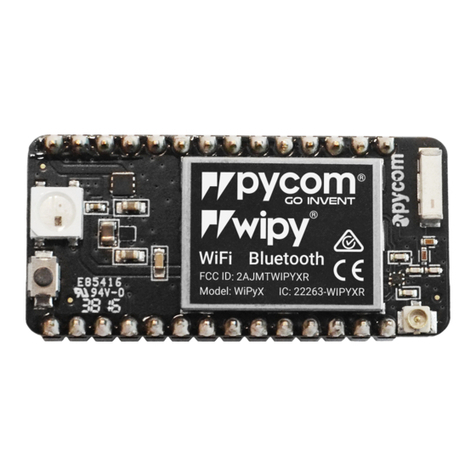

Teracom TCW280 User manual

TCW280_R1.2 – February 2019 Page 2

1. Short description

TCW280 is an analog output module with Ethernet interface and galvanic isolation between power

supply and outputs.

It has 2 analog output channels. Every channel can work either in voltage (0/5 or 0/10V) or current loop

(0/20, 4/20 or 0/24mA) mode. Generated signals have excellent stability and 12-bit resolution.

The device has also 4 digital (open drain) outputs. The digital outputs work in two modes – ON/OFF or

PWM. In ON/OFF mode they can be used as a standard digital output to control devices with dry contact

activation. In the PWM mode, the output can be used as an “analog” output for appropriate processes

– DC motor control, LED dimming, etc. The frequency in PWM mode can be up to 2 kHz.

TCW280 has also 2 relays with normally closed and normally open contacts. Both relays can be activated

from the WEB interface, M2M protocol or by the schedule.

The scheduling functionality offers 4 different schedules for single or repeated (weekly) tasks.

The module supports MODBUS TCP/IP, SNMP, and HTTP API for M2M communication.

2. Features

•Galvanically isolated outputs;

•10/100 Mbit Ethernet connectivity;

•Password protected WEB interface;

•2 analog outputs with voltage and current loop modes;

•0/20, 4/20 and 0/24mA ranges for current loop mode of analog output;

•0/5 or 0/10V ranges for voltage mode of analog output;

•4 digital (open drain) outputs with ON/OFF or PWM modes;

•2 relays with NO and NC contacts;

•Dynamic DNS support;

•4 schedules with single and weekly mode;

•NTP support;

•SNMP v2 support;

•SNMP traps to up to 5 recipients;

•MODBUS TCP/IP support;

•Periodical HTTP post with current status in XML or JSON file to the remote server;

•HTTP API commands in server and client mode;

•HTTP Post to up to 3 different servers;

•Back/restore of settings for easy device multiplication;

•Firmware update over the Internet;

•DIN-Rail/wall-mountable enclosure.

3. Applications

The possible application of TCW280 are:

•Direct electronic valve actuators control;

•DC motor speed control;

•Direct dimming of RGB LED’s;

•Variable frequency drive control;

•Solenoid valve control;

•Solid state relay control;

•Remote transmission (tunneling) of analog signals.

TCW280_R1.2 – February 2019 Page 3

4. Specifications

•Physical characteristics

Dimensions: 115 x 90 x 40 mm

Weight: 170 g

Mounting: wall and DIN rail

•Environmental limits

Operating Temperature: -10 to 55°C

Storage Temperature: -20 to 70°C

Ambient Relative Humidity: 10 to 80% (non-condensing)

•Standards and Certifications

Safety: EN 60950-1:2006+A11:2009+A1:2010+A12:2011+A2:2013

EMC: EN 55032:2015, EN 55024:2010+A1:2015, EN 61000-3-2:2014, EN 61000-3-3:2013

RoHS: Compliant

•Warranty

Warranty period: 3 years

•Power requirements

Input Voltage: 10 to 32 VDC

Input Current: 220 mA @ 12 VDC (all relays are on and both analog outputs are at 24mA)

•Analog outputs

Isolation: Isolated (1000V)

Type: Single ended

Resolution: 12 bits

Mode: Voltage or Current loop (WEB interface selectable)

Ranges: 0/5V, 0/10V, 0/20mA, 4/20mA, and 0/24mA

Accuracy: ±1%

•Digital outputs

Isolation: Isolated (1000V)

Type: Open drain

Maximum drain voltage: 24VDC

Maximum drain current: 0.3A

Mode: ON/OFF or PWM (WEB interface selectable)

PWM resolution: 10 bits

PWM frequencies: 1, 5, 10, 50, 100, 500, 1000, and 2000 Hz

•Relay outputs

Type: Form C (N.O. and N.C. contacts)

Contact current rating: 0.5 A @ 24 VDC, 30 VAC (resistive load)

Initial insulation resistance: 100 mega-ohms (min.) @ 500 VDC

Mechanical endurance: 10 000 000 operations

Electrical endurance: 100 000 operations @ 0.5 A resistive load

Contact resistance: 100 milli-ohms max. (initial value)

Pulse output: 0.1 Hz at rated load

•Internal FLASH memory

Endurance: 100 000 cycles (Every relay status and settings change is a memory cycle.)

TCW280_R1.2 – February 2019 Page 4

5. Installation and setup

This device must be installed by qualified personnel.

This device must not be installed directly outdoors.

The installation consists of mounting the device, connecting to an IP network, connecting inputs and

outputs, providing power and configuring via a web browser.

5.1. Mounting

TCW280 should be mounted in a clean and dry location on a not flammable surface. Ventilation is

recommended for installations where the ambient air temperature is expected to be high.

Mount the device to a wall by using two plastic dowels 8x60mm (example Würth GmbH 0912 802 002)

and two dowel screws 6x70mm (example Würth GmbH 0157 06 70). Attach the screws to the surface

vertically. See Appendix-A, fig. 1 for mechanical details.

Maintain spacing from adjacent equipment. Allow 50 mm of space on all sides, as shown in fig.2 in

Appendix A, this provides ventilation and electrical isolation

TCW280 can be mounted to a standard (35mm by 7.55mm) DIN rail. Attach the controller to the DIN

rail by hooking the hook on the back of the enclosure to the DIN rail and then snap the bottom hook

into place.

5.2. LED indicators

The following indicators show the status of the controller:

•Relay1/Relay2 (green) – these LEDs are illuminated whenever the corresponding relay is

activated (the NO contact is closed and the NC contact is open);

•PWR (red) – in working mode shines, blinks together with STS if there is a hardware error;

•STS (yellow) – flashes when the main program of the controller is executed;

•NET (orange) – network status - ON when a link is established, blinks if there is an activity.

5.3. Connections

Attention! Disconnect power supply before wiring.

The correct wiring procedure is as follows:

•Make sure power is turned off;

•Make wiring connections to the terminals;

•Apply power.

It is recommended to test and configure TCW280 without any controlled device. In this case,

unexpected turn on will be avoided.

Make sure that wires are properly attached to the terminals and that the terminals are tightened.

Not proper wiring and configuration can cause permanent damage to TCW280 or the equipment to

which it is connected or both.

TCW280_R1.2 – February 2019 Page 5

Inputs and outputs locations are shown below:

Connector 1

Ethernet - RJ45

Connector 5

Pin1 – Relay1-NC

Connector 2

Power - 2.1x5.5mm connector

(central positive)

Pin2 – Relay1-COM

Pin3 – Relay1-NO

Connector 3

Pin1 – Power positive

Connector 6

Pin1 – Relay2-NC

Pin2 – Power negative (GND)

Pin2 – Relay2-COM

Connector 4

Pin1 – Open drain OUT4

Pin3 – Relay2-NO

Pin2 – SGND

Connector 7

Pin1 – IOUT1

Pin3 – Open drain OUT3

Pin2 – SGND

Pin4 – Open drain OUT2

Pin3 – VOUT1

Pin5 – SGND

Connector 8

Pin1 – IOUT2

Pin6 – Open drain OUT1

Pin2 – SGND

Pin3 – VOUT2

5.3.1. Power supply connection

TCW280 is designed to be supplied by adapter SYS1308-2412-W2E or similar, intended for use in

the conditions of overvoltage category II. The power supply equipment shall be resistant to short

circuit and overload in a secondary circuit.

When in use, do not position the equipment so that it is difficult to disconnect the device from the

power supply.

5.3.2. Analog outputs

TCW280 has two isolated analog channels. Every channel can be programmed to work either in

voltage or current loop mode. In the voltage mode, two ranges are supported - 0 to 5 and 0 to 10

volts. In the current loop mode, three ranges are supported – 0 to 20, 4 to 20, and 0 to 24 mA. In

the current loop mode, there is an alarm notification for open loop.

Voltage and current loop outputs are single-ended and are assigned to different connectors. Using

the selected mode requires connecting to the appropriate connector.

TCW280_R1.2 – February 2019 Page 6

The output schematic is as follows:

Analog inputs can be used to direct control of devices with voltage or current loop inputs –

electronic valve actuators, motor inverters, etc.

5.3.3. Open drain outputs

TCW280 has four isolated open drains (digital) outputs. Every digital output can be programmed

to work either in ON/OFF or PWM (Pulse-width modulation) mode.

In PWM mode a few frequencies are supported. The working frequency of PWM has to be higher

than the effect which is expected in the load. Every output can be set on a different Pulse-width,

but the frequency is the same for all outputs in this in this mode.

PWM is an easy way to have an analog control through a digital signal. The duty cycle of the PWM

corresponds to the average value of voltage fed to the load.

TCW280_R1.2 – February 2019 Page 7

The output schematic is as follows:

The open drain outputs in PWM mode can be used for control dimming of LEDs, speed control of

PMDC motor, control the angle of servo motors, etc.

The open drain outputs in ON/OFF mode can be used as a standard digital output. They can control

directly the “dry contact” inputs of the controlled device. For high current loads, external solid

state relay or mechanical relay should be used.

TCW280_R1.2 – February 2019 Page 8

5.3.4. Relays connection

TCW280 has 2 relays. They can be used for switching on or off electrical and electronic devices.

The relay contacts are internally connected directly to the terminal connectors. For both relays

normally open, normally closed and common contacts are available. For loads with higher

switchable current/voltage than specified, an external relay should be used.

When mechanical relays switch inductive loads such as motors, transformers, relays, etc., the

current will arc across the relay contacts each time the contacts open. Over the time, this cause

wears on the relay contacts which shorten their life. When switching an inductive load, it is

recommended that relay contact protection devices are used.

5.3.5. Network connection

The Ethernet port of TCW280 should be connected to 10/100 Base-T Ethernet hub, switch or

router.

For configuration, TCW280 may be connected directly to the Ethernet port on a computer. The

device support Auto-MDIX and it is not necessary to use “crossover” cable, standard “straight-

through” can be also used.

TCW280_R1.2 – February 2019 Page 9

TCW280 can be used in a wireless network by connecting through a wireless router.

5.4. Communication setup

By default TCW280 is delivered with the following network settings:

IP address: 192.168.1.2, Subnet Mask: 255.255.255.0, Default Gateway: 192.168.1.1

Communication with TCW280 can be established by assigning a temporary IP address to the

computer. For computers with Windows OS assigning of IP address is made in “Local area connection

properties”:

This address should be on the same network - for example 192.168.1.3:

TCW280_R1.2 – February 2019 Page 10

To get access to the web interface, you should type http://192.168.1.2 into the browser.

If the network settings are correct, the login pop-up window will appear:

All TCW controllers connected to LAN can be easily found by the free tool “TCW discoverer”.

It is available for Win and Mac operating systems and can be downloaded from

www.teracomsystems.com.

6. Web interface

The web interface allows configuration, monitoring, and control.

All pages are UTF-8 encoded.

If the controller is properly addressing, login pop-up window appears.

Authorization data must be entered (by default username=admin, password=admin).

It is recommended to change the username and password to prevent unauthorized access to the

controller.

The controller supports a few active session.

6.1. Monitoring

On this page can be monitored the temporary status of all outputs. There is a possibility to change

them.

The page consists of three sections - "Analog outputs", "Digital outputs" and "Relays". Each section

can be added/removed from the page for better observation. This is done by the "Setup->System-

Display".

For convenience in the footer of the page, there is system information for the product.

TCW280_R1.2 – February 2019 Page 11

6.1.1. Analog outputs section

This section contains information about the current state of each analog output as well as its

operating range.

Entering a new value and pressing "Set" button changes the status of the output. There is

protection against entering values outside the selected range.

The selected output value is stored in non-volatile memory, and after a power-restore cycle, it is

automatically set. This is so unless in the "Setup-> Outputs" a specific value is selected that will

appear at the output when the power is turned on.

In "Setup-> Outputs" you can also change the description of each analog output, its operating

mode, and its operating range.

Besides through the WEB interface, the status of analog outputs can be changed by HTTP API,

SNMP, and MODBUS TCP/IP.

6.1.2. Digital outputs section

This section contains information about the current state of each digital output and its operating

mode.

The control section is different for both output modes. For PWM mode, there is protection against

entering invalid values. For ON/OFF mode there are activation buttons, similar to relay section.

The selected output value is stored in non-volatile memory, and after a power-restore cycle, it is

automatically set. This is so unless in the "Setup-> Outputs" a specific value is selected that will

appear at the output after the power is turned on.

In "Setup-> Outputs" you can change the description of each output and its mode of operation.

Besides through the WEB interface, the status of digital outputs can be changed by HTTP API,

SNMP, and MODBUS TCP/IP.

6.1.3. Relays section

This section contains information about the current state of the relays and buttons for their

control.

Each relay can be activated either remotely by WEB, SNMP, HTTP API, and MODBUS TCP/IP or

locally, from the status of assigned schedule.

For WEB control every relay has “On”, “Off” and “Pulse” buttons. There are also “All On”, “All Off”

and “Pulse All” for common control of relays. Pulse duration in seconds can be set separately for

each relay in “Setup->Outputs”.

TCW280_R1.2 – February 2019 Page 12

For locally activated relays a text description of the controlling parameter is displayed rather than

buttons. The local relay activation can be set in “Setup->Outputs”.

6.2. Setup

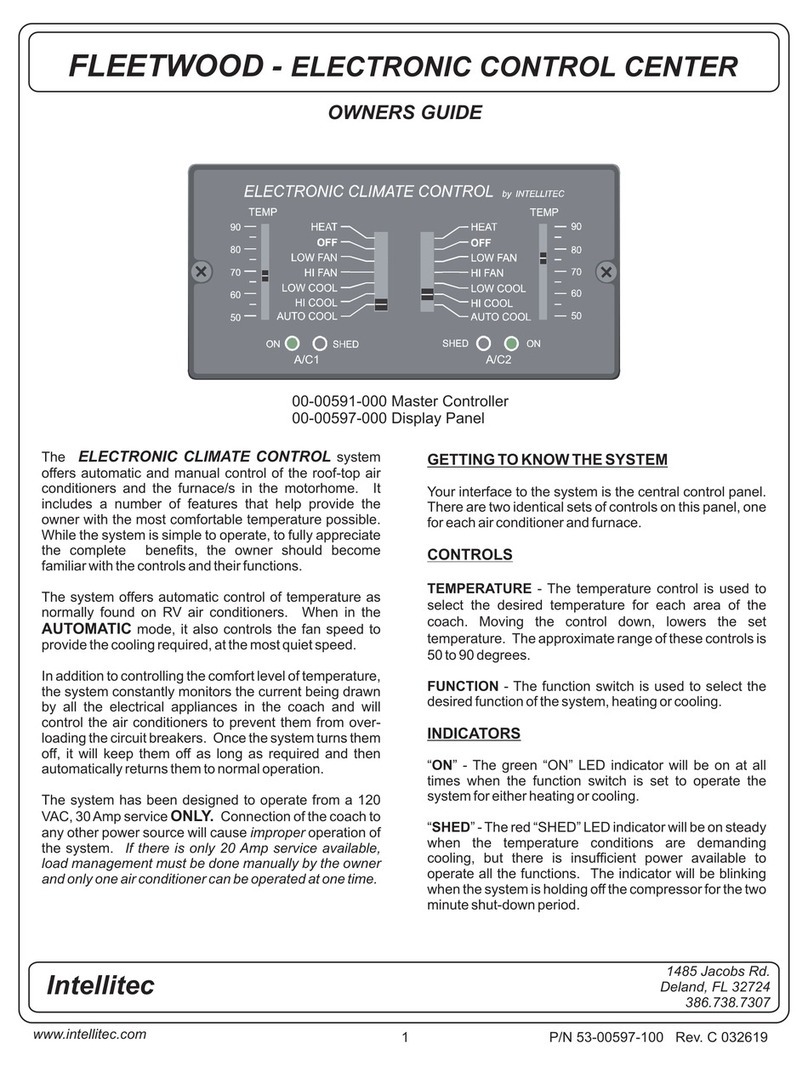

6.2.1. Network

The network parameters are set on this page.

The controller supports static and dynamic IP addresses.

It is good practice to change the default IP address of the controller immediately after first power-

on. This will avoid collisions if many devices are used on the same network.

It may be necessary to clear the arp cache, each time you connect a new device to the network.

This is done by typing arp -d in the command prompt window of the computer.

The “Hostname” is up to 15 characters. It is shown in the search results of TCW discoverer.

It is recommended to use public DNS server (8.8.8.8, 8.8.4.4 etc.) rather than the default gateway.

6.2.2. Outputs

On this page, descriptions and operating modes of each output can be set. After pressing "Save"

button, all changes are stored in non-volatile memory.

6.2.2.1. Analog outputs

For every analog output, a description up to 15 characters can be set. The description is used

to specify the output on Monitoring page and XML/JSON files.

Here you set the operating mode for each output, its operating range, and the value after power

on. By default, it is the last remembered one.

For current loop mode, in case of an open circuit, it is possible to send alarm messages (HTTP

Post or SNMP trap).

6.2.2.2. Digital outputs

For every digital output, a description up to 15 characters can be set. The description is used to

specify the output on Monitoring page and XML/JSON files.

TCW280_R1.2 – February 2019 Page 13

Here you set the operating mode for each output, its operating range, and the value after power

on. By default, it is the last remembered one.

For PWM mode, the frequency can be selected from a drop-down menu, but it is the same for

all outputs.

For ON/OFF mode, the pulse duration can be different for every digital output. The pulse

duration can be in a range of 0.1 to 999999 seconds.

6.2.2.3. Relays

For every relay, a description up to 15 characters can be set. The description is used to specify

the relay on Monitoring page and XML/JSON files.

Here you can choose how the relay will be activated as well as its status after the power is

turned on. By default, it is the last remembered one.

The pulse duration can be different for every relay. It can be in a range of 0.1 to 999999 seconds.

6.2.3. System

On this page, some general settings can be made.

6.2.3.1. General

The information in this section serves to identify the device in M2M communication.

6.2.3.2. WEB access

In this section, WEB access authentication can be deactivated. By default, authentication details

are admin/admin. It is strongly recommended to change them in “Administration->User/Pass”.

HTTP port for WEB access can be changed. This is useful for some routers which don’t support

different outside/inside ports for port forwarding. By default HTTP port is 80.

6.2.3.3. HTTP API

In this section, HTTP API access authentication can be activated/deactivated. By default it is

active.

Authentication details are same as WEB access. The controller support two types of

authentication – see an explanation for HTTP API below.

TCW280_R1.2 – February 2019 Page 14

6.2.3.4. Monitoring page automatic refresh

Monitoring page refresh interval can be set between 0 and 253 seconds. Zero means no

automatic refresh.

6.2.3.5. Display

All three sections on Monitoring page can be added/removed independently by appropriate

setup here.

6.2.4. Time

For proper operation of schedules, there is an internal real-time clock (RTC). It can be set either

manually or automatically.

For automatic clock synchronization, the controller supports NTP (Network Time Protocol) and all

necessary parameters for automatic synchronization are available in this section.

By default NTP synchronization is disabled, server – time.google.com, Time zone +00:00 and

interval of 12 hours.

It is strongly recommended to use time.google.com as a time server.

TCW280_R1.2 – February 2019 Page 15

6.3. Services

6.3.1. Modbus

TCW280 supports Modbus TCP/IP.

By default Modbus is disabled. Standard port for this protocol is 502. More about this functionality

can be read at MODBUS section below.

6.3.2. SNMP

TCW280 supports SNMP v.2.

In this section, all necessary parameters for proper operation of SNMP can be set.

By default SNMP is disabled, the port is 161, read community is “public” and write community is

“private”.

In an alarm condition, SNMP trap can be sent up to 5 independent recipients. All they can be with

different port and community. There is an independent button for trap test.

SNMP traps can be sent:

•In case of an open circuit for analog output in current loop mode;

•After restart;

•After power on.

Actual MIB file can be downloaded from here.

TCW280_R1.2 – February 2019 Page 16

6.3.3. HTTP Post

TCW280 can periodically upload a file to a dedicated server, using HTTP Post. The period of the

post is between 10 and 3600 seconds. The file format can be XML or JSON.

In addition to the periodical post, the file can be uploaded at any alarm condition. In this case

“Connect on any alarm” should be checked.

The HTTP Post can be sent simultaneously up to 3 different servers.

If “Process Answer” option is enabled, TCW280 will process the answer (command) of the chosen

server only. The list of valid commands is described in section HTTP API commands below.

The “Key” field value is sent in the XML/JSON and can be used for device identification.

6.3.4. Schedule

TCW280 supports four schedules. In every schedule, up to four different tasks can be set.

The schedules are useful for creating tasks that vary with calendar dates.

TCW280_R1.2 – February 2019 Page 17

There are two types of schedule depending on repetition and duration:

•A single task for a time period:

With the above setting, there will be an event on 04.12.2018 starts at 10:00:00 and ends in

11:00:35.

The resolution for “OFF time” is 0.1 seconds, which gives a possibility for very short pulses

support.

•A weekly task for a time period:

With the above setting, there will be an event on Wednesdays, Fridays, and Saturdays

starting at 21:00:00 and ending in 22:25:20.

6.3.5. Dynamic DNS

With dynamic DNS, TCW280 can be accessed from the public Internet without investing in a

broadband account that has a static IP address.

TCW280 supports the following DNS services – DynDNS, No-IP, and DNS-O-Matric.

6.4. Administration

6.4.1. User/Pass

The TCW280 supports one user only. It has administrative rights.

The username and password can be up to 31 characters long.

6.4.2. Backup/Restore

The TCW280 supports backup and restore of all user setting. All settings are saved in XML backup

file. This file can be used after this for restore on many devices. This is very useful for multiplying

similar settings to a batch of controllers.

TCW280_R1.2 – February 2019 Page 18

6.4.3. FW update

The TCW280 can be updated via a WEB interface.

To update the device follow the steps below:

•Go to www.teracomsystems.com and download the latest firmware;

•From Administration->FW update select downloaded .cod file and press “upload” button;

•After the firmware update is completed, the Login page will appear.

Attention! Don’t turn off the power supply during the update. Turning off the power supply will

damage the device.

6.5. Logout

The TCW280 support multisession, but the good practice is to log out after finishing the work.

TCW280_R1.2 – February 2019 Page 19

7. Protocols and API

7.1. SNMP

Simple Network Management Protocol (SNMP) is a standard internet protocol for managing devices

on IP networks. In typical uses of SNMP, one or more administrative computers, called managers,

monitor and control devices on LAN. Each controlled device, at all times, executes a software

component called an agent which reports information via SNMP to the manager.

The TCW280 can be configured and monitored through SNMP.

This could be done using every SNMP v.2 compatible program. Parameters that can be changed, are

grouped according to their functions in the tables below. To obtain a valid OID number it is necessary

to replace the “x” symbol with ”1.3.6.1.4.1.38783”.

To save the changes configurationSaved (OID x.2.3.5.0) should be set to "1".

product

OID

Name

Access

Description

Syntax

x.2.1.1.0

name

read-only

Device name

DisplayString

x.2.1.2.0

version

read-only

Firmware version

DisplayString

x.2.1.3.0

dateTime

read-only

Date and time

DateAndTime

setup -> network

OID

Name

Access

Description

Syntax

x.2.2.1.1.0

deviceID

read-only

Device ID is Default MAC Address

MacAddress

x.2.2.1.2.0

hostName

read-only

Host Name

DisplayString

x. 2.2.1.3.0

deviceIP

read-only

Device IP Address

IpAddress

setup -> outputs -> anOutSetup -> anOut1Setup

OID

Name

Access

Description

Syntax

x.2.2.2.1.1.1.0

anOut1description

read-write

Analog out 1 description

DisplayString

x.2.2.2.1.1.2.0

anOut1mode

read-write

Analog out 1 mode

Integer {

voltage(0),current(1)}

x.2.2.2.1.1.3.0

anOut1range

read-write

Analog out 1 range

Integer {

volt0to5(0),volt0to10(1),

ma4to20(5),

ma0to20(6),

ma0to24(7)}

x.2.2.2.1.1.4.0

anOut1restvalue

read-write

Analog out 1 restart value

Integer {

lastValue(0),volt0of5(1),

volthalfof5(2),

volt5of5(3),

volt0of10(4),

volt5to10(5),

volt10of10(6),ma0(7),

ma2(8), ma4(9),

ma10(10),

ma12(11),ma20(12),

ma22(13),ma24(14)}

TCW280_R1.2 – February 2019 Page 20

setup -> outputs -> anOutSetup -> anOut2Setup

OID

Name

Access

Description

Syntax

x.2.2.2.1.2.1.0

anOut2description

read-write

Analog out 2 description

DisplayString

x.2.2.2.1.2.2.0

anOut2mode

read-write

Analog out 2 mode

Integer {

voltage(0),current(1)}

x.2.2.2.1.2.3.0

anOut2range

read-write

Analog out 2 range

Integer {

volt0to5(0),volt0to10(1),

ma4to20(5),

ma0to20(6),

ma0to24(7)}

x.2.2.2.1.2.4.0

anOut2restvalue

read-write

Analog out 2 restart value

Integer {

lastValue(0),volt0of5(1),

volthalfof5(2),

volt5of5(3),

volt0of10(4),

volt5to10(5),

volt10of10(6),ma0(7),

ma2(8), ma4(9),

ma10(10),

ma12(11),ma20(12),

ma22(13),ma24(14)}

setup -> outputs -> digOutSetup-> digOut1Setup

OID

Name

Access

Description

Syntax

x.2.2.2.2.1.1.0

digOut1description

read-write

Digital Out 1 description

DisplayString

x.2.2.2.2.1.2.0

digOut1mode

read-write

Digital out 1 mode

Integer {

onoff(0),pwm(1)}

x.2.2.2.2.1.3.0

digOut1pulseWidth

read-write

Digital out 1 Pulse x100ms

Integer32

x.2.2.2.2.1.4.0

digOut1controlledBy

read-write

Digital out 1 control logic

Integer {

webORm2m(0),

shedule1(1),

shedule2(2),

shedule3(3),

shedule4(4)}

x.2.2.2.2.1.5.0

digOut1reststate

read-write

Digital out 1 restart state

Integer {

lastState(0),

on(1),off(2),

percent0(3),

percent50(4),

percent100(5)}

setup -> outputs -> digOutSetup-> digOut2Setup

OID

Name

Access

Description

Syntax

x.2.2.2.2.2.1.0

digOut2description

read-write

Digital out 2 description

DisplayString

x.2.2.2.2.2.2.0

digOut2mode

read-write

Digital out 2 mode

Integer {

onoff(0),pwm(1)}

x.2.2.2.2.2.3.0

digOut2pulseWidth

read-write

Digital out 2 Pulse x100ms

Integer32

x.2.2.2.2.2.4.0

digOut2controlledBy

read-write

Digital out 2 control logic

Integer {

webORm2m(0),

shedule1(1),

shedule2(2),

shedule3(3),

shedule4(4)}

x.2.2.2.2.2.5.0

digOut2reststate

read-write

Digital out 2 restart state

Integer {

lastState(0),

on(1),off(2),

percent0(3),

percent50(4),

percent100(5)}

Table of contents

Other Teracom Control Unit manuals

Popular Control Unit manuals by other brands

ICP DAS USA

ICP DAS USA tM-AD5 quick start guide

BFT

BFT BEBA Z-WAVE quick guide

Allen-Bradley

Allen-Bradley 1771-QRD Installation and user manual

Pycom

Pycom WiPy 3.0 manual

Conbraco Industries

Conbraco Industries Apollo 70-600 Series Installation, operation and maintenance guide

Fluidmaster

Fluidmaster 402CARHR Quick install guide