Teshow TS81B User manual

Digital PIDController

TS80B-E1

Carefully readall theinstructions inthis manual.Please place

this manualin aconvenient locationfor easyreference.

WARNING

CAUTION

(4) Control output[OUT]:

M:Relay contact V: Voltagepulse

8: Current(DC4 ~20 mA) 5:DC0-5VDC

6: DC0-10VDC T:Trigger (fortriac driving)

(5) Remark:

N: No

(6) Alarm1[AL1 for highalarm] See"5.5 "

N: No alarm

A: Deviationhigh alarm H:Process high alarm

(7) Alarm2[AL2 for lowalarm] See"5.5 "

N: No alarm

B: Deviation lowalarm J: Processlow alarm

(8) Power

A: 220VAC B 85-265VAC D 24VDC E 24VAC

Initial Setting

Initial Setting

!

TS80B-E1

INSTRUCTION MANUAL

1

An externalprotection device must be installed iffailure of this

instrument could resultin damage to the instrument, equipment

or injury topersonnel .

All wiringmust be completedbefore power inturned on toprevent

electric shock, fireor damage toinstrument and equipment .

This instrument must be used in accordance with the

specifications to prevent fire or damage to instrument and

equipment.

This instrument is not intended for use in locations subject to

flammable or explosivegases.

Do not touch high-voltage connections such as power supply

terminals , etc.to avoid electricshock.

This instrument is protected from electric shockby reinforced

insulation. Provide reinforced insulation between the wirefor

the input signal and the wires forinstrument power supply, source

of power and loads.

This instrument is design for installation in an enclosed

instrumentation panel. All high-voltage connections such as

power supply terminals must be enclosed in the instrumentati on

panel to avoid electric shock byoperating personnel.

All precautions describedin this manual should be taken to avoid

damage to the instrument or equipment.

All wiring mustbe in accordance with local codes andregulations.

Always observe precautions described in this manual.

Otherwise serious injury or accidentmay result.

Do not allow metalfragments or lead wire scraps to fallinside this

instrument. This may cause electricshock, fire or malfunction.

Firmly tighten each terminal screw at the specified torque.

Otherwise electric shock or fire mayresult.

Do not place any obstacle around this instrument in order

not to impede radiation of heat.And do not close ventilationholes.

Do not connect wires tounused terminals.

Before cleaning the instrument,always turn off the power supply.

Remove stains from thisinstrument using a soft,dry cloth. Do not

use a volatile solvent such asthinner in order toavoid deformation

or discoloration.

Do not rub norstrike the display unit of this instrumentwith a hard

object.

-

1. PRODUCTCHECK

-

(1) Control action

F: PID reverseaction with autotuning

(1)(2) (3) (4) (5) (6)(7) (8)

(2) Input type,(3) Range code: See"8.INPUTRANGE TABLE"

Check MODELand CODE

is very importantwhen ordering.

2.1 MountingCautions

2. MOUNTING

(1) Use this Instrument within the following ambient

temperature and ambienthumidity.

Allowable ambienttemperature: 0 to50

Allowable ambienthumidity: 45 to85% RH

(2) Avoidthe following whenselecting the mountinglocation.

Rapid changes inambient temperature whichmay cause condensation.

Corrosive or inflammablegases.

Direct vibration orshock to themainframe.

Water,oil,chemicals,vaporor steam splashes.

Excessive induction noise,static electricity,magnetic fields ornoise.

Direct air flowfrom an airconditioner.

Exposure to directsunlight.

Excessive heat accumulation.

C

TS81B/TS84B/TS85B/TS87B/TS89B

TS85B

TS84B

TS89B

TS87B

TS81B

Example

Model: TS89B Specification:

Model of thecontroller:TS89B

Size: 96mm x96mm

Control action: PIDreverse action

Input: K typethermocouple

Out put: Relayoutput

Alarm: 1 deviationhigh alarm (AL1)

Power: AC220V

Code: FKA4-MN*AN-A

2.2 Dimensions

TS81B

50 14.6

50

44.0

44.0

58.0

80

13.6

11

TS84B

TS85B

50 14.6

96

44.0

90.0

104.0

80

13.6

11

74 14.6

74

67.5

67.5

80.0

80

13.6

11

UP

TS87B TS89B

90

96 14.6

96

90.0

104.0

80

13.6

11

UP

Unit:mm Unit:mm

Unit:mm Unit:mm

2

(1) Prepare thepanel cutout asspecified in 2.2Dimensions.

(2) Insert theinstrument through thepanel cutout.

(3) insert themounting bracket intothe mounting

groove of theinstrument. Fig.1

(4) Pull tillchick sounds tothe direction

shown by thearrow.(Fig.2)

(5) The other mounting bracketshould be installed

the same waydescribed in 3.to 4.

2.3 MoutingProcedures

Fig.1

Mounting bracket

UP

Fig.2

UP

3. WIRING

3.1 Wiringcautions

(1) For thermocoupleinput, use thespecified compensation wire.

(2) For RTDinput , useleads with lowresistance and havingno resistance differencesamong the 3leads.

(3) Conduct inputsignal wiring awayfrom instrument power, electric equipmentpower and loadlines to avoidnoise induction.

(4) Conduct instrumentpower wiring soas not tobe influenced bynoise from theelectric equipment power. If theinstrument may beaffected

by external noise,a noise filtershould be used.

* Shorten thedistance between twistedpower supply wirepitches. The

shorter the distancebetween the pitches,the more effectivefor noise

reduction.

* Install thenoise filter onthe panel whichis always groundedand minimize

the wiring distancebetween the noisefilter output sideand the instrument

power terminals.

* Do notinstall fuses and/orswitches on thefilter output signalsince this may lessen filter effect.

(5) For wiring,use wires conformingto the domesticstandard of eachcountry.

(6) Abot4 to 5seconds are requiredas the preparationtime for contactoutput after poweron. Use adelay relay whenthe output lineis used foran

external interlock circuit.

(7) This instrumenthas no powersupply switch norfuses. Therefore, installthe fuse closeto the instrumentand the switch,if required.

*Recommended fuse rating:Rated voltage; 250V Rated current; 1A * Fuse type;Time-lag fuse

(8) Do notexcessively tighten theterminal screws. Inaddition, use thesolderless terminal appropriateto the screwsize.

(9) To the instrumentwith power supplyof 24V, please besure to supplythe power fromSELV circuit.

instrument power Twist theseleadwires

IN OUT

Noise filter

Shorten distance between

pitches Minimize

distance

Instrument

power

terminals

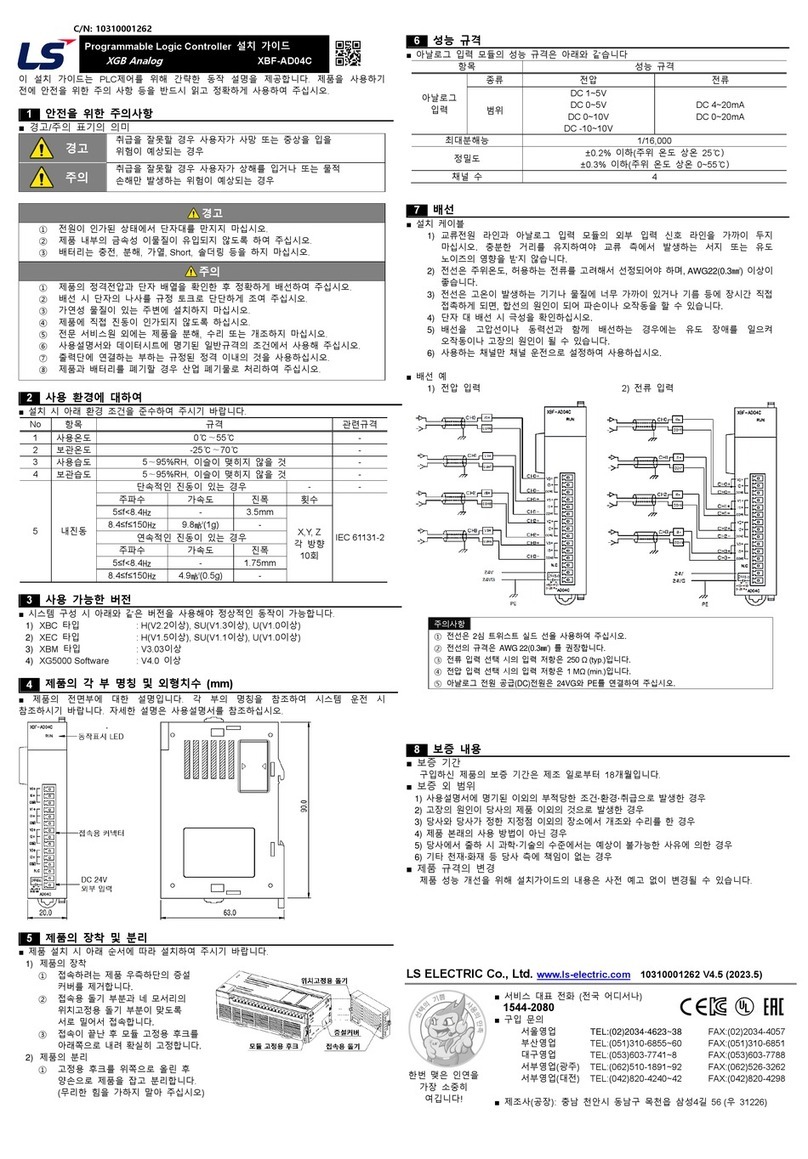

3.2 Terminal Configuration

TS81B TS84B TS85B TS89B

11

12

13

14

NO

LN

1

NO

RTD

TC,VDC

2

3

4

5

6

7

8

9

10

A

B

B

NO

AL1

OUT Voltage Current

For SSR mA

AC220V 10%

AC220V 10%

AC220V 10% AC220V 10%

mA

AL2

TS87B

L

N

1

NO

RTD

TC,VDC

2

3

4

5

8

9

10

11

12

A

B

B

OUT

6

7

13

14

NC

AL2

NO

Voltage

For SSR

NO

Current

mA,V

AL1

mA

NC

L

N

1

TC VDC

2

3

4

5

6

7

8

9

10

NO

NO

AL1

OUT

RTD

A

B

B

11

12

13

14

15

NO

NC

AL2

16

17

18

19

20

mA

Current

mA,V

Voltage

For SSR

Powersupplyvoltage:

(Frequency 50/60Hz Rating 200~240VAc)

7VAmax(at 100VAC) 10VA max(at 240VAC)

5VAmax(at24VAC) 160mAmax (at24VDC)

Alarmoututrated:

22to26VAC

(Frequency 50/60Hz Rating 24VAC)

22to26V DC Rating 24VDc

Powerconsumption

Relaycontactoutput TS84B TS85B TS87B TS89B 250VAC,3A(Resistiveload)

TS81B250VAC1A(Resistive load)

Controloutputrated

Relaycontactoutput: 250VAC,3A(Resistiveload)

Voltagepulseoutput:0/12V DC(Loadresistance 600 or more)

Currentoutput:4 to20mADC(Load resistance500 or less)

Triggeroutput(fortriacdriving):100Aor less Theterminalarrangement of TS85B is as shown inthe

followingdiagram, butthe terminalconfigurationof

TS85Bisthe same asthatofTS84B. TS80B-E1

(1)All the underhookups are onlyfor reference.

(2)For wiring, pleaseaccording to thehookup label whichwas glued onthe plastic caseof controller.

CAUTION

4. PARTS DESCRIPTION

1

2

3

4

567

Toavoid damage toinstrument, never usea sharp

object to presskeys.

1. Measured value(PV) display [Green]

* Displays PVor various

parameter symbols

3. Indication lamps

*Control output lamps(OUT,OFF)

[Green] OUT:Light when output is turned on.

[Red]OFF:Light when outputis turned off.

4. (Set key)

Used for parameter

calling up andset

value registration

7. (Up key)

Decrease numbers

6. (Down key)

Decrease numbers

CAUTION

5. Shift &Assistant key

2. Set value(PV)display [Red]

* Displays SVor various

parameter set values

SET

*Alarm output lamps(AL1,AL2)

[Red]

AL1: Lightswhen alarm 1output

is turned on.

Al2: Lightswhen alarm 2output

is turned on.

*Autotuning (AT) [Green]

Flashes when autotuningis

activated.

5. SETTING

5.1 Callingup procedureof eachmode *1. Input typeand input rangedisplay

This instrument immediatelyconfirms input typeand range followingpower on.

Example: For acontrolleer with theK thermocouple inputtype and rangefrom 0 to1300 C.

1. Input typedisplay

:Indicates input type(See table **A)

**A: Input typetable(see "14.0 Inputrange table")

Power on

Power on

Input type display

Input range display

Display changes automatically

(Display for

approx.5 sec)

PV/SV display mode

(Normal display)

The instrument returns tothe PV/SV

display mode statusif key operation

is not performedfor more than1 minute.

SV setting mode

Parameter Setting Mode

(PID level)

Press theSET key Press the

SET key

*1

Initialization Mode

(Input level)

Press theSET key

for 3 sec.

Press the

SET key

for 3 sec .

Press the

SET key

for 3 sec .

SV

PV

: Input rangehigh

Display

Display

Input

Input

K

Pt100

J

Cu50

ES

DC0-5V orDC0-10V DC2-10V

N

DC1-5V or

T

Thermocouple

Standard analog signal(Voltage and current)

Resistance thermometer

B

W5Re/W26/Re

R

DC0-20mA DC4-20mA

Press the keywhile

pressing theSET key for

3 secretary.

5.4 PIDlevel (ParameterList)

Press the "SET "key for 3seconds to PIDlevel

The followingparameter symbols aredisplayed one byone every timethe SETkey is pressed.

After the valuebe registered ,youcan press "SET"keyfor 3 seconds to return theinstrument

to the PV/SVdisplay mode.

Symbol Name Setting range Description

#1: Factory setvalue

#1

Alarm2 setvalue

AL2 for low alarm

Alarm1set value

AL1 for high alarm

Deviation orProcess alarm,

-1999 to 9999

Deviation orProcess alarm,

-1999 to 9999

Set the alarm1set value forhigh alarm.

Alarm differential gap=HYS,when P 0

Set the alarm2set value forlow alarm.

Alarm differential gap=HYS,when P 0

10

200

PV bias -1999 to +9999

0 to 9999

Sensor correction ismade by addingbias

value to measuredvalue(PV). 0.0

0

Differential gap

for alarm oroutput Alarm differential gap=HYS,whenP 0(PID action)

Out differential gap=HYS,whenP=0 (ON/OFF action)

(4) Set valueentry

After finishing thesetting, Press

the SET key, Allof the setvalue

digits stop flashand as aresult

the instrument returnto

PV/SV display mode.

PV

SV

5.2 Settingset value(SV)

Example: Followingis anexample ofset value(SV)to 200 C

(2)Shift of thedigit brightly lit (3) Numeric value change

Press the UPkey to set"2".

Pressing the UPkey increase

numerals, and pressingthe

DOWN key decrease

numerals.

PV

SV

PV

SV

PV

SV

(1)Set to theSV setting mode

In the normaldisplay mode

Press the SETkey to enterthe

SV setting mode.

The digit whichflashing

is settable.

Press the shiftkey to

shift the digitwhich lights

brightly up tothe hundreds

dights

Caution *Even if thedisplayed value ischanged, it isnot registered. To register it, press theSET key.

The setting proceduresare the sameas those ofexample (2) to(4) in theabove "Setting setvalue (SV)". Pressthe SETkey after the

setting end shiftsto the nextparameter. Whenno parameter settingis required, returnthe instrument to the PV/SV displaymode.

5.3 Settingparameters otherthan setvalue (SV)

Continued on the next page

TS80B-E1 3

5.5 InitialSetting (ParameterList)

Press the keywhile

pressing theSET key for 3s.

Press the keywhile

pressing theSET key

for 3 s.(Fig.3) Press theSET

key for 3s.

Press theSETkey.

Press the SETkey.

Press theSETkey. Press theSETkey.

Press theSETkey.

Press theSETkey. Press theSETkey. Press theSETkey.

Press theSETkey. Press theSETkey. Press theSETkey.

Press theSETkey.

Normal display Password mode Password mode

Input level

Setting the

password to 0101

Press theSET key.

Press the

SET key

Press the

SET key Press the

SET key Press the

SET key

0

1.0~200.0 seconds Relay contact output:20S

Voltage pulse(for SSR) :2S

Performs set datachange enable/disable.

20.0

or 2.0

Proportioning

cycle

Auto tuning

At) 0:ATend or cancel

1:ATstart or execution Use AT function toautomatically calculate andset the

optimize PID valuefor your system.

Turns theautotuning ON/OFF

0

Set data lock

(LCK) 0: Allparameters can bechanged

1: Only SVcan be changed

2: No parameterscan be changed

Symbol Name Setting range Description

#1: Factory setvalue

#1

Proportional

band 0.0~999.9 ON/OFF control ifset to 0(0.0)

ON/OFF action differential gap=HYS

20.0

Integral time 0~3600 seconds 150

Set the timeof integral actionto eliminate

the offsetoccurring in proportionalcontrol.

Derivative time 0.0~999.9 seconds

Set the time of derivative action to improve

control stability bypreparing for outputchanges.

30.0

PV/SV display mode

(Normal display)

INPUT LEVEL

PASS WORD

MODE

INPUT LEVEL

PASS WORD

MODE

The instrument returns to the PV/SV

display mode status if key operation

is not performed for more than 1 minute.

(Fig.3)

Input type

select

(InPt)

Alarm type

selection

(Ald)

Low setting

limiter

(LSPL)

Up setting

limiter

(USPL)

Proportional

reset

(rE)

PV follow-up

(SOFT)

Overshooting

turn off

(OFF)

Lowest value

of PV display

(PAL)

Highest value

of PV display

(PAH)

Decimal point

(dP)

Output

manipulated

variable

lowest limit

(OTL)

Output

manipulated

variable

highest limit

(OTH)

Setting the

password to 0101.

4TS80B-E1

Symbol Name Description

#1: Factory setvalue

#1

The followingparameter symbols aredisplayed one byone every timethe SETkey is pressed.

InPt Setting

-50 to1350 C

K

-50 to1000 C

J

-50 to 1750 C

S

-20 to1300 C

N

-20 to400 C

T

E

-50 to1000 C

**A: INPUTTYPE SYMBOLTABLE

Input type

Range

Main input typeselect

(InPt) Input type selectionas:thermocouple(TC),RTD,etc.

See **A "INPUTTYPE SYMBOLTABLE" K

Alarm type selection

(ALd) Select the typeof alarm1 andalarm 2

range:0~3 See **B "ALARM TYPETABLE" 3

Low setting limiter

(LSPL)

Lowest value of PV display

(PAL)

Highest value of PV display

(PAH)

Set lower pointwithin input

see 14. chapter"INPUT RANGETABLE" 0

Up setting limiter

(USPL) Set higher pointwithin input

see 14. chapter"INPUT RANGETABLE" 400

10

Proportional reset

(rE) Overshooting restricted bythe proportional effect.

2

3

0

5000

0

0

100

PV follow-up

(SOFT) PV variable-value control, Setting range: 0to 10

PV will responseslower if SOFTis bigger.

Output forced turningoff whenthe PV valueovershooting .

Setting range: 0to 100

Lowest valuedisplay when analog signal inputs,Such as 4-20mA input.

Highest value display when analogsignal inputs,Such as 4-20mA input.

The value of PV displaywhen input 4 mA. tandardanalog signalinput.Only for s

The value of PV displaywhen input 20mA. tandard analogsignal input.Only for s

Overshooting turn off

(OFF)

Only for standardanalog signal input(current or voltageinputs) .

Range:0~3

Decimal point

(dP)

Output manipulated variable

lowest limit (OTL)

Output manipulated variable

highest limit (OTH)

Output manipulated variable lowest limit .

Or lowlimit output calibrationwhentheoutput is continuous currentor

voltage,such as 4-20mAoutput. Range : 0to 100%

Output manipulated variable highest limit .

Or high limitoutput calibrationwhenthe outputis continuous current or

voltage,such as 4-20 mAoutput. Range: 0to 100%

50 to1800 C

BR

-20 to1750 C

W5Re/W26Re

0 to2300 C

InPt

-1999 to 9999 -1999 to 9999

0-5VDC 0-10VDC

**

**

-199 9to 9999 -199 9to 9999

1-5VDC 2-10VDC -1999 to 9999

DC0-20mA

-1999 to 9999

DC4-20mA

-199.9 to600.0 C

-50.0 to150.0 C

Pt100 Cu50

1 All input changein the abovegroups is possibleby keyboard,

except for 0to 10VDC and2 to 10VDC.

2 If you needthe 0 to10VDC & 2-10VDCinput type, pleaseexplain

when ordering.

Because the hardware

of these 2inputs are different.

*

After thevalue be registered,when no parametersetting is required,after the valuebe registered ,Pressthe SETkey for 3s to returnthe

instrument to thenormal display.

PVvalue

PVvalue

PVvalue

PVvalue

PVvalue

PVvalue

PVvalue

PVvalue

PVvalue

PVvalue

PVvalue

PVvalue

ALd=0

AL1 alarm mode(High alarm) AL2 alarm mode(Low alarm)

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

HIGH

LOW

LOW

LOW

LOW

LOW

LOW

LOW

LOW

LOW

LOW

LOW

LOW

AL1

AL1

AL2

AL2

SV+AL1

SV+AL1

SV+AL1

SV+AL1

AL1 0

AL1 0

AL2 0

AL2 0

AL1<0

AL1<0

ALd=1

SV-AL2

SV-AL2

SV-AL2

SV-AL2

AL2<0

AL2<0

ALd=2

ALd=3

HYS

HYS

HYS

HYS

HYS

HYS

HYS

HYS

HYS

HYS

HYS

HYS

**B: ALARMTYPE TABLE

Alarm code Alarm specification :SV :Alarm set value

ALd set value

SV

SV

SV

SV

SV

SV

SV

SV

AL1:Process alarm

AL1:Process alarm

AL2:Process alarm

AL1:Deviation alarm

AL1:Deviation alarm

AL2:Deviation alarm

AL2:Deviation alarm

AL2:Process alarm

AL1 Process highalarm

AL1 Process highalarm

AL2 Process lowalarm

AL2 Process lowalarm

Alarm1 ON

Alarm1 ON

Alarm1 ON

Alarm1 ON

Alarm1 ON

Alarm1 ON

Alarm2 ON

Alarm2 ON

AL1 Deviation highalarm

AL1 Deviation highalarm

AL2 Deviation lowalarm

AL2 Deviation lowalarm

AL2 Deviation lowalarm

AL2 Deviation lowalarm

AL1 Deviation highalarm

AL1 Deviation highalarm NOTE:

Alarm differential

gap=HYS,when

P 0(PID action)

TS80B-E1 5

NOV.2009.5,000(P)

R

8. INPUTRANGE TABLE

N

N

N

N

0

0

0

to

to

to

400

1000

1300

A4

A0

B3

N

0

to

800 A8

R

0

to

1750 B8

S

S

0

to

1000 A0

S

S

0

0

to

to

1600

1750 B6

B8

2 to 10VDC

V

A

A

09

03

02

4 to 20mA

0 to 20mA

or

to

9.999

-1.999

(*1) 0 to 400 : Accuracy is not guaranteed.

C

(*2)This input type cannot be selectedby keyboard. Because the hardware ofthe inputs

are different.

*1

*1 *1

*1

*1 *1

*1

*1 *1

*1

*2

*2

*1

*1

K

K

K

K

K

K

K

K

0

0

0

0

0

0

0

to

to

to

to

to

to

100

200

400

600

1000

1300

1350

A1

A2

A4

A6

A0

B3

B4

K

0

to

800 A8

to

J

J

J

J

J

J

0

0

0

0

0

to

to

to

to

100

200

300

400

600

A1

A2

A3

A4

A6

J

J

0

0

to

to

800

1000 A8

A0

to

B

B

50

to

1300 B3

B

50

to

1800 B8

R

R

R

0

0

to

600

1000 A6

A0

R

0

to

1300 B3

to

0

0

to

to

800

1000 A8

A0

E

E

E

E

E

E

E

E

E

0

0

0

0

0

0

to

to

to

to

to

100

200

300

400

500

600

A1

A2

A3

A4

A5

A6

to

T

T

T

T

0

0

0

0

to

to

to

100

200

300

400

A1

A2

A3

A4

to

T

T

T

T

0

0

0

to

to

to

1600

2000

2300

B6

B0

C3

W5Re/

W26Re

C

C

C

0.0

to

to

to

50.0

100.0

150.0

D5

D1

D2

0.0

0.0

C

C

-50.0

to

to

+50.0

+100.0 C5

C1

-50.0

C

-50.0

to

+150.0 C2

CU50

Pt100

D

D

D

D

0.0

to

to

to

to

100.0

200.0

300.0

400.0

D1

D2

D3

D4

0.0

D

D

to

to

500.0

600.0 D5

D6

0.0

0.0

D

D

D

to

to

to

+200.0

+100.0

+100.0 E2

F1

E1

-199.9

-100.0

-199.9

D

to

+200.0 F2

-100.0

0.0

0.0

D

to

+50.0 G0

-50.0

D

D

D

to

to

to

+100.0

+600.0

+200.0 G1

E6

G2

-50.0

-199.9

-50.0

0 to 5VDC

0 to 10VDC

1 to 5VDC

V

03

V

V

04

08

to

9999

-1999

or

to

99.99

-19.99

to

999.9

-199.9

or

Overscale and Underscale

Error display

Requirements forATstart

Autotuning (AT) start

Requirements forATcancellation

7.ERROR DISPLAYS

!

Toprevent electric shock,always turn

off thepower before replacingthe

sensor.

Measured value(PV)

[Flashing] PV is outsideof input range

Overscale:

PV is abovethe high inputdisplay range limit.

RAM failure(Incorrect setdate write or check sensor and

sensor connection,etc.)

Underscale:

PV is belowthe low inputdisplay range limit.

WARNING

[Flashing]

[Flashing]

[Flashing]

Check input type,input range, sensor

and sensor connection..

Turn offthe poweronce. Ifan error occurs

after the power is turned on again, please

contact TESHOW sales officeor the agent.

6 PIDAUTOTUNING (AT) FUNCTION

Autotuning (AT) automatically measures,calculates and setsthe

optimum PID.The following conditionsare necessary tocarry out

autotuning and theconditions which willcause the autotuningto

stop.

Start the autotuningwhen all followingconditions are satisfied:

(1) Prior tostarting theATfunction, end allthe parameter settings

other than PID.

(2) Confirm theLCK function hasnot been engaged.

The autotuning iscanceled if anyof the followingconditions exist.

(1) When the is changed.

(2) When thepower is turnedoff.

(3) When powerfailure longer than20ms occurs.

parameter "AT "value

When the autotuningis finished, thecontroller will

automatically return toPID control.

Caution for usingthe Autotuning(AT)

When a temperaturechange(UP and/orDown) is 1 or less

per minute duringAutotuning,Autotuning may becancelled

before calculating PIDvalues. In thatcase, adjust thePID

If theATis canceled, thecontroller immediately changesto

PID control.The PID valueswill be thesame as beforeAT

was activated.

When AT iscompleted, the controllerimmediately changes to

PID control. Ifthe control systemdoes not allowthe AT cycling

process, set eachPID constant manuallyto meet theneeds of

the application.

values manually. It ispossible to happenwhen the setvalue

is around theambient temperature oris close tothe maximum

temperature achieved bythe load.

1) Press the"SET" key for3 seconds to PID level.

2) Looking forthe parameter "AT ".

3) Set "AT" value from0 to 1.

4) Press the"SET" key startauto tuning.

5) Press the"SET" key for3 seconds toreturn to

(If AT bestarted ,theATlamp will belighted on and the lamp is

flashing)

the instrument to

the PV/SV displaymode.

ON OFF ON OFF

PV PV

SV

Time

100%

0%

Output %

ON/OFF control

(Autotuning) PID control

(After autotuning

6

TS80B-E1

Input type Input type

Input type

Input type

Input type

Input type

Input type

Input type

Input type

Input type

Input type

Input type

Code Code

Code

Code

Code

Code

Code

Code

Code

Code

Code

Code

AN THAI CORPORATION

TESHOW ELECTRONIC TECHNOLOGYCO., LTD.

This manual suits for next models

4

Table of contents

Popular Controllers manuals by other brands

A10

A10 Harmony Controller 2000 installation guide

Contemporary Controls

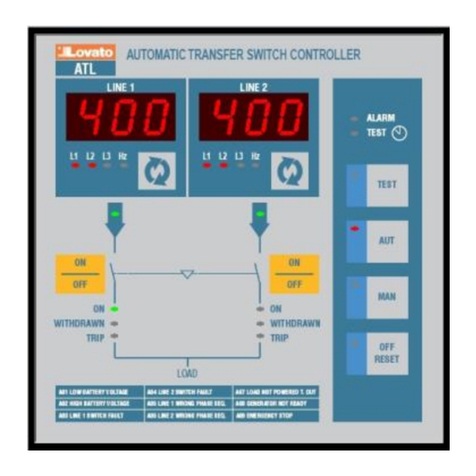

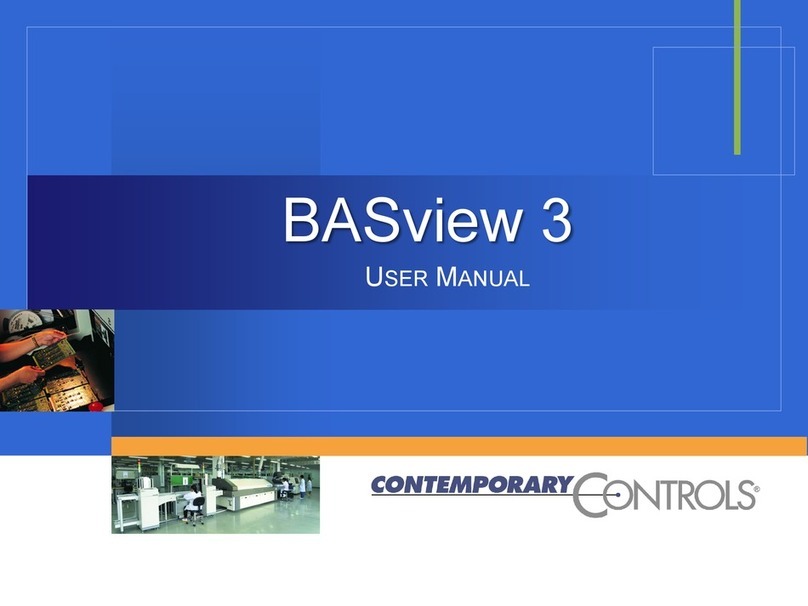

Contemporary Controls BASview 3 user manual

NuWhirl

NuWhirl TOUCHSTONE CSLC-317-02-01-01 Installation & operating manual

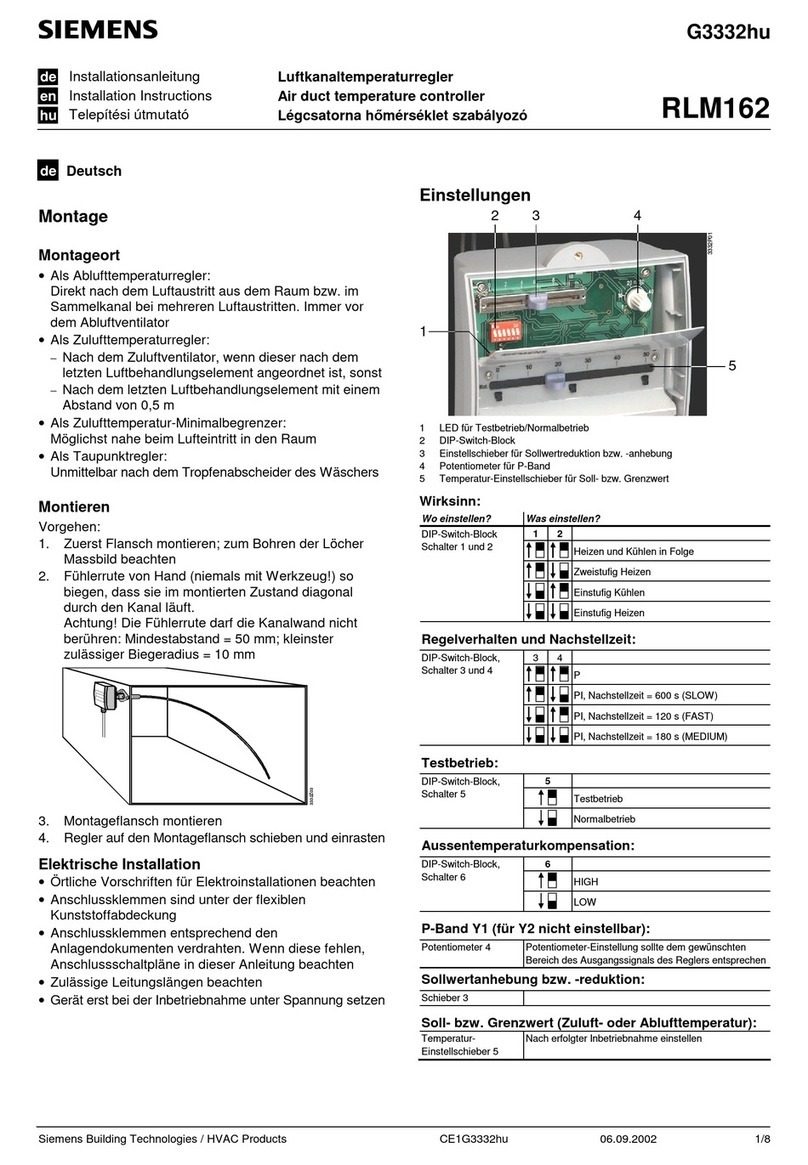

Siemens

Siemens RLM162 installation instructions

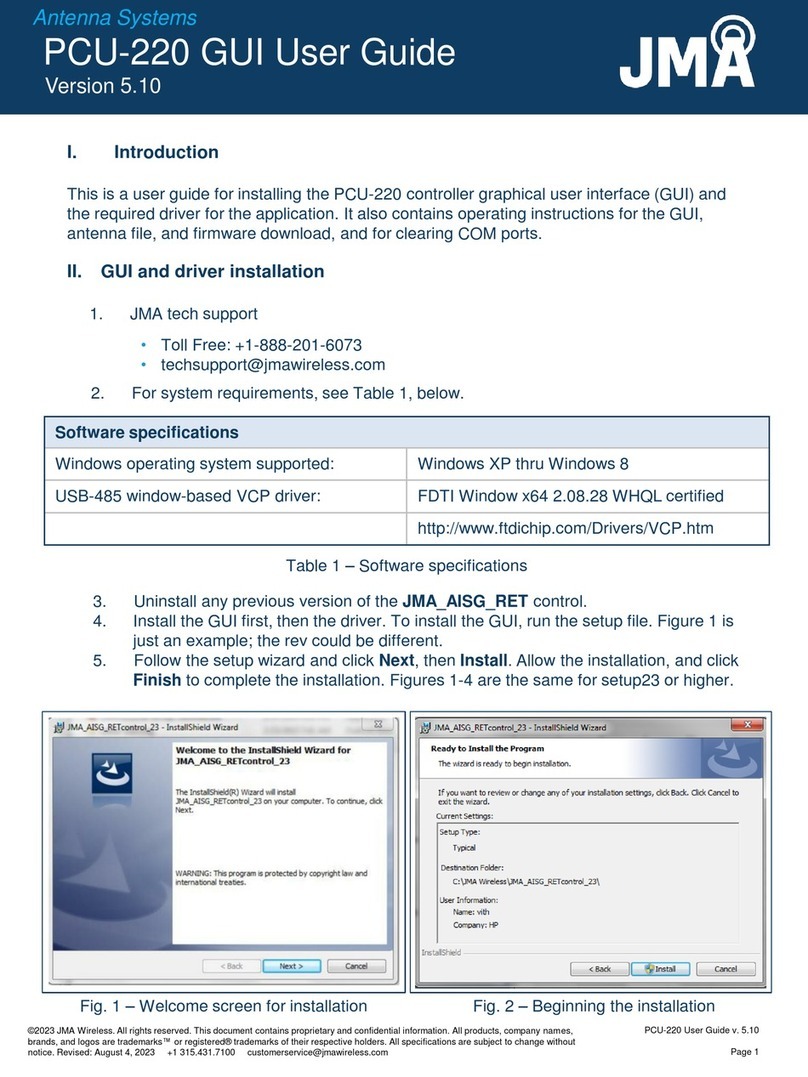

JMA

JMA PCU-220 GUI User Guide

Swagelok

Swagelok RS Series user manual