AWT420 | UNIVERSAL 4-WIRE, DUAL-INPUT TRANSMITTER | INF/ANAINST/012-EN REV. A 7

4 Hazardous area considerations

Health & Safety

Safety precautions

Be sure to read, understand and follow the instructions

contained within this manual before and during use of the

WARNING

Serious damage to health/risk to life

The AWT420 transmitter is a certified product suitable for

use in hazardous area locations. Before using this product

refer to the product labeling for details of hazardous area

certification. Maintenance and installation must be carried

out only by the manufacturer, authorized agents or persons

conversant with the construction standards for hazardous

Potential safety hazards

WARNING

Bodily injury

following points must be observed:

• Up to 240 V AC may be present. Be sure to isolate the

supply before removing the terminal cover.

described in this manual or any relevant Material Safety

Company, together with servicing and spares information.

Safety standards

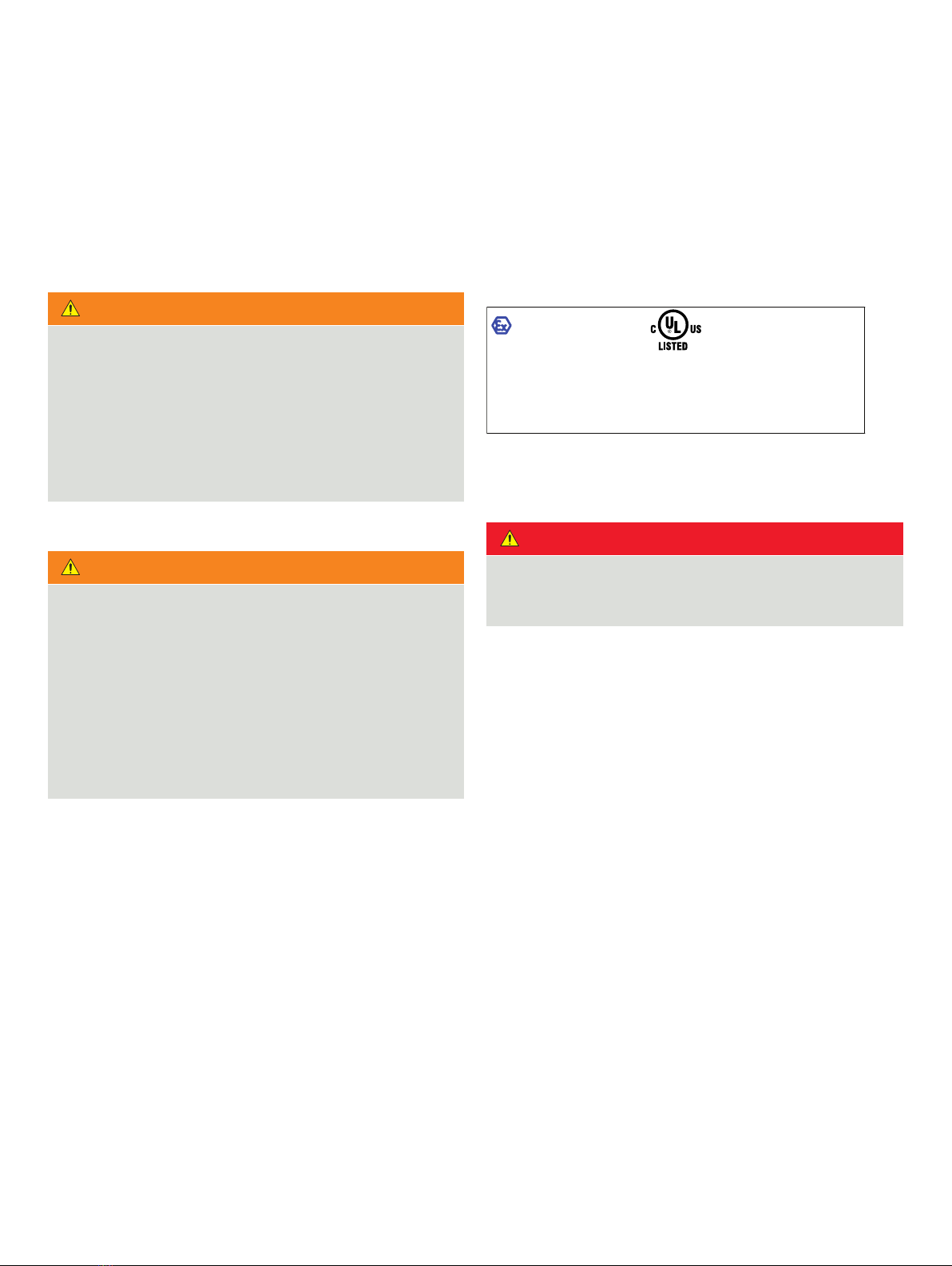

Name plate/Certification label

The following name plate is an example only. The name plate

attached to the transmitter may be different.

Transmitters with cULus approval and ATEX IECEx

(Aluminum Enclosure)

Figure 3 Example of hazardous area name plate

Service and repair

DANGER

The product has no live maintenance facility. The instrument

must be de-energized before any maintenance is

performed.

If the instrument is located in a hazardous area none of the

instrument’s components can be serviced by the user. Only

personnel from ABB, its approved representative(s) or persons

conversant with the construction standards for hazardous area

the system and only components formally approved by the

manufacturer should be used. Any attempt at repairing the

instrument in contravention of these principles could cause

damage to the instrument and corporal injury to the person

carrying out the repair. It renders the warranty null and void and

could compromise the hazardous area certification, correct

working of the instrument, electrical integrity and the CE

compliance of the instrument.

If you have any problems with installation, starting or using the

instrument please contact the company that sold it to you. If

this is not possible, or if the results of this approach are not

satisfactory, please contact the manufacturer’s Customer

Service.

E474414

WARNING – DO NOT OPEN IN AN AREA WHERE

AN EXPLOSIVE ATMOSPHERE MAY BE PRESENT

PROCESS CONTROL EQUIPMENT FOR

USE IN HAZARDOUS LOCATIONS

EZLink channels fitted,

Class I, Div 2, Gps A, B, C, D, T4 providing

non-incendive field wiring outputs for Class I

Div 2 Grps A, B, C, D Hazardous locations

No EZLink channels fitted,

Class I, Div 2, Gps A, B, C, D, T4

-10

C

≤ Ta ≤

+45

C

USA: Installation Drg 3KXA005001U0101

Canada: Installation Drg. 3KXA005001U0201

IECEx ULD 20.0009X

The equipment shall only be used in an

area of at least Pollution Degree 2,

as defined in IEC 60664-1

General Arrangement Drg.3KXA005002U0101

Installation Drg. 3KXA005001U0301

EZLink channels fitted,

II 3(3) G Ex ic ec nC [ic Gc] IIC T4 Gc,

No EZLink channels fitted,

II 3 G Ex ic ec nC IIC T4 Gc,

-10

C ≤ Ta ≤

+45

C, IP66,

DEMKO 20 ATEX 2259X

AVERTISSEMENT – NE PAS OUVRIR DANS UN EMPLACEMENT

OÙ UNE ATMOSPHÈRE EXPLOSIVE PEUT ÊTRE PRÉSENTE