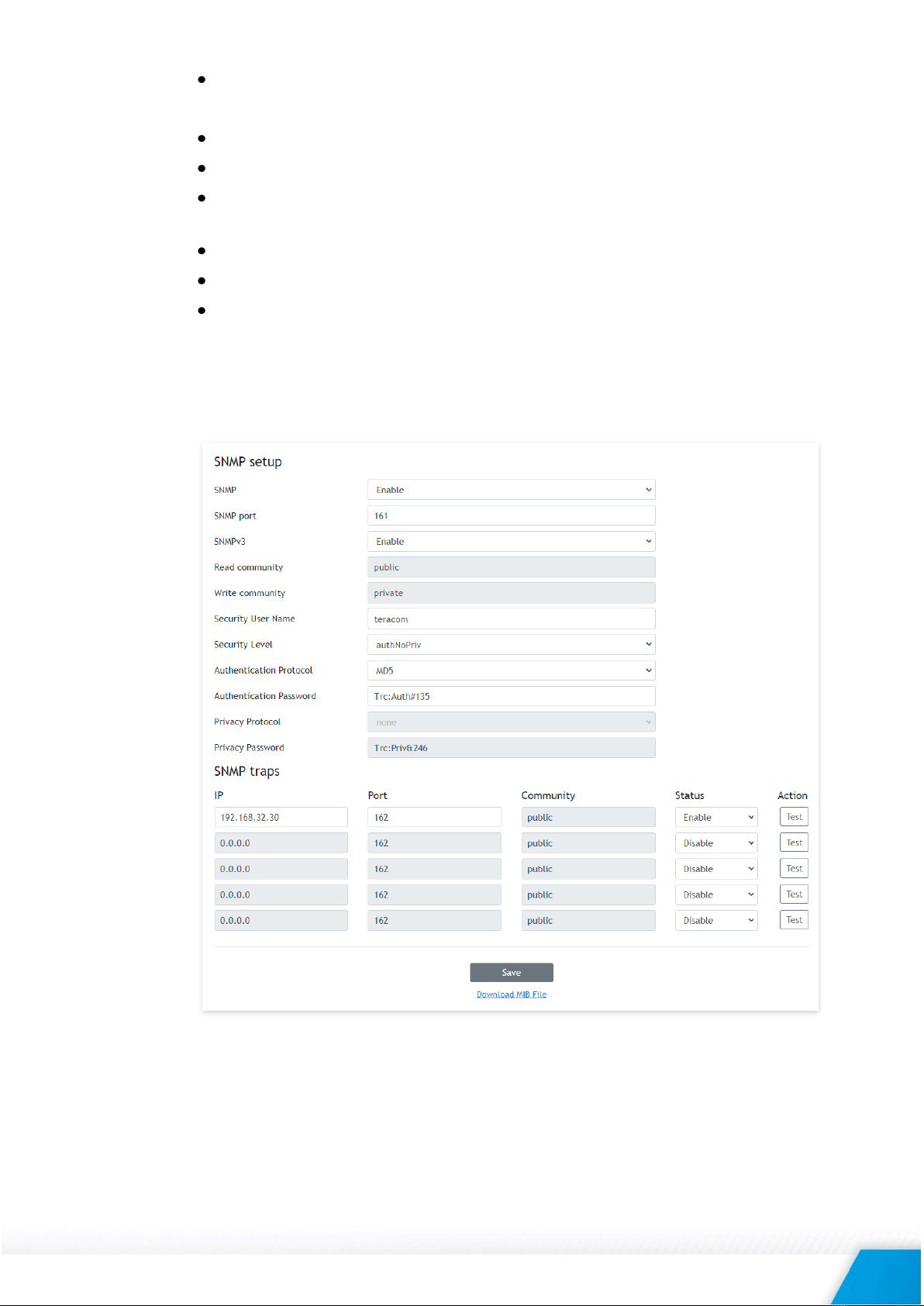

8.3.2. SNMP

TCW242-S supports SNMPv2 and SNMPv3.

The default parameters are:

SNMP disabled

Port 161

SNMPv3 disabled

read community public

write community private

Security User Name teracom

Security Level noAuthNoPriv

Authentication Protocol none

Authentication Password Тrc:Аuth#135

Privacy Protocol none

Privacy Password Тrc:Priv&246

The more advanced SNMPv3 offers security management for administration, authentication, and

privacy.

SNMPv3 provides the following configuration possibilities:

No authentication and no privacy (noAuthNoPriv) - usually for monitoring;

Authentication and no privacy (authNoPriv) - usually for control;

TCW242-S_R1.0 –July 2021 Page 20

Authentication and privacy (authPriv) - usually for downloading secrets.

User-based Authentication Mechanism is based on the following:

MD5 message-digest algorithm in HMAC;

SHA, an optional alternative algorithm;

None authentication.

User-based Privacy Mechanism is based on the following:

Data Encryption Standard (DES);

Advanced Encryption Standard (AES);

None encryption.

For alarm notification, an SNMP trap can be sent to up to 5 independent recipients. Different

ports and communities can be used for every trap.

SNMP trap is sent also after reset.

The actual MIB file can be downloaded from the link at the bottom of the web page.

Table of contents

Other Teracom Control Unit manuals

Popular Control Unit manuals by other brands

PASCO

PASCO EM-3534 Replacement instructions

NETGEAR

NETGEAR AGM731F - ProSafe SFP Transceiver Module installation guide

Beninca

Beninca DA.24A operating instructions

Becker

Becker Beck-O-Tronic 6 Assembly and operating instructions

WNC

WNC XRBH-1 user manual

Elster

Elster ACM M-BUS WIRE operating instructions