Termal HKED 261 X User manual

Technical Manual (07/2010 - VA1)

Monosplit “Wall” type Air Conditioners

“Personal Line DC Inverter” Models

Outdoor Units:

HCND 261 X

HCND 351 X

HCND 511 X

HCND 631 X

Indoor Units:

HKED 261 X

HKED 351 X

HKED 511 X

HKED 631 X

Monosplit “Wall” Personal Line DC Inverter - Table of Contents

- Table of Contents -

Table of Contents

1. GENERAL INFORMATION ........................................................................................................................... IG-1

1.1 GUIDELINES TO CONSULTATION & WARNINGS .......................................................................................IG-1

1.2 ESSENTIAL FEATURES OF THESE MODELS ..................................................................................................IG-2

1.3 APPEARANCE OF UNITS ............................................................................................................................IG-8

1.4 OUTLINE OF INDOOR & OUTDOOR UNITS ..............................................................................................IG-13

1.5 IR REMOTE CONTROL ..............................................................................................................................IG-14

1.6 LED PANEL ON INDOOR UNITS................................................................................................................IG-18

1.7 OPERATING USE CONDITIONS ................................................................................................................IG-20

1.8 HOW TO ADJUST AIR DIRECTION ............................................................................................................IG-21

1.9 EMERGENCY OPERATION & “SELF-CHECK” ..........................................................................................IG-23

1.10 AUTO-RESTART FUNCTON AFTER A BLACKOUT ...................................................................................IG-25

1.11 SUGGESTIONS FOR ECONOMIC USE OF SYSTEM ................................................................................IG-26

2. GENERAL TECHNICAL DATA .....................................................................................................................DG-1

2.1 SPECIFICATIONS .......................................................................................................................................DG-1

2.2 DIMENSIONS OF UNITS .............................................................................................................................DG-5

2.3 REFRIGERANT CIRCUIT DIAGRAMS .........................................................................................................DG-8

3. ELECTRICAL DATA .......................................................................................................................................DE-1

3.1 WIRING DIAGRAMS ..................................................................................................................................DE-1

3.2 R/T FEATURES OF TEMPERATURE SENSORS ..............................................................................................DE-5

4. CONTROL LOGIC FUNCTIONS ................................................................................................................... FU-1

4.1 HARDWARE FEATURES .............................................................................................................................. FU-1

4.2 SOFTWARE FEATURES ................................................................................................................................ FU-2

4.3 BASIC FUNCTIONS ................................................................................................................................... FU-13

4.4 SOME INDICATIONS OF MALFUNCTIONS & PROTECTION FUNCTIONS .............................................. FU-19

5. INSTALLATION ..............................................................................................................................................IN-1

5.1 CHECKS AND PRELIMINARY OPERATIONS ...............................................................................................IN-3

5.2 INSTALLATION OF INDOOR UNITS HKED 261, 351, 511, 631 X .................................................................IN-6

5.3 INSTALLATION OF OUTDOOR UNITS HCND 261, 351, 511, 631 X .......................................................... IN-21

5.4 VACUUM PROCEDURE AND REFRIGERANT CHARGE ..........................................................................IN-30

6. DIAGNOSTIC & MAINTENANCE ................................................................................................................DM-1

6.1 AUTODIAGNOSIS OF MALFUNCTIONS: ERROR CODES ON INDOOR UNIT ..........................................DM-2

6.2 FLOWCHARTS FOR MALFUNCTIONS’ SOLUTION ...................................................................................DM-7

6.3 CLEANING & MAINTENANCE OF AIR CONDITIONER .........................................................................DM-13

IG-1

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

1. GENERAL INFORMATION

1.1 GUIDELINES TO CONSULTATION & WARNINGS

This Manual describes operation, installation and procedures for solving operation malfunctions of

HOKKAIDO Air Conditioners Monosplit “Wall” Personal Line DC Inverter HKED-HCND 261, 351, 511,

631 X”.

This Manual is addressed to Installers and to Authorized Technical Service, that is charged to interventions

for malfunction diagnosis and for repairing and/or servicing of system.

This Manual implies that Installers and Authorized Technical Service do know well the equipments and

tools which are usually used for repairing electric, mechanical parts and refrigerant components of

air-conditioning systems with R410A refrigerant. Furthermore, people who this Manual is addressed to

should know terms of current use that are used for describing relevant operations.

In particular, it is recommended to read and follow carefully Safety Precautions and Warnings that are listed

in this Manual. Missed observance of above prescriptions may lead to serious injuries to people, and even

to death.

Relevant Documents

This Manual is not exhaustive about system operation, so it has to be consulted together with the User

Manual, the Installation Sheets of Units and Spare Parts List referred to this Models of Units.

General Precautions and Warnings

WARNING

In order to avoid the risk of death or of serious personal injuries caused by electric shocks, disconnect the

power cable of Units before whatever intervention of repairing or maintenance.

WARNING

In order to avoid the risk of death or of serious personal injuries caused by electric shocks, NEVER tamper

with the ground wire for any reason. The appliance must always been equipped with a ground wire. Do not

remove the Safety label referred to ground wire, which is on the power cable. If the electric system on

installation site is not equipped of ground wire, please contact a qualified Electrician, for conforming electric

system to current Regulations.

WARNING

In order to avoid the risk of death or of serious personal injuries caused by overheating of the system’s

components, it is recommended to always make the system checked for verifying if there are malfunctions

or if the system often stops suddenly.

WARNING

In order to avoid the risk of death or of serious personal injuries caused by electric shocks, earth cables and

cables whose sheath colour corresponds to ground wires, must not be used for power lines of Phase and

Neutral. Standard colour of Ground wires is Green or Yellow/Green. The electric components such as

compressor and fan motors are provided of an individual Ground wire, connected to a metal part of the

appliance. When interventions of repairing or maintenance are carried out, the above Ground wires must

not be disconnected, unless dismantling and replacing of components are needed. Before ending whatever

intervention of repairing or maintenance, it is extremely important to connect again all Ground wires

eventually disconnected before.

IG-2

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

1.2 ESSENTIAL FEATURES OF THESE MODELS

â Power modulation by DC Inverter control

Power supplied by system changes according to thermal load in installation environment. When

temperature inside the room reaches a value which is close to value set by User, compressor rotation

lowers, so as to allow a sensible reduction in power consumption. Moreover, as regards to traditional

thermostatic control systems (On-Off), compressor’s stops and restarts are less frequent - thus

permitting a reduction in power consumption and allowing an immediate increase in comfort.

â Energy high efciency (Class A/A)

All capacities (261, 351, 511, 631) of these systems meet requirements of Class “A” Energy Efciency,

both for operation in Cooling mode and for operation in Heating mode.

â “Ozone friendly” R410A refrigerant

R410A refrigerant does not damage ozone at all (ODP=0). Best performances assured by R410A

refrigerant allow a sensible reduction in refrigerant amount, which is required for the operation of

system. Both factors reduce the environmental impact of system.

â Advanced control for malfunction diagnosis

In case of eventual operation malfunctions, the most common among them will be shown by “Error

Codes” (“F_”) on LED Display of Indoor Unit and by the status of “Running” LED and “Timer”

LED placed on Indoor Unit’s frontal panel.

This allows targeted and therefore quicklier interventions for solving of eventual malfunctions.

â Operation control by infrared remote control (IR)

On IR remote control, there is a wide range of options, that is:

The possibility to program Timer operation (“Timer On”, or “Timer Off”) of system, within max.

24 hours, by steps of ±1 hour.

By “SLEEP” function, noise level of Indoor Unit can be reduced, as well as power consumption.

This operation option, that foresees rotation of Indoor Unit’s fan at Low speed and gradual “correction”

of temperature set by remote control, is available both in Cooling mode and in Heating mode.

“TURBO” function allows to reach desired temperature value quickier, as indoor fan speed is

set to max. available speed (“Ultra-HIGH”), for increasing the volume of air treated by Indoor Unit.

IG-3

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

This operation option - which however is detrimental to noise level produced by Indoor Unit - is

available both in Cooling mode and in Heating mode.

“SWING” option: automatic swinging downwards and upwards of air outlet horizontal louver,

for a uniform distribution of air supplied in the room by Indoor Unit.

“Natural ow” option: sequence which consists in the upwards and downwards swinging of the

air outlet horizontal louver, for twice, followed by a 30-seconds’ stop of the louver and so on. This

is for simulating a light air current in the room.

“AIR FLOW” option: automatic swinging rightwards and leftwards of air outlet vertical louvers,

for a uniform distribution of air supplied in the room by Indoor Unit (this function is available on

HKED 511 X and HKED 631 X Models only).

â Automatic restart of Units after a power failure

Normally, after 3 minutes since power is restored, the system is able to restart with the settings

that were selected before the blackout. This means there is no need to press the “ON/OFF” button.

However, if “TIMER” operation had been previously selected, it will be cancelled and need to

be set again.

“SLEEP” function (see above), has to be expressly selected again as well.

“TURBO” function (see above), has to be expressly selected again as well.

In the same way, if “SWING” and/or “AIR FLOW” options (see above) were active when the

blackout occurred, they will be expressly selected again.

â Devices for a higher salubrity of air

HKED 261, 351, 511, 631 X Indoor Units are equipped of lters of mechanical type (net lters) at high

efciency air inlet, which can be easily reached for periodical cleaning.

â Advanced control of rotation of Indoor Unit’s fan

During starting in Heating mode, indoor fan will start rotating only after Indoor Unit’s heat exchanger

has reached a temperature which avoids cold air supply by Indoor Unit. This “preheating” may require

a time interval variable from 2 minutes to 5 minutes.

During thermostatic pauses in Heating mode, indoor fan speed will be reduced to the lowest

speed to avoid cold air supply by Indoor Unit.

At the end of operation in Cooling mode, indoor fan will keep on rotating for a certain time interval

since compressor’s stop, so as to allow the removal of the humidity left over on Indoor Unit’s heat

IG-4

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

exchanger. This logic of operation is in order to prevent humidity stagnation and the consequent

forming of mould on Indoor Uni’s heat exchanger.

â Operation in Heating mode with very low temperature

These systems are able to operate in Heating mode also if outdoor temperature is very low: in

fact, the lowest value of operating range in Heating mode is - 15°C. However, in these extreme

conditions, as a consequence of the operation principle of “heat pump” systems, the performance

of system will result remarkably reduced as regards environmental normal use conditions of the

system itself.

â Appearance and functions: Indoor Units HKED 261, 351, 511, 631 X

Operation in Emergency mode: also if the IR remote control is temporarily unavailable or

malfunctioning, in any case it will be possible to start the system in “Auto Mode”. To that end, it

will be necessary to press the special button placed below the up-and-over frontal panel of Indoor

Unit. Therefore, the control electronics will automatically select the operation mode, on the basis of

temperature conditions inside the room.

These Indoor Units have a new design, so as to t harmoniously in residential environments.

Moreover, for each capacity of Indoor Unit it is available on demand a range that includes 4 frontal

decorative boards in different colours (available colours: “Black”, “Gold”, “Silver”, “Light-Blue”), in

addition to the white decorative board preinstalled in factory. The installation of one of frontal decorative

board allows to adapt Indoor Unit’s appearance to different residential environments. This operation

must be carried out only by qualied Personnel.

On these Indoor Units there is a LED Display, of orange colour, with 2 alphanumeric characters,

that is able to display alternatively the following information: set temperature value (°C), remaining

time (hours) of operation programmed by “Timer” function, starting up of automatic defrosting function

or an eventual “Error/Protection Code” in case of a malfunction of the system. As a consequence of

this, it is always possible to carry out an instant monitoring of the system’s operation status.

LED Display, which is usually off during system operation, may be lighted up according to User’s

needs by pressing “LAMP” button on IR remote control. For turning off LED Display, it is necessary

to press “LAMP” button again on IR remote control. By turning off LED Display, sources of light inside

the room can be reduced, thus making night rest more comfortable.

â Appearance and functions: Outdoor Units HCND 261, 351, 511, 631 X

Frontal grille and back grille are both treated against corrosion, and the same is true for bolts

IG-5

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

and xation screws placed outside the chassis.

The refrigerant ttings (service valves) and the electrical connections (terminal blocks) are protected

from atmospheric agents (inltrations of rainwater) by panels and service covers.

IG-6

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

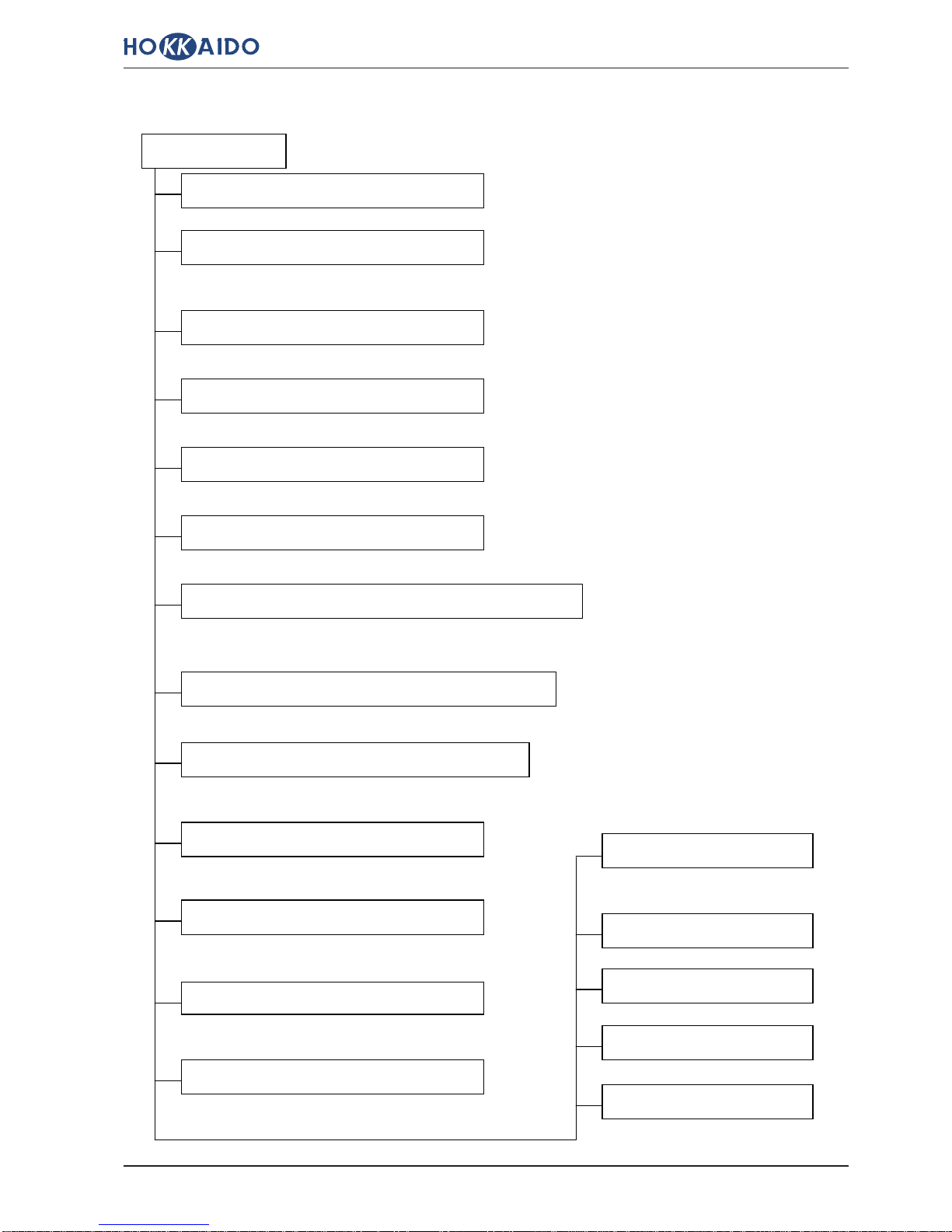

Recapitulatory outline of main available functions on Units

Wide range of Error/Protection Codes that can be shown

on bright Display of Indoor Unit. “Self-Check” programme.

Indoor Units

ON/OFF by IR remote control

Indoor temperature sensor and outdoor temperature sensor.

Indoor heat exchanger temperature sensor and outdoor heat exchanger sensor.

Monitoring of temperature values

Room temperature is kept on the basis of temperature value set by remote control, by thermostat under microcomputer

control and compressor operation at variable speed (control by DC Inverter).

Ambient temperature control

During starting phase in Heating mode, indoor fan will rotate at set speed after a delay of a few seconds.

Anti-cold drafts prevention function

Between each ON/OFF cycle of system and the following one, at least 3 minutes must elapse.

Protection against close ON/OFF

“ULTRA-HIGH” speed, “HIGH” speed, “MED” speed, “LOW” speed, “BREEZE” speed.

Speed ranges of indoor fan

“Running” (Operation indicator), “Timer” (Indicator of starting up of Timer function, and corresponding remaining

time), “dF” (Defrosting), “F_” (Error Code) and “P_” (Protection Intervention): Indications on LED Display with 2 digits).

Logic control of horizontal air outlet flap

“Sleep”: Control of indoor fan and of set temperature for reducing noise level and electric power consumption.

“Turbo”: “ULTRA-HIGH” speed of indoor fan and max. frequency of compressor rotation, for reaching desired comfort quickier.

“Sleep” function and “Turbo” function

In environments with high humidity, this function allows to

restore quicklier your desired comfort conditions.

“DRY” function

Indications by Display + LED on frontal panel

Operation in Auto Mode

Simplified connections

Automatic defrosting

“TIMER On/Off” function

For preventing cold air supply during

starting in Heating mode.

“HOT- KEEP” function

Auto-Restart after a blackout

Autodiagnosis of malfunctions function

During starting phase, operation mode is automatically

selected according to indoor temperature conditions.

If you press “SWING” button on remote control to select “natural flow” mode, the horizontal air outlet flap on Indoor Unit

is controlled so as to simulate a light natural air inside the room.

Besides fixed stop positions, the automatic swinging of

air outlet flaps is also available.

Stop/swinging of air outlet flaps

IG-7

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

Min. interval between ON/OFF cycles of compressor is of 3 minutes.

Outdoor Units

Timed ON/OFF of compressor

This kind of control allows a continuous modulation of system operation on the basis of thermal load and of desired comfort,

and allows to reduce power consumption especially at medium-low speed.

Control of compressor rotation speed by DC Inverter technology

For reducing noise level of outdoor fan, the shape of fan wheel has been expressly redrawn.

Outdoor fan with “silent” shape

Aluminium fins of outdoor heat exchanger ensure a higher efficiency in heat exchange.

Special fins in treated aluminium

It absorbs energy during operation in Heating mode only.

Protection against compressor’s overload

Anticorrosive surface treatment of chassis

Protection covers for electrical & refrigerant connections

Operation in Heating mode up to -15°C outdoor temperature

4-ways valve “energy saving” control

IG-8

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

1.3 APPEARANCE OF UNITS

Indoor Units “Wall” Personal Line DC Inverter:

Models HKED 261 X, HKED 351 X

Frontal board standard “White” (by factory)

Models HKED 261 X, HKED 351 X

Frontal board optional “Black” (HSD-2-BCK)

Models HKED 261 X, HKED 351 X

Frontal board optional “Gold” (HSD-2-GLD)

IG-9

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

Indoor Units “Wall” Personal Line DC Inverter:

Models HKED 261 X, HKED 351 X

Frontal board optional “Silver” (HSD-2-SLV)

Models HKED 261 X, HKED 351 X

Frontal board optional “Light-Blue” (HSD-2-LBL)

IG-10

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

Indoor Units “Wall” Personal Line DC Inverter:

Models HKED 511 X, HKED 631 X

Frontal board standard “White” (by factory)

Models HKED 511 X, HKED 631 X

Frontal board optional “Black” (HSD-3-BCK)

Models HKED 511 X, HKED 631 X

Frontal board optional “Gold” (HSD-3-GLD)

IG-11

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

Indoor Units “Wall” Personal Line DC Inverter:

Models HKED 511 X, HKED 631 X

Frontal board optional “Silver” (HSD-3-SLV)

Models HKED 511 X, HKED 631 X

Frontal board optional “Light-Blue” (HSD-3-LBL)

IG-12

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

Outdoor Units Personal Line DC Inverter:

Models HCND 511 X, HCND 631 X

Models HCND 261 X, HCND 351 X

IG-13

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

Indoor Unit

Air inlet

Louver for adjusting air in

horizontal direction. The louver

is motorized on HKED 511, 631X

Models only.

Flap for adjusting air in

vertical direction.

Display Panel & LED Indicators

High efficiency air filter

Air inlet Electrical & refrigerant connections

Emergency button

a) Panel’s opening

Frontal panel of Indoor Unit

It removes impurities on air inlet.

Drain tube

Outlet air

Outdoor Unit

Air outlet

b) Panel’s closing

Press both sides of panel and pull the panel

towards you till max. opening angle (about 60°

as regards vertical position).

Never force the panel more than max. opening

angle.

Below the panel there is the Emergency Button,

which allows operation (in Auto Mode) if IR remote

control is not available.

Push the panel downwards till closing position,

indicated by the “click” of blockage mechanism.

Frontal panel

1.4 OUTLINE OF INDOOR & OUTDOOR UNITS

Note:

The Figures sideways are for explicative aim

only. The real appearance of components of

Units may be different from what is shown in

Figures.

IG-14

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

1.5 IR REMOTE CONTROL

nIR Remote Control for Models HKED (261, 351, 511, 631) X

Notes:

¦For a detailed explication concerning the function of each button of IR remote control, and concerning

symbols which are shown on remote control’s LCD Display, please refer to the “User Manual” provided with

Indoor Units, or to the following pages.

¦For a detailed explication about options and operation modes of system, please refer to the “User Manual”

provided with Indoor Units.

¦Concerning these Models HKED-HCND (261, 351, 531) G (On-Off), even if “TURBO” button and “LAMP”

button are available on remote control, they refer to unavailable functions. Consequently, if you press these

buttons, there will be no effect on these systems.

IG-15

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

n Outline of IR remote control’s buttons

Set Temperature “ON/OFF” Button

“SWING” Button

“AIR FLOW” Button

“SLEEP” Button

“LAMP” Button

“HOLD” Button

Operation Mode

Fan Speed

“Turbo” Button

“Timer” Button

Reception of signals trasmitted to Indoor Unit

To start/stop the system.

To select operation in “SLEEP” mode.

To change fan speed:

• LOW:

• MED:

• HIGH:

• AUTO:

(flashing).

MODE

FAN SPEED

TURBO

SWING

TIMER

HOLD

AIR FLOW

SLEEP

LAMP

These buttons allow to adjust

ambient temperature.

If you press “+” button, set

temperature is increased by 1°C.

If you press “-” button, set

temperature is reduced by 1°C.

The range of temperatures that

can be set is the following: 16°C ~

32°C.

(In “AUTO” mode and in “DRY”

mode, temp. is automatically set to

25°C and cannot be modified by

the User).

To select operation mode:

• “AUTO”

• “COOL”

• “DRY”

• “HEAT”

• “FAN”.

In COOL and HEAT modes, if you

press this button, operation in

“Turbo” mode is started up.

This function is not available on

these Models On-Off.

To programme the automatic start

(TIMER ON) or the automatic stop

(TIMER OFF) of system.

To select position of motorized

louvers for air outlet in horizontal

direction (left/right).

Flaps may swing continuously, or

stop in fixed position.

This function is available on

HKED 511 X, HKED 631 X Models

only.

To light up/go out the Display on

the Indoor Unit.

This button is not operating on

these Models.

To lock/unlock all buttons of remote

control.

If buttons of remote control are pressed by orienting correctly remote

control itself towards the IR receiver on Indoor Unit, signals will be transmitted

to Indoor Unit.

If signals have been correctly received, the buzzer on Unit emits a sound.

+

-

• “natural flow”: (ON).

• Swinging: (flashing).

• Fixed position : (ON).

To adjust motorized flap for air

outlet in vertical direction

(up/down):

In “DRY” mode, the flap’s angle is

adjusted in fixed position.

IG-16

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

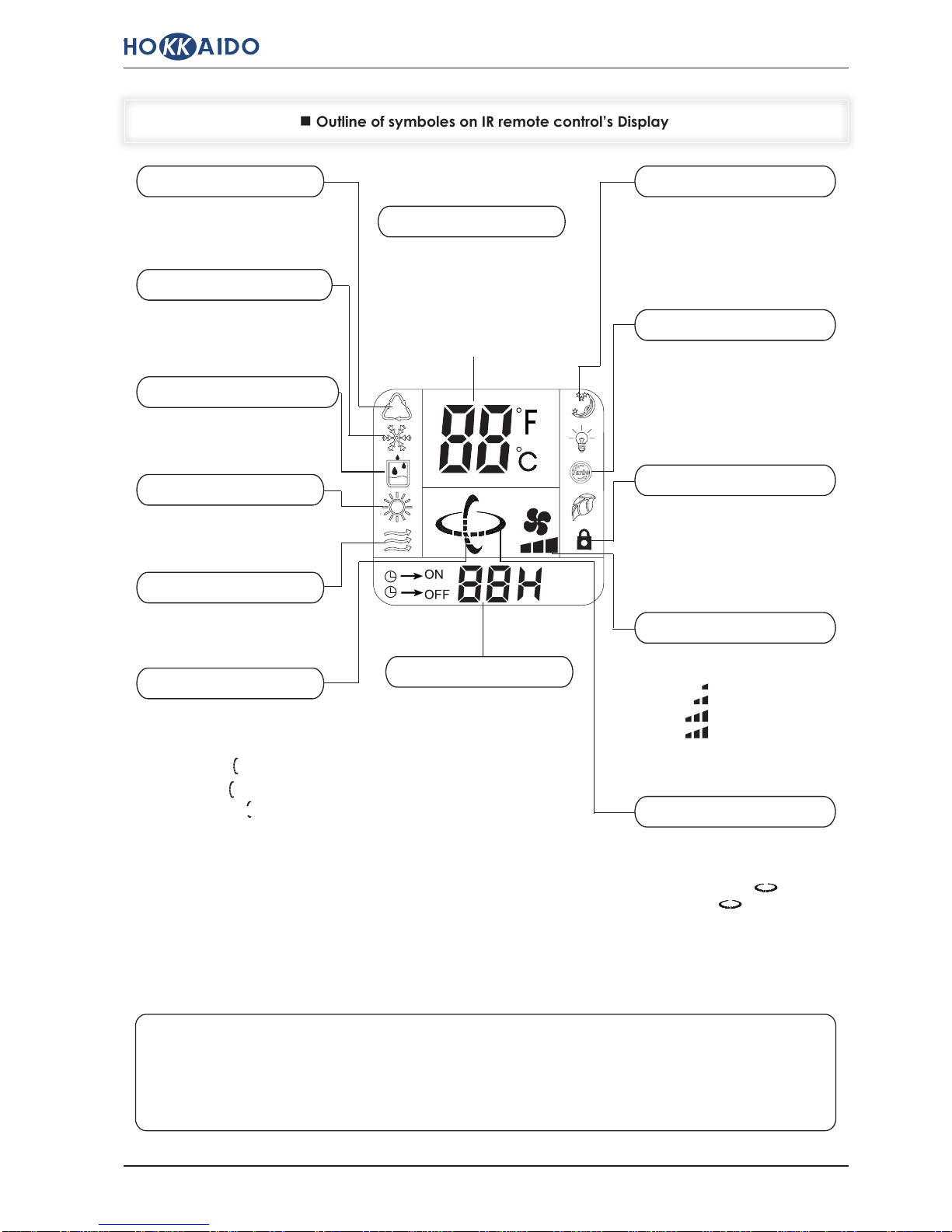

n Outline of symboles on IR remote control’s Display

TEMPERATURE

This indicator shows set temperature.

Range of temperature that can be

set is the following: 16°C ~ 32°C.

(In AUTO and DRY modes,

temperature is automatically set to

25°C and it cannot be adjusted by

the User).

Automatic Mode

Cooling Mode

Drying Mode

Heating Mode

Fan only Mode

“SWING” Indicator TIMER

It indicates TIMER setting.

“SLEEP” Indicator

“TURBO” Indicator

“KEY LOCK” Indicator

“FAN SPEED” Indicator

“AIR FLOW” Indicator

Notes:

The Figure above shows all possible indications that can be displayed on IR remote control’s

Display.

In reality, only indications referred to current operation selections will be displayed.

This symbol indicates that “AUTO”

Mode has been selected.

This symbol indicates that “COOL”

Mode has been selected.

This symbol indicates that “DRY”

Mode has been selected.

This symbol indicates that “HEAT”

Mode has been selected.

This symbol indicates that “FAN”

Mode has been selected.

It indicates that “SLEEP” mode has

been selected.

In COOL and HEAT modes, this

indicator lights up if “TURBO”

mode has been selected.

This function is not available on

these Models On-Off.

This indicator is displayed if remote

control’s buttons have been locked.

It indicates current setting of fan

speed:

• LOW:

• MED:

• HIGH:

• AUTO:

(flashing).

It indicates current setting of

motorized louvers for horizontal

adjustment (right/left) of air outlet:

• Automatic swinging: (flashing).

• Fixed angle: .

This function is available on

HKED 511 X, HKED 631 X

Models only.

• “natural flow”: (ON).

• Swinging: (flashing).

• Fixed position: (ON).

It indicates the setting of motorized

flap for air outlet in vertical direction

(up/down):

In “DRY” mode, the angle of flap is

adjusted in fixed position by control

electronics.

IG-17

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

Make sure that batteries (“AAA” type, 1.5V) are fully charged and correctly tted in the special case

on remote control, by respecting the polarity marked on remote control itself. The average life of

batteries is of about 1 year. Never use rechargeable batteries.

Use the remote control by turning it towards the Indoor Unit at no more than 8 metres from the Unit’s

IR receiver.

Remote control will not work properly if curtains, doors or other objects placed between remote

control and Indoor Unit’s IR receiver do not allow the transmission of signals sent to Indoor Unit. In

these cases, the operating range of remote control will be remarkably reduced.

If remote control is placed sideways as regards the signal receiver, remote control will operate within

a maximum angle of 30° on the right or on the left of receiver. If remote control is xed on its wall

bearing, it will work within a side max. distance of 0.5 metres on the right or on the left of receiver.

If IR receiver on Indoor Unit is exposed to direct sunlight, remote control (and consequently the air

conditioner) may not work properly.

In order to avoid interferences, keep remote control at least 1 metre away from Hi-Fi, TV, etc.

If remote control does not work properly, press “RST” button (reset of settings) placed on the back

of the remote control itself. Check if remote control do operate properly now. Otherwise, remove

both batteries from remote control, then wait for a few minutes and reinstall batteries in their case.

Never wet the remote control and prevent any liquid from falling on it.

Do not use any liquid, solvent or detergent for cleaning the remote control. Use only a soft cloth,

clean and dry.

Maximum allowed distance: 8 metres

n Recommendations for the correct use of IR remote control

IR receiver for remote

control

IG-18

Monosplit “Wall” Personal Line DC Inverter - Section 1: General Information

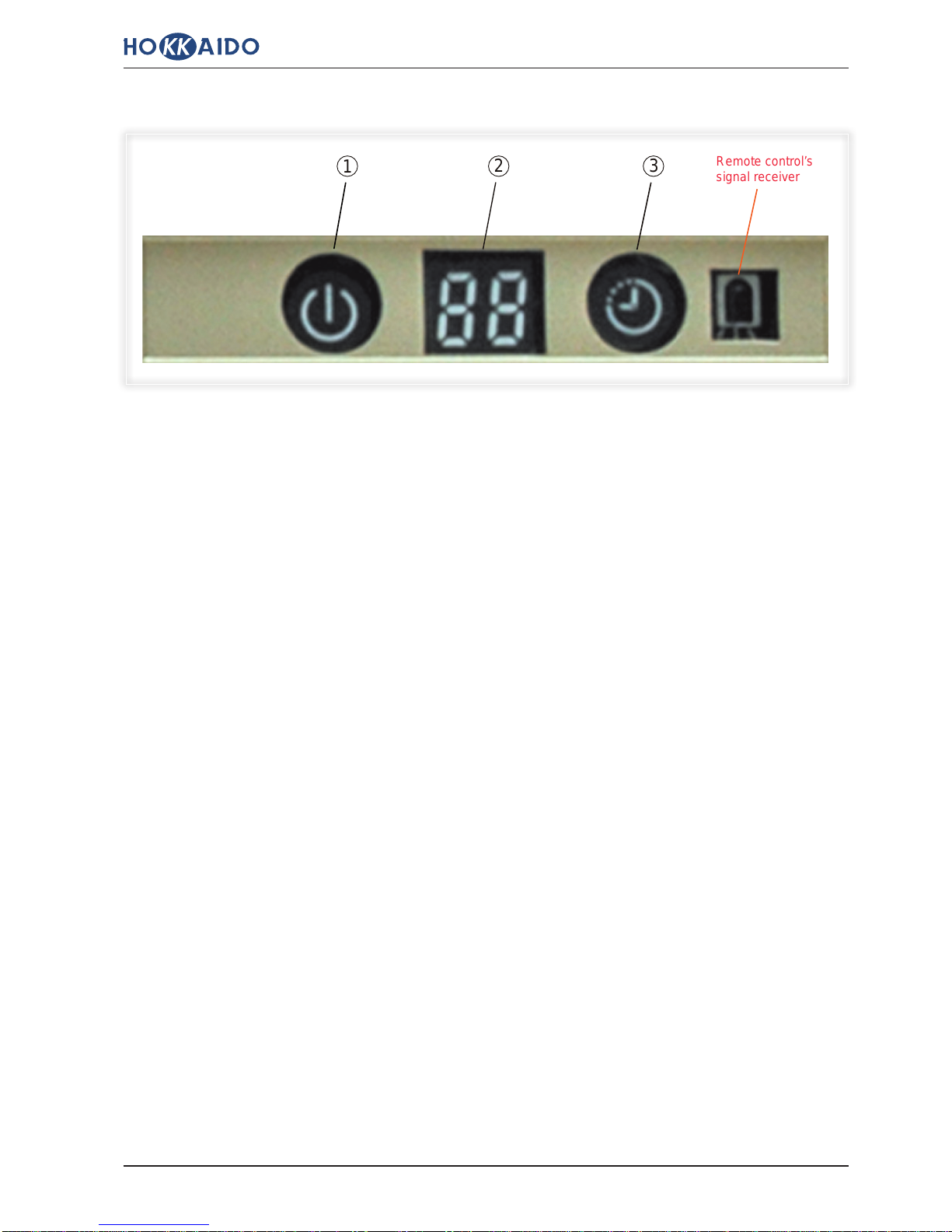

Remote control’s

signal receiver

1

“Running” LED (Orange):

It lights up when the Indoor Unit is operating.

It goes out when the Indoor Unit is OFF (stop by remote control).

It flashes (once/second) when at operation start in Heating mode, the preheating of heat exchanger on

Indoor Unit is in progress (Indoor Unit’s fan is still stopped).

It flashes in different ways or it lights up (see “Section 6: Diagnostic & Maintenance” of this Technical

Manual), respectively when a system’s malfunction occurs or in case of intervention of a protection function.

LED Display with 2 alphanumeric characters (Orange):

During normal operation, it displays temperature value set by IR remote control.

If one of Timer options has been selected (“Timer On”, or “Timer Off”), LED Display shows the remaining

time interval (hours) before the programmed start or stop. The same time interval is shown on LCD Display of

IR remote control.

While automatic defrosting is in progress (with reversal of refrigerant cycle as regards operation in Heating

mode), LED Display shows “dF ” indication.

If control electronics diagnoses a malfunction which is in the list of codified malfunctions, LED Display shows

the corresponding Error Code [F _ ]. In case of intervention of a protection, LED Display shows the

corresponding Protection Code [P _ ]. For the list of Error Codes or Protection Codes, please refer to “Section

6: Diagnostic & Maintenance” of this Technical Manual.

“Timer” LED (Orange):

It lights up when one of Timer options has been selected (“Timer On”, or “Timer Off”).

It lights up or flashes in different ways (see “Section 6: Diagnostic & Maintenance” of this Technical Manual),

respectively when a system malfunction occurs or in case of intervention of a protection function.

3

2

1.6 LED PANEL ON INDOOR UNITS

This manual suits for next models

7

Table of contents

Other Termal Air Conditioner manuals

Popular Air Conditioner manuals by other brands

Mitsubishi Electric

Mitsubishi Electric Mr. Slim PUZ-M200YKA2.UK Service manual

Panasonic

Panasonic CU-2S18NBU-1 Service manual

Sanyo

Sanyo STB0811C1-S parts list

GE

GE AHE18 Series Owner's manual and installation instructions

Mitsubishi Electric

Mitsubishi Electric MFZ-KA25VA Service manual

LG

LG LS243HLV3 Engineering manual