KRB-5404

1. SAFETY NOTICES 5

2. RECEIVING AND HANDLING 7

2-1. Transportation Precautions 7

2-1-1. Transporting the ACB 7

2-1-2. Transporting the breaker body 8

2-1-3. Transporting the draw-out cradle 8

2-2. Storage Precautions 8

2-3. Installation Precautions 9

3. GENERAL 16

3-1. Types and Descriptions 16

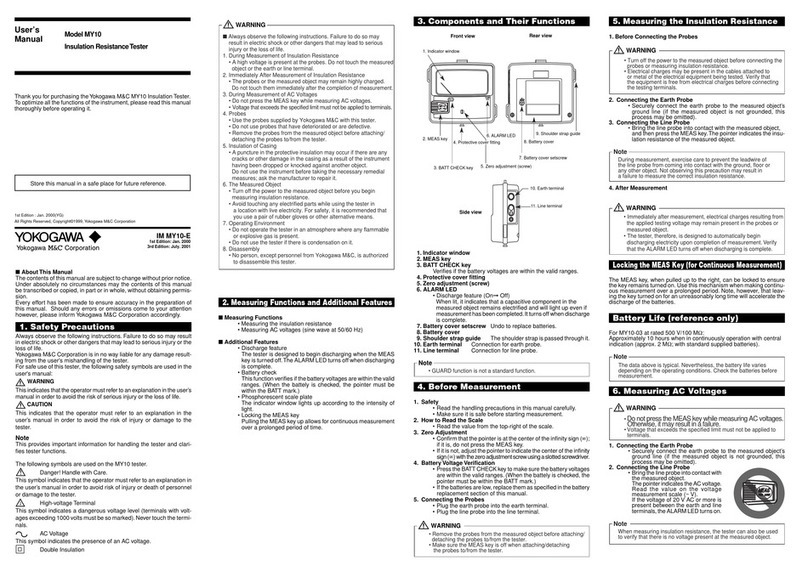

3-2. Parts and Functions 20

3-3. Circuits and Ratings 24

4. OPERATION 31

4-1. Charging and Opening operation 31

4-1-1. Charging operation 31

4-1-2. Closing operation 32

4-1-3. Opening operation 32

4-1-4. Motion of trip indication and spring charge

indication switches 32

4-1-5. Motion of operation mechanisms 33

4-2. Draw-out and Insertion Operation 35

4-2-1. General 35

4-2-2. Draw-out operation 36

4-2-3. Putting the breaker body back into the draw-out

cradle 37

4-2-4. Contact status of auxiliary and position switches 39

4-3. ON-OFF Button Cover Locking Procedure 39

4-4. Lock in OFF Procedure 40

4-5. Position Lock Lever Locking Procedure 40

4-6. Breaker Fixing Bolt Securing Procedure 41

4-7. OCR Cover Locking Procedure 41

5. OVERCURRENT RELEASE (OCR) 42

5-1. Specifications 42

5-2. Characteristics 44

5-2-1. L characteristic for general feeder 44

5-2-2. R characteristic for general feeder 47

5-2-3. S characteristic for generator protection 51

5-3. OCR Setting Procedure 53

5-3-1. OCR Setting Procedure (AGR-11B type) 53

5-3-2. OCR Setting Procedure (AGR-21B,22B,31B type)

54

5-3-2-1. General 54

5-3-2-2. Available screens 55

5-3-2-3. Monitor screen 57

5-3-2-3-1. Monitor screen (AGR-21B,22B) 57

5-3-2-3-2. Monitor 1 screen (AGR-31B) 58

5-3-2-3-3. Monitor 2 screen (AGR-31B) 59

5-3-2-4. Setup screen 61

5-3-2-4-1. Setup screen(AGR-21B,22B) 61

5-3-2-4-2. Setup screen(AGR-31B) 63

5-3-2-5. Reset screen 66

5-3-2-5-1. Reset screen (AGR-21B,22B) 66

5-3-2-5-2. Reset screen(AGR-31B) 67

5-3-2-6. Setting 1 screen 68

5-3-2-7. Setting 2 screen 70

5-3-2-8. Maintenance screen 73

5-4. OCR Function Check 74

5-5. Operation Indication and Indication Resetting

Procedure 76

5-5-1. Operation Indication (AGR-11B type) 76

5-5-2. Operation Indication and Indication Resetting

Procedure (AGR-21B,22B,31B type) 77

6. MAINTENANCE, INSPECTION AND PARTS

REPLACEMENT 79

6-1. Inspection Procedures 80

6-2. Parts Replacement Procedure 83

6-2-1. Preparation 83

6-2-2. Arc chambers 86

6-2-3. Stationary contact 87

6-2-4. Moving contact 89

6-2-5 Latch release coil (LRC) 91

6-2-6. Shunt trip device (SHT) 92

6-2-7. Control relay 93

6-2-8. Magnet hold trigger (MHT) 96

6-2-9. Auxiliary switches 97

7. TROUBLESHOOTING FLOWCHARTS 99

8.DOOR INTERLOCK 102

9. MECHANICAL INTERLOCK DEVICE. (HORIZONTAL

TYPE) 104