Chisel Scaler SC 29 PG

Operation & Maintenance Guide

(For 12.7mm A/F Square body and releasing slot at back type Chisel)

FF - MM - 108 REV - 1

Sheet 3 of 5

MAINTENANCE:

To dis-assemble chisel scaler remove chisel (10) from the tool as described as above. Remove steel ball (09)

through hole of ring (07). Pull out ring (07) with little force. Remove both ‘O’ rings (05), loosen socket head bolt

(18) on chisel housing (08). Unscrew chisel housing (08). Hold the cover assembly (01) of the tool in soft jaw

vice and with the help of spanner unscrew cylinder (02) from the cover assembly (01) slide out the piston (03)

from cylinder (02). Remove ‘O’ rings (04 & 19) from the cylinder (02). If necessary dis-assemble the throttle

components by opening valve cap (12) with the help of screw driver. Carefully pull out valve stem (11) along

with valve spring (13), ‘O’ ring (17). Remove ‘O’ ring (14) from valve cap (12). If necessary, punch out roll pin

(16) and take out throttle lever (15) from valve body (20). If rubber handle grip (21) is to be removed, hold

A/F sides of valve body (20) in soft jaw vice. Rotate cover assembly (01) and take out. Pull out rubber handle

grip (21).

Clean all metal parts in a light solvant and inspect carefully for signs of wear. Replace components that

appear worn or damaged. Coat all components with recommended oil and re-assemble in reverse sequence.

SAFETY INSTRUCTIONS:

Always wear suitable protection such as ‘eye gogles’, ear muffs, safety shoes etc. To safeguard against possibility

of flying particles etc.

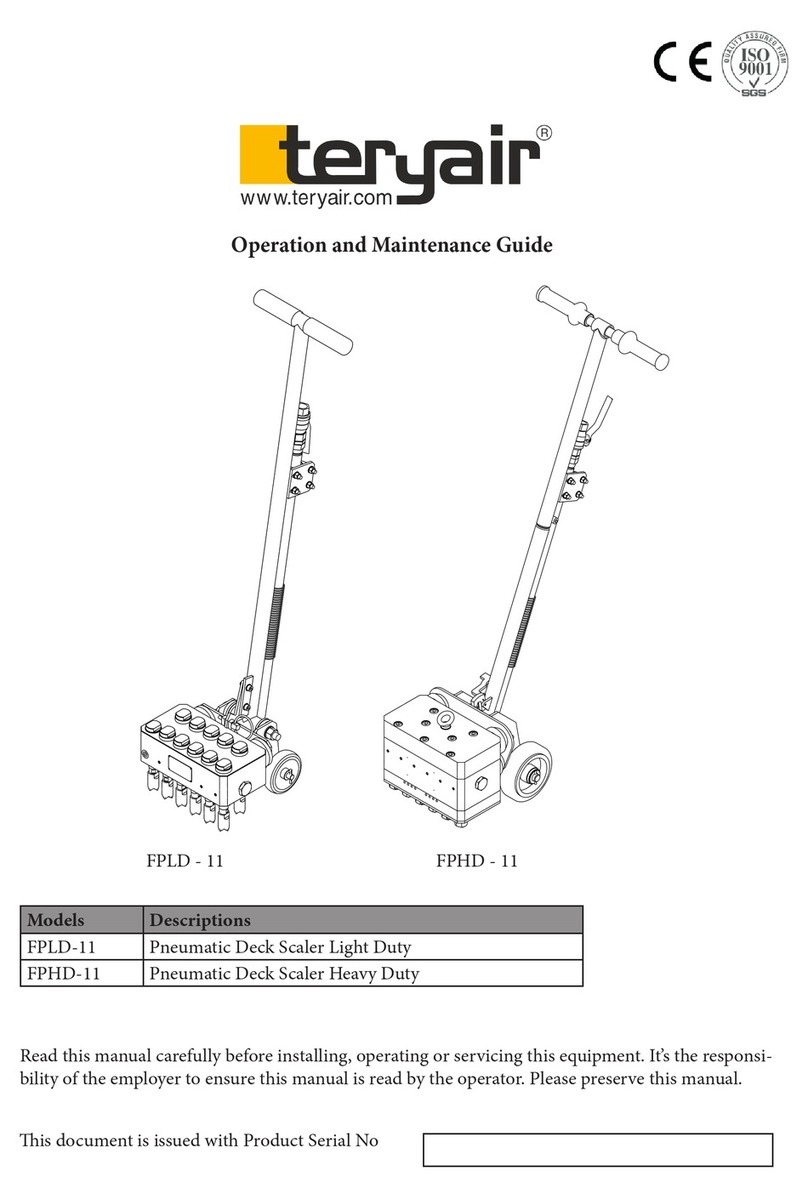

INTENDED USE

Chisel Scalers are intended to use for removing layers of paint, corrosion, chemical coating etc from metal &

nonmetal surfaces & for general purpose chipping & scaling. Many different chisels options are available.

Chisel scalers are intended use for descaling of rust & corrosion from metal surfaces like sea going vessels &

offshore platforms.

Long reach scalers are intended used for cleaning residues, roofing material, paints, floor tiles, plasters, and

chemical spillages.

Long Reach Scalers are specifically designed to reduce the risk of back injury and to extend their use into

previously inaccessible areas. These tools are ideal for a variety of uses from construction and marine to general

factory maintenance and flooring services. It can be use for stippling of plain concrete for keying & decorative finish.

Never operate the tool over the rated 7 bar pressure. Do not exert excessive pressure against the work surface.

Keep hose in good condition. Check hoses for wear and ensure that fittings are secure. Accidental disconnection

while tool is in use can make the hose whip and can be a safety hazard.

Please check the hose connection prior to starting Chisel Scaler.

Be aware that these scaler can create dust & flying debris.

Keep hands & clothing away from moving parts.

Store these scaler in secure & dry environment.

Do not allow the scaler to run unattended.

Do not modify this scaler in any way as this will invalidate the warranty and could lead to serious injury.

Do not hold the exposed Chisel whilst the tool is in use this could cause vibration damage to the hands.

Do not use the scaler in potentially explosive ennments.

Do not drag this scaler by air hose.