Terumo BCT T-SEAL MOBILE User manual

LCT-7010en 12/2015

2

INTRODUCTION

Every effort has been made to ensure that the information in this document is correct, but

we make no guarantee to this effect and would appreciate any observations regarding the

contents of this document. We may make improvements and alterations to the instrument

and these changes will be incorporated in new issues of this publication when practicable.

Print: Uffe Tryckare, Upplands Väsby, 2015

3

INTRODUCTION

CONTENTS

1INTRODUCTION ........................................................................................... 4

2SYMBOLS/MARKINGS DESCRIPTION ......................................................... 5

3WARNINGS AND CAUTIONS ........................................................................ 6

4SPECIFICATIONS, PARTS AND ACCESSORIES ............................................7

4.1 Specifications.............................................................................................................................. 7

4.2 Parts .............................................................................................................................................8

4.3 Accessories ................................................................................................................................9

4.4 User Interchangeable Parts .....................................................................................................9

5INSTALLATION............................................................................................ 10

5.1 Unpacking and Inspection ..................................................................................................... 10

5.2 Environmental Requirements................................................................................................ 10

5.3 Installation Procedure ..............................................................................................................11

6FUNCTIONAL DESCRIPTION....................................................................... 12

6.1 Description of Sealing ............................................................................................................. 13

6.2 Description of Equipment....................................................................................................... 13

6.3 Checking the Battery unit....................................................................................................... 14

7OPERATING INSTRUCTIONS....................................................................... 15

7.1 Preparation before Use .......................................................................................................... 15

7.2 How to Seal Tubes .................................................................................................................. 15

7.3 If the Sealer Doesn´t Start....................................................................................................... 16

7.4 LED indications......................................................................................................................... 16

8TROUBLESHOOTING .................................................................................. 17

8.1 Battery Unit ............................................................................................................................... 17

8.2 Hand Unit................................................................................................................................... 18

9CLEANING .................................................................................................. 19

9.1 Battery unit................................................................................................................................ 19

9.2 Hand Unit.................................................................................................................................. 20

10 WARRANTY AND SERVICE ......................................................................... 21

10.1 Warranty .................................................................................................................................... 21

10.2 Service ....................................................................................................................................... 21

10.3 Product Disposal..................................................................................................................... 22

11 EMC TABLES ............................................................................................. 23

12 DECLARATION OF CONFORMITY .............................................................. 27

4

INTRODUCTION

1INTRODUCTION

This chapter contains a description and specifications of the T-SEAL MOBILE, a Portable

Battery sealer from Terumo BCT.

T-SEAL MOBILE is a fully automatic system for sealing PVC or EVA tubes, especially for tubes

in blood pack systems. Following the sealing procedure the tube is easily pulled apart, due to

the distinct sealing pattern, with no damage to the blood inside the tubes. Segments are

formed by inserting the tubing into the slot at the front of the Hand unit to create a series of

seals.

T-SEAL MOBILE is comprised of a Hand unit and Battery unit which is connected to the Hand

unit with the integrated cable. It is complete with inbuilt sealing head and ready to operate.

The moving electrode front can be easily removed for cleaning. Different types or sizes of

tubes can be used and the necessary sealing time is self-adjustable to suit the tubes that are

being used.

T-SEAL MOBILE works with radio frequency (RF) energy to generate heat for sealing. Users

are requested to be cautious of potential electrical shocks or hazards while handling this

sealer.

5

SYMBOLS/MARKINGS DESCRIPTION

2SYMBOLS/MARKINGS DESCRIPTION

On instrument and labels:

This marking reflects compliance with the Council Directive 93/42/EEC on

Medical Devices.

This marking reflects compliance with EN 60601-1 and national standards for

USA (ANSI/AAMI ES60601-1:2005) and Canada (CSA C22.2 No. 60601-1)

Markets

Class II Battery charger: double insulation during charging.

Battery charger UL recognized component for Canada and U.S.A.

Symbol for “CATALOGUE NUMBER”.

Symbol for “WARNING”.

Follow instructions.

Symbol for “SERIAL NUMBER”.

Symbol for “DATE OF MANUFACTURE”.

Symbol for “Manufacturer”.

Storage conditions - Symbol for “TEMPERATURE”.

Storage conditions - Symbol for “RELATIVE HUMIDITY”.

Symbol for “Non-ionizing radiation”.

Symbol (WEEE 2002/96/EC) - Do not dispose Product as municipal waste.

Collect Product separately. Use collection and return systems available to you.

Product brought to EU market after August 13th, 2005.

Indicates information about the battery

6

WARNINGS AND CAUTIONS

3WARNINGS AND CAUTIONS

The general safety information in the manual is for operating personnel. Specific notes,

cautions and warnings are found throughout the manual where applicable. Please read the

Instructions For Use (IFU) carefully before use.

NOTE Identifies conditions that should be noted carefully.

CAUTION Identifies conditions that could result in damage to the equipment.

WARNING Identifies conditions that could result in personal injury or loss of life.

WARNINGS T-SEAL MOBILE must be used in compliance with all specifications

and operational procedures listed in this manual.

Only trained personnel should use the T-SEAL MOBILE

Cables and accessories, others than those specified, may result in

increased emission or decreased immunity of the equipment or

system. Only accessories designed for use with T-SEAL MOBILE

should be used.

The equipment or system should not be used adjacent to or stacked

with other equipment. If adjacent or stacked use is necessary, the

equipment or system should be observed to verify normal operation

in the configuration in which it will be used.

If any of the components of T-SEAL MOBILE are exposed to blood,

they must be cleaned with an appropriate disinfectant solution.

The T-SEAL MOBILE generates RF energy during the sealing

procedure and during movement of the electrode.

T-SEAL MOBILE is not intended for use in an oxygen rich

environment.

T-SEAL MOBILE is not intended to be used with flammable

anesthetics and not intended for use in conjunction with flammable

agents.

CAUTION ELECTROMAGNETIC INTERFERENCE REGULATIONS

This equipment fulfils EN 60601-1-2:2007 Standards Electromagnetic

Compatibility. Nevertheless this equipment uses radio-frequency (RF)

energy to generate heat while the tube is being sealed and can affect

other Medical Electrical Equipment.

See table 1 for guidance.

If

installation and use is not performed in accordance with the IFU, it

could cause interference with radio, television and instrument

communications.

7

SPECIFICATIONS, PARTS AND ACCESSORIES

4SPECIFICATIONS, PARTS AND ACCESSORIES

4.1 Specifications

The table below lists the physical specifications.

Terumo BCT code............... T5460

T-SEAL MOBILE, a complete sealing system, which includes

Battery unit, Hand unit, Charger and IFU.

Type of PVC (EVA) tube ..... Different types and sizes of tubes up to 6.2 mm (5.4 mm)

outer diameter can be sealed due to a sophisticated sensing

system, which automatically adapts sealing time.

Sealing capacity ................... Approximately 1500 seals/charge with PVC tubes up to 5 mm

outer diameter at 20 °C (68 °F)

Continuous seal capacity ... 50

Mode of operation............... Operation: 25%, Intermittent: 75%

Sealing time .......................... 0.4 up to 3 sec. depending on tubing

Intended Use ........................ The T-SEAL MOBILE is an automatic system for sealing PVC

and EVA tubes connected to blood bags included either in

Blood Packs or in Apheresis Disposable Sets. The sealing can

be performed when the donor is still connected to the Blood

Pack or the Apheresis Disposable Set.

Input Power .......................... Charger 110-240 V~ / 50/60 Hz

Battery 29.6 VDC, 1.5 Ah, Li-Ion Mangan

Consumption........................ Charger: 30 W, Sealer: 150 W max

Fuses ..................................... Charger: T2 A 250 V (internal)

Battery: 2 A (input) / 10 A (output) (internal)

RF Output.............................. 80 W max. / 50 Ω/ 40.680 MHz

Size (W x H x D) Battery unit 165 x 106 x 32 mm (6.5 x 4.2 x 1.2 in)

Weight kg (Ib) ....................... Battery unit: 0.68 kg (1.50 lb)

Hand unit: 0.39 kg (0.86 lb)

Temperature......................... Operating: 15 to 35 °C (60 - 95 °F)

Storage: - 20 up to + 70 °C (- 4 up to 158 °F)

Humidity................................. Operating: 10 up to 90% Rh (non condensing)

Storage: 10 up to 90% Rh (non condensing)

Altitude................................... Operating: maximum 3000 meters (9842 feet)

In compliance with............... EN 60601-1: 2006

General Reqirements for basic safety and essential

performance

EN 60601-1-2: 2007

Collateral standards for Electromagnetic Compatibility

8

SPECIFICATIONS, PARTS AND ACCESSORIES

Electrical safety .................... During charging Class II.

During use: Internal power supply.

The T-SEAL MOBILE is used in the same environment as

medical equipment (hospitals and blood banks).

It must be used by highly qualified personnel.

Manufacturer according to

MDD .......................................

Conroy Medical AB:

Valhallavaegen 1

S-194 63 Upplands Vaesby

SWEDEN

Distributor.............................. Terumo BCT Europe NV

Ikaroslaan 41

1930 Zaventem

Belgium

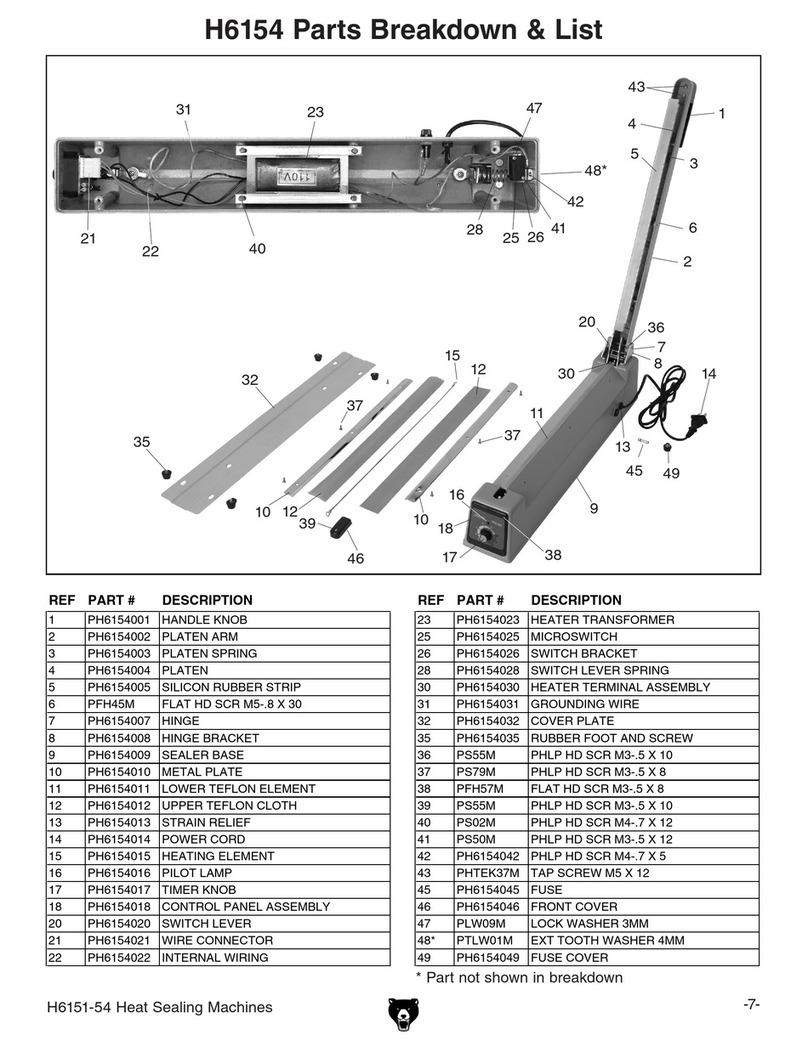

4.2 Parts

T-SEAL MOBILE comprises the parts listed below:

Description Hand unit Battery unit Battery charger

without plug

Kit Primary

Adaptors

Part No. 546900000 547900000 544900000 54410120

List of all cables and maximum lengths of cables, transducers and other electrical

accessories with which the manufacturer claims compliance (cables, accessories used

other than those listed may impact emission/immunity):

Part Reference Specification

Battery charger

without plug

8METSM003 Input: 100-240 V~/50-60 Hz/700 mA

Output: 18VDC/1.66A

Kit Primary Adaptors 8METSM037 Euro mains connector

UK mains connector

Australia mains connector

USA/Japan mains connector

IEC 320 mains connector

9

SPECIFICATIONS, PARTS AND ACCESSORIES

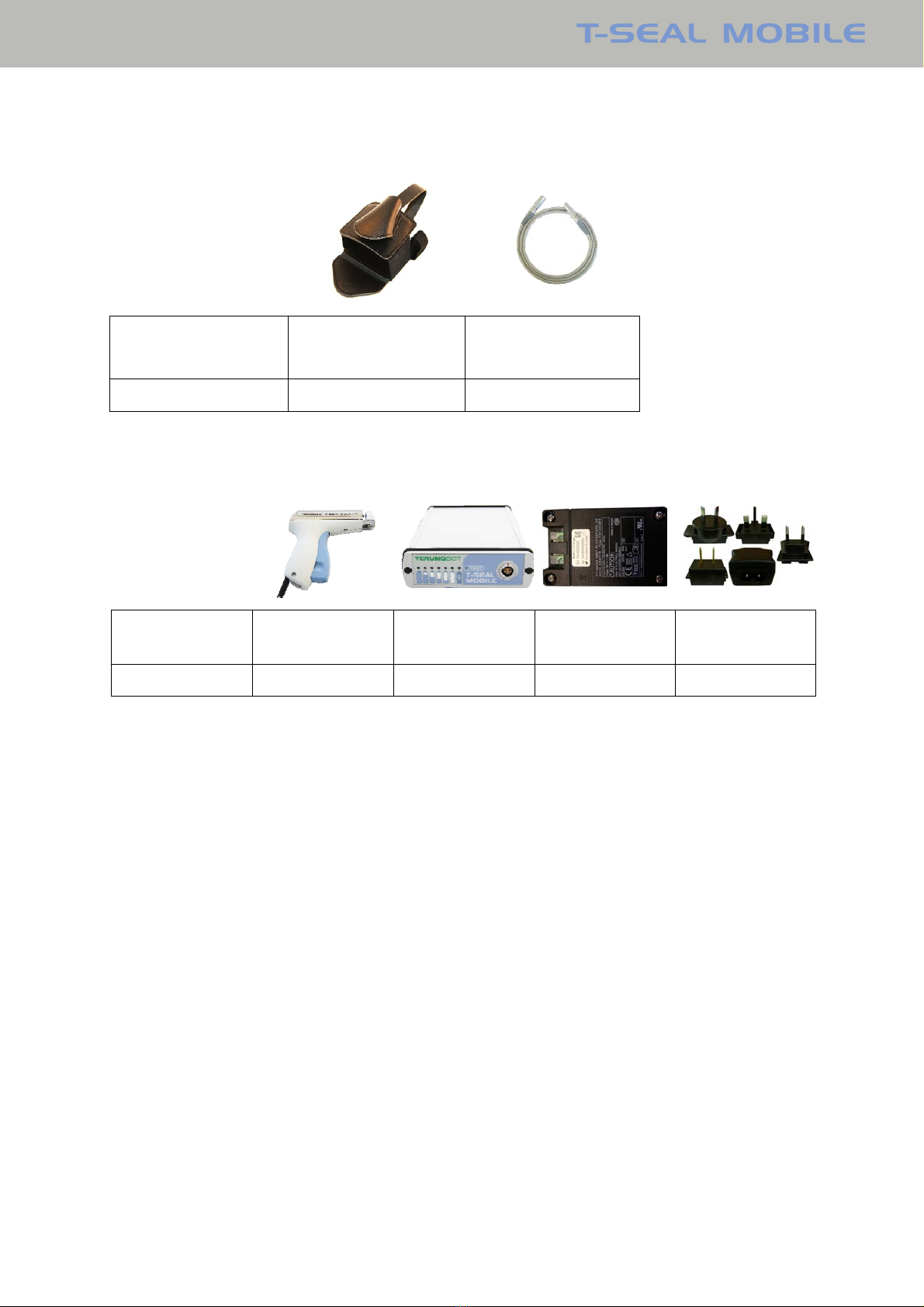

4.3 Accessories

Description Holster Extension cord

1.2 m 5-pol

REF 8METSM004 8METSM005

4.4 User Interchangeable Parts

Description Hand unit Battery unit Battery charger

without plug

Kit Primary

Adaptors

REF 8METSM001 8METSM002 8METSM003 8METSM037

10

INSTALLATION

5INSTALLATION

This chapter involves unpacking, temperature requirements and installation of the

instrument.

5.1 Unpacking and Inspection

1. Visually inspect the cardboard box for damage. Report any damage immediately.

2. Lift the instrument out of the cardboard box and place it on a flat surface.

The instrument is shipped in one cardboard box that includes:

I. 1 Hand unit

II. 1 Battery unit

III. 1 Battery charger without plug

IV. 1 IFU (English)

V. 1 Kit Primary Adaptors

3. The above list is subject to change, refer to the packing list for accurate description of

contents. If any parts are missing or if the parts are damaged, report it immediately.

4. Please keep all shipping and packaging materials, as they may be required for later

transportation, at least during the warranty time.

5.2 Environmental Requirements

To keep the instrument operating at its best, please observe the following:

•The instrument should be placed on a flat surface free from dust, solvents and acidic

vapor.

•Use the instrument in an area free from vibration and with a room temperature of 15 -

35°C (60 - 95°F), and relative humidity 10% - 90%.

•Handle the components with care in a clean environment.

11

INSTALLATION

5.3 Installation Procedure

Preparing the sealer for use

1. Fit correct mains input plug to the Battery charger.

2. The changeable mains connector is available for European continent (standard), UK,

USA/Canada and Australia/New Zealand and as IEC standard 320 C8.

3. Connect the charger (grey on connector) to the combined Hand unit/Battery charger

cable connector.

4. Plug the charger into the mains. The charger can be connected to mains voltages

between 100 and 240 V AC.

5. It takes about three hours to charge the Battery unit completely. When the charging

level indication on the unit indicates 100% and the recharge indication flashes, the

battery is fully charged.

6. Charge the battery to 100% before the first use.

7. Connect the Hand unit cable (grey at end of the cable) into the Battery unit connector.

Make sure the connector snaps in secured position.

8. Perform a test seal on an empty or water filled tube to ensure proper operation.

CAUTION Only use the enclosed Battery charger for charging the Battery unit.

NOTE Ensure that cable to handle is connected before use.

12

FUNCTIONAL DESCRIPTION

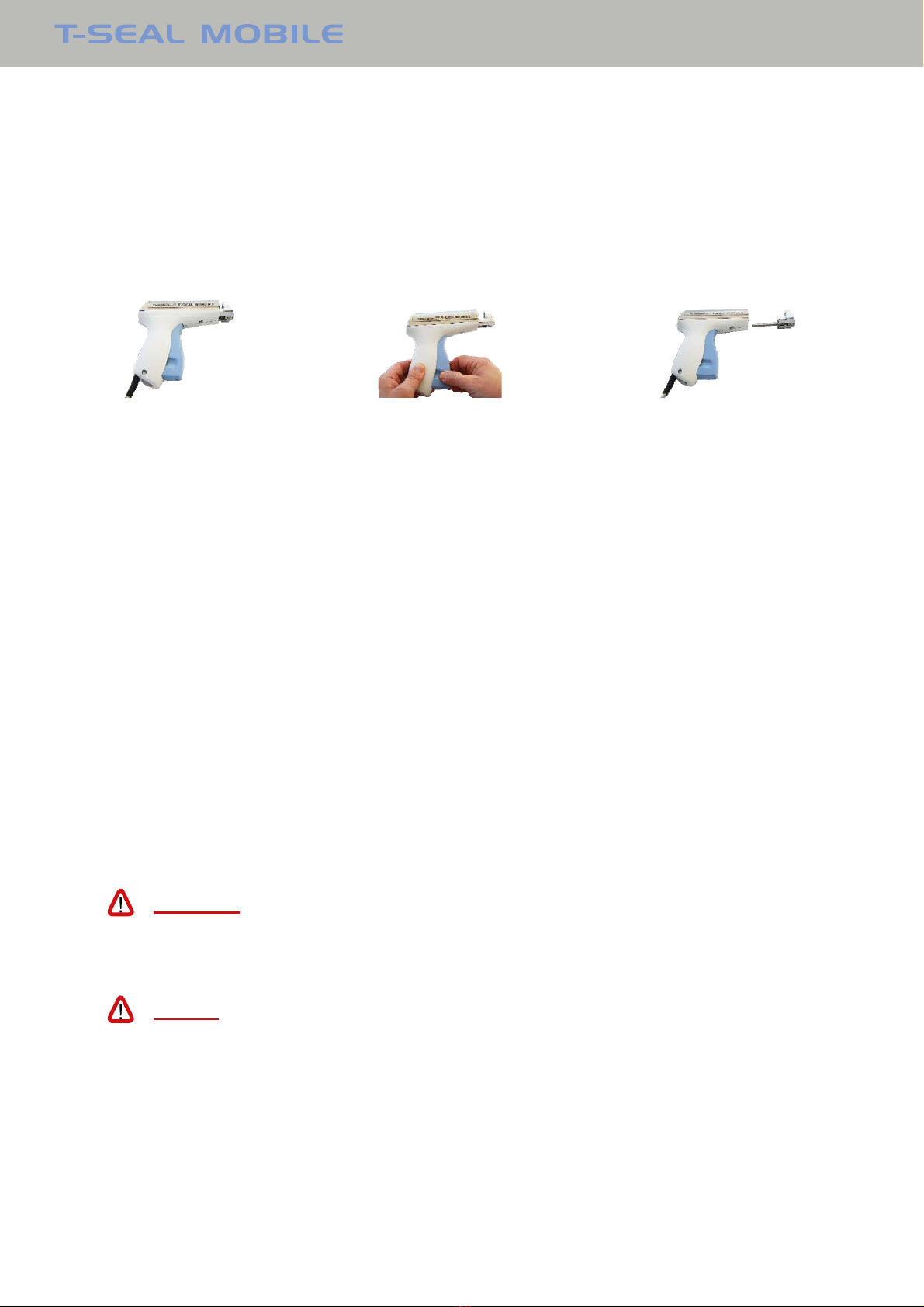

6FUNCTIONAL DESCRIPTION

This chapter describes how T-SEAL MOBILE works, where the connectors and the

indications are placed on the unit and their functions.

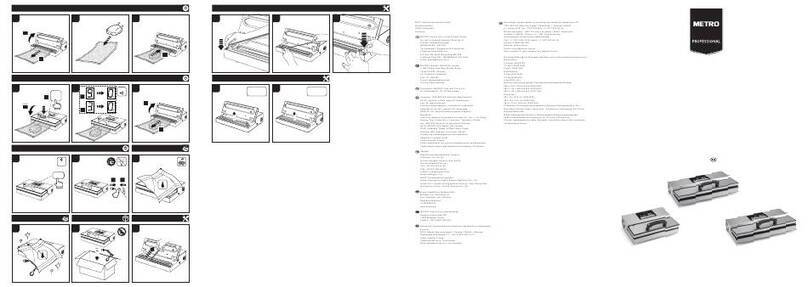

Front view of Battery unit

Charge level

indicator

Recharge

indicator

Battery test

button

Hand unit/Battery

charger cable

connector

Rear view of Battery unit

View of Hand unit

Seal indicator

Tube slot

Spring lock

Trigger

Electrode remove grip

13

FUNCTIONAL DESCRIPTION

View of Charger

6.1 Description of Sealing

The tube to be sealed is placed in the slot of the Hand unit, between the electrodes. When

the user presses the trigger on the Hand unit, the tube is pressed together and the sealing

procedure will commence automatically. The radio frequency (RF) generator starts and the

energy is transferred from the fixed electrode to the tube, which melts to a sterilized welding

pattern.

During the whole sealing process the orange Seal light on the front of the Hand unit is lit.

When this light goes out, the sealing is complete and the trigger may be released. The

intelligent sense control in the Hand unit detects, controls, and adjusts the necessary sealing

activity to give the best sealing quality for the type of tubes that are being used.

See section 7.4 for a description of the different LED indications on the Hand unit in case of

problems.

6.2 Description of Equipment

T-SEAL MOBILE consists of a Battery unit and a Hand unit. Below is a short description of

each component.

The Hand unit consists of an RF-generator with intelligent sense control, ergonomic handgrip

with trigger, the moving electrode (which can be removed for cleaning) and the cable with

connector. The Hand unit takes no power between sealing.

The Battery unit consists of the environmental friendly LiIonMn battery pack, built-in optic

charge level indicator and the combined charger/handle connector. The charge in the

Battery unit is sufficient for approximately 1500 seals.

Power indicator

14

FUNCTIONAL DESCRIPTION

6.3 Checking the Battery unit

To check the battery, just press the “TEST” button ❸and the battery charge level indicator

❶lights up. The capacity indication is in steps of twenty percent. The battery can be

recharged at any time or at least when zero (red) remains. The zero level is also indicated on

the handle with the red light and when seal is attempted, the seal function will be blocked.

Recharging the battery:

Connect the Battery charger to the Battery unit ❹and the charger to the mains. The

recharge indicator ❷lights up.

When the recharge indicator starts flashing, the battery is fully charged and the charge

current is automatically turned off. The charge can be interrupted at any time without

damage to the cells, but a full recharge will take less than three hours and is recommended.

❶❷❸❹

CAUTIONS Always check the seals when the battery capacity is low (20% or

less). See section 7.2 for sealing pattern.

Only use the enclosed Battery charger for charging battery in the

Battery unit.

NOTES To guarantee a long lifetime for the rechargeable battery, please

observe the following requirements: Charge the battery at

temperature between 5 and 35°C (40-95°F).

If the indicator ❷does not light up, check the connection to the

charger and mains.

15

OPERATING INSTRUCTIONS

7OPERATING INSTRUCTIONS

This chapter describes the use of the instrument.

WARNINGS T-SEAL MOBILE uses radio frequency (RF) energy to generate heat

for sealing. Users should be cautious of potential electrical shocks or

hazards while handling this sealer. Always keep your fingers away

from the electrodes in the slot. Never place any object other than the

tube between the electrodes.

This machine emits a low level of electromagnetic (non-ionizing)

radiation while sealing. It should not be used near high frequency

sensitive electronic equipment.

See table 1 for guidance.

Do not allow the Hand unit to come directly in contact with the donor.

Do not perform a seal within 8 cm (3 in) of needle to preclude an RF

burn at the needle entry point.

CAUTIONS Inspect all parts of the instrument for defects before use. Check

sealing pattern if Hand unit is dropped.

Always check the seals when the battery capacity is low (20% or

less).

7.1 Preparation before Use

1. Place the instrument on a flat surface near the working place or in the holster.

2. Check that there is sufficient battery capacity by pushing the “TEST” button.

3. Connect the Hand unit cable into the combined Hand unit/Battery charger cable

connector.

NOTE Do not try to connect other sealers to the T-SEAL MOBILE Battery

unit than the Terumo BCT T-SEAL MOBILE Hand unit.

7.2 How to Seal Tubes

1Put the tube to be sealed down to the bottom of the slot in the Hand unit.

2Check that the tube is placed between the electrodes in the slot.

3Press the trigger to bring the two electrodes closer together until the light on top of the

Hand unit comes on. The sealing time is normally 0.4 to 0.9 seconds; after a

maximum of 3 seconds the RF is turned off.

4When the light goes out, sealing is finished. Release the trigger and remove the tubing.

5The center of the sealed pattern is very thin and pulling both sides will divide the tube

into two pieces.

6Check the tube for leakage.

CAUTION If you should make two or more seals, they should not be within 1 cm

(0.4 in) of each other, otherwise the resulting pressure in the tube

may cause microscopic cracks and holes in the seals.

16

OPERATING INSTRUCTIONS

CAUTIONS In case of sealer malfunction (intermittent operation, poor seal quality,

the sealing time seems too long or too short) contact your local

Terumo BCT representative for assistance.

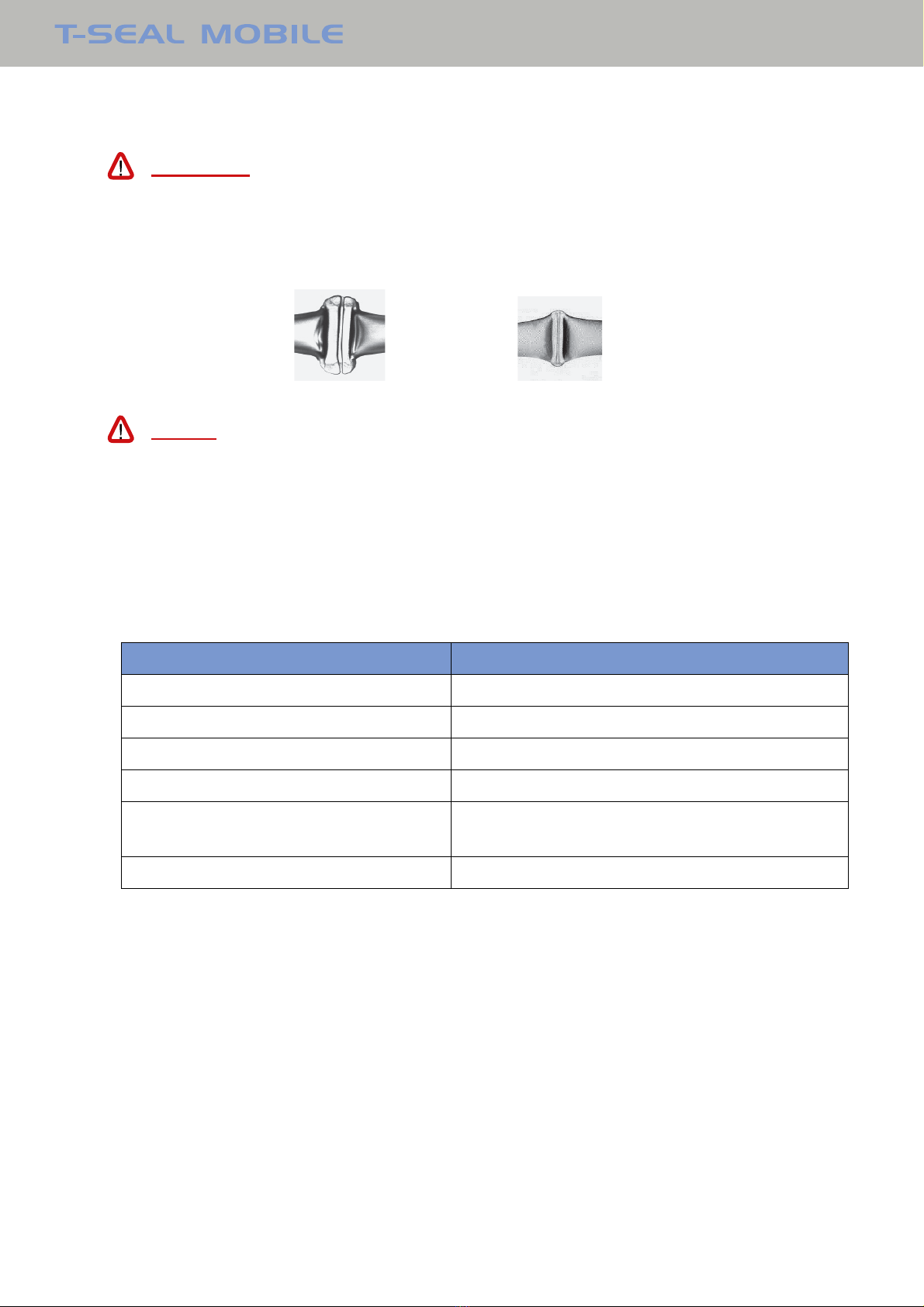

Periodically check whether the shape of the seal is symmetrical and

there is a clear line in the middle of the seal (see picture below).

Good sealing pattern Bad sealing pattern

NOTES The tube must be dry on the outside.

Do not pull the tube and keep the trigger fully pressed down until the

light goes out. If the trigger is released the sealing process stops.

7.3 If the Sealer Doesn´t Start

The Sealer has several safety functions. Before sealing, these functions control and identify

whether it is possible to seal the tube. The table below covers the common probable causes

for problems and suggests some recommended actions.

Probable cause Recommended action

Leaky or wet tube Dry the tube and try again

Tiny arcs between the electrodes Dry the electrodes and try again

Wet or dirty electrodes Clean and dry the electrodes

Low/no capacity in battery Check/charge battery

Overheated (Hand unit LED red blinking)

Let the Hand unit cool down.

No seals Check Battery unit and connection.

If the sealer still doesn’t start, see chapter 8 for further information

7.4 LED indications

Battery unit

•“Colored LEDs bar indicating battery status.”

•“TEST”: button to check the battery. When pressed, the battery charge level indicator

lights up. Refer to section 6.3.

Hand unit

•Indicator lights orange when RF-energy is being applied to the fixed electrode and

turns off when sealing is completed.

•Indicator flashes red at overheating, sealing function is blocked.

•Indicator lights red one second in case of short circuit, sealing function is blocked.

•Indicator lights red in case of battery low level, sealing function is blocked.

17

TROUBLESHOOTING

8TROUBLESHOOTING

Maintenance performed by the user is limited to changing Battery unit and Hand unit. The

following information covers common problems and offers suggested solutions.

8.1 Battery Unit

Problem Probable cause Recommended action

Charge level LEDs doesn’t

light.

Battery too low voltage. Charge battery for 3 hours.

Fuse blown. Contact your local Terumo BCT representative.

Other cause. Contact your local Terumo BCT representative.

Charge Level LEDs do not

light up during charge

No voltage Charge battery for 48 hours

Fuse blown. Contact your local Terumo BCT representative.

Other cause. Contact your local Terumo BCT representative.

Charge Level LEDs do not

light up after 48 hours

charge

Battery unit defective. Change battery unit or contact your local

Terumo BCT representative.

18

TROUBLESHOOTING

8.2 Hand Unit

Problem Probable cause Recommended action

The sealing doesn’t start. Wet electrodes. Dry the electrodes, see chapter 9.2.

Dirty electrodes. Clean the electrodes, see chapter 9.2.

Wet tube. Dry the tube and electrodes, try again.

Tiny arcs between the

electrodes.

Dry the electrodes and try again.

The trigger does not “click"

when it is fully squeezed.

Change Hand unit or contact your local Terumo

BCT representative.

The trigger cannot fully

engage when it is

squeezed

Hand unit defective.

Battery not charged/low

charge.

Charge battery for 3 hours.

Cable broken. Contact your local Terumo BCT representative.

Other cause.

Bad sealing. Low battery charge. Check the Battery unit charge level.

Charge battery if needed.

Moving electrode doesn’t

move smoothly in handle.

Clean and oil electrode shaft,

see chapter 9.2.

Wet electrodes. Dry the electrodes and try again.

Dirty electrodes. Clean the electrodes, see chapter 9.2.

Moving electrode out of

position.

See chapter 9.2, assembly of electrode.

Hand unit defective. Change Hand unit or

contact your local Terumo BCT representative.

Other cause. Contact your local Terumo BCT representative

Hard to divide tube after

seal.

Moving electrode doesn’t

move smoothly in handle.

Clean and oil electrode shaft, see chapter 9.2.

Wet electrodes. Dry the electrodes and try again.

Dirty electrodes. Clean the electrodes, see chapter 9.2.

Rim on moving electrode

damaged. Contact your local Terumo BCT representative.

Other cause.

Intermittent sealing. Hand unit defective. Change Hand unit or contact your local Terumo

BCT representative.

Cable broken. Contact your local Terumo BCT representative.

Battery unit defective

Hand unit LED still alight

after seal trigger has been

released.

Hand unit defective Change Hand unit or contact your local Terumo

BCT representative.

Hand unit LED doesn’t

light.

Hand unit defective Contact your local Terumo BCT representative.

Hand unit LED flickers. Cable broken Contact your local Terumo BCT representative.

Other cause

Electrode cannot be

inserted after cleaning

Trigger has been pressed

during cleaning which

means that internal spring

can come out of position.

The spring can be reset to its correct position by

pulling out the trigger to the outer locked

position. Thereafter carefully insert a pin (Ø3-

4mm, 100mm long) in the front hole where the

electrode is inserted and slightly push it

downwards. Be careful; do not scratch the

surface with the pin.

19

CLEANING

9CLEANING

This chapter gives information on the cleaning (procedure, frequency) of the Battery and

Hand units. The Sealer requires minimal maintenance for efficient operation. Follow the

cleaning procedure below.

WARNINGS For you own safety always disconnect the Hand unit or charger from

the Battery unit.

Blood and blood products must be treated as potentially infectious at

all times. In the event of blood spillages, appropriate protective

clothing should be worn during cleanup procedures.

After removing residual biological material, surfaces which have been in contact with blood or

components must be disinfected using a chemical agent considered to be “sterilizing”

(isopropyl Alcohol 70%,....). Alternatively, a freshly prepared sodium hypochlorite (household

bleach) solution may be used to disinfect surfaces. Diluted solutions of 1 part bleach to 10

parts water may be used.

Regardless of the “sterilant” or disinfection solution used, remember to remove any residue

to ensure that surfaces of the equipment are not subject to corrosion or discoloration.

Discard all materials in contact with blood according to institutional policies regarding disposal

of biohazardous materials.

CAUTIONS Do not disinfect or sterilize any part of the Sealer through autoclave,

or with ethylene oxide gas. To do so will render the Sealer unusable

and invalidate the warranty.

Do not use chemical or abrasive cleaners such as acetone, ammonia

or similar. Do not use sharp edged tools for cleaning, which could

damage the finish of the units.

Do not allow liquid to flow in the electronic part of the machine.

9.1 Battery unit

Cleaning may be required as a result of spilled drops of blood or once per month.

If spillage occurs, the unit must immediately be removed from service and cleaned

completely before resuming use.

Use a soft lint-free tissue, moistened with a mild detergent to clean the outside of the Battery

unit.

CAUTION Do not, under any circumstances, submerge the Battery unit in any

kind of liquid. This will damage the battery and void the warranty.

20

CLEANING

9.2 Hand Unit

Clean once per week or more frequently, as required, if spillage of blood occurs.

For cleaning the electrodes remove the moving electrode.

Removal of moving electrode:

1. Pull the blue trigger to “click” to release the moving electrode. Push spring lock

forward.

2. First push inward, then pull out the electrode.

Clean the handle and both electrodes with a soft lint free cloth moistened with mild

detergent. Dry carefully and ensure that the electrodes are completely dry to prevent sparks.

To clean the electrode shaft, use a dry cotton swab.

After cleaning, inspect the electrodes for any mechanical damage or wear out. Do not use

damaged part.

For proper function, add a drip of light machine oil on electrode shaft after each cleaning!

Assemble the parts in reverse order.

Make sure the trigger and spring lock is in full forward position before electrode insertion.

Insert the moving electrode ensuring that it is positioned so as to be parallel with the fixed

electrode. Press the trigger twice and ensure that the moving electrode moves smoothly, is

in position and not loose.

CAUTION The hand unit is not waterproof. Do not, under any circumstances,

submerge the hand unit in any kind of liquid. Doing so will generate

tiny electric discharges, cause the device to malfunction, and void the

warranty.

NOTES Some sealing tests are recommended before resuming use.

Compare the pattern against picture in section 7.2.

Do not push the trigger in after removing the electrode since this may

block the locking mechanism.

If electrode cannot be inserted after cleaning, the trigger is probably

pressed during cleaning. To insert the front electrode again, see

chapter 8.2.

This manual suits for next models

1

Table of contents