DLP Design DLP-MAVLCD1 User manual

Rev. 1.0 (February 2012) 1 © DLP Design, Inc.

D

DL

LP

P-

-M

MA

AV

V-

-

L

LC

CD

D1

1

LEAD FREE

LCD / MICROCONTROLLER MODULE

The DLP-MAV-LCD1 combines a 2x16-character backlit LCD display with a TI MSP430

microcontroller to form a MAVRK-supported display module. The MSP430 is preprogrammed with

basic functionality for driving the LCD display via either the MAVRK platform or a simple, 5-pin TTL

serial interface.

FEATURES:

•Simple ASCII Command Set

•Requires 3.0-3.3V Supply

•LED Backlight

•5-Switch Joystick (Left, Right, Up, Down and Select)

•Can Be Used Standalone or with the MAVRK Platform

1.0 GENERAL DESCRIPTION

The DLP-MAV-LCD1 provides the MAVRK platform with a means of displaying data that does not

require a connected host PC.

To send data from the host processor on the MAVRK platform via the 2-wire TTL serial interface, the

host firmware sends the data to be displayed using the format described below in Section 3.

When the 5-switch joystick is operated, the DLP-MAV-LCD1 issues switch closure information to the

host processor using the MAVRK platform protocol. This protocol consists of a printable ASCII format

using a synchronization character “^”, and a termination character “~”. (This protocol is further

described in Section 3.)

The DLP-MAV-LCD1 is ready to accept commands immediately upon power up. (Initial baud rate and

serial parameters are outlined in Section 3.)

Rev. 1.0 (February 2012) 2 © DLP Design, Inc.

2.0 MAVRK QUICK START GUIDE

This guide requires the use of a MAVRK platform (purchased separately).

1. Connect the DLP-MAV-LCD1 module to one of the four LTE positions on the MAVRK platform

via the connector on the bottom side of the DLP-MAV-LCD1 module:

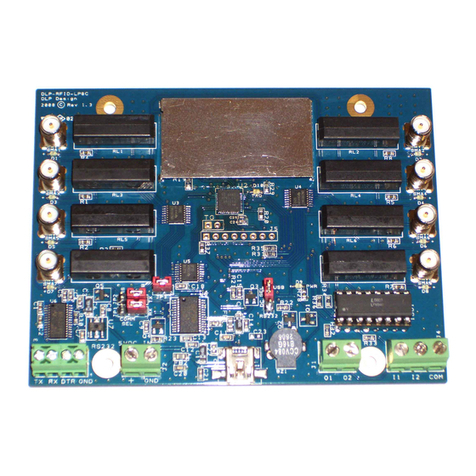

Figure 1: MAVRK Board with DLP-MAV-LCD1 Installed in Position AFE #4

2. Install the firmware as described on the MAVRK wiki pages:

http://processors.wiki.ti.com/index.php/MAVRK_Introduction, specifically the “How do I

get started with MAVRK?” section. Begin by creating a SVN folder at C:\svn.

3. Once installed, locate the project:

C:\svn\mavrk\mavrk_embedded\Modular_EVM_Projects\System_Demo_Projects\MSP43

0F5438-MVK_UART_Passthrough

4. Open the project in Code Composer 5.1 or later.

5. Find the file “MSP430F5438_UART_Passthrough_main.c”, then edit the following lines in the

function main():

// mvk_Configure_UART_Passthrough (MAVRK_UART_RF, MAVRK_UART_TUSB);

// mvk_Configure_UART_Passthrough (MAVRK_UART_TUSB, MAVRK_UART_RF);

6. Add the following lines in the function main() under the ones you just commented out above:

mvk_Configure_UART_Passthrough (MAVRK_UART_P1P2, MAVRK_UART_TUSB);

mvk_Configure_UART_Passthrough (MAVRK_UART_TUSB, MAVRK_UART_P1P2);

7. Rebuild the project, and reload the MAVRK platform with your new flash.

Rev. 1.0 (February 2012) 3 © DLP Design, Inc.

8. Now you can connect the USB cable to the MAVRK debug port and open a terminal interface

(ex: HyperTerminal) to the MAVRK platform using the following settings: Baud: 460800, N,

8, 1.

9. Once connected, actuating the joystick will result in data being displayed that indicates which

joystick button was pressed. The terminal window may also be used to send commands and

data characters to the LCD.

The DLP-MAV-LCD1 module is shipped preprogrammed with firmware for either communicating

directly with the MAVRK platform or for operation in standalone mode via the 5-pin header.

Figure 2: DLP-MAV-LCD1 Module Ready to Start Right Out of the Box

Figure 2 will be displayed for 5 seconds, and then the display will be clear as shown in Figure 3:

Figure 3: Clear (After 5 Seconds)

At this point, the DLP-MAV-LCD1 is ready for use. (Note that the unit will appear non-responsive on

the MAVRK platform until you build and load your new MAVRK platform flash file as described in

Section 2.)

Alternatively, you can communicate directly with the unit in standalone mode. Troubleshooting

information will also be available on the MAVRK wiki pages referenced above.

Rev. 1.0 (February 2012) 4 © DLP Design, Inc.

3.0 COMMAND AND DATA SET

The command and data set syntax communicates via a two-wire serial TTL interface:

Parameter Value

Baud Rate 460800

Data 8 Bit

Parity None

Stop Bit 1

Flow Control None

Table 1: Sample Data and Commands

Changing the Baud Rate via the Menu:

Figure 4: Splash Screen on Power Up

Changing the baud rate may be accomplished; however, you must press Select (joystick straight

down) to initiate the Baud Rate Menu. (Note that this must be done during the first 5 seconds when

the splash screen shown above is displayed.)

Figure 5: Baud Rate Menu

Once Select has been pressed, the Baud Rate Menu (see Figure 5) will be displayed.

Rev. 1.0 (February 2012) 5 © DLP Design, Inc.

From this Baud Rate Menu, press the up or down buttons on the toggle to increase or decrease the

baud rate. (Standard baud rates are detailed in Table 3 below.)

Figure 6: Baud Rate 9600

You may now press the Select button once your baud rate is displayed. This saves the selected baud

rate into flash. On subsequent power ups, the following screen will be displayed indicating the saved

baud rate:

Figure 7: Power Up Splash Screen

Changing the Baud Rate via the Terminal Emulator:

To change the baud rate, first set the baud rate of the terminal to 460800 as described above. Then

send the command ^b9600~, at which point the new baud rate will immediately be in effect. (You will

have to change your terminal to 9600 immediately to continue processing any further commands.)

The TTL interface requires the specific formatting described below for all message traffic to and from

the LCD:

Rev. 1.0 (February 2012) 6 © DLP Design, Inc.

Function Synchronization

Characters Command or Data

Buffer Termination

Character Example

Sending Data ^d Hello World ~ ^dHello World~

Sending

Commands ^c 01 ~ ^c01~

Sending a New

Baud Rate ^b 9600 ~ ^b9600~

Receiving Keys ^k U ~ ^kU~

Table 2: Data and Commands Syntax

Command Sent Text Baud Rate

1200 ^b1200~ 1200

2400 ^b2400~ 2400

4800 ^b4800~ 4800

9600 ^b9600~ 9600

14400 ^b14400~ 14400

19200 ^b19200~ 19200

38400 ^b38400~ 38400

57600 ^b57600~ 57600

115200 ^b115200~ 115200

230400 ^b230400~ 230400

460800 ^b460800~

460800

(Default)

921600 ^b921600~ 921600

Table 3: Standard Baud Rates

Data that exceeds the 16 character lines will be truncated based on the length of the display. Both

the top and bottom LCD lines require separate data commands.

Joystick Received Text Description

Up ^kU~ Key Up was Pressed

Down ^kD~ Key Down was Pressed

Left ^kL~ Key Left was Pressed

Right ^kR~ Key Right was Pressed

Select ^kS~

Key Select (Center Down)

was Pressed

Table 4: Key Definitions

Keys will be sent to the connected terminal with de-bounce. If you hold the key down longer than

500mS, it will repeat.

Rev. 1.0 (February 2012) 7 © DLP Design, Inc.

Command Sent Text Description

80 ^c80~

Cursor Location to Row 1/Column 1

(see Table 6)

C0 ^cC0~

Cursor Location to Row 2/Column 1

(see Table 6)

F1 ^cF1~ Turn the LCD Backlight On

F0 ^cF0~ Turn the LCD Backlight Off

E1 ^cE1~ Turn Echo On

E0 ^cE0~ Turn Echo Off (Default)

01 ^c01~ Clears the Screen

02 ^c02~ Return Home

08 ^c08~ Display OFF

Cursor OFF

Cursor Position OFF

09 ^c09~ Display OFF

Cursor OFF

Cursor Position ON

0A ^c0A~ Display OFF

Cursor ON

Cursor Position OFF

0B ^c0B~ Display OFF

Cursor ON

Cursor Position ON

0C ^c0C~ Display ON

Cursor OFF

Cursor Position OFF

0D ^c0D~ Display ON

Cursor OFF

Cursor Position ON

0E ^c0E~ Display ON

Cursor ON

Cursor Position OFF

0F ^c0F~ Display ON

Cursor ON

Cursor Position ON

7x ^c70~

Set Contrast Value to x Where x is

0,1,2,3,4,5,6,7,8,9,A,B,C,D,E or F

Table 5: Commands Definition

The table below describes the Cursor Location Commands for each on-screen position based on the

row and column required. Once each command has been issued, the next data command will start

writing text from this location and will automatically increment to the next location based upon the

length of the text string:

Rev. 1.0 (February 2012) 8 © DLP Design, Inc.

Row Column Command Example

1 1 80 ^c80~

1 2 81 ^c81~

1 3 82 ^c82~

1 4 83 ^c83~

1 5 84 ^c84~

1 6 85 ^c85~

1 7 86 ^c86~

1 8 87 ^c87~

1 9 88 ^c88~

1 10 89 ^c89~

1 11 8A ^c8A~

1 12 8B ^c8B~

1 13 8C ^c8C~

1 14 8D ^c8D~

1 15 8E ^c8E~

1 16 8F ^c8F~

2 1 C0 ^cC0~

2 2 C1 ^cC1~

2 3 C2 ^cC2~

2 4 C3 ^cC3~

2 5 C4 ^cC4~

2 6 C5 ^cC5~

2 7 C6 ^cC6~

2 8 C7 ^cC7~

2 9 C8 ^cC8~

2 10 C9 ^cC9~

2 11 CA ^cCA~

2 12 CB ^cCB~

2 13 CC ^cCC~

2 14 CD ^cCD~

2 15 CE ^cCE~

2 16 CF ^cCF~

Table 6: Cursor Location Definitions

The table below describes sample strings sent to the DLP-MAV-LCD1 to include clearing the screen

and positioning the cursor prior to writing text:

Rev. 1.0 (February 2012) 9 © DLP Design, Inc.

Data Example Description

Hello ^dHello~ Displays “Hello”

Testing 123 ^d Testing 123~ Displays “ Testing

123” (note that the

spaces are valid)

Beyond the

Maximum Text

Length of 16

^dBeyond the

Maximum Text Length

of 16~

The Data is

Ignored

Line 1 Here ^c01~^c80~^dLine 1

Here~

Clears the Screen,

Goes to Row 1/

Column 1 and

Displays “Line 1

Here”

Line 2 Here ^c01~^cc0~^dLine 2

Here~

Clears the Screen,

Goes to Row 2/

Column 1 and

Displays “Line 2

Here”

Table 7: Sample Commands

4.0 STANDALONE MODE

Alternatively, when used in standalone mode, the DLP-MAV-LCD1 board may be powered externally

and communicated with utilizing the 5-pin, TTL serial header described below:

15

Figure 8: DLP-MAV-LCD1 Standalone Pins

Pin # Description

1 FROM EXTERNAL HOST (In) – TTL serial from host processor

2 TO EXTERNAL HOST (Out) – TTL serial to host processor

3 GROUND

4 RESET (In) – Pull to ground to reset MSP430 on DLP-MAV-LCD1

5 3.0 - 3.3V (In) – Power supply for module

Table 8: TTL 5-Pin Header Descriptions

Rev. 1.0 (February 2012) 10 © DLP Design, Inc.

5.0 MECHANICAL DRAWINGS

Both inches and (millimeters) in parentheses are shown below for each measurement:

2 x 0.157 typ

(4.0 typ)

1.515 typ

(38.5 typ)

1.50 typ

(38.1 typ)

0.963 typ

(24.5 typ)

1.64 typ

(41.7 typ)

Figure 9: DLP-MAV-LCD1 Dimensions

6.0 DISCLAIMER

Neither the whole nor any part of the information contained within or the product described in this

datasheet may be adapted or reproduced in any material or electronic form without the prior written

consent of the copyright holder.

This product and its documentation are supplied on an as-is basis, and no warranty as to their

suitability for any particular purpose is either made or implied. DLP Design will not accept any claim

for damages whatsoever arising as a result of use or failure of this product. Your statutory rights are

not affected.

This product or any variant of it is not intended for use in any medical appliance, device or system in

which the failure of the product might reasonably be expected to result in personal injury.

This document provides preliminary information that may be subject to change without notice.

Rev. 1.0 (February 2012) 11 © DLP Design, Inc.

7.0 CONTACT INFORMATION

DLP Design, Inc.

1605 Roma Lane

Allen, TX 75013

Phone: 469-964-8027

Fax: 415-901-4859

Website URL: http://www.dlpdesign.com

Table of contents

Other DLP Design Control Unit manuals

Popular Control Unit manuals by other brands

Parker

Parker LINKnet TechBox Series product manual

Allen-Bradley

Allen-Bradley 1769-SDN user manual

Mark

Mark Interface+ Technical manual

Bray

Bray 19L Series Installation, operation and maintenance manual

Pego

Pego PLUS300 Expert VD 4 Use and maintenance manual

piezosystemjena

piezosystemjena d-Drive pro instruction manual