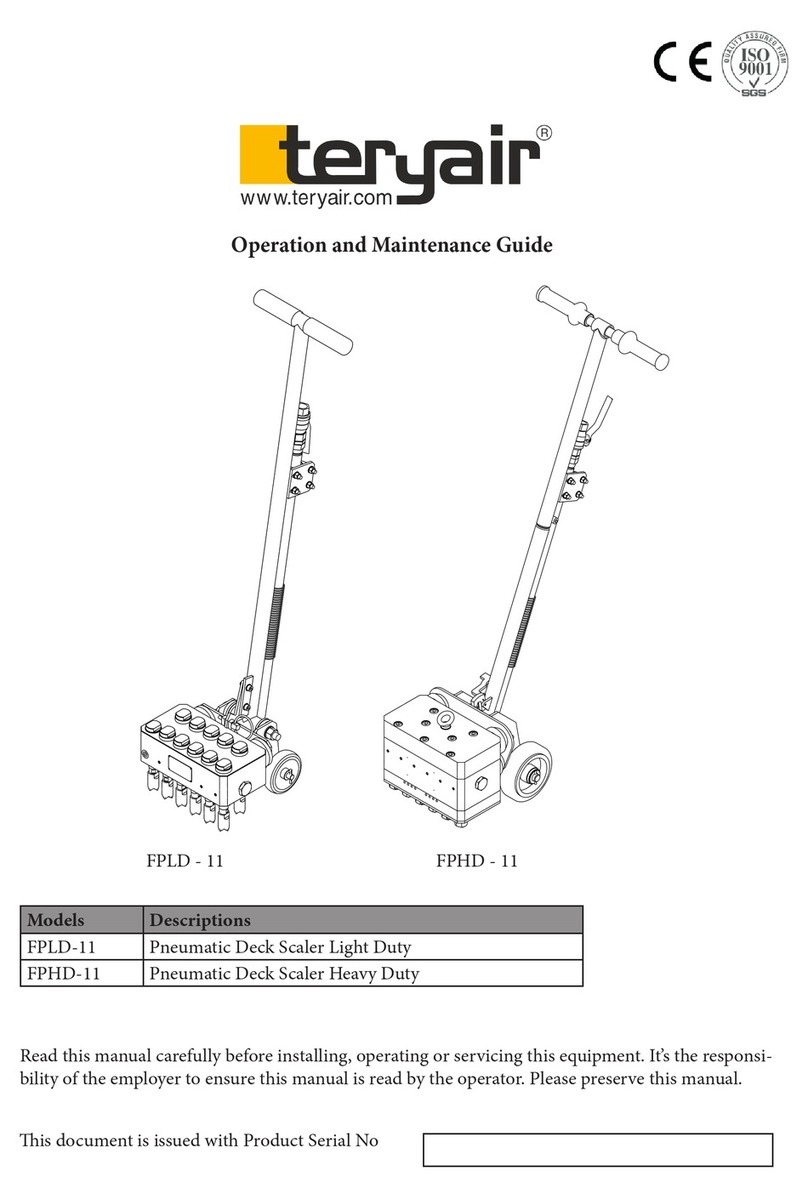

Needle Scaler SN 16 PG

Operation & Maintenance Guide

AIR SUPPLY:

The Scalers work best at 6.2 bar(90psi) air pressure. The air should be clean, dry and lubricated. Install a FRL unit as close as

operation will permit.

CAUTION:

Assemble Nipple and reducer in the Housing (12) (supplied separately)

REPLACING NEEDLES:

Always turn off the air supply and disconnect the air supply hose. Remove the safety band (8) from the groove. Loosen the stop

ring (6) and remove. Take out the needle supporter (2) by pulling out the needles (1) Topple down needle supporter (2) and

extract the needles (1) -29nos. Whenever the needles are damaged during operation, they must be replaced. After replacing

needles, assemble in the reverse manner of disassembly

MAINTENANCE:

To disassemble SN16PG Needle Scaler, disconnect air supply hose. Remove the safety band (8) from the groove. Loosen the

stop ring (6) and remove. Take out the needle supporter (2) by pulling out the needles (1) Topple down needle supporter (2) and

extract the needles (1) -29 nos. Slide out throttle anvil (3) unscrew rear bolt (12), remove rear washer (11). Topple down housing

(9) so that piston (4) will come out. Pull out cylinder (5) from front, remove ‘O’ Ring (10) To dismantle throttle valve assembly-

unscrew valve cap (13), remove valve packing (14). Pull out throttle valve assembly along with ‘O’ Ring(18) and spring (19). If

throttle lever (16) is to be removed,punch out lever pin(17) and remove lever(16).

Examine all components for wear after washing with light diesel oil or suitable solvent. Replace any worn or damaged parts.

Coat parts with recommended light oil and re-assemble carefully in the reverse sequence.

RECOMMENDED LUBRICANTS:

LUBRICATION REQUIREMENTS:

Always install a line lubricator on the air line as close to the tool as possible. A Filter Regulator Lubricator unit (FRL) is strongly

recommended. Keep the lubricator bowl topped up with recommended grade of oil and check that the oil is reaching the tool.

Running the tool without lubrication is likely to cause damage to the components causing premature replacement.

DAILY BEFORE OPERATION:

Disconnect air hose from the tool and pour in 1 to 2 ounce of recommended oil to the air line port of the tool. Then re-connect

and idle run the tool for a few seconds so that the oil should reach every part in the tool

OPERATION:

This tool is for scaling work pieces using needles. The quick reciprocating needles of the needle scaler adjust automatically to the

surface contour during cleaning. Slight depression of the needles against the work surface is sufficient for work performance. An

upright tool position is the best. The tool will clean uneven surfaces efficiently and get into grooves, corners and gaps, clean out

side and inside surfaces and clean spaces in access able or too confined for other types of tools.

ABOVE 270C - 800F 50C-270C 400F-

800F

BELOW 50C 400F

SHELL Toona R. 72 Toona R. 41 Toona R.27

MOBIL Almo 529 Almo 527 Almo 525

ESSO ----- Arox.EP.65 Arox EP.45

CALTEX Rando Oil 100 Rando Oil 100 Rando Oil 46

CP ----- ----- Airolene Tool Oil

TEXACO Regal oil F (R&O) Regal Oil PE (P&E) Regal Oil PE (R&O)

DALTRON Silkolene 881 Silkolene 548/T Silkolene 733

BURMAH CASTROL Castrol RD Oil 3 Castrol Rd Oil Light Megna SPX

DUCKHAM Garnet 7 Garnet 6 Zero Fio 5

STERNOL Merlin 87 Merlin 71 Merlin 54

PETROFINA Purifoc 53 Purifoc 46 Purifoc 32

CHEVRON Vistac Oil 18X Vistac Oil 19X Vistac Oil 9X

IND OIL Servo Spyn – 22 ----- -----