TEREN DPTR User manual

DPTR Rail Mount Differential Pressure Transmitter-Operation Manual Edition:A/3

1

DPTR Rail Mount Differential Pressure Transmitter

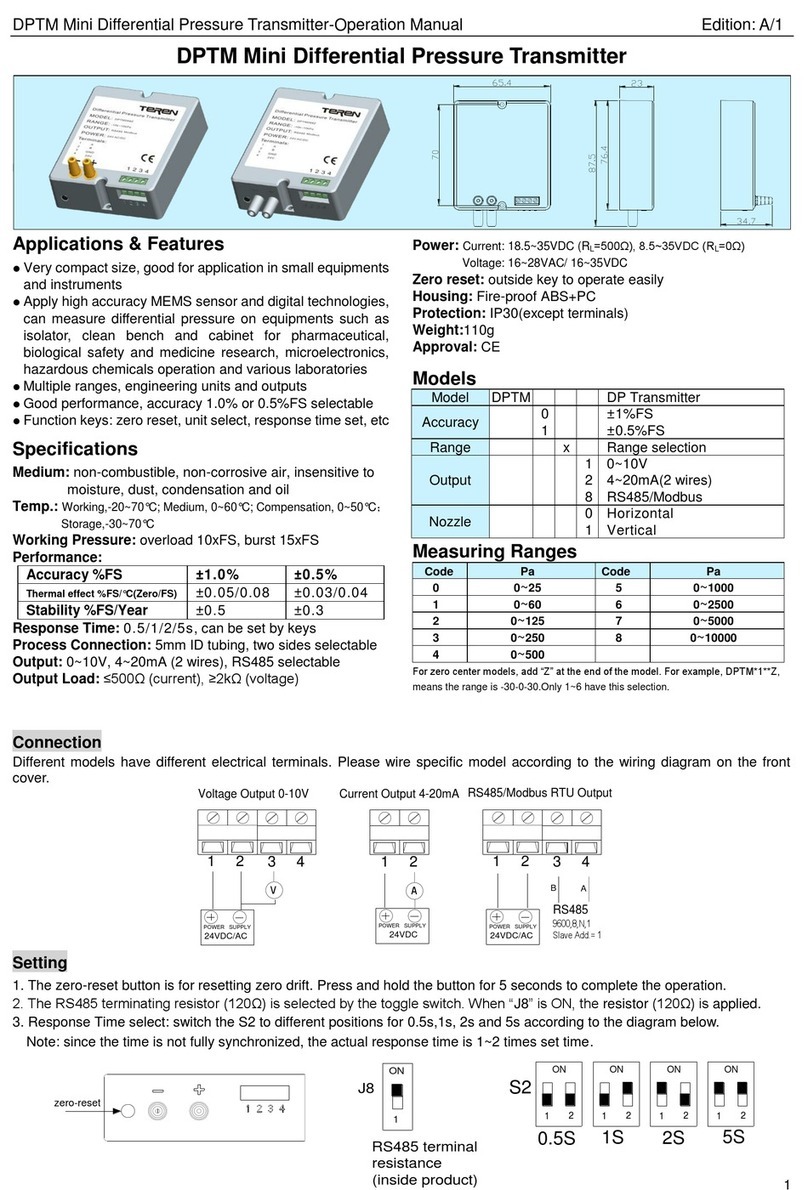

Applications & Features

Mount on standard 35mm DIN rail, small enough for

compact installation in equipments and instruments

Apply high accuracy MEMS sensor and digital technologies,

can measure differential pressure on equipment such as

isolators and clean benches for pharmaceutical production,

biological and medicine research, microelectronics,

hazardous chemicals operations, and general laboratories

Multiple ranges, engineering units and outputs

Good performance, accuracy 1.0% or 0.5%FS selectable

Function keys: zero reset, unit select, response time set,

etc

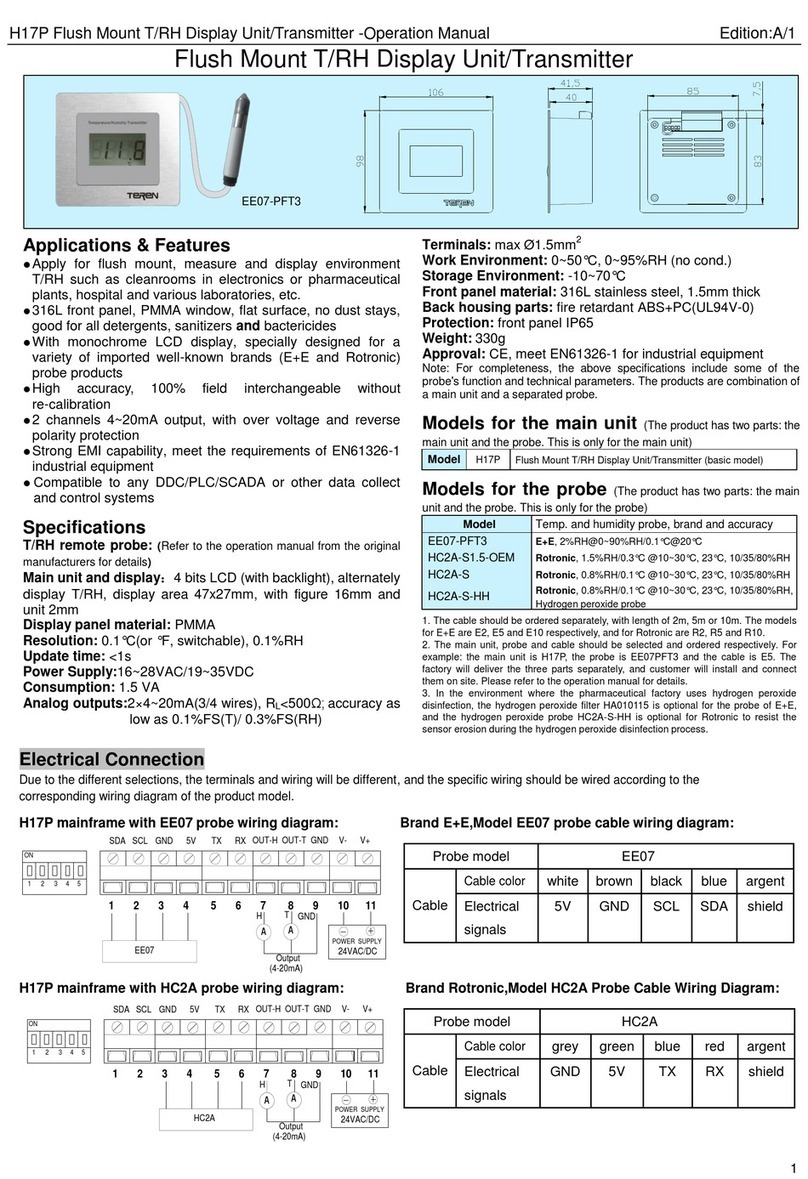

Specifications

Medium: non-combustible, non-corrosive air, insensitive to

moisture, dust, condensation and oil

Temp.: Working,-20~70°C; Medium, 0~60°C; Compensation, 0~50°C

Storage: -30~70°C

Working Pressure: overload 10xFS, burst 15xFS

Performance:

Accuracy %FS

±1.0%

±0.5%

Thermal

effect %FS/°C(Zero/FS)

±0.05/0.08

±0.03/0.04

Stability %FS/Year

±0.5

±0.3

Response Time: 0.5/1/2/5s, can be set by keys

Process Connection: 5mm ID tubing

Output: 0~10V, 4~20mA (2 wires), RS485 selectable

Output Load: ≤500Ω (current), ≥2kΩ (voltage)

Power: Current: 18.5~35VDC (RL=500Ω)8.5~35VDC (RL=0Ω)

Voltage: 16~28VAC/ 16~35VDC

Zero reset: outside key to operate easily

Materials: Fire-proof ABS+PC

Protection: IP30

Weight: 110g

Approval: CE

Models

Model

DPTR

Rail Mount DP Transmitter

Accuracy

0

±1%FS

1

±0.5%FS

Range

x

Range selection(See table)

Output

1

0~10V

2

4~20mA(2 wires)

8

RS485/Modbus

Measuring ranges

Note: For zero center models, add “Z” at the end of the model. For example,

DPTR*1*Z, means the range is -30-0-30.Only 1~6 have this selection.

Connection

Different models have different electrical terminals. Please wire specific model according to the wiring diagram on the front

cover.

Setting

1. The zero-reset button is for resetting zero drift. Press and hold the button for 5 seconds to complete the operation.

2. The RS485 terminating resistor (120Ω) is selected by the toggle switch. When “J8” is ON, the resistor (120Ω) is applied.

3. Response Time select: switch the S2 to different positions for 0.5s,1s, 2s and 5s according to the diagram below.

Note: since the time is not fully synchronized, the actual response time is 1~2 times set time.

Code

Pa

Code

Pa

0

0~25

5

0~1000

1

0~60

6

0~2500

2

0~125

7

0~5000

3

0~250

8

0~10000

4

0~500

RS485

9600,8,N,1

Slave Add.= 1

3 4

A

1 2

POWER SUPPLY

B

24VDC/AC

V

3 4

POWER SUPPLY

24VDC

A

3 4

POWER SUPPLY

1 2

Current Output 4-20mA

Voltage Output 0-10V RS485/Modbus RTU Output

24VDC/AC

ON

12

ON

12

ON

12

ON

12

0.5S 1S 2S 5S

S2

RS485 terminal

resistance

(inside product)

ON

1

J8

zero-reset

DPTR Rail Mount Differential Pressure Transmitter-Operation Manual Edition:A/3

2

Installation:

Figure 1 Figure 2 Figure 3 Figure 4

● Install into the DIN rail: it is recommended that the pressure ports to be installed vertically downwards, as shown in above

figures. As Figure 1 and 2, insert the transmitter’s upper hook into DIN-rail, then buckle the lower white plastic hook into DIN-

rail, as Figure 3. The plastic hook can be pulled down to help.

● Pressure connection: connect the tube to the two pressure ports correctly, making sure to air-tighten to prevent leakage.

● Electrical connection: As figure 4, unplug the terminals of the transmitter and wire correctly, then plug back.

Zero reset & Calibration

● Due to different environment and sensor characteristics, after long term of using, the sensor’s accuracy maybe drift. The

transmitter should be zero reset after initial installed to meet the specified accuracy. It is better to be “zero reset” after the initial

7 days continuous working. Usually it need to be zero reset periodically in every 6-12 months’ working.

●Zero reset: keep the high (+) and low (-) pressure ports unconnected in stable air, or directly connect the two, press the button

“ZERO” for 5s. It means to remove the zero drift of the transmitter in order to improve the accuracy. It is recommended that

this operation to be done periodically.

●Initial zero reset: when initial power on, it should be zero reset after fully warm-up and stable, to meet the specified accuracy.

●Long term zero drift & reset: It may have long term zero drift after continuous working; customers can reset it periodically.

●Re-calibration & zero reset: when re-calibration needed, zero reset should be done first. A qualified standard manometer is

needed for re-calibration operation.

Attention

It should be power OFF during installing and wiring. When using 24VAC, it is strongly recommended to power the unit with

independent transformer. If sharing a 24VAC transformer with other equipments such as controllers, transmitters or actuators,

please make sure the terminals 24V and GND are connected correctly. Otherwise, it may reduce serious damages.

Warranty

● It has limited warranty for eighteen (18) months after the production date.

● It does not extend to any unit that has been subjected to misuse or accident.

● It is, in any event, strictly limited to the replacement or repair of the product itself.

Shenzhen TEREN Control Technology Co. Ltd.

Add: 3F, 2nd Industrial Zone, Nankeng, Longgang

District, Shenzhen,Guangdong,P.R.CHINA

Tel: 0755-23935155 Fax: 0755-23935156

web: www.teren.com.cn

TEREN website Alibaba shop

Table of contents

Other TEREN Transmitter manuals