Content

3

Content

1Declaration of Warranty ............................................................................................... 5

1.1. Type of Designation .......................................................................................................................5

1.2. Manufacturer ................................................................................................................................5

1.3. Warranty .......................................................................................................................................5

2Precautions ................................................................................................................... 5

2.1. Foreword.......................................................................................................................................5

2.2. Liabilities .......................................................................................................................................5

2.2.1. Liability to Content...............................................................................................................6

2.3. Copyright ©...................................................................................................................................6

3Safety ............................................................................................................................ 6

3.1. Risk Types......................................................................................................................................6

3.1.1. Aerosol Contamination.........................................................................................................6

3.1.2. Hot Surfaces –Burn Hazards.................................................................................................6

3.1.3. Electrical Safety.................................................................................................................... 6

3.1.4. Mechanical Shock.................................................................................................................6

3.2. Labels and Explanations.................................................................................................................7

4System Overview........................................................................................................... 8

4.1. Dilution and Conditioning .............................................................................................................. 8

4.1.1. Principle...............................................................................................................................8

4.1.2. ThermoDilution....................................................................................................................8

4.2. Definitions ..................................................................................................................................... 9

4.3. Abbreviation, Units and Symbols.................................................................................................... 9

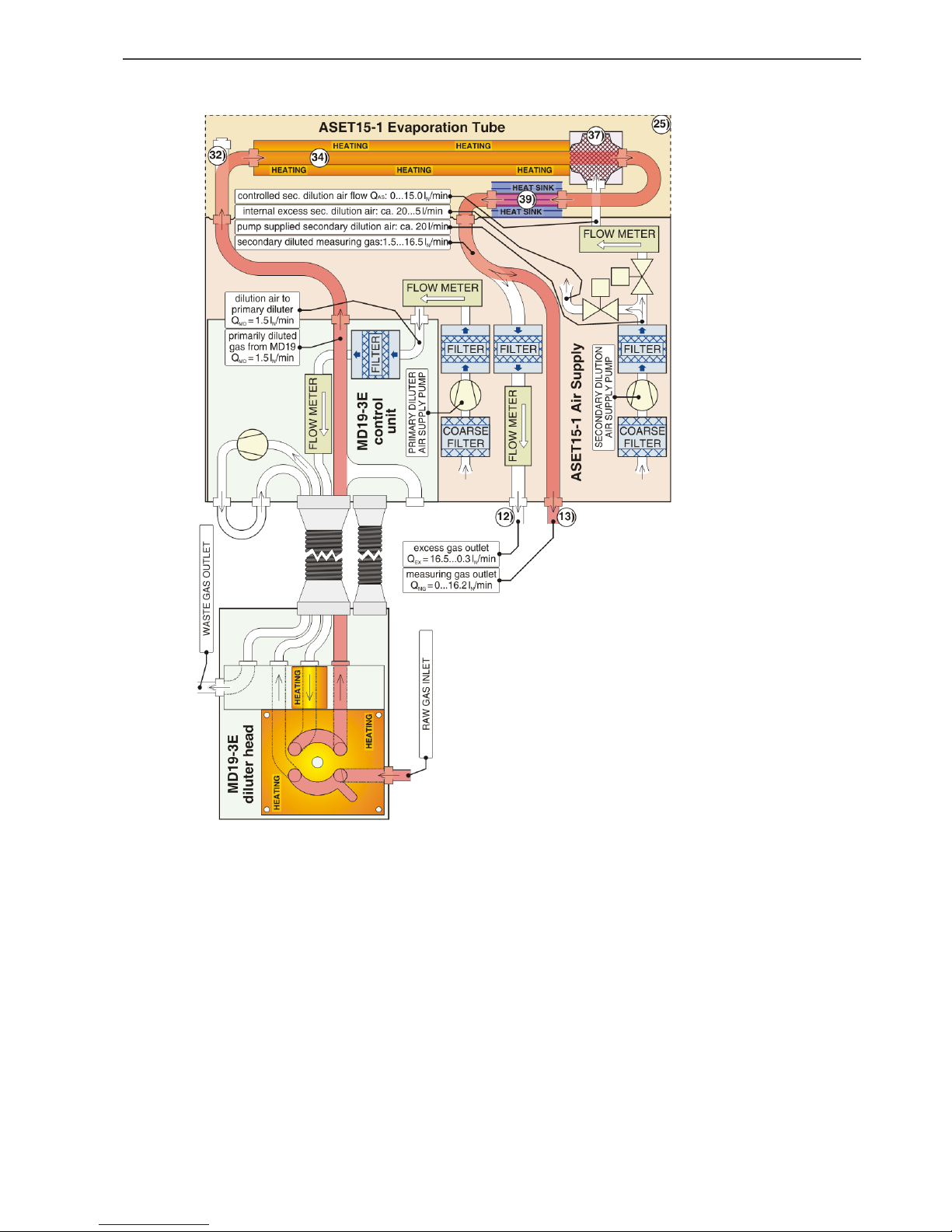

4.4. The System .................................................................................................................................. 10

4.5. Control Elements and Connections............................................................................................... 11

4.5.1. Important Remarks ............................................................................................................ 11

4.5.2. Front View ......................................................................................................................... 11

4.5.3. Gas Connectors.................................................................................................................. 12

4.5.4. Rear View........................................................................................................................... 13

5Installation and Setup ................................................................................................. 14

5.1. Integrating testo MD19-3E into the testo ASET15-1...................................................................... 14

5.2. Gas/Aerosol Connections............................................................................................................. 15

5.2.1. Quick Couplings at the front of testo ASET15-1................................................................... 15

5.2.2. Connect a Sensor to the Measuring Gas Inlet of the Evaporation Tube................................ 15

6Operating Instructions ................................................................................................ 16

6.1. Start Up....................................................................................................................................... 16

6.2. Evaporation Tube Heating Up Procedure...................................................................................... 16

6.3. Flows and Control LED's in Air Supply Part.................................................................................... 17

6.3.1. Signal LED Information ....................................................................................................... 18

6.3.2. Flow Settings and Dilution Factors...................................................................................... 18