6

Quick Start Setup Instrucons for Trimble’s FM

750, FM1000, FMX Rate Controller

PO Box 1611

Kearney, NE 68848

877.218.1981

www.agxcel.com

PLEASE NOTE: Your setup may vary. Not all screens are shown. See Trimble’s Opera-

tor’s Manual for safety informaon and addional setup/operang informaon. Please

ensure you have the latest rmware installed!

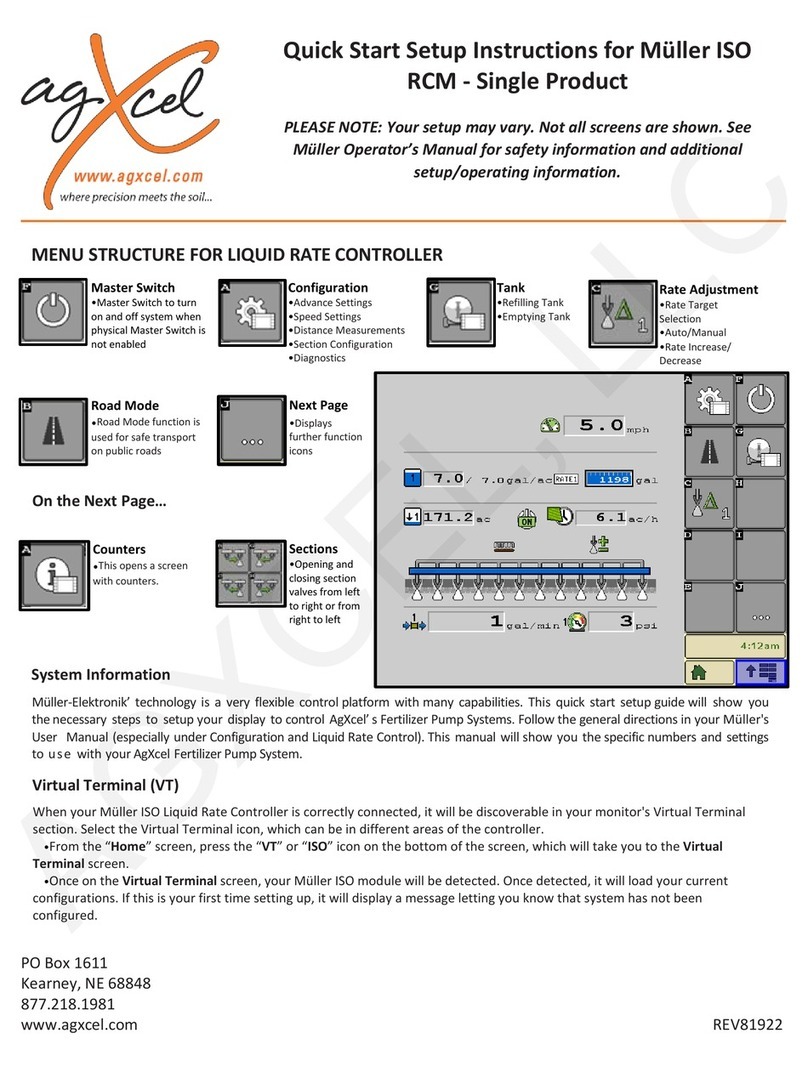

MENU STRUCTURE FOR LIQUID RATE CONTROLLER

System Informaon

From the home screen, you can select 3 tabs; Support, Sys-

tem Informaon and Camera. The System Informaon tab is

shown above. This will show what Trimble components are

properly connected to your display. If your ferlizer system

quits funconing, rst check that the Control Module is sll

recognized on the display. If not, inspect the Trimble wiring

harness connecons or consult your Trimble dealer.

CFX-750 and FM750 Users

Informaon in this manual is applicable to the 750 except for

screen shots shown in the Setup & Operaon. The calibraon

and setup values in this secon DO apply to the 750. How-

ever, the 750 has a completely dierent screen layout and

menu structure that is not shown in this manual. Use your

Trimble manual to navigate, then enter the appropriate num-

bers from the AgXcel manual.

Conguraon – Setup & Calibrate

In the Setup & Calibrate menus, you will set the Trimble Field-IQ to work

properly with the AgXcel Ferlizer System. Carefully follow these steps to

rst make sure you have the proper sengs. Then, run the tests shown to

verify your ferlizer system is ready to go to the eld.

• From the home screen, choose Setup & Diagnoscs.

• The Conguraon screen below will appear. Choose Field-IQ. The Setup & Cali-

brate buons will be locked, shown by a padlock next to them.

• Push Setup, then enter “2009”

• Aer entering the code, the locks will disappear. Push Setup to proceed to the

next steps.

Home

• Support

• System Informaon

• Camera

Conguraon

• Setup

• Calibrate

• Diagnoscs

Cong Selecon

• Display

• Vehicle

• Implement

AGXCEL INTEGRATION INTO THE TRIMBLE

(Read Instructions Completely before Beginning Installation)

PLEASE NOTE: Your setup may vary. Not all screens are shown.

See Trimble’s Operator’s Manual for safety informaon and ad-

dional setup/operang informaon. Please ensure you have the

latest rmware installed!