TEREN DPTH User manual

DPTH High Accuracy Differential Pressure Transmitter-Operation Manual Edition: A/2

1

DPTH High Accuracy Differential Pressure Transmitter

Applications & Features

Apply high accuracy MEMS sensor and digital technology,

can measure positive, negative or differential pressure, and

air velocity or volume

It can measure system pressure of fan, blower, filter,

furnace draft and orifice plate and can apply to various

clean room, biological safety cabinet, clean bench, ducts

collection, medical or pharmaceutical machine, etc.

Excellent temperature compensation and electromagnetic

interference (EMI) ability, good for applications in complex

EMI environments of industrial systems or equipments

Multiple ranges, engineering units and outputs

High accuracy up to 0.5% and range as low as 25Pa

Function keys: zero reset, units select, response time set,

square root output set (air velocity or volume), K factor

calibrate and area parameter’s input, etc.

Field upgradable LCD display module with unit indication

Square root output: when applying along with pitot tubes or

other air velocity or volume sensor, can supply linear output

for air velocity or volume

Specifications

Medium: on-combustible, non-corrosive air, insensitive to

moisture, dust, condensation and oil

Working Temp.: -20~70°C

Medium Temp.:0~60°C

Temp. Compensation: 0~50°C

Storage Temp.:-20~70°C

Working Pressure: overload 10xFS(<=1kPa)/8xFS(>1kPa)

burst 20xFS(<=1kPa)/10xFS(>1kPa)

Accuracy: ±0.5%FS(±1.0%FS@25Pa range)

Long term stability: ±0.5%FS /Year

Thermal effect: <0.03%FS/°C (zero), <0.04%FS/°C (FS)

Response Time: 0.5~30s, can be set by keys

Process Connection: 5mm ID tubing

Display: 4 digits LCD, with unit indication, field upgradable

Output: 0~10V, 4~20mA (2 wires), RS485 selectable

Output Load: ≤500Ω (current), ≥2kΩ (voltage)

Power: Voltage: 16~28VAC/ 16~35VDC

Current: 18.5~35VDC(RL=500Ω), 8.5~35VDC(RL=0Ω)

Unit select: by keys

Zero set: easy to reset by keys

Air velocity/volume: square root output set (air velocity or

volume), K factor calibrate and area parameter’s input

Materials: fire retardant ABS+PC(UL94V-0)

Protection: IP65

Weight: 180g

Approval: CE, meet EN61326-1 for industrial equipment

Models

Model

DPTH

High accuracy DP

transmitter

Range

X

Range selection

Output

1

0-10V

2

4-20mA(2 wires)

8

RS485/Modbus

Display

0

N/A

1

LCD

Measuring Ranges

Code

UNIT & Range & Display Resolution

Pa

Pa

kPa

in w.c.

mm w.c.

mbar

0

0-25

25.00

0.025

0.100

2.500

0.250

1

0-60

60.00

0.060

0.250

6.000

0.600

2

0-125

125.0

0.125

0.500

12.00

1.250

3

0-250

250.0

0.250

1.000

25.00

2.500

4

0-500

500.0

0.500

2.000

50.00

5.000

5

0-1000

1000

1.000

4.000

100.0

10.00

6

0-2500

2500

2.500

10.00

250.0

25.00

7

0-5000

5000

5.000

20.00

500.0

50.00

8

0-10000

10000

10.000

40.00

1000.0

100.00

1. Set the 5 engineering units by button keys and the related LCD indicator will be on.

2. For zero center models, add “Z” at the end of the model. For example, DPTH1**Z, means the range

is -30-0-30Pa. Only ranges 0~6 have this selection.

DPTH High Accuracy Differential Pressure Transmitter-Operation Manual Edition: A/2

2

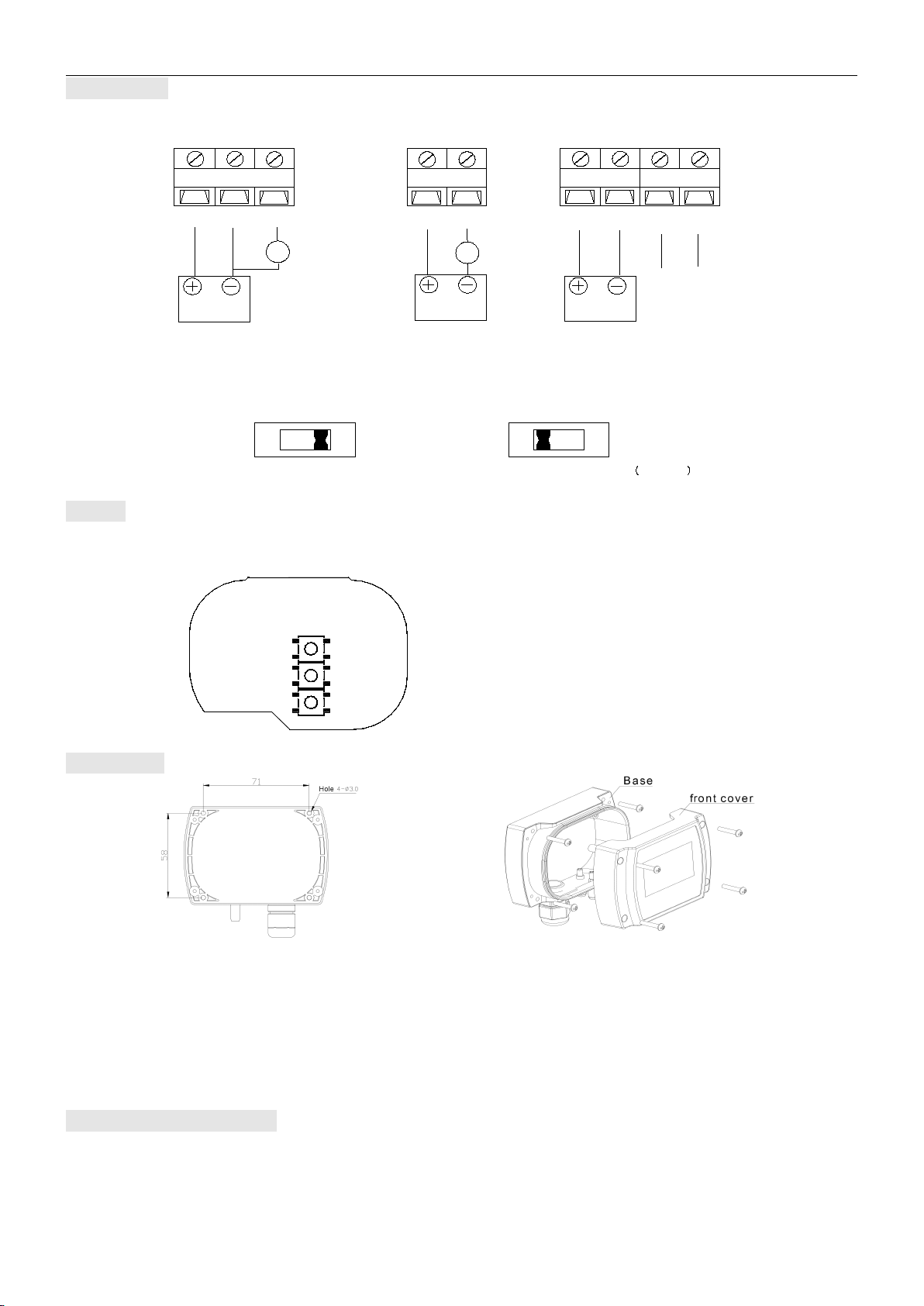

Connection

Different models have different electrical connections.

RS485/Modbus communication refer to “DPT series Modbus Communication Manual”. RS485 terminal resistance jumper J8 is

described as follows:

Terminal resistance 120 Ω:the jumper J8 is at position “on”

Terminal resistance 0 Ω(None):the jumper J8 is at position “off”

As shown below:

Button

“SET”: Set/Confirm/Save; “SEL”: Bit Select/Decrease/ Zero Reset(press for 5s); “ADJ”: Adjust/Increase;

See the operation instruction for the button operation.

SET

SEL

ADJ

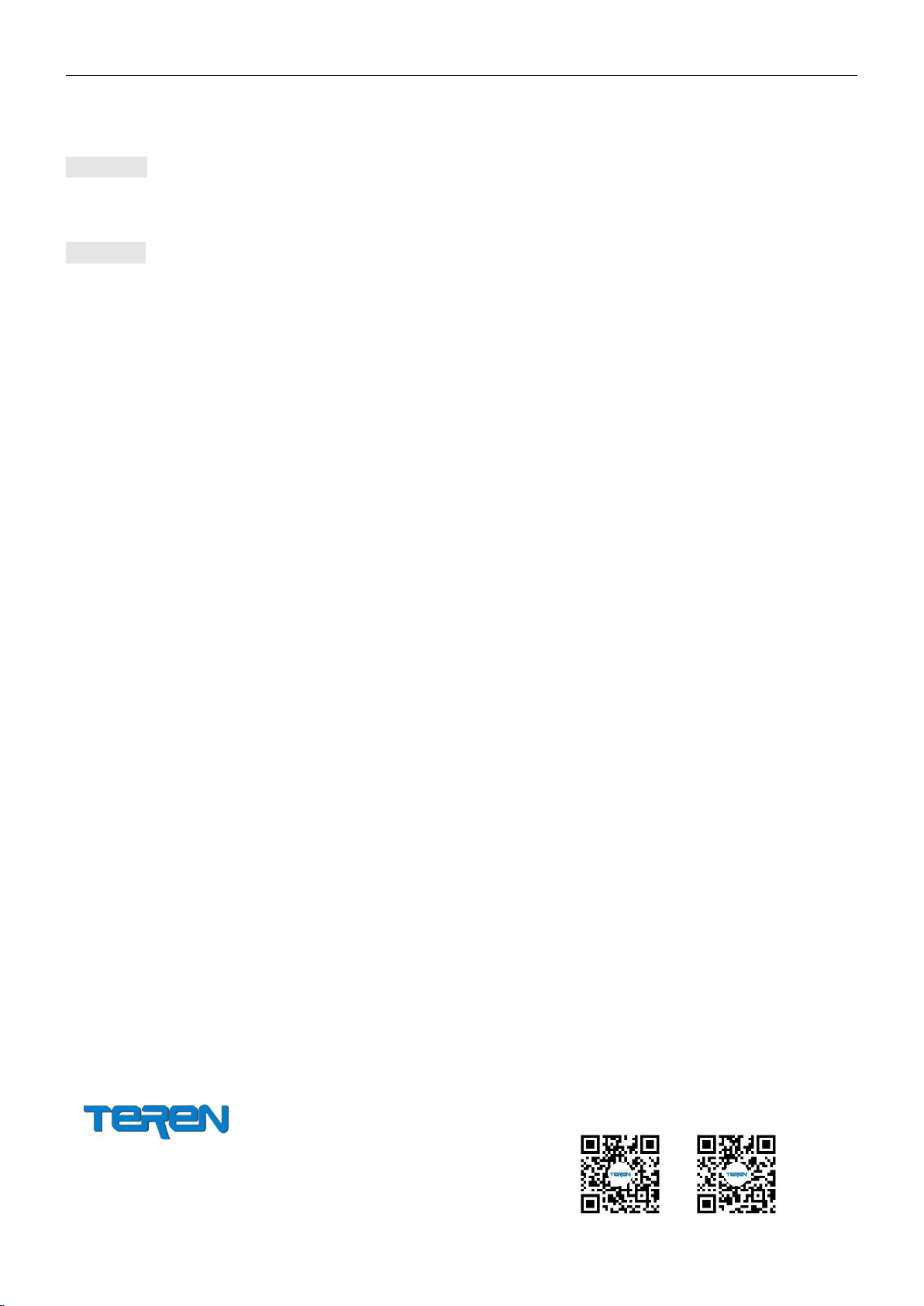

Installation

● The installation site should be far away from heater, cooler, fan or other humidity and ventilation sources. Figure 1 is bottom

view of the product, for opening the 4 holes on the mounting surface.

● It should to be installed vertically on the wall, with the outlet gland downwards, shown as figure 2. Open the front cover and

screw the base on the mounting surface with 4 mounting screws.

● Feed the cable into the base through the cable gland, finish wiring according to the wiring diagram. Restore the front cover and

finish the pressure connection, pay attention to the difference between high (+) and low (-) pressure ports. Make sure to

completely air-tighten the gland to the base and the cover to the base with the seal rings, thus the housing overall protection

rate could meet up to IP65.

Zero reset & Calibration

According to different environment and sensor’s characteristics, for long term of using, the sensor’s accuracy maybe drift. The

transmitter should be zero reset after initial power on to meet the specified accuracy, and be zero reset periodically in every 6-12

months’ using. It is recommended to be “zero reset” after the initial 7 days continuous working.

Zero reset: keep the high(+)/low(-)pressure ports unconnected in stable air, or directly connect them, press the button “SEL”

for 5s to perform “zero reset”. It means “remove the zero drift of the transmitter in order to improve the accuracy”. It

isrecommended that this operation could be done periodically.

RS485

9600,8,N,1

Slave Add.= 1

BA

V

POWER SUPPLY

24VDC

A

POWER SUPPLY

24VDC/AC

V+ GND OUT

Voltage Output Model Current Output RS485 Model

POWER SUPPLY

24VDC/AC

V+ OUT V+ GND B A

120

J8

ON

1

120

J8

ON

1

Terminal resistance:120 Ω Terminal resistance:None Default

Figure 1

Figure 2

DPTH High Accuracy Differential Pressure Transmitter-Operation Manual Edition: A/2

3

Initial zero reset: when initial power on, it should be zero reset after fully warm-up and stable, to meet the specified accuracy.

Long term zero drift & reset: It may have long term zero drift after continuous working; customers can reset it periodically.

Re-calibration & zero reset: when re-calibration needed, zero reset should be done first. A qualified standard manometer is

needed for re-calibration operation. Please follow the operation procedures below.

Attention

It should be power OFF during installing and wiring. When using 24VAC, it is strongly recommended to power the unit with

independent transformer. If sharing a 24VAC transformer with other equipments such as controllers, transmitters or actuators,

please make sure the terminals 24V and GND are connected correctly. Otherwise, it may reduce serious damages.

Warranty

● It has limited warranty for eighteen (18) months after the production date.

● It does not extend to any unit that has been subjected to misuse or accident.

● It is, in any event, strictly limited to the replacement or repair of the product itself.

DPTH High Accuracy Differential Pressure Transmitter - Operation Instruction

(need LCD to apply)

Button definition:

“SET”: Set/Confirm/Save; “SEL”: Bit Select/Decrease/ Zero Reset(press for 5s); “ADJ”: Adjust/Increase;

Zero reset: keep the high(+)/low(-)pressure ports unconnected in stable air, or directly connect the two, press the button “SEL”

5s to reset the actual “zero point”. It means “remove the zero drift of the transmitter in order to improve the accuracy”. It is

recommended that this operation could be done periodically.

Operation instruction:

1."P810": Reset

SET→SEL/ADJ→P810→SET

User can restore the factory default set. Input “P810”, “Pret” will blink, press button SET, all factory default set will restore.

2. "P075": Set the response time (Default set: 0.5s, available range: 0.5-30.0s)

SET→SEL/ADJ→P075→SET→SEL/ADJ→XXX→SET. (XXX means set time).

3. "P083": Check LED display function, it will display the 4 digits one by one.

SET→SEL/ADJ→P083→SET

4."P081": Set Engineering Unit (Default set: 1, for engineering unit Pa, available ranges: 1-5)

SET→SEL/ADJ→P081→SET→SEL/ADJ→XXX→SET (XXX means the code of engineering unit),then the relevant LED on.

(Index: 1: Pa; 2: kPa; 3: mbar; 4: mmW.C.; 5: inW.C.)

5."P485": Set RS485 address(Default set: 1, available ranges 1~255, but recommend 1~32)

SET→SEL/ADJ→P485→SET→SEL/ADJ→XXX→SET (XXX means RS485 address)

Note:Refer to the communication data table

6."P483": Set RS485 Baud Rate (Default set: 9600, available 9600 or 4800)

SET→SEL/ADJ→P483→SET→SEL/ADJ→XXX→SET (XXX means Baud Rate index)

Index:1: 9600; 2: 4800.

7."P482": Set RS485 Parity Bit (Default set: 0, available 0,1 or 2)

SET→SEL/ADJ→P482→SET→SEL/ADJ→XXX→SET (XXX means Parity Bit index)

Index:0: none; 1: odd;2: Even.

System Error signal:

Err 1 Keys input operation code is wrong

Err 2 Input data is not available

Err 3 Modbusattempt to write read only register error

Err 4 Modbus CRC check error

Err 6 Password Key input error

Shenzhen TEREN Control Technology Co. Ltd.

Add: 3F, 2nd Industrial Zone, Nankeng, Longgang

District, Shenzhen,Guangdong,P.R.CHINA

Tel: 0755-23935155 Fax: 0755-23935156

web: www.teren.com.cn

TEREN website Alibaba shop

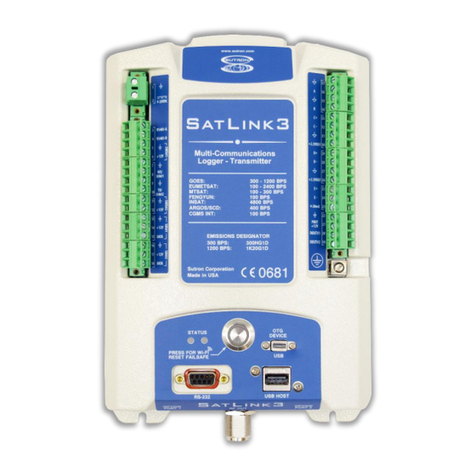

Table of contents

Other TEREN Transmitter manuals