7

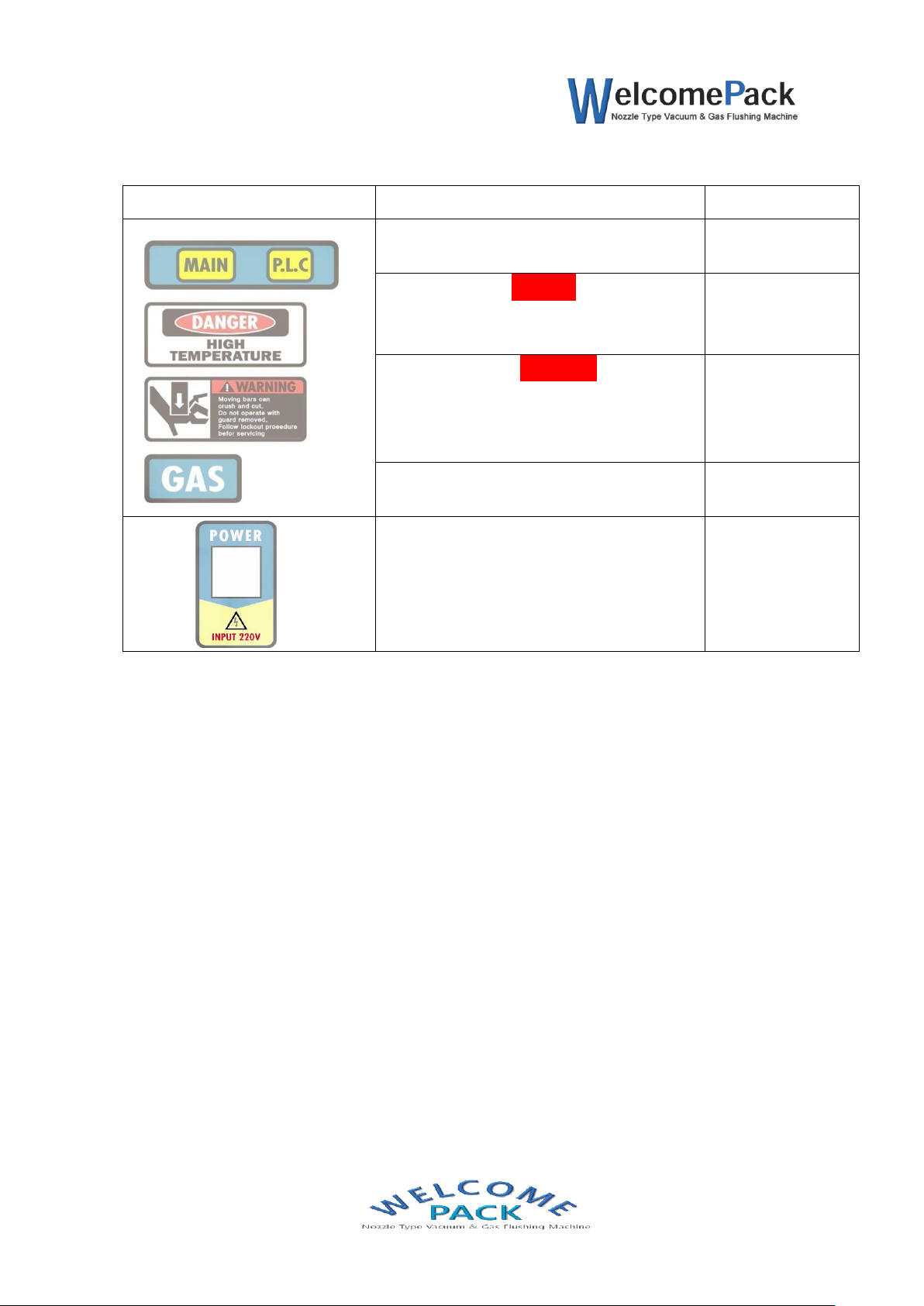

3. CAUTION FOR USE

3-1 Caution for safety

1) In case of emergency, please pull off the electric cord. The machine has the

noise filter and the fuse to cut off any irregular electric shock. Nevertheless, if

there is any emergency such as breaking out of a fire on the Teflon tape, please

cut off electric inflow from the machine.

2) The electricity specified in the manual must be used and use of multi tap is

not recommended. Especially, Home-use multi tap could be cause of overheat,

short machine life, quality degradation and a fire. If the user has no choice but to

use multi tap, please consult with electric expert.

3) In case of exchanging any part of the machine, the electric cord must be

pulled off. And, to prevent any malfunction or accident, it is prohibited for the

user to use any machine parts different from the specification stipulated by the

manufacturer.

4) It is prohibited for the user to re-build the machine and its parts without

permission from the manufacturer

5) It is prohibited for anything except for vacuum bag to be inserted between

sealing bars.

* There is electric flow between sealing bars so that inserting metal material

could lead to electric shock.

(This machine uses earth wire to reduce the risk of safety accident.)

* Especially, Long time use of machine could accumulate heat on heat wire so

that if the finger is caught between the sealing bars it could result in burn as

well as hurting.

6) If the N.F.B turns off automatically, the cause must be checked and solved

before turning the N.F.B on again.(Refer to 17-3)

7) The user must avoid installing the machine in the place full of dust, high

temperature or high humidity. The temperature of work place suitable for this

machine is 0°C ~ 40°C; 30°and the machine must avoid any direct or continuous

air from air conditioner located within 10 m from the machine.

8) For any wrong work, press the STOP button or EMERGENCY button. Then, all

work is stopped and the nozzle moves back and the upper sealing bar go up.

9) Please check up whether there is any damage on the Teflon sheet, Teflon

tape and sealing rubber, compression sponge, the between sealing bars and

heat wire holder before use of the machine. Any damage on these parts could

result in short circuit around heat wire. Or, it could lead to wire’s exposure to air

during sealing resulting in overheat.