TerraMarc Industries Lockwood 472H Owner's manual

Manual P/N 18054-00

9/10/04

Companion to 18055-00

Lockwood Mfg.

A Division of TerraMarc Industries

237 12th St. NW • P.O. Box 849

West Fargo, ND 58078-0849

(701)282-5520 • FAX: (701)282-9522

www.lockwoodmfg.com

OWNER /OWNER /

OWNER /OWNER /

OWNER /

OPERAOPERA

OPERAOPERA

OPERATT

TT

TOR’SOR’S

OR’SOR’S

OR’S

MANUMANU

MANUMANU

MANUALAL

ALAL

AL

472H PO472H PO

472H PO472H PO

472H POTT

TT

TAA

AA

ATT

TT

TOO

OO

O

HARVESTERHARVESTER

HARVESTERHARVESTER

HARVESTER

472H Potato Harvester Owner Operator’s Manual

Disclaimer

This document is based on information available at the time of its publication. While efforts have been made to be accurate,

the information contained herein does not purport to cover all details or variations, nor to provide for every possible contin-

gency in connection with installation, operation, or maintenance. Features may be described herein which are not present

in all systems. Lockwood assumes no obligation of notice to holders of this document with respect to changes subse-

quently made.

Lockwood assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of the information con-

tained herein.

SPECIFICATIONS AND DESIGN ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Lockwood is continually making improvements and developing new equipment. In doing so, we reserve the right to make

changes or add improvements to our product without obligation for equipment previously sold.

Because modification to this machine may affect the performance, function, and safety of its operation, no modifications are

to be made without the written permission of Lockwood. Part replacements should be with original equipment supplied by

Lockwood.

LOCKWOOD STATEMENT OF PRODUCT SAFETY

As a manufacturer of specialized agricultural equipment, Lockwood, fully recognizes its responsibility of providing its

customers products that perform their expected use in a reasonably safe manner. Safety considerations shall be an integral

and high priority part of all engineering/design analysis and judgments involving Lockwood products. It is our stated policy

that our products will be manufactured to comply with the safety standards specified by the American Society of Agricultural

Engineers, the National Electrical Code, The Society of Automotive Engineers, and/or any other applicable recognized

standards at the time manufactured. However, this statement should not be construed to mean that our product will

safeguard against a customer’s own carelessness or neglect in violating common safety practices specified in each product’s

manual, nor will we be liable for any such act.

Copyright

© 2003, Lockwood. All rights reserved. Produced and printed in the USA.

Trademark Information

Any trademarks not directly mentioned are also acknowledged.

Preface

This manual is intended for use with the 472H Potato Harvester

Is a trademark of the American

Society of Agricultural Engineers

(ASAE) and is so acknowledged.

Is a trademark of the Occupa-

tional Safety & Health Adminis-

tration (OSHA) and is so acknowl-

edged.

Is a trademark of the National Fire

Protection Association (NFPA)

and is so acknowledged.

Is a trademark of the Society of Auto-

motive Engineers (SAE) and is so ac-

knowledged.

Is a trademark of the American Na-

tional Standards Institute (ANSI) and

is so acknowledged.

Is a trademark of the National Elec-

trical code (NEC) and is so acknowl-

edged.

I472H Potato Harvester Owner Operator’s Manual

LOCKWOOD

LIMITED WARRANTY

Lockwood warrants for each original retail purchaser of new goods from Lockwood or a Lockwood Dealer, that such

goods are at the time of delivery to such purchaser, free from defects in material and workmanship.

Electrical components operated on direct current (D.C.) circuits must be operated with respect to proper polarity and

not above or below the voltage specified by Lockwood. Electrical components operated on alternating current (A.C.) circuits

must be operated at not more than five percent (5%) above or below that voltage and frequency specified by Lockwood.

GOODS MUST BE ELECTRICALLY WIRED AND GROUNDED ACCORDING TO N.E.C. REQUIREMENTS AND INSPECTED

AND APPROVED BY LOCAL OR STATE INSPECTING AUTHORITIES.

Lockwood’s obligation under this warranty, unless otherwise specified is limited to (1) repairing, or at its option, (2)

replacing with factory specified replacement parts, without cost, at a designated Lockwood Dealer, any parts which in

Lockwood’s judgment proved defective in material or workmanship within twelve (12) months after date of delivery to the

original purchaser, unless the goods are purchased for commercial use, in which event the warranty period will be forty-five

(45) days from the date of delivery to the original purchaser. This warranty will not be valid if the goods are not assembled,

operated and serviced in accordance with the Operator’s Manual.

GENERAL PROVISIONS - FIELD EQUIPMENT

The following general provisions are applicable to field equipment. The date of delivery shall be deemed to be the date

shown on the delivery and warranty registration form signed by the Purchaser and delivered to Lockwood (which is the date

of retail delivery).

No warranty shall apply to (1) normal maintenance, service or adjustments, (2) any Lockwood goods which shall have

been repaired or altered in any way so as, in Lockwood’s judgment, to affect adversely their stability, operational character-

istics or safety, nor which have been subject to misuse, negligence, accident, poor assembly or improper installation. Non-

Lockwood manufactured products and/or components will be subject to warranties of their respective manufacturers.

To make this warranty effective. (1) the purchaser’s Warranty Registration form furnished with each piece of equip-

ment must be completed and on file at Lockwood factory, West Fargo, North Dakota prior to submitting any claims, (2) the

warranty claim must be completed and the parts claimed to be defective must accompany the completed warranty claim if

required.

FREIGHT

Dealer must prepay freight on warranty components returned to Lockwood. The components will be replaced F.O.B.

Factory.

LIMITATIONS

This Lockwood warranty is expressly in lieu of other warranties, expressed or implied, including without limitation,

warranties of MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, and any other obligation or liability

including crop damage or loss of crops for liability for incidental or consequential damages on the part of Lockwood.

There are no warranties on used goods, USED GOODS ARE SOLD AS IS.

Lockwood shall not be liable or responsible in any way or to any extent for property damages, personal injury, or death

resulting from the modification or alteration to Lockwood goods or from the purchaser’s failure to assemble, install, main-

tain, or operate the goods in accordance with the provisions of the Operator’s Manual.

No statement, representation, agreement or understanding, oral or written, made by an agent, authorized Dealer,

Lockwood representative or employee other than an officer of Lockwood in writing, which is not contained in the Warranty

and Disclaimer will be recognized or enforceable or binding upon Lockwood.

Any action for breach of any Lockwood warranty must be commenced within one year after date on which such cause

of action occured.

PRE - DELIVERY CHECKLIST

This checklist is provided to identify items to be checked and adjusted if necessary by the dealer prior to

delivery of a new machine.

Check the following and adjust if necessary.

Machine matches sales order (correct serial number

and row spacing).

List machine’s serial number on warranty and registra-

tion form.

No parts of the unit have been damaged during ship-

ment. Check for such things as dents and loose or

missing parts.

The belt sheaves and roller chain sprockets are aligned

and idlers are correctly spaced.

Roller chain and V-belt tensions are correct.

Bearing lock collars are secured and tightened in direc-

tion of rotation.

All nuts and bolts are tight.

Safety shields and safety decals are on and properly

placed.

Wheel lug bolts are tightened to specified torque.

The side elevator inlet section is properly located rela-

tive to the rear cross conveyor and deviner roller.

The rod or belted chain pitches are matched with the

sprockets.

Test hydraulic controls for proper operation.

Smooth hydraulic operation with no leaks.

The tire pressure is at the appropriate psi.

Set screws and keys are set and secure.

The open center screw and closed center screw on the

electro-hydraulics valve are properly oriented to match

the tractor hydraulics.

All points are properly lubricated. (See lubrication in

the service and maintenance section.)

Attachment of the hydraulic hoses and components is

correct.

DELIVERY - CHECKLIST

Review the following with the customer at the time the unit is delivered

Review the operator’s manual specifically the Safety

Precautions.

Explain the importance of thoroughly reading and un-

derstanding this manual.

Review the operation section.

Review the Service and Maintenance section.

Be sure customer understands the location and func-

tion of controls, safety decals and safety devices.

Explain adjustments for machine operation.

Explain the importance of proper lubrication and main-

tenance.

Explain warranty to customer.

Both dealer and customer must sign the Delivery And

Warranty registration form.

II 472H Potato Harvester Owner Operator’s Manual

III472H Potato Harvester Owner Operator’s Manual

HOHO

HOHO

HOWW

WW

W TT

TT

TO REAO REA

O REAO REA

O REACH USCH US

CH USCH US

CH US

Address Hours Telephone / Fax

Number

E-mail

Internet

Lockwood Mon. - Fri. For Parts and Service: For Service: serv@crary.com

237 12th St. NW 8 A.M. to 5:00 P.M. 1-800-247-7335 For Parts: potsales@crary.com

P.O. Box 849 Central Time Fax: 1-701-282-9522 Visit us on the W eb @

West Fargo, ND 58078-0849 www.lockwoodmfg.com

IV

Section Description Page

472H Potato Harvester Owner Operator’s Manual

Contents

1.0 INTRODUCTION ........................................................................................................................ 2

2.0 SAFETY .................................................................................................................................... 3

2.1 GENERAL SAFETY ................................................................................................................... 4

2.2 OPERATING SAFETY ................................................................................................................ 5

2.3 MAINTENANCE SAFETY ........................................................................................................... 5

2.4 HYDRAULIC SAFETY ................................................................................................................ 6

2.5 PTO (POWER TAKEOFF) SAFETY ........................................................................................... 6

2.6 TRANSPORT SAFETY ............................................................................................................... 7

2.7 STORAGE SAFETY ................................................................................................................... 7

2.8 TIRE SAFETY ............................................................................................................................ 7

2.9 SAFETY DECALS ...................................................................................................................... 7

2.10 SAFETY DECAL LOCATIONS .................................................................................................. 10

2.11 SIGN-OFF FORM ..................................................................................................................... 12

3.0 OPERATION .............................................................................................................................. 13

3.1 TO THE NEW OPERATOR OR OWNER ................................................................................... 13

3.2 PRE-OPERATION CHECKLIST ................................................................................................. 13

3.3 MACHINE COMPONENTS ........................................................................................................ 14

3.4 INITIAL OPERATING PROCEDURE ........................................................................................... 15

3.4.1 PRE-START INSPECTION ......................................................................................... 15

3.4.2 AFTER OPERATING FOR 2 HOURS ......................................................................... 15

3.4.3 AFTER OPERATING FOR 10 HOURS ....................................................................... 15

3.5 CONTROLS ............................................................................................................................... 16

3.6 OPERATING .............................................................................................................................. 17

3.6.1 ATTACHING IMPLEMENT TO TRACTOR ................................................................... 17

3.6.2 UNHOOKING IMPLEMENT FROM TRACTOR ........................................................... 18

3.7 TRANSPORTING ....................................................................................................................... 19

3.7.1 TRANSPORTING THE HARVESTER ......................................................................... 19

3.8 DIGGING .................................................................................................................................. 19

3.8.1 DIGGER NOSE ......................................................................................................... 19

3.8.2 DIGGER BLADE ........................................................................................................ 20

3.8.3 NOSE ROLLERS....................................................................................................... 21

3.9 COULTERS ............................................................................................................................... 22

3.9.1 COULTER ADJUSTMENT ......................................................................................... 22

3.10 PRIMARY BELTED CHAINS ...................................................................................................... 23

3.11 SECONDARY BELTED CHAINS ................................................................................................ 23

3.12 OVERRIDE BELTED CHAIN ...................................................................................................... 24

3.13 REAR CROSS CONVEYOR ...................................................................................................... 24

3.14 SLIP CLUTCHES ....................................................................................................................... 25

3.15 SIDE ELEVATOR ....................................................................................................................... 26

3.16 PICKING TABLE ........................................................................................................................ 27

3.17 BULK BOOM ............................................................................................................................. 27

3.17.1 TRANSPORTING POSITION ...................................................................................... 27

3.18 WHEELS .................................................................................................................................. 28

3.19 OPTIONS .................................................................................................................................. 29

3.19.1 CLEANING TABLES .................................................................................................. 29

3.19.2 SNAPPER ROLLERS ................................................................................................ 31

3.19.3 SHAKERS ................................................................................................................. 32

3.19.4 SHAFT MONITOR ..................................................................................................... 34

3.19.5 ROLLER SCRAPERS ................................................................................................ 38

V

472H Potato Harvester Owner Operator’s Manual

Section Description Page

Contents

3.20 OPERATING HINTS ................................................................................................................... 39

3.20.1 PREPARING SOIL AND CROP .................................................................................. 39

3.20.2 LOADING THE TRUCK .............................................................................................. 39

3.20.3 ADVERSE CONDITIONS ........................................................................................... 39

3.20.4 HARVESTING EFFICIENCY ...................................................................................... 40

3.21 GENERAL LOW DAMAGE POTATO HARVESTING .................................................................. 40

3.21.1 DIGGER BLADES ..................................................................................................... 40

3.21.2 BELTED CHAINS ....................................................................................................... 40

3.22 HEX BORE SPROCKETS ......................................................................................................... 42

3.23 EQUATION ................................................................................................................................43

3.24 STORAGE ................................................................................................................................. 44

3.24.1 POST-SEASON MAINTENANCE ............................................................................... 44

3.24.2 REMOVING FROM STORAGE /PRE-SEASON MAINTENANCE .............................. 45

3.25 DRIVE CHAIN TENSION ............................................................................................................ 46

3.26 DRIVE BELT TENSION .............................................................................................................. 46

3.27 BELTED CHAIN ......................................................................................................................... 46

4.0 SERVICE AND MAINTENANCE ................................................................................................ 47

4.1 SERVICE .................................................................................................................................. 47

4.1.1 FLUIDS AND LUBRICANTS ....................................................................................... 47

4.1.2 GREASING ............................................................................................................... 47

4.2 SERVICE RECORD ................................................................................................................... 48

4.3 PTO SERVICE .......................................................................................................................... 49

4.4 MAINTENANCE ......................................................................................................................... 49

4.4.1 PREVENTIVE MAINTENANCE .................................................................................. 49

4.4.2 REPAIR OF BELTED CHAIN ..................................................................................... 50

4.4.3 CHANGING HYDRAULIC OIL FILTER ........................................................................ 51

4.4.4 BLEEDING THE SYSTEM ......................................................................................... 52

5.0 TROUBLE SHOOTING .............................................................................................................. 53

5.1 HARVESTER TROUBLESHOOTING ......................................................................................... 53

5.2 PREVENTABLE DAMAGE TO PTO SHAFT .............................................................................. 55

5.3 SHAFT MONITOR TROUBLESHOOTING .................................................................................. 56

6.0 SPECIFICATIONS ..................................................................................................................... 58

6.1 GENERAL SPECIFICATIONS .................................................................................................... 58

6.2 CHAIN PITCH AND ROD CONFIGURATIONS ............................................................................ 59

6.3 CHAIN PATTERNS .................................................................................................................... 62

6.4 CHAIN COVERINGS ................................................................................................................. 65

6.4.1 PEGS ........................................................................................................................ 65

6.4.2 FLIGHTS ................................................................................................................... 65

6.4.3 RUBBER COVER ...................................................................................................... 66

6.4.4 PILLOW CUSHIONS ................................................................................................. 67

6.4.5 C-FLEX ...................................................................................................................... 68

6.4.6 EARS ........................................................................................................................ 69

6.5 BOLT TORQUE.......................................................................................................................... 70

6.6 HYDRAULIC FITTING TORQUE ................................................................................................. 71

6.7 TIRE INFLATION PRESSURES ................................................................................................. 72

Page 1472H Potato Harvester Owner Operator’s Manual

SERIAL NUMBER LOCATION

Always give your dealer the serial number of your Lockwood 472H Harvester when ordering parts, requesting service or other

information.

The serial number decal is located on the right side of the machine. Please mark the number in the space provided for easy

reference. Record the serial number on the Delivery And Warranty Registration form and on this page of your manual.

REPLACEMENT PARTS

Use only genuine Lockwood replacement parts to repair the machine. Your Lockwood dealer offers Lockwood replacement

parts. To obtain prompt, efficient service, remember to give the dealer the correct part description and serial number of the

machine.

Serial # ________________________

Fig. #2 Serial number decal

YXXXXX

Fig. # 1 Serial number decal location

Page 2 472H Potato Harvester Owner Operator’s Manual

1.0 INTRODUCTION

Congratulations on your purchase of a new Lockwood 472H Harvester to complement your farming operation. Lockwood

has designed and manufactured this equipment to meet the needs of a discerning agricultural industry for the efficient

harvesting of potatoes.

Safe, efficient, and trouble free operation of your harvester requires that you and anyone else who will operate or maintain

the machine, read and understand the safety, operation, maintenance, and trouble shooting information contained within the

Operators Manual. Check each item referred to and acquaint yourself with the adjustments required to obtain efficient

operation.

Keep this manual handy for frequent reference and to pass along to new operators or owners. Call your Lockwood dealer or

distributor if you need assistance, information, or additional copies of the manuals.

Many people have worked on the design, production, and delivery of this machine. They have used the highest quality of

materials and workmanship. The manual’s information on the knowledge, study, and experience of these people through

years of manufacturing specialized farming machinery.

The machine’s performance depends upon proper maintenance and adjustment. Whether an experienced operator of this or

similar equipment or not, we ask you to read the Operators Manual before running the machine. Keep the manual handy for

future reference. Lockwood has carefully prepared, organized, and illustrated this manual to assist you in finding the

information you need. Your Lockwood dealer will be happy to answer any further questions you may have.

OPERATOR ORIENTATION - The directions left, right, front, rear, as mentioned throughout the manual, are as seen from

the driver’s seat of the tractor facing the direction of travel.

Page 3472H Potato Harvester Owner Operator’s Manual

This Safety Alert Symbol means

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The Safety Alert symbol identifies important

safety messages on the Lockwood 472H Har-

vester and in the manual. When you see this

symbol, be alert to the possibility of personal

injury or death. Follow the instructions in the

safety message.

Accidents Disable and Kill

Accidents Cost

Accidents Can Be Avoided

3 Big Reasons

SIGNAL WORDS:

Note the use of the signal words DANGER, WARNING,

CAUTION, IMPORTANT and NOTE with the safety mes-

sages. The appropriate signal word for each message

has been selected using the following guidelines:

2.0 SAFETY

SAFETY ALERT SYMBOL

Why is SAFETY important to you?

DANGER - Indicates an imminently hazardous

situation that, if not avoided, will re-

sult in death or serious injury. This

signal word is to be limited to the most

extreme situations, typically for ma-

chine components that, for functional

purposes, cannot be guarded.

WARNING - Indicates a potentially hazardous situ-

ation that, if not avoided, could result

in death or serious injury, and includes

hazards that are exposed when

guards are removed. It may also be

used to alert against unsafe practices.

CAUTION - Indicates a potentially hazardous situ-

ation that, if not avoided, may result in

minor or moderate injury. It may also

be used to alert against unsafe prac-

tices.

IMPORTANT- Follow instructions to ensure proper

installation/operation of equipment.

NOTE - General statements to assist the

reader

Page 4 472H Potato Harvester Owner Operator’s Manual

2.1 GENERAL SAFETY

1. Read and understand the

Operator’s Manual and all

safety signs before operat-

ing, maintaining, adjusting

or servicing the Lockwood

472H Harvester.

2. Only trained persons shall

operate the Lockwood 472H Harvester. An untrained

operator is not qualified to operate

the machine.

3. Have a first-aid kit available for use

should the need arise and know how

to use it.

4. Provide a fire extinguisher for use in

case of an accident. Store in a highly

visible place.

5. Do not allow children, spectators or by-

standers within hazard area of machine.

6. Wear appropriate protective gear. This

list includes but is not limited to:

- A hard hat

- Protective shoes

with slip resistant

soles

- Protective goggles

- Heavy gloves

- Hearing protection

- Respirator or filter

mask

7. Wear suitable ear protection

for prolonged exposure to ex-

cessive noise.

8. Do not allow riders on the

machine.

9. Place all controls in neutral or off, stop tractor engine,

set parking brake, remove ignition key, wait for all

moving parts to stop, then properly block machine

before servicing, adjusting, repairing, or unplugging.

10. Review safety related items annually with all person-

nel who will operate or maintain the Lockwood 472H

Harvester.

2.0 SAFETY

The responsibility for SAFE operation and maintenance of

your Lockwood 472H Potato Harvester rests on YOU. YOU

must ensure that those who will operate, maintain or work

around this machine familiarize themselves with all operat-

ing, maintenance, and SAFETY information contained in

this manual. This manual discusses good safety practices

necessary to safely operate the Lockwood 472H.

Remember, YOU are the key to safety. Good safety prac-

tices protect you and the people around you. Make these

practices a working part of your safety program. Familiar-

ize EVERYONE who operates this equipment with the rec-

ommended operating and maintenance procedures and

ensure they follow all the safety precautions.You can pre-

vent most accidents. Do not risk injury or death by ignoring

good safety practices.

• Lockwood 472H owners must review operating instruc-

tions to operators or employees before allowing them

to operate the machine, and at least annually thereaf-

ter per OSHA (Occupational Safety and Health Admin-

istration) regulation 1928.57.

• The most important safety device on this equipment is

a SAFE operator. The operator is responsible to read

and understand ALL Safety and Operating instructions

in the manual and to follow them. You can avoid most

accidents.

• A person who has not read and understood all operat-

ing and safety instructions does not qualify to operate

the machine. An untrained operator exposes himself

and bystanders to possible serious injury or death.

• Do not modify the equipment in any way. Unautho-

rized modification may impair the function and/or safety

and could affect the life of the equipment.

• Think SAFETY! Work SAFELY!

WARNING

Lockwood recommends that you always turn off the hy-

draulic and electrical power to the Harvester hydraulic valve

and control box when towing the Harvester on the road.

Page 5472H Potato Harvester Owner Operator’s Manual

WRONG CORRECT

Always face ladder when

climbing up or down

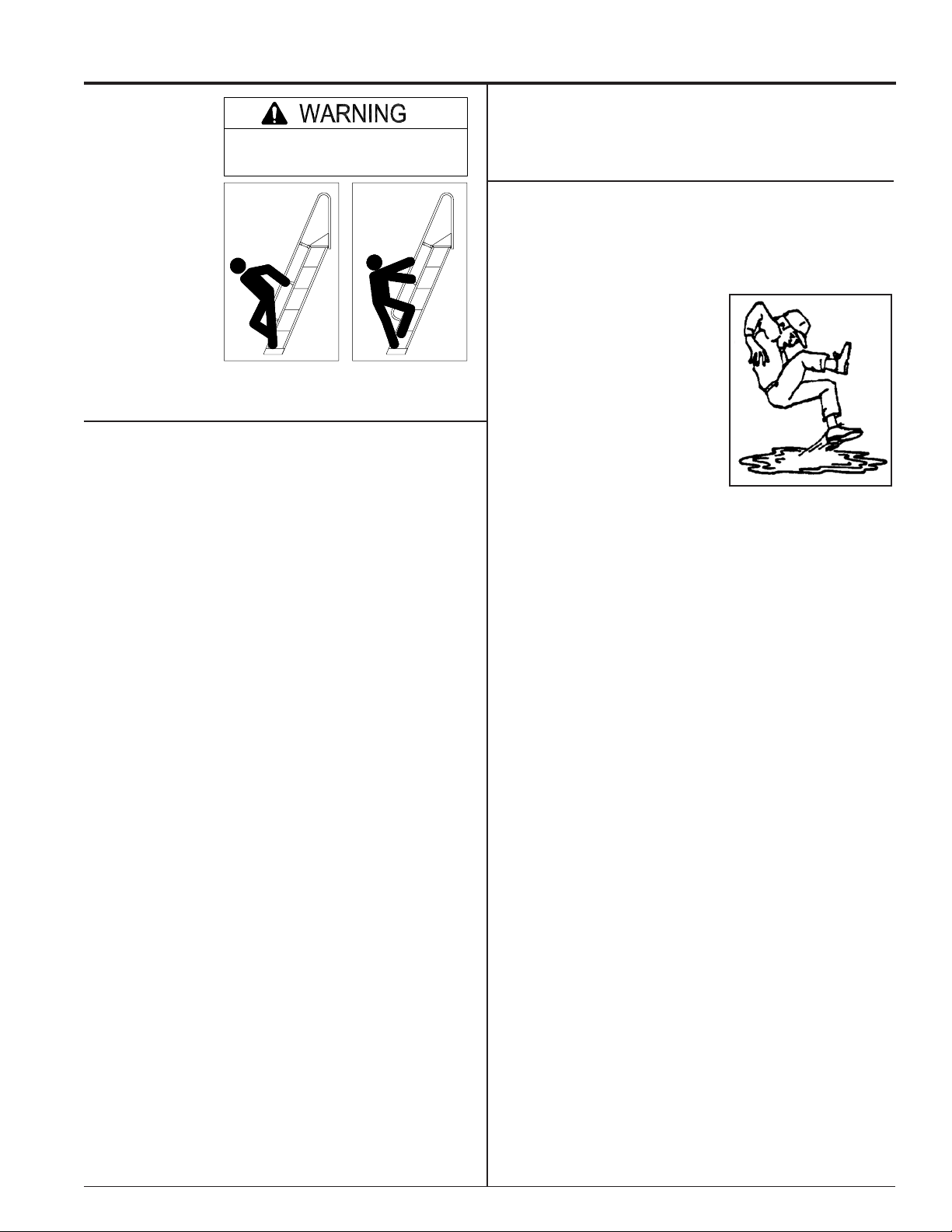

11. When climbing

ladders, face

ladder when

climbing up or

down. Keep

body centered

between side

rails. Maintain

three points of

contact with the

ladder when

climbing or de-

scending.

2.1 GENERAL SAFETY

2.2 OPERATING SAFETY

1. Install and secure all guards and shields before start-

ing or operating.

2. Clear the area of bystanders, especially small children,

before starting the tractor.

3. Place all machine controls in neutral before starting

the tractor.

4. Keep hands, feet, hair and clothing away from all mov-

ing and/or rotating parts.

5. Keep all hydraulic lines, fittings, and couplers tight and

free of leaks before and during use.

6. Clean reflectors and lights before transporting.

7. Review safety related items annually with all personnel

who will operate or maintain the harvester.

8. Be careful when operating on uneven terrain, or near

ditches to avoid the potential of overturning the ma-

chine.

9. Use only recommended tractor sizes with proper weight

and equipment for operating the machine.

10. Never stand between the tractor and the machine when

the tractor backs up for hookup.

11. Use the correct size hitch pin to prevent unhitching.

12. When backing up the machine, all persons must stand

away from the back of the unit due to the operator’s

impaired vision.

13. Be careful during field and transport operation not to

contact trees, power poles, and electrical lines with

the machine’s row marker. Electrocution can occur

without direct contact.

14. Shut the tractor off when connecting or disconnecting

the machine hydraulics.

2.3 MAINTENANCE SAFETY

1. Follow ALL the operating, maintenance, and safety in-

formation in the manual.

2. Support the machine with blocks or safety stands when

changing tires or working beneath it.

3. Follow good shop practices:

•Keep service area clean

and dry.

•Properly ground all

electrical outlets and

tools.

•Use adequate light for

the job at hand.

4. Use only tools, jacks, and

hoists of sufficient capacity for

the job.

5. Place all controls in neutral or off, stop tractor engine,

set parking brake, remove ignition key, wait for all mov-

ing parts to stop; then properly block machine before

servicing, adjusting, repairing, or unplugging.

6. Before resuming work, install and secure all guards af-

ter completing all maintenance work.

7. Relieve pressure from hydraulic circuit before servicing

or disconnecting from tractor.

8. Clear the area of bystanders, especially small children,

when carrying out any maintenance and repairs or mak-

ing any adjustments.

9. Keep safety decals clean. Replace damaged or un-

readable decals.

10. First-class maintenance is a prerequisite for the safest

operation of your machine. Perform maintenance, in-

cluding lubrications, with the machine stopped and prop-

erly blocked.

Page 6 472H Potato Harvester Owner Operator’s Manual

2.4 HYDRAULIC SAFETY

1. Always place all tractor hydraulic controls in neutral

before disconnecting from tractor or working on the

hydraulic system.

2. Keep all components in the hydraulic system in good,

clean condition.

3. Relieve pressure before working on the hydraulic sys-

tem.

4. Replace any worn, cut, abraded, flattened or crimped

hoses.

5. Do not attempt any makeshift repairs to the hydraulic

fittings or hoses by using tape, clamps or cements.

The hydraulic system operates under extremely high-

pressure. Such repairs will fail suddenly and create a

hazardous and unsafe condi-

tion.

6. Wear proper hand and eye pro-

tection when searching for a

high-pressure hydraulic leak.

Use a piece of wood or card-

board as a backstop instead of

hands to isolate and identify a

leak.

7. If injured by a concentrated

high-pressure stream of hydrau-

lic fluid, seek medical attention

immediately. Serious infection

or toxic reaction can develop from hydraulic fluid pierc-

ing the skin surface.

8. Before applying hydraulic pressure to the system,

tighten all components and check for damaged lines,

hoses, and couplings.

• Think SAFETY! Work SAFELY!

2.5 PTO (POWER TAKE-OFF)

SAFETY

1. Keep bystanders, especially children, away from drive

shafts.

2. Be extremely careful when working around PTO

shafts, drivelines, or other rotating shafts.

3. Do not remove or

modify protective

shields or guards.

4. Do not step

across a PTO or driv-

eline or use it as a

step.

5. Keep guards and

shields in place at all

times while operating.

6. Replace all damaged or missing parts or shields with

the correct original manufacturer’s parts.

7. Grease, clean, and maintain PTO components ac-

cording to original manufacturer’s specifications and

information in this manual.

8. Operator must wear fairly tight clothing. Never wear

loose-fitting jackets, shirts, or pants when working

around the drive shafts. Tie long hair back or put un-

der a cap.

9. Keep hydraulic hoses, electric cords, chains, and

other items from contacting the drive shafts.

10. Do not clean, lu-

bricate, or adjust the

drive shafts with the

PTO engaged and the

tractor running.

Page 7472H Potato Harvester Owner Operator’s Manual

2.8 TIRE SAFETY

1. Failure to follow proper procedures when mounting a

tire on a wheel or rim can produce an explosion which

may result in serious injury or death.

2. Do not attempt to mount a tire unless you have the

proper equipment and experience to do the job.

3. Have a qualified tire dealer or repair service perform

required tire maintenance.

1. Comply with all local regulations regarding transport-

ing equipment on public roads and highways.

2. Ensure the SMV (Slow Moving Vehicle) emblem and

all the lights and reflectors required by the local

highway and transport authorities are in place, are

clean and can be seen clearly by all overtaking and

oncoming traffic. Add extra lights or pilot vehicles

when transporting at night or during periods of lim-

ited visibility.

3. Ensure that the machine securely attaches to the

tractor and all retainer pins are installed.

4. Do not allow riders on any part of the machine during

transportation.

5. Towing speed should not exceed 10 MPH due to

farm rated tires and wheels. Reduce speed on rough

roads and surfaces.

6. Always use hazard warning flashers on the tractor

when transporting unless prohibited by law.

7. Be careful when transporting on public highways or

roads.

8. Towing vehicle should weigh at least twice as much

as the towed machine.

9. Exercise extra caution in keeping the towing vehicle

and the machine under control when going down long

and/or steep grades.

10. Be careful during field and transport operation not to

contact trees, power poles, and electrical lines with

the machine’s row marker. Electrocution can occur

without direct contact.

2.6 TRANSPORT SAFETY

2.7 STORAGE SAFETY

1. Store the unit in an area away from human activity.

2. Do not permit children to play on or around the stored

machine.

3. Store the unit in a dry, level area.

2.9 SAFETY DECALS

1. Keep safety decals clean and legible at all times.

2. Replace missing or illegible safety decals.

3. Replaced parts that displayed a safety decal should

also display the current decal.

4. When replacing decals, put the new decal back in

the original location.

5. Safety decals are available from your dealer or the

factory.

How to Install Safety Decals:

1. Clean and dry the installation area.

2. Be sure temperature is above 50°F (10°C).

3. Decide on the exact position before you remove

the backing paper.

4. Remove the smallest portion of the split backing

paper.

5. Align the decal over the specified area and care-

fully press the small portion with the exposed sticky

backing in place.

6. Slowly peel back the remaining paper and care-

fully smooth the remaining portion of the decal in

place.

7. Pierce small air pockets with a pin and use a piece

of decal backing paper to smooth out the decal.

Page 8 472H Potato Harvester Owner Operator’s Manual

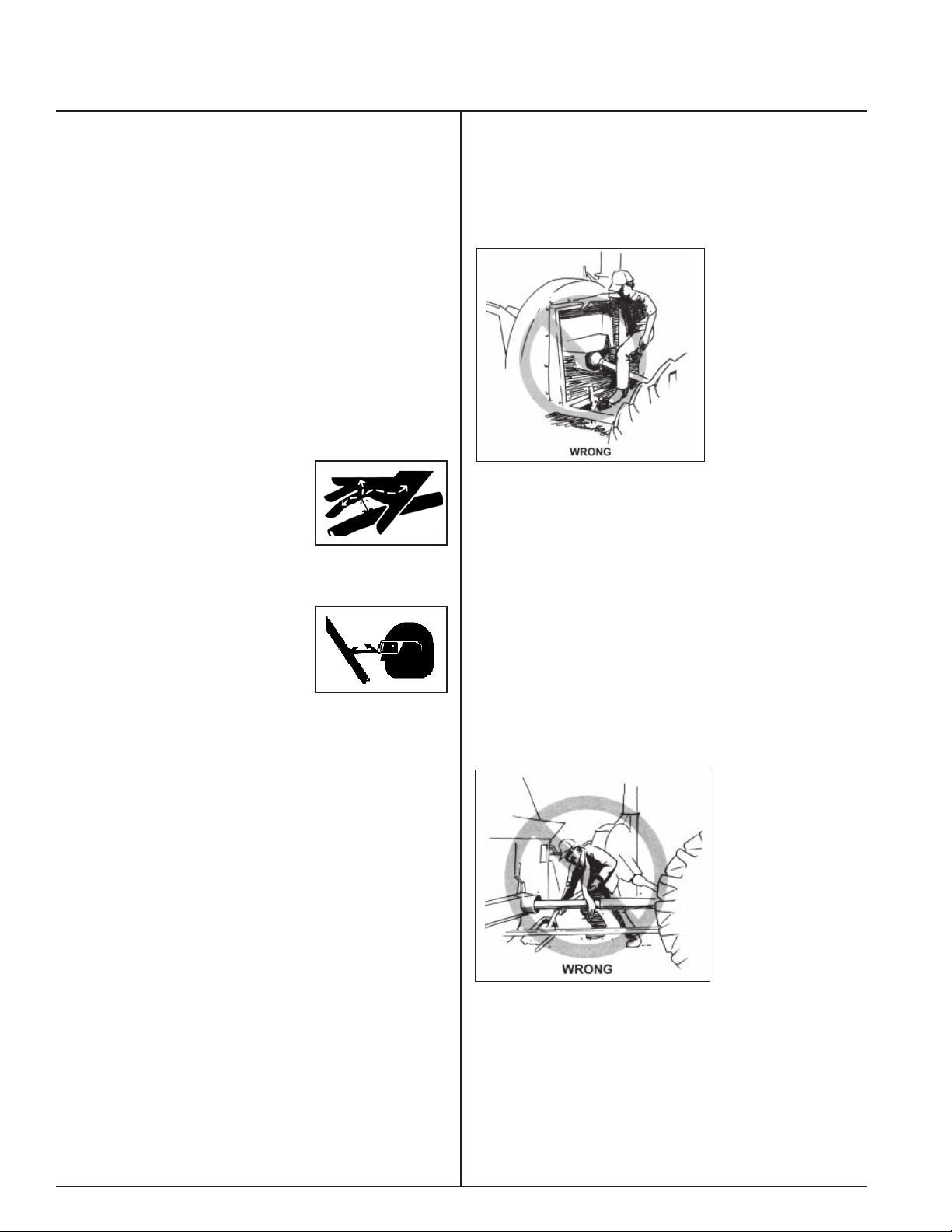

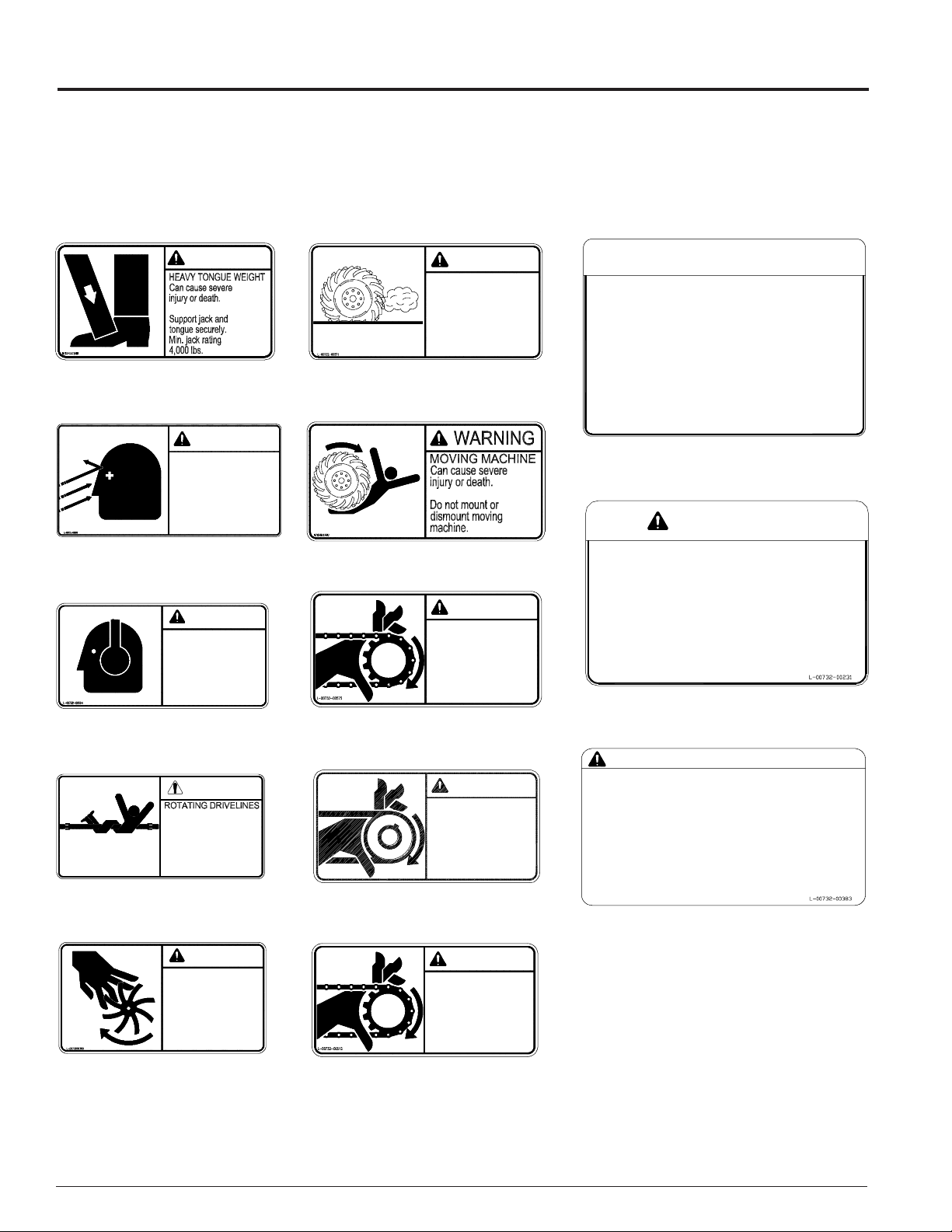

2.9 SAFETY DECALS

The types of safety decals and locations on the equipment are shown in the pictures below. Good safety requires that you

familiarize yourself with the various safety decals, the type of warning and the area, or particular function related to the areas

that require your SAFETY AWARENESS.

• Think SAFETY! Work SAFELY!

REMEMBER - If safety decals have been damaged, removed, become illegible or parts replaced without safety decals,

apply new decals. The manufacturer or an authorized dealer will have new decals available.

Part # 0732-0441-00

8

WARNING

Part # 0732-0371-00

CAUTION

injury or machine

Can cause severe

LOW SPEED TIRE

10 m.p.h.

Do not exceed

damage.

6

L-00732-00585

Securely attach both

ends of driveline.

Keep all driveline

Can cause severe

shields in place.

injury or death.

DANGER

Part # 0732-0585-00

16

L-00732-00598

Can cause severe

place while machine

Keep all shields in

injury.

is running.

WARNING

EXPOSED DRIVE

Figure # 0732-0598-00

24

Use ear protection.

Can damage hearing.

HIGH NOISE LEVEL

CAUTION

Part # 0732-0504-00

21

MOVING BLADES

working in this area.

wait for machinery

Shut off tractor and

Can cause severe

to stop before

injury or death.

WARNING

Part # 0732-0390-00

23

5

Part # 0732-0233-00

CAUTION

MOVING DRIVES

Can cause severe

injury.

Shut off power before

removing shields.

Part # 0732-0575-00

15

place while machine

is running.

Keep all shields in

Can cause severe

EXPOSED DRIVE

injury.

WARNING

Part # 0732-0512-00

12

Keep clear of fan

discharge at all

times.

Can cause severe

FLYING OBJECTS

WARNING

injury.

Part # 0732-0505-00

22

10

Part # 0733-0034-00

NOTICE

SLIP CLUTCHES

Adjustment

0732- 04 70- 00

Attention

A.) Tighten bolts until head contacts spring.

B.) Tighten two full turns beyond initial contact.

C.) Test by running machine under load.

D.) Readjust as necessary to carry load by tightening

in 1/4 turn increments.

E.) Do not over tighten: Overtightening may damage

drive train or conveyors.

After long periods of no use, rust and weather can cause

clutch to stick. Release all spring tension and allow clutch

to slip. Readjust as specified above.

Part # 0732-0383-00

WARNING PRECAUCION ATENTION

ALL DECALS ON THIS MACHINE ARE IN ENGLISH. OBTAIN

ACCURATE TRANSLATION PRIOR TO OPERATING THIS MACHINE.

FAILURE TO COMPLETELY UNDERSTAND AND COMPLY WITH ALL

INSTRUCTIONS MAY RESULT IN SEVERE OR FATAL INJURY.

LAS INSTRUCCIONES QUE APARECEN EN VARIAS PARTES DE ESTA

MAQUINA ESTAN IMPRESAS EN IDIOMA INGLES. OBTENGA UNA

TRADUCCION CORRECTA ANTES DE OPERARLA. ATENTAR SU USO

SIN CONOCER SU FUNCIONAMIENTO O NO SEGUIR FIELMENTE LAS

INSTRUCCIONES PUEDE CAUSAR HERIDAS GRAVES O MORTALES.

CHAQUE INDICE ICI EST EN ANGLAIS. PROCUREZVOUS DES

TRANSDUCTIONS EXACTES AVANT D’OPERER CETTE MACHINE.

UNE MANQUE DE COMPRENDRE COMPLETEMENT ET DE SE

CONFORMER A CHAQUE INSTRUCTION PEUT ABOUTIR A UNE

BLESSURE SERIEUSE OU FETALE.

7

WARNING

Power driven machinery.

Can cause severe injury.

Disconnect power before servicing.

Keep hands, feet, clothing away from

power driven parts.

Do not run machine until all shields are

in place.

Read operator’s manual before servicing.

Part # 0732-0231-00

4

Page 9472H Potato Harvester Owner Operator’s Manual

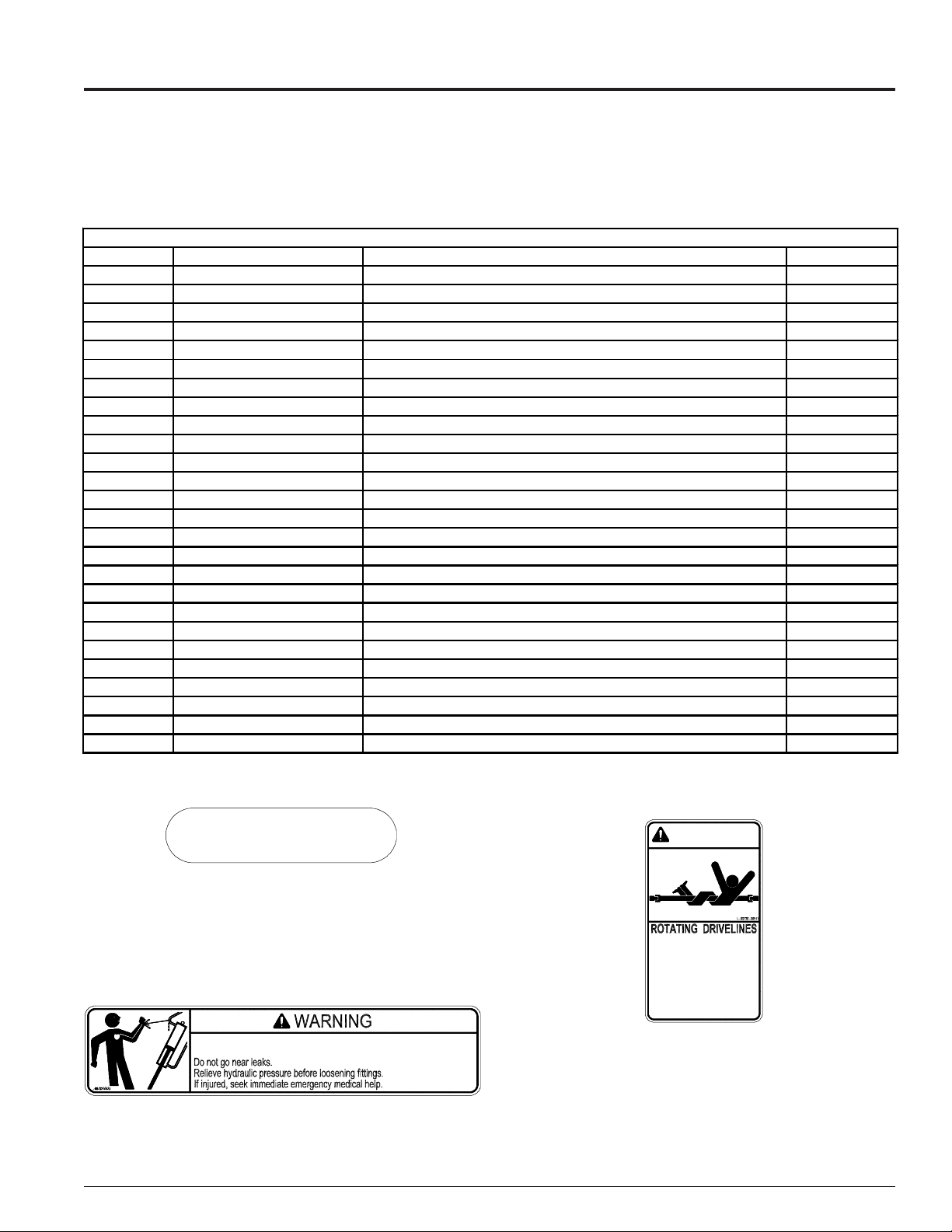

ITEM PART NUMBER DESCRIPTION QTY

10732-0056-00 DECAL, 1-1/4" X 3" CHECK OIL (NOT SHOWN) 2

20732-0092-00 DECAL, AMBER 2" X 9" 3

30732-0093-00 DECAL, RED 2" X 9" 3

40732-0231-00 DECAL, WARNING POWER MACHINERY 2

50732-0233-00 DECAL, MOVING MACHINE 1

60732-0371-00 DECAL, 10 MPH 1

70732-0383-00 DECAL, TRI-LINGUAL WARNING 1

80732-0441-00 DECAL, WARN TONGUE 4000 (HOR) (NOT SHOWN) 1

90732-0462-00 DECAL, DEPTH INDICATOR (NOT SHOWN) 1

10 0732-0470-00 DECAL, SLIP CLUTCH 3

11 0732-0511-00 DECAL, DANGER DRIVELINES (VER) 3

12 0732-0512-00 DECAL, WARNING DRIVES (HOR) 5

13 0732-0517-00 DECAL, WHITE LOCKWOOD & LOGO (NOT SHOWN) 2

14 0732-0543-00 DECAL, "MADE IN USA" (NOT SHOWN) 1

15 0732-0575-00 DECAL, CAUTION DRIVES (HOR) 6

16 0732-0585-00 DECAL, DANGER DRIVELINES (HOR) 2

17 0732-0631-00 DECAL, WARNING HYD LEAKS 7

18 0732-0641-00 DECAL, STRIPES BLACK & WHITE (NOT SHOWN) 36

19 0732-0659-00 DECAL, LOCKWOOD (NOT SHOWN) 3

20 0732-0669-00 DECAL, PATENT FIELD EQUIPMENT 1

21 0732-0504-00 DECAL, EAR PROTECTION (HOR) 2

22 0732-0505-00 DECAL, FLYING OBJECTS (HOR) 2

23 0732-0390-00 DECAL, WARNING, ROTOR BLADES 1

24 0732-0598-00 DECAL, WARNING DRIVES (HOR) 1

25 0732-0591-00 DECAL, WARNING TONGUE (10,000) (VER) 2

26 14432-00 DECAL, ORANGE 2" X 9" 3

472H DECALS

2.9 SAFETY DECALS

The types of safety decals and locations on the equipment are shown in the pictures below. Good safety requires that you

familiarize yourself with the various safety decals, the type of warning and the area, or particular function related to the areas

that require your SAFETY AWARENESS.

• Think SAFETY! Work SAFELY!

REMEMBER - If safety decals have been damaged, removed, become illegible or parts replaced without safety decals,

apply new decals. The manufacturer or an authorized dealer will have new decals available.

Part # 0732-0631-00

17

Can cause serious injury or death.

HIGH PRESSURE OIL

Part # 0732-0092-00 (amber)

Part # 0732-0093-00 (red)

Part # 14432-00 (orange)

2, 3, 26

injury or death.

both ends of

Securely attach

shields in place.

Keep all driveline

Can cause severe

DANGER

driveline.

Part # 0732-0511-00

11

Page 10 472H Potato Harvester Owner Operator’s Manual

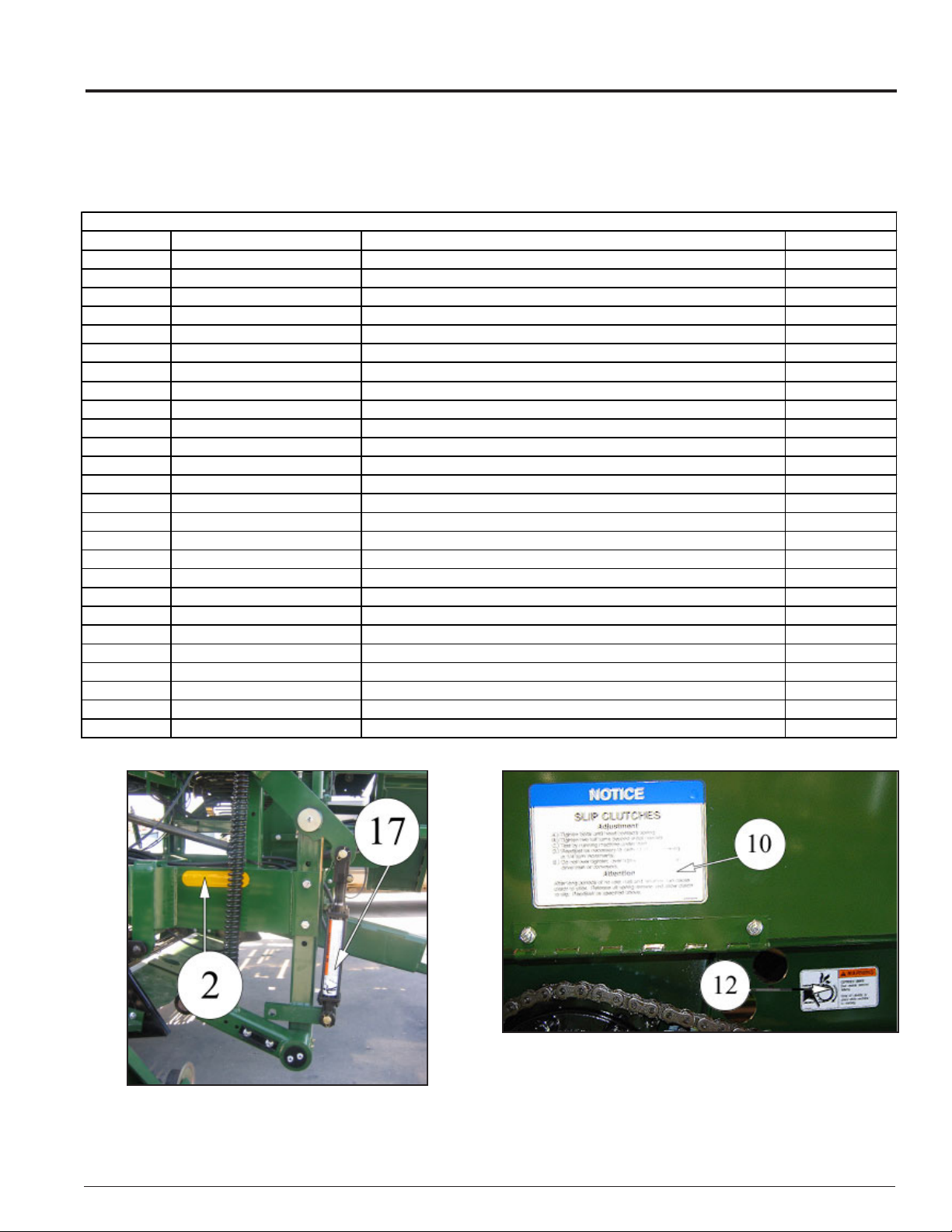

2.10 SAFETY DECAL LOCATIONS

The types of safety decals and locations on the equipment are shown in the pictures below. Good safety requires that you

familiarize yourself with the various safety decals, the type of warning and the area, or particular function related to the areas

that require your SAFETY AWARENESS.

• Think SAFETY! Work SAFELY!

REMEMBER - If safety decals have been damaged, removed, become illegible or parts replaced without safety decals,

apply new decals. The manufacturer or an authorized dealer will have new decals available.

Figure #3 Various Decal Locations

Page 11472H Potato Harvester Owner Operator’s Manual

2.10 SAFETY DECAL LOCATIONS

The types of safety decals and locations on the equipment are shown in the pictures below. Good safety requires that you

familiarize yourself with the various safety decals, the type of warning and the area, or particular function related to the areas

that require your SAFETY AWARENESS.

• Think SAFETY! Work SAFELY!

REMEMBER - If safety decals have been damaged, removed, become illegible or parts replaced without safety decals,

apply new decals. The manufacturer or an authorized dealer will have new decals available.

ITEM PART NUMBER DESCRIPTION QTY

1 0732-0056-00 DECAL, 1-1/4" X 3" CHECK OIL (NOT SHOW N) 2

2 0732-0092-00 DECAL, AMBER 2" X 9" 3

3 0732-0093-00 DECAL, RED 2" X 9" 3

4 0732-0231-00 DECAL, W ARNING POWER MACHINERY 2

5 0732-0233-00 DECAL, MOVING MACHINE 1

6 0732-0371-00 DECAL, 10 MPH 1

7 0732-0383-00 DECAL, TRI-LINGUAL W ARNING 1

8 0732-0441-00 DECAL, W ARN TONGUE 4000 (HOR) (NOT SHOW N) 1

9 0732-0462-00 DECAL, DEPTH INDICATOR (NOT SHOW N) 1

10 0732-0470-00 DECAL, SLIP CLUTCH 3

11 0732-0511-00 DECAL, DANGER DRIVELINES (VER) 3

12 0732-0512-00 DECAL, WARNING DRIVES (HOR) 5

13 0732-0517-00 DECAL, WHITE LOCKWOOD & LOGO (NOT SHOWN) 2

14 0732-0543-00 DECAL, "MADE IN USA" 1

15 0732-0575-00 DECAL, CAUTION DRIVES (HOR) 6

16 0732-0585-00 DECAL, DANGER DRIVELINES (HOR) 2

17 0732-0631-00 DECAL, W ARNING HYD LEAKS 7

18 0732-0641-00 DECAL, STRIPES BLACK & WHITE (NOT SHOWN) 36

19 0732-0659-00 DECAL, LOCKW OOD (NOT SHOW N) 3

20 0732-0669-00 DECAL, PATENT FIELD EQUIPMENT 1

21 0732-0504-00 DECAL, EAR PROTECTION (HOR) 2

22 0732-0505-00 DECAL, FLYING OBJECTS (HOR) 2

23 0732-0390-00 DECAL, W ARNING, ROTOR BLADES 1

24 0732-0598-00 DECAL, WARNING DRIVES (HOR) 1

25 0732-0591-00 DECAL, W ARNING TONGUE (10,000) (VER) 2

26 14432-00 DECAL, ORANGE 2" X 9" 3

472H DECALS

Figure #4 Decal Locations

Figure #5 Decal Locations

Page 12 472H Potato Harvester Owner Operator’s Manual

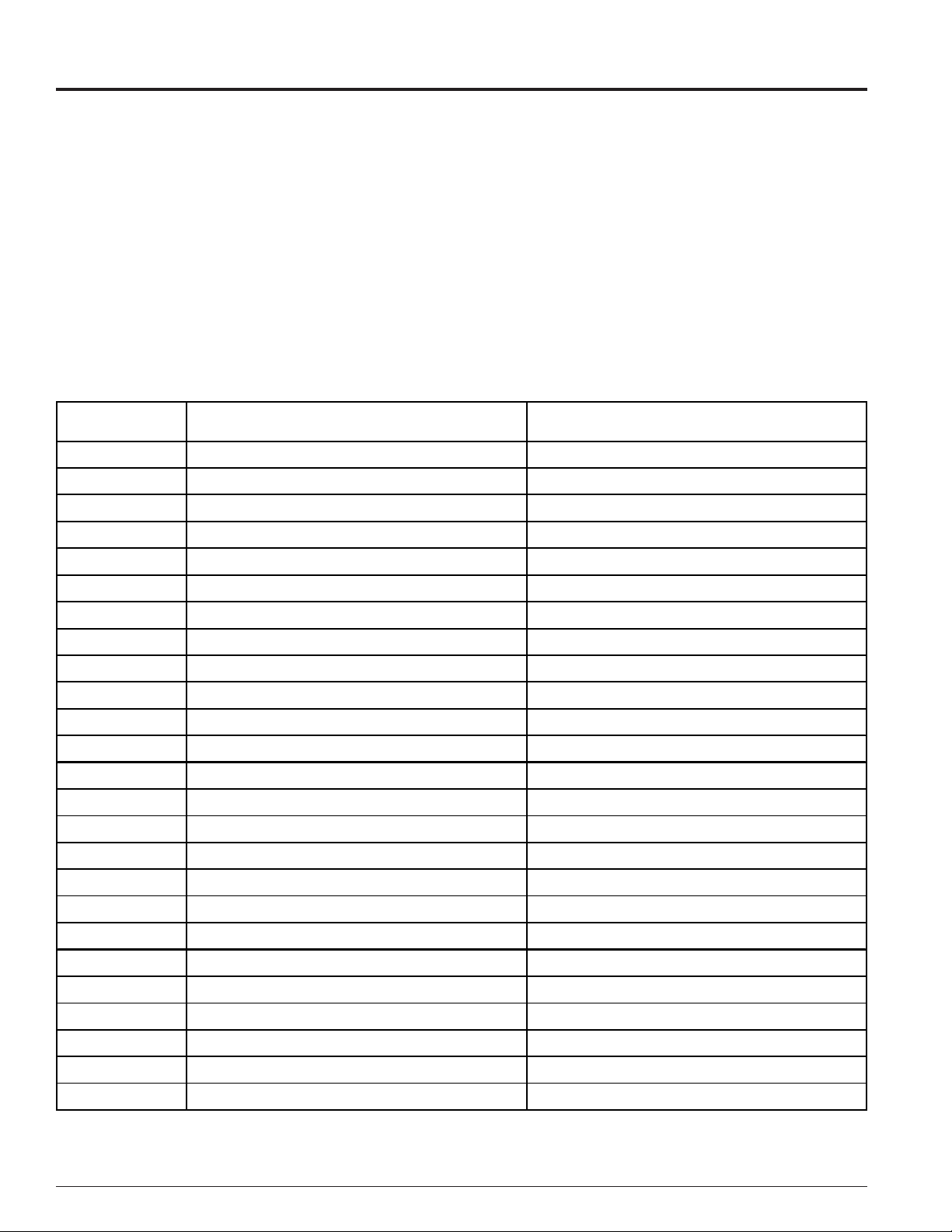

2.11 SIGN-OFF FORM

Lockwood follows the general Safety Standards specified by the American Society of Agricultural Engineers (ASAE) and the

Occupational Safety and Health Administration (OSHA). Anyone who will operate and/or maintain the equipment must read

and clearly understand ALL Safety, Operating and Maintenance information presented in this manual.

Do not operate or allow anyone else to operate this equipment until after reviewing the provided information. Annually review

this information before the season start-up.

Make these periodic reviews of SAFETY and OPERATION a standard practice for all of your equipment. An untrained

operator does not qualify to operate this machine.

A sign-off sheet is provided for your record keeping to show that all personnel who will work with the equipment have read

and understood the information in the Operator’s Manual and have been instructed in the operation of the equipment.

SIGN-OFF FORM

DATE EMPLOYEES SIGNATURE EMPLOYERS SIGNATURE

Table of contents

Popular Farm Equipment manuals by other brands

ABI Attachments

ABI Attachments TR3-E Series Setup guide

Quivogne

Quivogne TINEMASTER Operating, Maintenance and Spare Parts Manual

Lumag

Lumag MD300 Operator's manual

New Holland

New Holland L215 Service manual

Walinga

Walinga Ultra-Vac 6614D Operator's manual

AgXcel

AgXcel Synergist GX40 System Reference manual