Teryair FPLD-11 Instruction Manual

Models Descriptions

FPLD-11 Pneumatic Deck Scaler Light Duty

FPHD-11 Pneumatic Deck Scaler Heavy Duty

Read this manual carefully before installing, operating or servicing this equipment. It’s the responsi-

bility of the employer to ensure this manual is read by the operator. Please preserve this manual.

is document is issued with Product Serial No

Operation and Maintenance Guide

FPLD - 11 FPHD - 11

FF-MM-403-REV - 00

Page 2

Operation and Maintenance Guide Pneumatic Deck Scalers

Table of Contents

3 Introduction

3 Technical Data

3 Safety Instructions

4 Operating Instructions

5 Suggested Lubricants

6 Diassembly and Re-assembly for FPLD-11

7 Bill of Materials for FPLD-11

8 Exploded View for FPLD-11

11 Diassembly and Re-assembly for FPHD-11

12 Bill of Materials for FPHD-11

13 Exploded View for FPHD-11

16 Repair Kits

17 Test Certicate Of Materials, Performance

18 Eu Declaration Of Conformity

19 Warranty Certicate

FF-MM-403-REV - 00

Page 3

Operation and Maintenance Guide Pneumatic Deck Scalers

Introduction

Teryair Pneumatic Deck Scalers are perfect for preparation of oor surfaces. ese machines are

ideally used for removal of oor coating like paint, chemical & corrosion. Pistons are tungsten

tipped & easily replaceable.

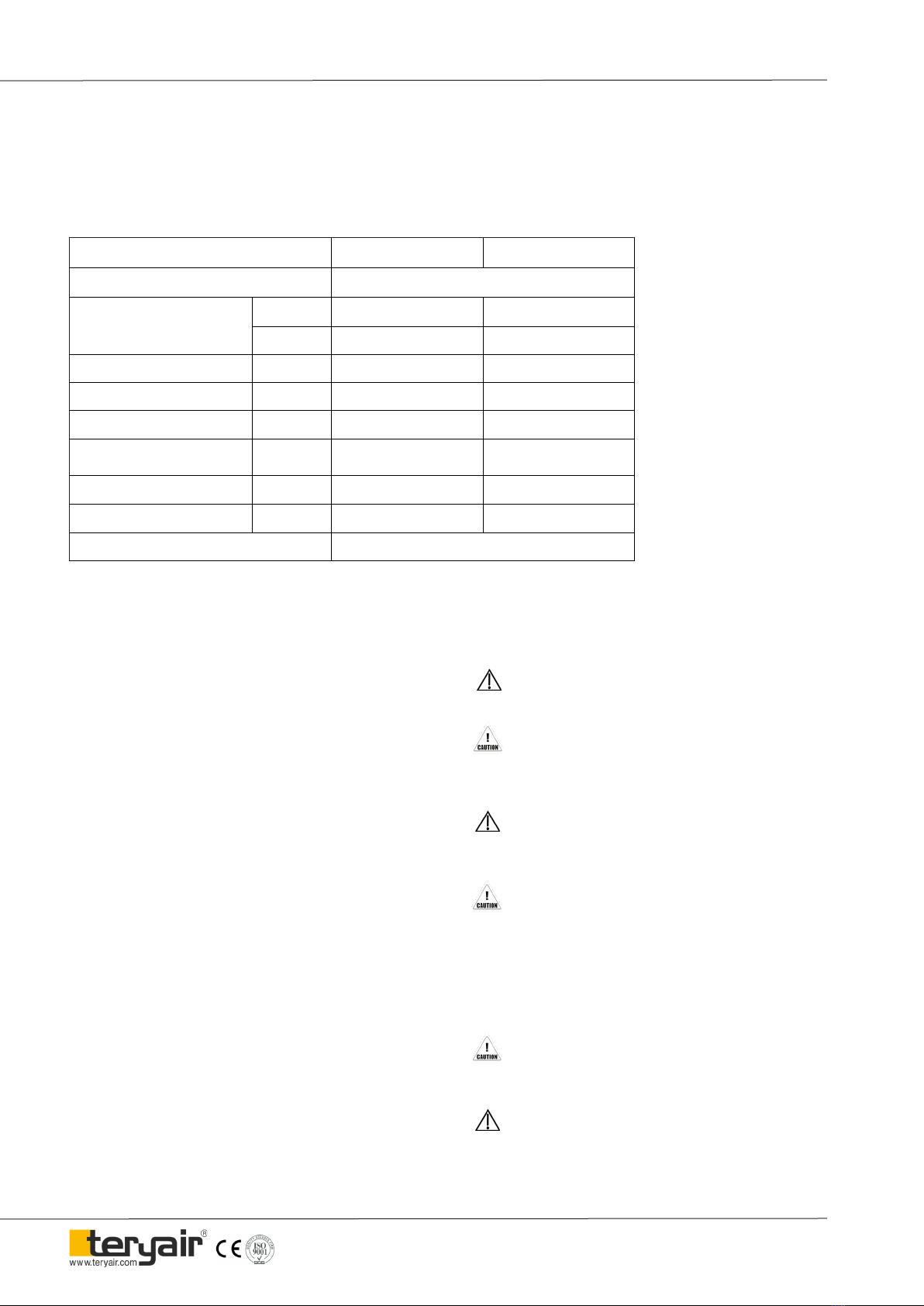

Technical Data

Teryair Model No FPLD11 FPHD11

Maximum operating pressure 6kg/cm2 (90 psi)

Air Consumption (No Load)

CFM 50 70

m3/ min 1.42 1.98

Working width (mm) 252 250

Height (mm) 1230 1290

Blows per min (BPM) 3000x11 2200x11

Sound Power Level (Load) LwA

db(A) 113.1 97

Vibration Level Primary m/s2 5.76 5.0

Mass (Weight) Kg 36 70

Thread Size of Air Inlet 3/4” BSP

Safety Instructions

Warning

If not followed could cause personal injuries

Caution

If not followed could result in damage to equip-

ment.

Warning

is manual must be read and the operating

instructions carefully followed.

Warning

Operators under eighteen not allowed to oper-

ate this Pneumatic Piston Scabbler. Operators

must be made familiar with the instructions in

this manual before attempting to operate the

Pneumatic Piston Scabbler. Ensure that job site

is clear of bystanders

Caution

Use only genuine Teryair or Teryair approved

accessories.

Warning

Never run the Piston Scabbler continuously in

the same place, as the cutter heads will dig into

thesurface.

Following symbols are used through out this

manual.

Intended Use

Floor preparation machines are intended for

preparation of oor surfaces. ese machines

are ideally used for removal of oor coating of

paint, chemical & corrosion. Floor preparation

machines are primarily designed for removal

of heavy rust, paint & scale from ships decks or

heavy steel surfaces. FPLD deck scaler is also

available tted with tungsten carbide tips. All

machines can be used both indoors &

outdoors.

Prohibitive use

• Any use in an explosive atmosphere is

prohibited

• Use on materials containing asbestos is

prohibited

• Use by an underage, untrained or person

who is under the inuence of drugs or

alcohol.

• Use with non-genuine spare parts or

accessories is prohibited

FF-MM-403-REV - 00

Page 4

Operation and Maintenance Guide Pneumatic Deck Scalers

is oor scaler can be used for removing scales

and surface paint from ship deck. Tungsten Car-

bide Tipped Cruciform cutter head is threaded

on to the pistons to make use of scalers on steel

surfaces for removal of heavy rust and scale. e

scaling head (6) has 11 pistons in reciprocating

motion and they are accomodated in single

screw cap design, so individual piston replace-

ment is simplied. e nylon brush seals at nose

end of pistons, clean every piston on each and

every stroke, thereby the tool performance is

improved. e scaling head (6) is assembled with

anti-vibration mountings and on trolley with

rubber wheels. Also the height of operating han-

dle is at a height so that the operator can stand

during use of scaler, he will not feel any jerks and

his eyes are protected from dust and chipped

material. e operator does not get tired early.

Daily Before Operating

Blow out any accumulated dirt in the hose line,

disconnect air supply. Tilt the scaling head (9),

unscrew adaptor (tool end) (23), pour in one to

two ounces of recommended oil into the tool

and screw on male adaptor (tool end) (40).

Lubrication Requirements

Always install a line lubricator on the air line as

close to the tool as possible. A Filter Regulator

Lubricator unit (FRL) is strongly recommended.

Keep the lubricator bowl topped up with recom-

mended grade of oil and check that the oil

is reaching the tool. Running the tool without

lubrication is likely to cause damage to the com-

ponents causing premature replacement.

Air Supply

Tool should not be operated at air pressure below

5.9 Bar (85psi) and above 6.9 bar (100psi).e

correct operating pressure is 6.2 bar (90 psi).

Ensure that only 3/8” (10 mm) bore airline is

used and all couplings are tight, leakproof and in

good condition. e air should be clean, dry and

lubricated. Install a FRL unit as close as opera-

tion will permit.

Operating Instructions

Warning

is Pneumatic Piston Scabbler is not de-

signed for use in an explosive environment.

Caution

Completely turn o the Pneumatic Piston

Scabbler and disconnect air supply line before

attempting any service. Read Assembly and

Disassembly instructions.

Warning

Take care not to exceed the maximum 7 bar

(100psi) supply air pressure. Use a lter and

regulator and lubricator as close to the Pneu-

matic Piston Scabbler inlet as operation will

allow ensuring a clean and regulated and

lubricated air ow.

Caution

Do not exert excessive pressure against the

work surface. Keep hoses in good condition.

Check hoses for signs of wear, cracks & bulges

and ensure that they are secure. Accidental

disconnection while hose is pressurized makes

the hose whip and can be a safety hazard.

Caution

Please check the hose connection prior to

starting Piston Scabbler. Be aware that these

Pneumatic Piston Scabbler can create dust

& ying debris. Keep hands & clothing away

from moving parts. Store these Pneumatic

Piston Scabbler in secure & dry environment.

Do not allow the Pneumatic Piston Scabbler

to run unattended. Do not modify this Pneu-

matic Piston Scabbler in any way as this will

invalidate the warranty and could lead to

serious injury.

Warning

• Eye and face and ear protection must be

worn at all times during operation of the

Pneumatic Piston Scabbler. ere is a

chance of ying debris from the jobsite

and the quality of wear should be such to

protect against such ying debris such as

akes of the removed layer.

• Suitable gloves must be worn at all times

during operation.

• Safety Shoes with toe cap protection are a

must during operation.

FF-MM-403-REV - 00

Page 5

Operation and Maintenance Guide Pneumatic Deck Scalers

Suggested Lubricants

Brand Above 27ºC / 80ºF 5ºC to 27ºC / 41ºF to 80ºF Below 5ºC / 80ºF

Shell Toona R 72 Toona R 41 Toona R 27

Mobil Almo 529 Almo 527 Almo 525

Esso -- Arox EP.65 Arox EP.45

Caltex Rando Oil 100 Rando Oil 100 Rando Oil 46

Cp -- -- Airolene Tool OiI

Texaco Regal Oil F (R&O) Regal Oil PE(P&E) Regal Oil PE(R&O)

Daltron Silkolene 881 Silkolene 548/T Silkolene 733

Burmah Castrol Castrol RD Oil 3 Castrol RD Oil Light Megna SPX

Duckham Garnet 7 Garnet 6 Zero Fio 5

Sternol Merlin 87 Merlin 71 Merlin 54

Petrona Purifoc 53 Purifoc 46 Purifoc 32

Chevron Vistac Oil 18X Vistac Oil 19X Vistac Oil 9X

Hoses

Daily before operation check the hoses for dam-

age or leaks.

Use genuine Teryair spares and if possible men-

tion the serial number of the Pneumatic Piston

Scabbler when ordering spares.

FF-MM-403-REV - 00

Page 6

Operation and Maintenance Guide Pneumatic Deck Scalers

Diassembly and Re-assembly for FPLD-11

a. Shut o air supply and allow residual Pres-

sure to bleed o.

b. Unscrew Cruciform Cutter Heads (1) from

Piston (4) to replace it with new ones.

c. Unscrew Screwed Cap (7) from Scaling

Head (9) & remove Compression Spring

(6), Spring Cap (5), Piston (4) and Cylin-

der (3) with Brush Seal (2) respectively to

replace it with new ones. (If found dam-

aged/worn-out)

d. Follow Step ‘b’ & ‘c’ to replace the remain-

ing piston assembly from Scaling Head

(9).

e. Unscrew Hexagonal Plug (8) with Sealing

Washer (10) from Scaling Head (9) and re-

place it with new ones. (If found damaged/

worn-out)

f. Remove Locking Pin (19) from Bracket

(14) & unscrew Nyloc Nut (29) with Plain

Washer (25 – Common) from Rubber

Mounting Block (28) to replace it with

new ones. (If found damaged/worn-out)

g. Unscrew Ball valve (33) from Male Adap-

tor (34) & unscrew Male Adaptor (34)

from Armoured Hose (35) to replace it

with new ones. (If found damaged/worn-

out)

h. Unscrew Nyloc Nuts (23) with Plain

washer (18-common) from U Bolt (21) to

replace it with new ones.

i. Unscrew Armoured Hose (35) from Scal-

ing Head (9) to replace it with new ones.

(If found damaged/worn-out)

j. Remove Scaling head assembly from Sub

Frame (24) and unscrew Rubber Mount-

ing Block from Scaling Head (9) to replace

it with new ones. (If found damaged/

worn-out)

k. Unscrew Nyloc Nut (13) with Plain Wash-

er (12) from Hex Bolt (11) and remove

Handle (31) from Sub frame (24)

l. Remove Rubber Mountings (32) from

Handle and replace it with new ones.

m. Now follow the above steps in reverse

manner to reassemble the FPLD-11.

FF-MM-403-REV - 00

Page 7

Operation and Maintenance Guide Pneumatic Deck Scalers

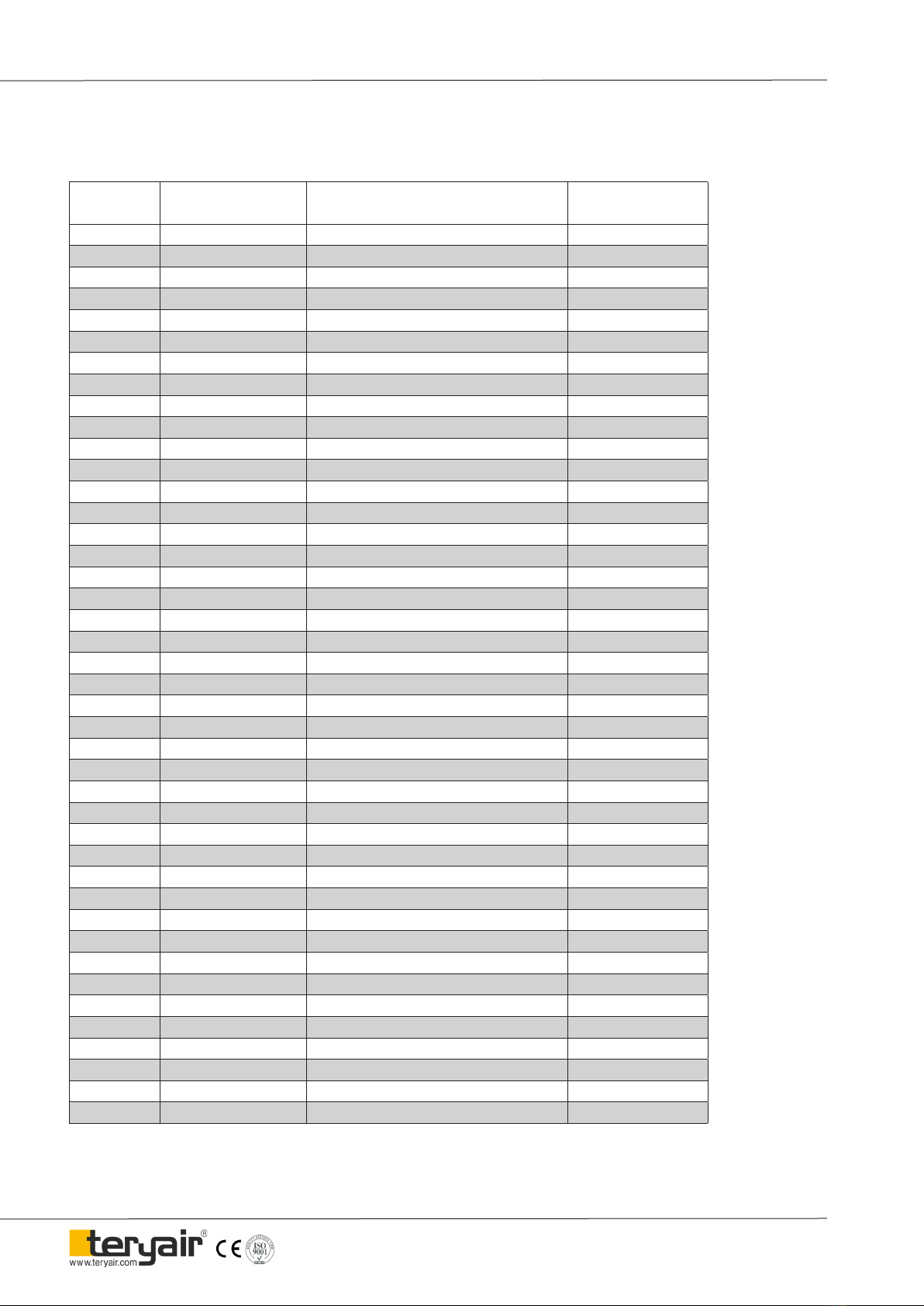

Bill of Materials for FPLD-11

Illustration

Number Part Number Description FPLD-11

1 128 21 01 Cylinder 11

2 128 21 02 Piston 11

3 128 21 03 Screwed Cap 11

4 128 21 04 Spring Seat 11

5 128 21 05 Wheel Mounting Pin 2

6 128 21 06 Stud For Front Wheel 1

7 128 21 07 Bush For Side Wheel 2

8 128 31 01 Cylinder Head 1

9 128 31 02 Front Mounting Plate (L Type) 1

10 128 31 03 Side Mouting Plate 2

11 128 33 01 Pipe Frame 1

12 128 40 01 P U Tube 1Mtr.

13 128 40 02 P U Tube 0.6Mtr.

14 128 40 03 O' Ring 11

15 128 50 01 Side Wheel For Pds 2

16 128 50 02 Front Wheel 1

17 128 50 05 Ball Valve 1

18 128 50 06 Ball Valve 1

19 128 50 08 Lubricator 1

20 128 51 01 Spring For Piston 11

21 128 51 02 Spring For Front Wheel 1

22 128 90 01 Hex Bolt 4

23 128 90 02 Spring Washer 4

24 128 90 05 Hex Bolt 2

25 128 90 06B Adaptor 1

26 128 90 07 Elbow (Push Type) 2

27 128 90 09B Adaptor 2

28 128 90 10 Push Type Connector 2

29 35.13.54 Plug Type Air Hose Connector 1

30 130 21 10 Plain Washer 3

31 140 40 10 O' Ring 11

32 195 10 21 Plain Washer 2

33 200 40 30 Hex. Nut 4

34 210 90 27 Hex. Bolt 4

35 210 90 35 Spring Washer 4

36 330 90 26 Plain Washer 4

37 340 30 24/ 03 Rubber Grip 2

38 342 90 24 Plain Washer 4

39 552 90 14 Hex. Nut 2

40 653 90 04 Spring Washer 2

41 671 90 05 Hex. Nut 2

42 671 90 06 Plain Washer 4

FF-MM-403-REV - 00

Page 8

Operation and Maintenance Guide Pneumatic Deck Scalers

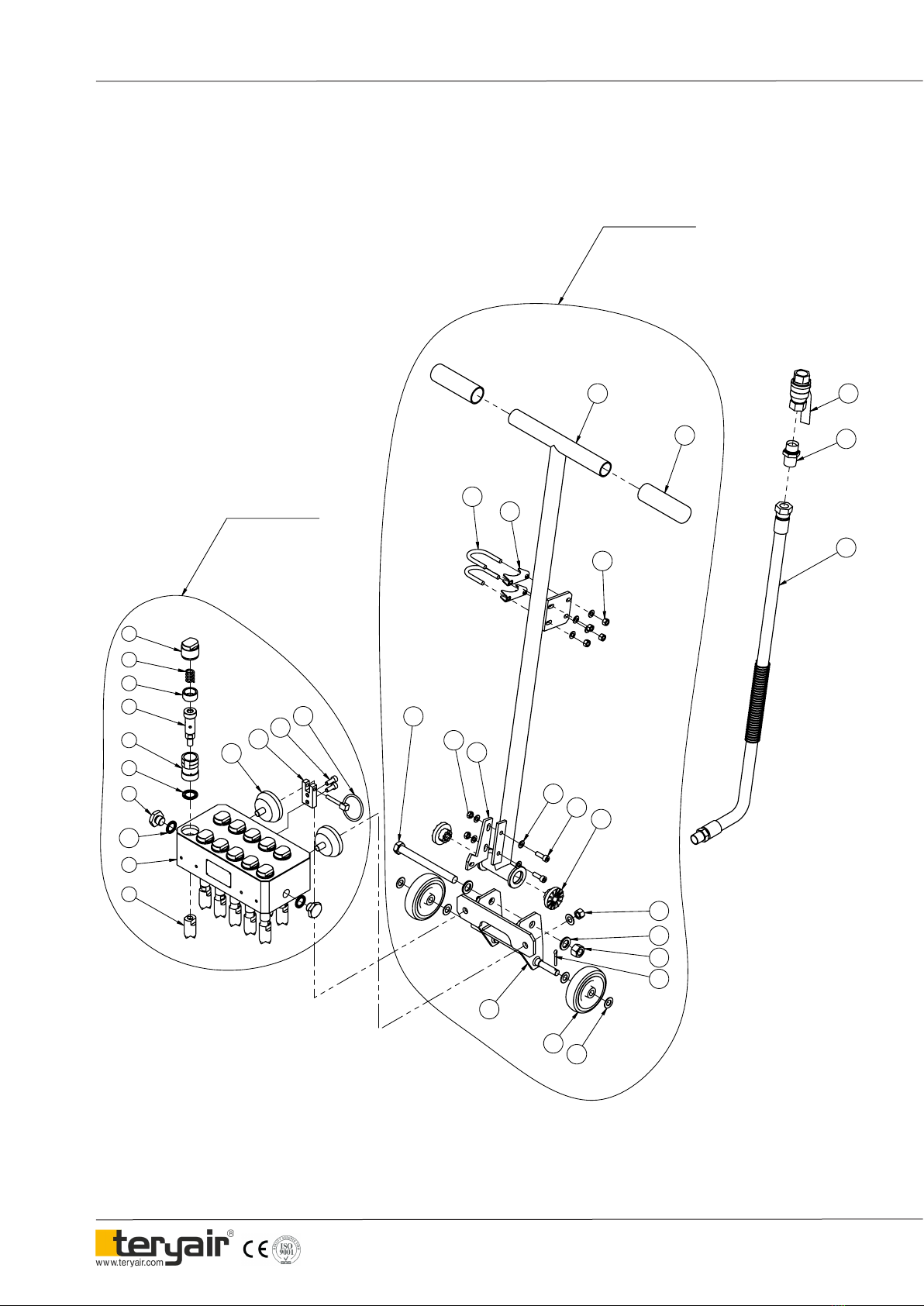

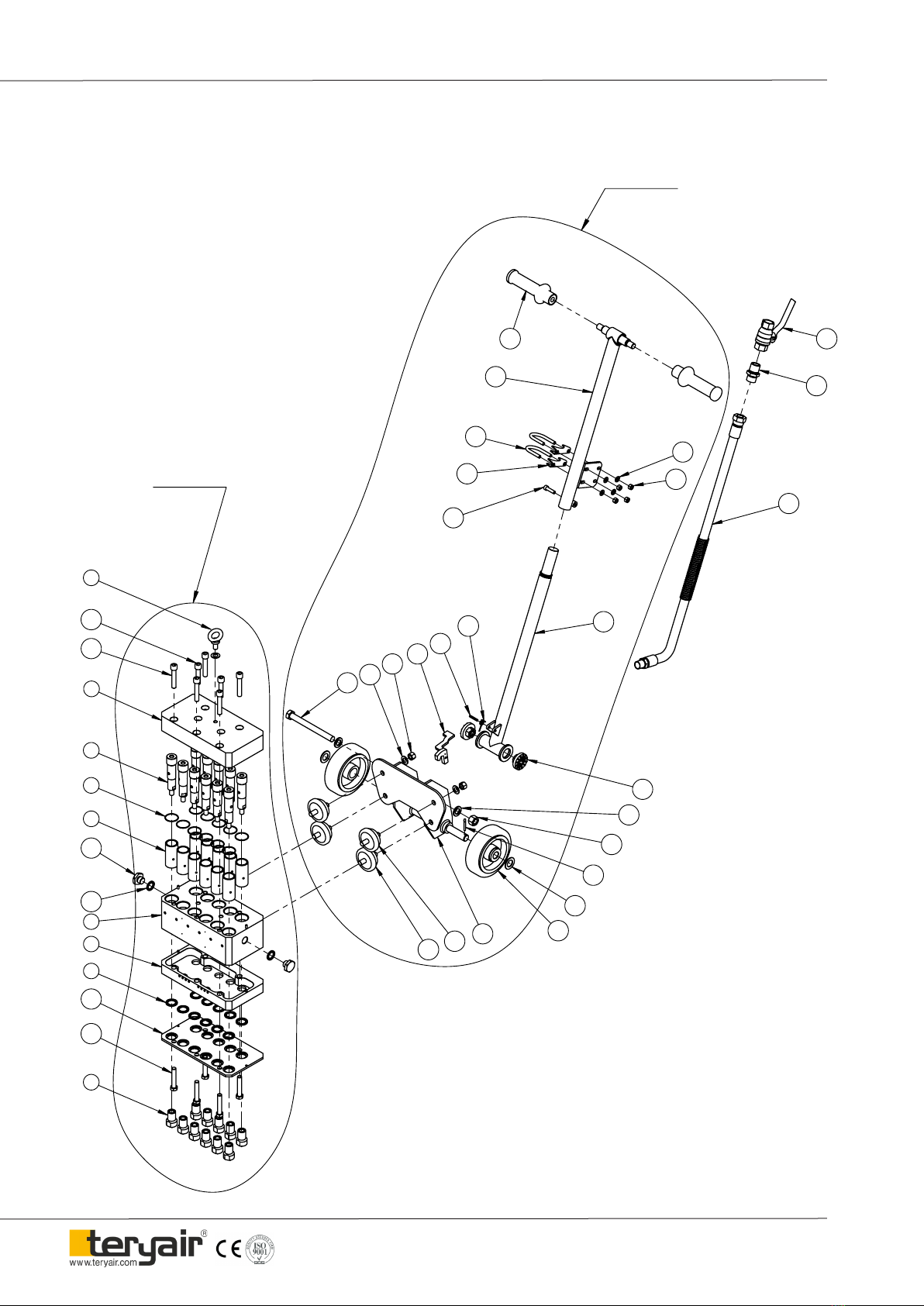

Exploded View for FPLD-11

7

6

5

4

3

2

1

10

8

9

11

13

12

28

14

20

19

15

16

17

18

21

22

23

24

25

26

27

29

30

31

32

33

34

35

DETAIL A

DETAIL B

FF-MM-403-REV - 00

Page 9

Operation and Maintenance Guide Pneumatic Deck Scalers

Exploded View Detail-A for FPLD-11

19

20

14

28

1

7

6

5

4

3

2

10

8

9

1

FF-MM-403-REV - 00

Page 10

Operation and Maintenance Guide Pneumatic Deck Scalers

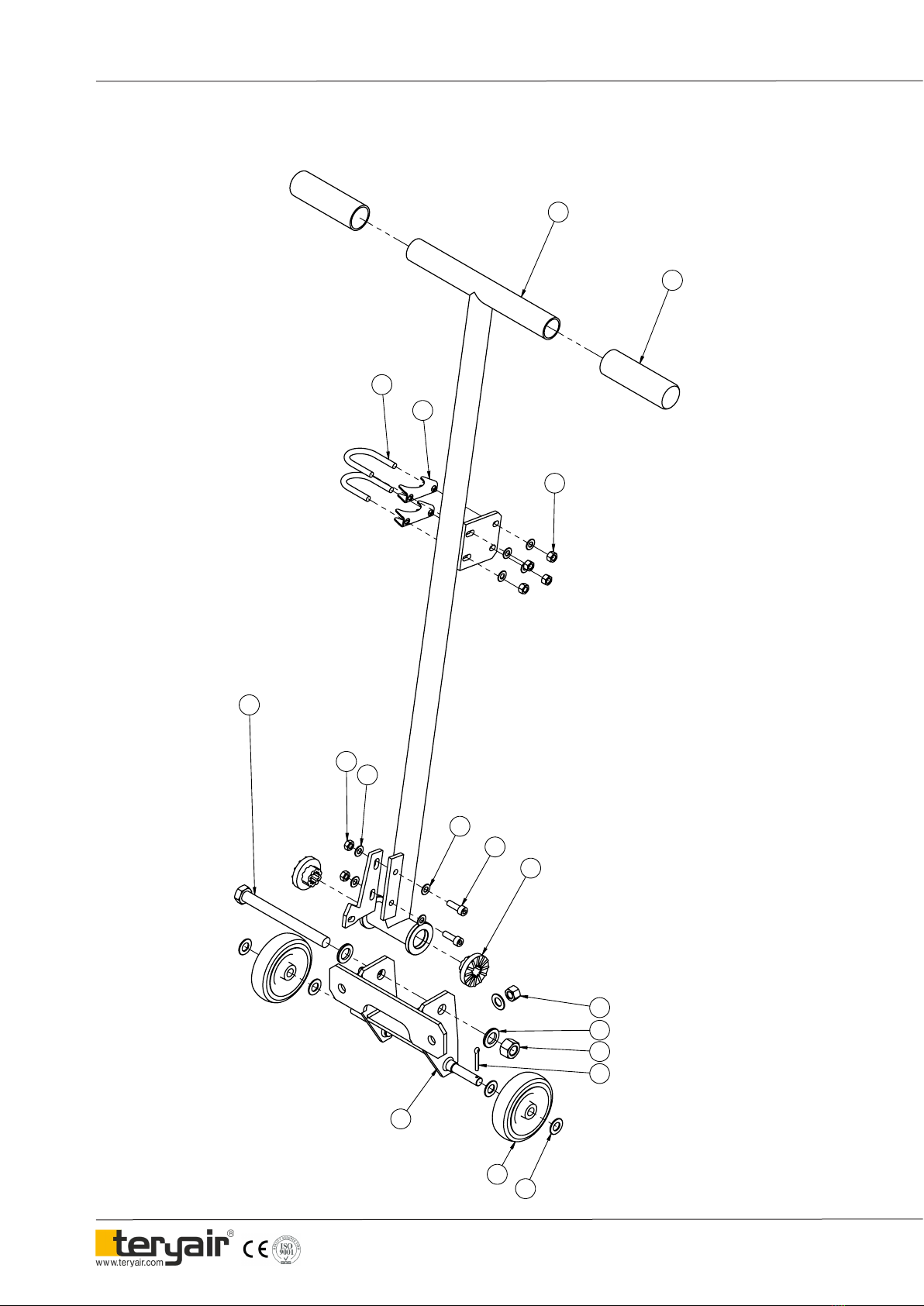

Exploded View Detail-B for FPLD-11

32

31

30

26

25

24

23

22

21

18

17

16

15

11

13

12

27

29

FF-MM-403-REV - 00

Page 11

Operation and Maintenance Guide Pneumatic Deck Scalers

Diassembly and Re-assembly for FPHD-11

a. Shut o air supply and allow residual Pres-

sure to bleed o.

Handle & Armoured Hose:

b. Unscrew Ball valve (15) from Male Adaptor

(16) & unscrew Male Adaptor (16) from

Armoured Hose (14) to replace it with new

ones. (If found damaged/worn-out)

c. Unscrew Nyloc Nuts (38) with Plain washer

(13-common) from U Bolt (36) to replace it

with new ones.

d. Unscrew Armoured Hose (14) from Cylin-

der Block (7) to replace it with new ones. (If

found damaged/worn-out)

e. Unscrew Nyloc Nuts (34) with Plain wash-

ers (35) from Rubber Mounting (33) and

Rubber Mountings (20) and replace it with

new ones. (If found damaged/worn-out)

f. Now remove the Rubber mountings (33)

and Rubber Mountings (20) with Cylinder

Block Assembly from Sub-Frame (26)

Cylinder Block Assembly:

g. Unscrew Allen Bolt (10) & Allen Bolt (11)

from Top Plate (6).

h. Unscrew Cruciform Cutter Heads (3) from

Piston (2) to replace it with new ones.

i. Remove O-ring (5), Piston (5), Cylinder

(1), Hexagonal Plug (40) and Sealing wash-

er from Cylinder Block (7) respectively to

replace it with new ones. (If found damaged/

worn-out)

j. Follow Step ‘c’ &‘d’ to replace the remaining

piston assemblies from Cylinder Block (7).

k. Unscrew Hex Head Bolts (39) from Sealing

Plate (12) & Remove Brush Seals (4) from

Sealing Plate (12) to replace it with new

ones. (If found damaged/worn-out).

l. Remove Pin Spiral (30) from Bottom han-

dle (17) & remove Torsion Spring (32) from

Latch (31) to replace it with new ones. (If

found damaged/worn-out).

m. Unscrew Nyloc Nut (23) with Plain Washer

(24) from Hex Bolt (22) and remove Bottom

Handle (17) from Sub frame (26)

n. Remove Rubber Mountings (25) from

Bottom Handle (17) and replace it with new

ones.

o. Now follow the above steps in reverse man-

ner to reassemble the FPHD-11.

FF-MM-403-REV - 00

Page 12

Operation and Maintenance Guide Pneumatic Deck Scalers

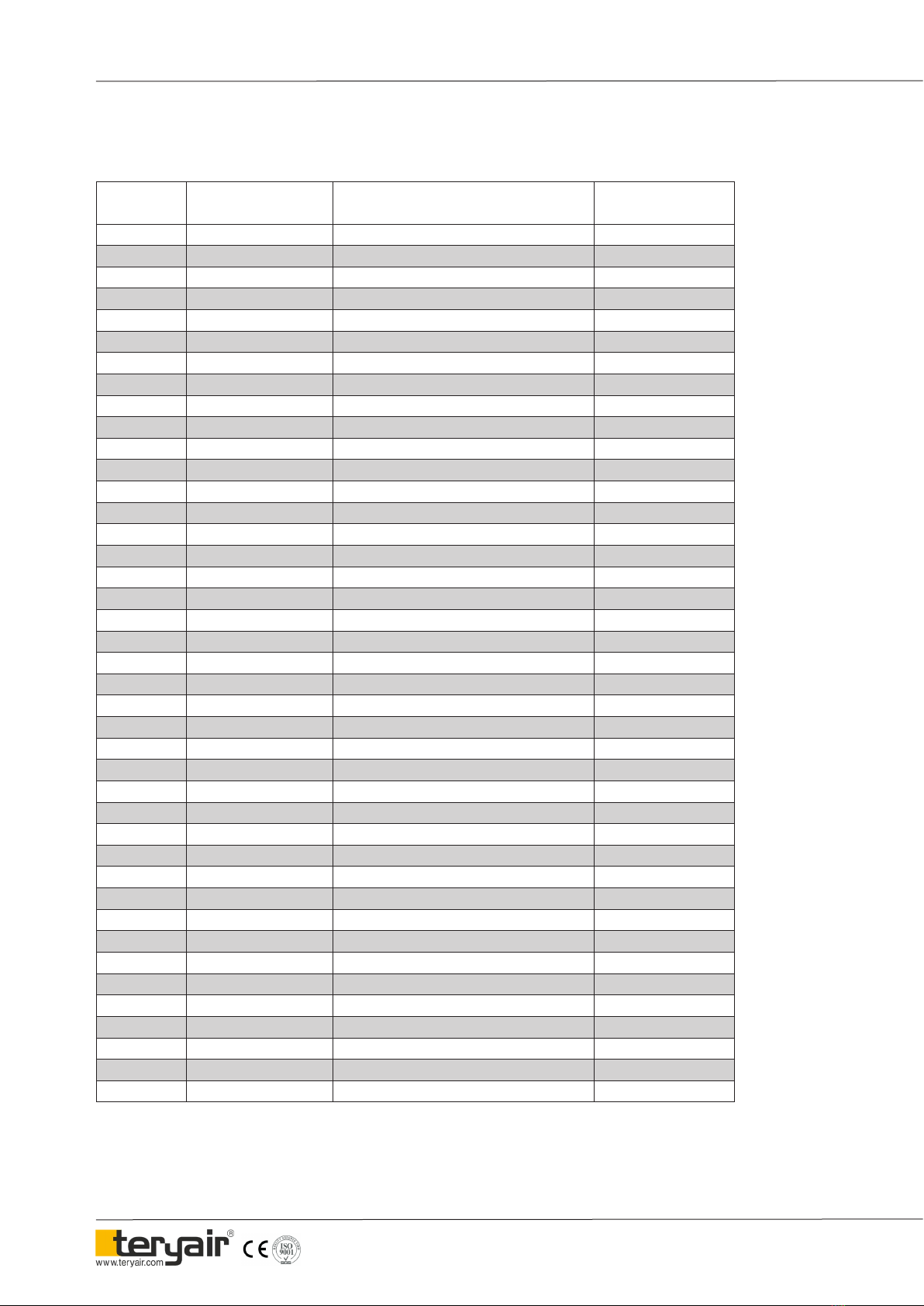

Bill of Materials for FPHD-11

Illustration

Number Part Number Description FPHD-11

1 130 21 04 CYLINDER 11

2 130 21 05 PISTON (THREADED) 11

3 130 21 06 BUSH HAMMER CUTTER HEAD 11

4 130 40 23 BRUSH SEAL 11

5 130 40 24 O' RING 11

6 130 30 14 TOP PLATE 1

7 130 30 15 CYLINDER BLOCK 1

8 130 30 26 INTERMEDIAT PLATE 1

9 126 90 35 EYE BOLT 1

10 130 90 14 SOCKET HEAD SCREW 5

11 130 90 34 SOCKET HEAD SCREW 2

12 130 30 17 SEALING PLATE 1

13 171 90 50 PLAIN WASHER 4

14 126 97 39 ARMOURED HOSE 1

15 250 90 40 BALL VALVE 1

16 250 21 41 THREADED MALE/ MALE ADAPTOR 1

17 130 97 19 BOTTOM HANDLE 1

18 130 97 18 TOP HANDLE 1

19 200 90 68 CAP HEAD SCREW 1

20 130 40 21 RUBBER MOUNTING 2

21 130 40 22 HANDLE GRIP 2

22 126 90 36 HEX HEAD BOLT 1

23 126 50 29 NYLOC NUT 1

24 126 90 37 PLAIN WASHER 2

25 126 40 26 RUBBER MOUNTING 2

26 130 30 11 SUB- FRAME FOR WHEEL 1

27 130 97 10 WHEEL 2

28 130 21 10 PLAIN WASHER 2

29 23.24.80.1.2 SPLIT PIN 2

30 130 90 31 PIN- SPIROL 1

31 130 30 13 LATCH 1

32 130 51 33 TORTION SPRING 1

33 130 40 31 RUBBER MOUNTING 2

34 126 50 31 NYLOC NUT 4

35 342 90 24 PLAIN WASHER 5

36 126 21 10 U BOLT 2

37 126 30 14 CLAMP 2

38 126 50 30 NYLOC NUT 4

39 130 90 27 HEX HEAD BOLT 5

40 121 21 18 HEXAGON PLUG 2

41 121 40 12 SEALING WASHER 2

FF-MM-403-REV - 00

Page 13

Operation and Maintenance Guide Pneumatic Deck Scalers

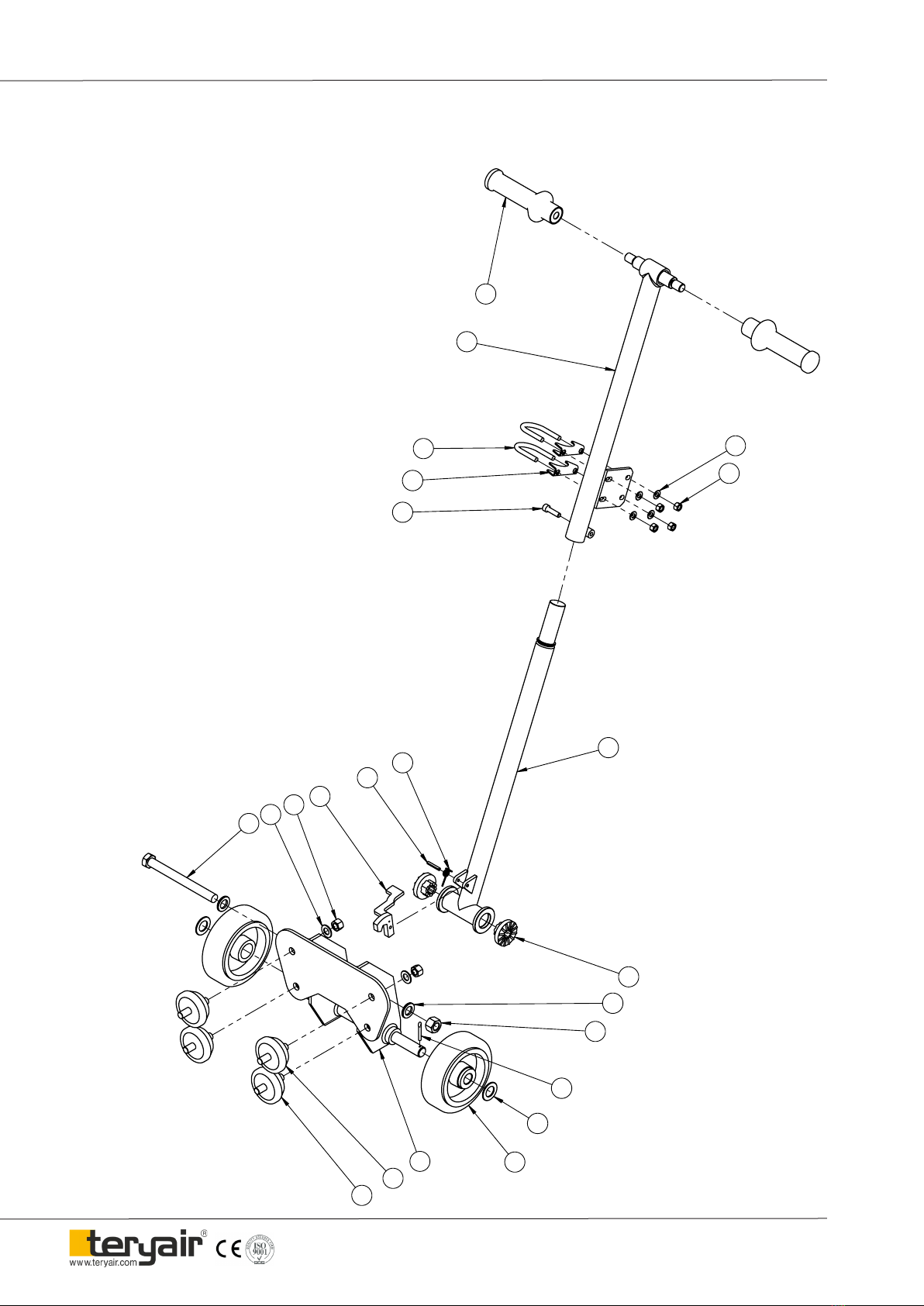

Exploded View for FPHD-11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26 27

28

29

30

32

31

33

34

35

37

36

38

39

40

41

DETAIL A

DETAIL B

FF-MM-403-REV - 00

Page 14

Operation and Maintenance Guide Pneumatic Deck Scalers

Exploded View Detail-A for FPHD-11

41

39

12

8

7

4

3

11

10

9

6

1

2

5

40

DETAIL A

35

FF-MM-403-REV - 00

Page 15

Operation and Maintenance Guide Pneumatic Deck Scalers

Exploded View Detail-B for FPHD-11

DETAIL B

38

36

37

35 34 31

32

30

22

21

19

18

17

13

20

23

24

25

26 27

28

29

33

FF-MM-403-REV - 00

Page 16

Operation and Maintenance Guide Pneumatic Deck Scalers

Repair Kits For FPLD - 11

Illu. No. Part No. Description 1269700

1 126 21 05 CRUCIFORM CUTTER HEAD 11

2 126 40 23 BRUSH SEAL 11

8 121 21 18 HEXAGON PLUG 2

10 121 40 12 SEALING WASHER 2

11 126 90 36 HEX HEAD BOLT 2

25 342 90 24 PLAIN WASHER 2

27 23.24.80.1.2 SPLIT PIN 2

28 130 40 21 RUBBER MOUNTING BLOCK 2

29 126 50 31 NYLOC NUT 2

32 126 40 26 RUBBER MOUNTING 2

34 250 21 41 THREADED MALE/ MALE ADAPTOR 1

35 126 97 39 ARMOURED HOSE 1

Repair Kits For FPHD - 11

Illu. No. Part No. Description 1309700

3 130 21 06 BUSH HAMMER CUTTER HEAD 11

4 130 40 23 BRUSH SEAL 11

5 130 40 24 O' RING 11

10 130 90 14 SOCKET HEAD SCREW 5

11 130 90 34 SOCKET HEAD SCREW 2

14 126 97 39 ARMOURED HOSE 1

16 250 21 41 THREADED MALE/ MALE ADAPTOR 1

20 130 40 21 RUBBER MOUNTING 2

25 126 40 26 RUBBER MOUNTING 2

29 23.24.80.1.2 SPLIT PIN 2

30 130 90 31 PIN- SPIROL 1

32 130 51 33 TORTION SPRING 1

33 130 40 31 RUBBER MOUNTING 2

34 126 50 31 NYLOC NUT 4

35 342 90 24 PLAIN WASHER 5

38 126 50 30 NYLOC NUT 4

39 130 90 27 HEX HEAD BOLT 5

40 121 21 18 HEXAGON PLUG 2

41 121 40 12 SEALING WASHER 2

FF-MM-403-REV - 00

Page 17

Operation and Maintenance Guide Pneumatic Deck Scalers

TEST CERTIFICATE OF MATERIALS, PERFORMANCE

Date :

Model number :

Part description & s.No. :

We hereby certify that the above referenced product has tested and inspected in accordance with our standard test procedures

and meets the specications for material and performance values as published in our literature. We further certify that the

product has been given our standard factory test and meets all quality and performance standards established by the company.

is product is certied to be produced in our factory, and is of current production.

Authorised Signatory

Q.A Manager

Place - Vasai, Maharastra

FF-MM-403-REV - 00

Page 18

Operation and Maintenance Guide Pneumatic Deck Scalers

EU DECLARATION OF CONFORMITY

We hereby certify that the Listed Product stipulated below comply with all relevant provisions of the machinery direc-

tive (2006/42/EC) and the national laws and regulations adopting this directive.

Description :

Model Number :

Date :

Serial Number :

Is in conformity with the provisions of the following European Directives: (2006/42/EC) Machinery Safety and

Harmonized standards

ISO 12100-1: 2010: Safety of Machinery –general Principles for Design –Risk Assessment and Risk Reduction.

Registered Oce : 416 Gundecha Industrial Complex, Akuril Road,

Kandivali East, Mumbai – 400101, Maharashtra, India.

Web site : www.teryair.com

Works : A-1, Tirupati Udyog Nagar, Sativali Road, Vasai East,

Palghar – 401208, Maharashtra, India.

CE certication registration no – C E 16832

Issued by – BMQR Certications Pvt Ltd.

www.cemarking-india.com

Valid Till – 03/11/2021

Signed for and on behalf of

TERYAIR EQUIPMENT PVT. LTD. Place of Issue:

Date:

FF-MM-403-REV - 00

Page 19

Operation and Maintenance Guide Pneumatic Deck Scalers

Warranty Certificate

Every product manufactured by Teryair

is built to meet the highest standards of quality.

Teryair warrants that the Products, accessories and parts manufactured or supplied

by the company be free from defects in material and workmanship for a period of six

months from date of Teryair authorized dealer invoice to customer, or one year from

date of Teryair invoice to dealer, whichever is earlier. Failure due to normal wear,

misapplication, or abuse is, of course, excluded from this warranty.

Since the use of Teryair products and parts is beyond our control, Teryair cannot

guarantee the suitability of any product or part for a particular application and Teryair

shall not be liable for any consequential damage or expense arising from the use or

misuse of its products on any application. Teryair does not warranty bought out

products or components such as electric motors and hardware but will assist in

directing warranty queries to the dealer/manufacturer responsible. Teryair

responsibility is limited solely to replacement or repair of defective Teryair products

or components.

Dealer/End User shall have no right or remedy and Teryair shall have no liability or obligation under the warranty, if:

(i) a Product is altered, changed, modified or tampered with in any way, (ii) a Product is damaged after deposit with the

transporter for shipment; (iii) a Product is not properly preserved, packaged, stored, processed or handled after receipt; (iv) a

Product is not used and maintained in accordance with Teryair's recommended operating and maintenance manuals,

instructions and procedures, if any; (v) a Product is not properly incorporated or installed in, or not properly combined with, an

Other Product; (vi) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises

out of, a failure, substandard performance or other issue with another product, material, component or part not supplied by

Teryair; (vii) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises out of,

compliance with any design, specification or other specific requirement of Dealer/End User; (viii) a Product is used in a manner,

with a substance or for a purpose other than the normal manner, substance and purpose for which it is intended or is otherwise

subjected to abnormal use or service; (ix) a Product is subjected to a power surge, brown out or other similar occurrence; (x)

the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises out of, normal wear

and tear of such Product (including, without limitation, things such as worn seals, diaphragms, balls, O rings, gaskets, chisels,

cutters, hoses and other such wearing components; (xi) the issue with a Product is directly or indirectly.

Dated :

Product Model Number :

Product Serial Numbar : Ajay Bhagat, Q.A. Manager

(Company Seal)

FF-MM-403-REV - 00

Page 20

Operation and Maintenance Guide Pneumatic Deck Scalers

is page is intentionally

Le blank.

This manual suits for next models

1

Table of contents

Other Teryair Media Converter manuals