Testomat 808 User manual

1

Testomat® 808

Online Analysis Instrument

for Water Hardness

Operating Instructions

Content

2

Content

Content.................................................................................................2

Important safety information .............................................................4

Intended use .........................................................................................4

Qualification of the staff ........................................................................4

Warning notices in these instructions ...................................................5

Notes and instructions to be observed ............................................5

General instructions..............................................................................5

Installation.............................................................................................6

Operation ..............................................................................................6

Cleaning................................................................................................6

De-installation .......................................................................................6

Disposal ................................................................................................6

Operating requirements........................................................................7

Scope of delivery ................................................................................7

Performance specifications...............................................................8

Indicators for Testomat® 808 instruments.............................................8

Functions of the operating and display elements...........................9

Switching Testomat® 808 on/off............................................................9

Front view Testomat® 808.....................................................................9

Operating elements/Function keys .....................................................10

Display elements/LEDs.......................................................................11

Installation.........................................................................................12

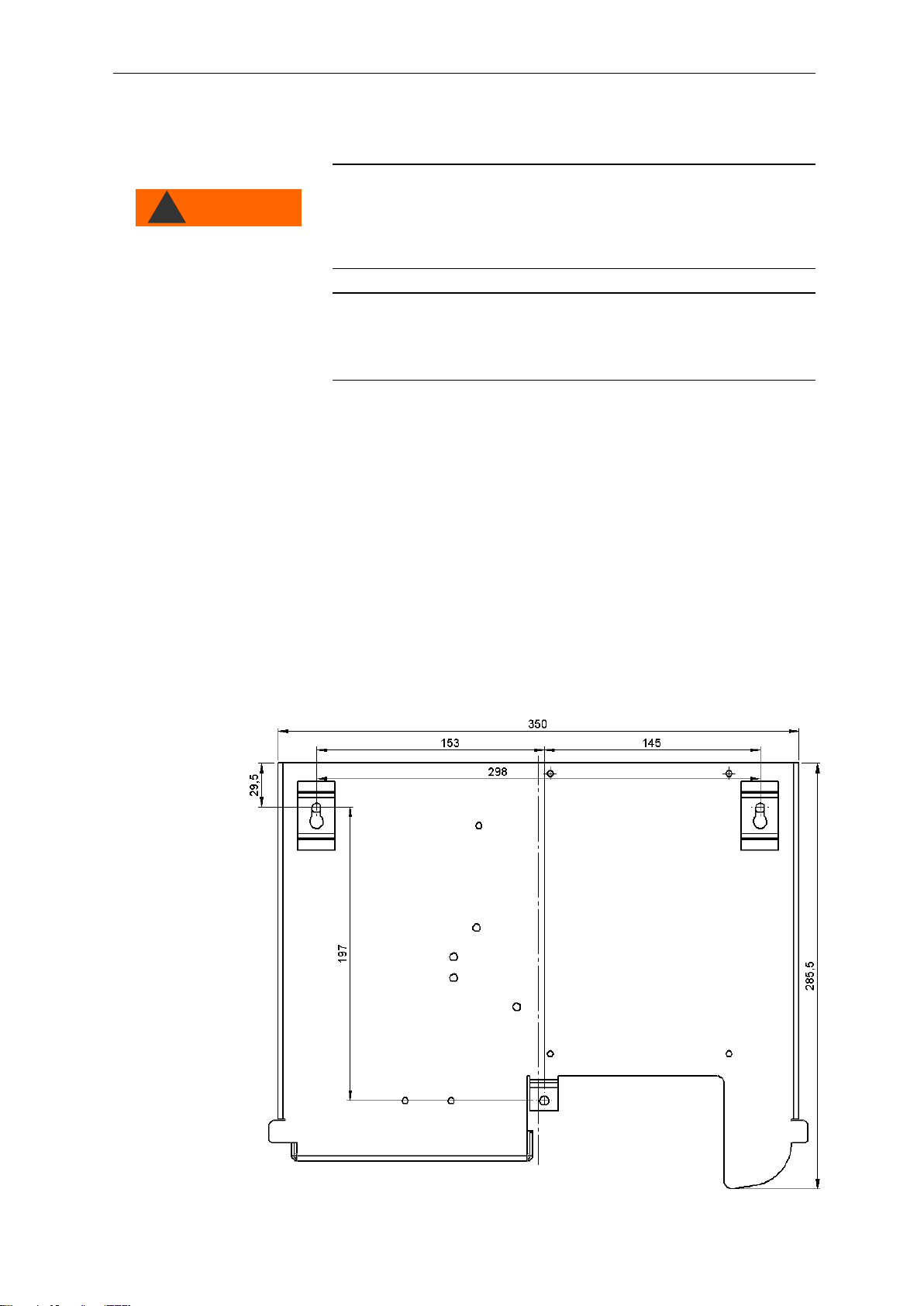

Installing Testomat®808.....................................................................12

Operating Testomat®808 in the pressure range 4 to 8 bar................12

Connecting the water inlet and outlet .................................................13

Water inlet...........................................................................................13

Water outlet.........................................................................................14

Connecting the power supply and devices .........................................14

Plant example Testomat® 808.............................................................15

Internal design Testomat®808............................................................16

Rear of the controller board................................................................16

Reset key S1.......................................................................................16

Function key S6 ..................................................................................16

Function key S7 ..................................................................................16

Slide switch T1....................................................................................17

Slide switch T2....................................................................................17

Plug connector J1 ...............................................................................17

Plug connector J2 ...............................................................................17

Plug connector J3 ...............................................................................17

Base circuit board Testomat®808 ......................................................18

Plug connector J2 ...............................................................................18

Plug connector J8 ...............................................................................18

Current interface .................................................................................18

Inputs DEL. EXT. and STOP ..............................................................19

Terminal block.....................................................................................19

Fuses ..................................................................................................19

Content

3

Connecting the mains voltage.............................................................20

Connecting the inputs and outputs .....................................................21

Description of the signal inputs......................................................23

Interfaces...........................................................................................23

Current interface .................................................................................23

Serial interface RS232........................................................................24

Description of the relay outputs......................................................24

Relay K3 –fault message...................................................................24

Relays K1 and K2 ...............................................................................24

Switching functions of the relays K1 and K2.......................................24

Commissioning.................................................................................26

Inserting the indicator bottle................................................................26

Bleeding the indicator lines.................................................................26

Opening the water inlet.......................................................................26

Instrument settings and analysis....................................................27

Instrument settings..............................................................................27

Selecting the indicator type and bottle size ........................................28

Carrying out an analysis .....................................................................28

Analysis process.................................................................................29

Further basic functions and settings..............................................30

Internal flushing...................................................................................30

External flushing .................................................................................30

Flush process –internal/external in manual mode.............................30

Interval pause .....................................................................................31

72 h operation (operation without permanent supervision) ...............32

Error messages/Troubleshooting ...................................................32

Alarm/Error message/Relay K3 ..........................................................32

Low water level ...................................................................................35

Measuring fault analysis .....................................................................35

Further possible instrument errors......................................................35

Maintenance ......................................................................................36

Service instructions.............................................................................37

Description of maintenance work........................................................37

Replacing the indicator bottle..............................................................37

Cleaning the measuring chamber and the sight-glass windows.........38

Pump head maintenance message ....................................................39

Testomat® 808 spare parts and accessories..................................41

Accessories - indicators......................................................................42

Technical data...................................................................................43

EC conformity Declaration..................................................................44

Product overview Testomat 2000®-Instruments ............................45

Important safety information

4

Important safety information

Please read these operating instructions carefully and completely

prior to working with the instrument.

Ensure that these operating instructions are always available for all

users.

These operating instructions must always be passed on to the new

owner should Testomat®808 change hands.

Always adhere to hazard warnings and safety information when

using reagents, chemicals and cleaning agents. Please adhere to

the respective safety data sheet! Download the safety data sheets

for the supplied reagents at http://www.heyl.de .

Intended use

Testomat®808 has been designed for use in the field of water treat-

ment (e.g. osmosis plants, electroplating, large boiler plants, laun-

dries, canteen kitchens). The feed water must be clear, colourless

and free of undissolved particles. The instrument is a limit value

measuring instrument which automatically monitors the residual total

hardness (water hardness) in water.

Always adhere to the performance limits stated in the section enti-

tled “Technical data”on page 43.

Always observe the application areas/application limits of the indi-

cators and the requirements of the medium being measured.

To ensure correct and intended usage, always read and understand

these instructions, especially the section entitled “Important safety

information”, prior to use.

The instrument is not used as intended if

it is used in areas not specified in these instructions.

it is used in areas which do not correspond to the ones described

in these instructions.

Qualification of the staff

Assembly and commissioning require fundamental electrical and

process engineering knowledge as well as knowledge of the respec-

tive technical terms. Assembly and commissioning should therefore

only be carried out by a specialist or by an authorised individual su-

pervised by a specialist.

A specialist is someone who due to his/her technical training, know-

how and experience as well as knowledge of relevant regulations can

assess assigned tasks, recognise potential hazards and ensure ap-

propriate safety measures. A specialist should always adhere to the

relevant technical regulations.

Notes and instructions to be observed

5

Warning notices in these instructions

The warning notices in these instructions warn the user about poten-

tial dangers to individuals and property resulting from incorrect han-

dling of the instrument. The warning notices are structured as follows:

Description of the type or source of danger

Description of the consequences resulting from non-observance

Preventive measures. Always adhere to these preventive

measures.

“DANGER” indicates an immediate hazardous situation which, if not

avoided, will result in death or serious injury.

“WARNING” indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

“CAUTION” indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injuries or property dam-

age.

“NOTE” indicates important information. If this information is not ob-

served, it may result in an undesirable result or state.

Notes and instructions to be ob-

served

General instructions

Adhere to health and safety regulations, electrical equipment safe-

ty regulations, and environmental protection regulations valid in the

country of use and at the installation site.

Adhere to national and local regulations during installation and

commissioning.

Always protect the instrument against moisture and humidity. It

should never come into contact with condensation or splash water.

Do not carry out any changes or modifications at the instrument

which are not described in these instructions;

failure to adhere to

these instructions will negatively affect any warranty claims that

you make thereafter

.

WARNING

!

WARNING

!

NOTE

CAUTION

!

DANGER

!

SIGNAL WORD!

Notes and instructions to be observed

6

Installation

Always completely disconnect the relevant plant part before in-

stalling the instrument or connecting/disconnecting it to/from the

power supply. Secure the plant against reconnection.

Only connect the instrument to the mains voltage specified on the

rating plate.

Always observe technical data and ambient parameters.

Testomat®808 requires an interference free and stable power

supply. If necessary, use a mains filter to protect Testomat®

against interference voltages caused, e.g., by solenoid valves or

large motors. Never lay connecting cables parallel to power cables.

Operation

Ensure that the maximum electrical load capacity of the relay out-

puts is never exceeded.

Immediately switch off Testomat®808 and contact service staff if

malfunctioning occurs. The warranty will be void if you tamper with

or attempt to repair Testomat® 808. Repairs must be carried out by

authorised service staff.

Cleaning

Only use a dry, lint-free cloth for cleaning.

De-installation

Prior to de-installing a defective instrument, always write down a

description of the error (failure effect). It is only possible to repair a

defective instrument (irrespective of the warranty period) if it has

been de-installed and returned to us with a description of the error.

Use to the enclosed error log to describe the error and return it to

us together with the instrument. If the error log is no longer availa-

ble, download it at www.heyl.de.

Disposal

Dispose of the instrument in accordance with national regulations.

WARNING

!

NOTE

Scope of delivery

7

Operating requirements

In order for Testomat®808 to operate reliably, use Heyl Tes-

tomat®indicators in the pH-range 4 –10.5!

Only operate the instrument with the parameters specified under

“Technical data”.

With Testomat®instruments for water hardness monitoring, larger

quantities of heavy metal ions in the softened water might influ-

ence the colour reaction, especially iron above 0.5 mg/I, copper

above 0.1 mg/I and aluminium above 0.1 mg/l (brownish-red col-

our display).

If the measuring water contains more than 20 mg/I CO2(carbonic

acid), incorrect evaluations cannot be excluded. In this case, use

an aerator (e.g. special Heyl accessories).

The concentration of influencing contents can be determined by

using our colorimetric TESTOVAL®test kit

Important! Excessive carbonate hardness and also the ex-

istence of disinfectants in the water can result in erroneous

evaluations.

Careful handling of the instrument increases both its operational

reliability and service life! Therefore, carry out a visual inspection

at regular intervals as described below:

- Has the use-by-date of the indicator expired?

- Are the hose connections of the dosing pump free of leaks?

- Is there any air inside the dosing hoses?

- Are all the water connections free of leaks?

- Are the doors of the instrument closed properly?

- Is the instrument heavily soiled?

- Are the measuring chamber and the drain duct/drain hose

clean?

Trouble-free operation is only possible when maintenance is car-

ried out on a regular basis! For more information, please refer to

the section entitled “Maintenance”on page 36.

If problems occur, please refer to the section entitled “Error mes-

sages/Troubleshooting”on page 32.

Scope of delivery

1x Testomat® 808

1x plastic bag containing a screw cap with a hole and an insert for the

screw cap of the indicator bottle

2x fuse

1x operating instructions

Special accessories (available separately): Filter inlet, candle filter as

well as pressure regulator

Required hose connections and supply lines for Testomat® 808 are

available from Heyl.

NOTE

CAUTION

!

Performance specifications

8

Performance specifications

Testomat®808 is used for the automatic monitoring of residual total

hardness (water hardness) in water. The limit value to be monitored

is determined by the indicator selection.

Limit values for residual hardness of 0.02 –10.0 °dH* deter-

minable by indicator selection

Analysis start:

- Automatic interval mode

(interval pause can be set from 0 –60 minutes)

- External control

- Manual start

Extended operating periods due to 500 ml indicator storage

bottle

RS232 interface for optional firmware update

Indicators for Testomat® 808 instruments

Indicators with various limit values are available for the application of

Testomat®808 instruments according to operational requirements.

Indicator

type

Monitoring

range

Limit value LEDs

(good/poor display)

Measuring result

(information on water quality)

300 –330

Residual hard-

ness

0.02 –10 °dH

“GOOD” green

Residual hardness < indicator limit

value

“POOR” red

Residual hardness > indicator limit

value

All indicator types are available in two bottle sizes (100 ml and

500 ml). Please refer to the section entitled “Testomat® 808 spare

parts and accessories” on page 41 for a detailed list of the individual

indicator types with the respective article numbers.

Functions of the operating and display elements

9

Functions of the operating and dis-

play elements

Operating statuses and measuring results are displayed at Testomat®

808 via LEDs. The input keys for operating the instrument are posi-

tioned below the LEDs.

Switching Testomat® 808 on/off

(1) Power switch

Switch the instrument on/off using the green power switch (after

opening the housing cover on the front of the instrument).

(2) Instrument fuse (internal)

These fuses protect Testomat® 808 and the outputs against over-

loads and short circuits.

DPlease refer to the sections entitled “Fuses”on page 19 and

“Error messages/Troubleshooting” on page 32 for descriptions of

the fuses.

Front view Testomat® 808

Functions of the operating and display elements

10

Operating elements/Function keys

All operating elements/function keys are assigned twice. The respec-

tive function is triggered by a short or long (min. 2 seconds) key

press.

Key 1

(manual)

Short key press: Starts an analysis (manual start),

the respective LED flashes.

Long key press: Switches the dosing pump for bleed-

ing the pipes on/off. The LED illuminates while the

pump is running.

Key 2

(flushing)

Short key press*: Switches the internal flush valve

on/off, the respective LED flashes as long as the

valve is open.

Long key press*: Activates an external flush valve via

relay K1 (on/off). The LED above key 2 and LED K1

illuminate as long as the external valve is activated.

Key 3

(standby)

Short key press: Switches the standby function

on/off. The respective LED flashes if standby is ac-

tive.

Long key press: The respective LED displays wheth-

er operation is possible for longer than 72 h (opera-

tion without supervision).

Key 4 (horn)

Short key press: Acknowledges current er-

rors/alarms.

Long key press: Sets the indicator display from 0% to

100% (the LEDs 10% to 90% illuminate).

Note: It is not possible to enter any indicator level.

* only in standby mode

Functions of the operating and display elements

11

Display elements/LEDs

All measuring results as well as activated functions are displayed at

Testomat®808 via LEDs.

The LEDs above the function keys illuminate/flash when the respec-

tive function is activated.

The LED illuminates if the instrument is switched

on via the power switch on the front of the instru-

ment and is operating.

Limit value LEDs (red/green) for displaying the

measuring result:

Limit value not achieved => green LED illuminates

Limit value exceeded => red LED illuminates

When a new measuring is running, the result of

the previous measurement flashes.

The LEDs K1 and K2 display the status of the

relays. They illuminate if the respective relay has

been switched (also see the section entitled

“Switching functions of the relays K1 and K2” on

page 24)!

10% –90%: These LEDs display the calculated

filling level of the indicator bottle (also see the

section entitled “Measuring fault analysis” on page

35).

E4 –E1: These LEDs display current errors after

simultaneously pressing key 3 and key 4 for ap-

prox. 2 seconds (also see the section entitled

“Error messages/Troubleshooting” on page 32).

E4 flashes: The pump head has been in operation

for 150 hours and must be replaced (also see the

section entitled “Pump head maintenance mes-

sage”on page 39)

Cancelling error messages/warning messages

Press key 4 to acknowledge the messages and,

if necessary, eliminate the cause of the fault.

NOTE

red

green

Installation

12

Installation

Risks resulting from incorrect installation!

Install Testomat® 808 at a location where it is protected against

dripping or splash water, dust and aggressive substances –e.g. in

a control cabinet or on a suitable wall.

Information for trouble-free operation

Install Testomat® 808 vertically and without mechanical stress.

Install Testomat® 808 at a vibration-free site.

Installing Testomat®808

Select an installation site where the water inlet hose can be kept as

short as possible (max. 5 m).

Drill the mounting holes as shown in the drawing below.

Use three screws to attach the instrument at a suitable position on

the wall.

NOTE

WARNING

!

Installation

13

Operating Testomat®808 in the pressure

range 4 to 8 bar

Prior to installation, please check whether a higher operating pres-

sure (between 4 and 8 bar) is required. Use a pressure controller (art.

no. 37602) for ranges between 4 and 8 bar. Optimum operation of

Testomat®808 is achieved with operating pressure of between 2 and

4 bar.

Information for trouble-free operation

The water pressure must be between 1 and 8 bar; a pressure re-

ducer should be used for the 4 to 8 bar range (special accesso-

ries). This pressure regulator must be set under flow pressure!

Avoid strong pressure fluctuations.

Connecting the water inlet and outlet

Information for trouble-free operation

Ensure there are no foreign particles bigger than 150 µm which

caused blocking. Use our candle filter (Art. No. 37583) at the front

end of the device if you have problems with blocking.

The measuring water temperature must be between 10°C and

40°C.

For water temperatures above 40°C, install the KCN type cooler in

the supply line of Testomat®808.

Water inlet

The measuring water is taken from the main water line of the water

treatment plant and fed to the inlet connection of Testomat®808. The

instrument is equipped with a plug connector for plastic hoses 6/4 x 1

(external diameter 6 mm/ internal diameter 4 mm, wall thickness 1

mm) as standard).

Install the connection for the branch line of Testomat®808 directly

at the main water line directly after the water treatment plant.

Always lay the branch line connection vertically upwards in order to

prevent dirt particles from entering the instrument from the main

water line.

We recommend you to install a manually operated stop valve (see

figure “Plant example Testomat® 808” on page 15) in the branch

line to Testomat®808.

Use an opaque plastic hose 6/4 x 1 (max. length 5 m) for the water

inlet .

Flush the supply line to remove any dirt particles.

Outlet

Inlet

NOTE

Installation

14

When using a cooler

The hot water can cause burns and damage wetted parts of

Testomat® 808.

Water outlet

The feed water flows through the measuring chamber to the drain via

the outlet hose.

Remove the red plug from the outlet connection.

Connect the outlet connection of Testomat®808 to an outlet hose

(internal diameter 4 mm).

Feed the hose to an outlet.

Transportation plug!

The outlet is sealed with a plug to prevent leakage during transporta-

tion. Keep and store the plug for possible transportation at a later

date.

Connecting the power supply and devices

Risk of electric shocks during installation!

If the power supply is not disconnected prior to installation, it may

result in personal injuries, destruction of the product or damage to

plant parts.

Always disconnect the relevant plant parts before installing Tes-

tomat® 808.

Only use tested cables with sufficient cross-sections for the con-

nections.

Risk of damages caused by electromagnetic fields!

If Testomat® 808 or the connecting cables are installed parallel to

power cables or in close proximity to strong electromagnetic fields,

the instrument may be damaged or measurements incorrect.

Ensure that connecting cables are as short as possible.

Always install connecting cables and power cables separately.

Connect the instrument to the protective earth conductor (for

230/115 VAC).

Shield the instrument against strong electromagnetic fields.

CAUTION

!

WARNING

!

NOTE

NOTE

Installation

15

Plant example Testomat® 808

Installation

16

Internal design Testomat®808

Rear of the controller board

Keys 1 to 4 are located at the front of the board. Please refer to the

section entitled “Functions of the operating and display elements”on

page 9 for a detailed description of its operating system and the dis-

play elements.

The following function keys and slide switches as well as plug con-

nectors are also provided:

Reset key S1

Use reset key S1 to execute a reset, i.e. to reset the firmware of

Testomat®808 after an update.

Function key S6

Use function key S6 to set the interval pause between measure-

ments. Please refer to the section entitled “Interval pause” on page

31 for an overview of possible switching positions and interval paus-

es. (The standard setting is 3.)

Function key S7

Use function key S7 to set the switching behaviour of the relays

K1 and K2. Please refer to the section entitled “Switching functions of

the relays K1 and K2” on page 24 for an overview of possible switch-

ing positions. (The standard setting is 3.)

S7

S6

Installation

17

Switch position

The respective switch position is read after evaluating a measuring

result and after a reset.

Slide switch T1

Switch position LEFT: If the slide switch is in the left position

and the instrument is switched on or the reset key pressed while the

instrument is switched on, the microcontroller executes the operating

program (firmware).

Switch position RIGHT: If the slide switch is in the right position

and the instrument is switched on or the reset key pressed while the

instrument is switched on, the instrument is set to a mode which ena-

bles a firmware update via the serial interface.

If your instrument requires a firmware update, Heyl will provide you

with further detailed information.

Switch position

The switch position is only read immediately after a reset.

Slide switch T2

Use the slide switch T2 to determine the size of the indicator bot-

tle. The following indicator bottle sizes are possible:

Indicator

Switch position

100 ml bottle

Left

500 ml bottle

Right

Switch position

The status of the slide switch T2 is read after resetting the indicator

display to 100% and after a reset.

Plug connector J1

The plug connector J1 is a programming interface. It is not im-

portant for instrument operation.

Plug connector J2

The connection to the base circuit board is established via the plug

connector J2 using a ribbon cable.

Plug connector J3

The connection to the RS232 interface is established via the plug

connector J3 using a ribbon cable. Please refer to the section

entitled “Serial interface RS232” on page 24 for a detailed descrip-

tion.

NOTE

Switch position right

(delivery status)

NOTE

Switch position left

(delivery status)

NOTE

!

Installation

18

Base circuit board Testomat®808

The illustration above provides an overview of the design of the base

circuit board.

Plug connector J2

The connection to the controller board is established via the plug

connector J2 using a ribbon cable.

Plug connector J8

The power switch is connected at plug connector J8 .

Current interface

Please refer to the section entitled “Interfaces”on page 23 for a de-

scription of the current interface .

Installation

19

Inputs DEL. EXT. and STOP

Please refer to the section entitled “Description of the signal inputs”

on page 23 for a description of the inputs “Delete externally” and

“Stop”.

Terminal block

Please refer to the sections entitled “Connecting the mains voltage”

on page 20 and “Connecting the inputs and outputs” on page 21 for a

description of the terminal block .

Fuses

The following fuses can be found on the base circuit board.

No.

Designation

Function

Comment

F1

Relay protection fuse

4 A

F2

Primary fuse

230 V / 0.1 A

115 V / 0.2 A

24 V / 1 A

F3

Secondary fuse

1 A

Please refer to the section entitled “Testomat® 808 spare parts and

accessories” on page 41 for the article numbers when reordering fus-

es.

Installation

20

Connecting the mains voltage

Only connect the instrument to the specified mains voltage. Refer to

the rating plate for the appropriate mains voltage. Connect the cables

as follows:

Open the housing cover and subsequently loosen the two fas-

tening screws at the top and bottom of the door to the interior of

Testomat® 808. The door can now be opened and the terminal box

accessed.

Feed the cable through one of the cable glands underneath the

housing into the terminal box.

Feed the cable through one of the cable glands underneath the

housing into the terminal box.

Subsequently pull back the cable until the bush has been turned

over (2).

Connect the power supply to the terminals PE, N, L.

To do so, insert the conductors into the round cable input at the

terminal block. Ensure that the strands are held securely in the

terminals.

To loosen the connection, insert a screwdriver into the square

opening without force in order to open the terminal. Once the ter-

minal has been opened, remove the conductor.

Terminal

description

Type

Function

Comment

PE

IN

Mains protective earth (4x)

Only with mains

115/230 V !

N

(U)

L

(V)

IN

Mains, N=neutral (U=24 V)

Mains, L=live (V=24 V)

Mains input 50-60 Hz

24 V / 115 V / 230 V

n

l

OUT

Neutral, switched (3x)

Live, switched (3x)

Mains for consumers,

max. 4 A

Table of contents

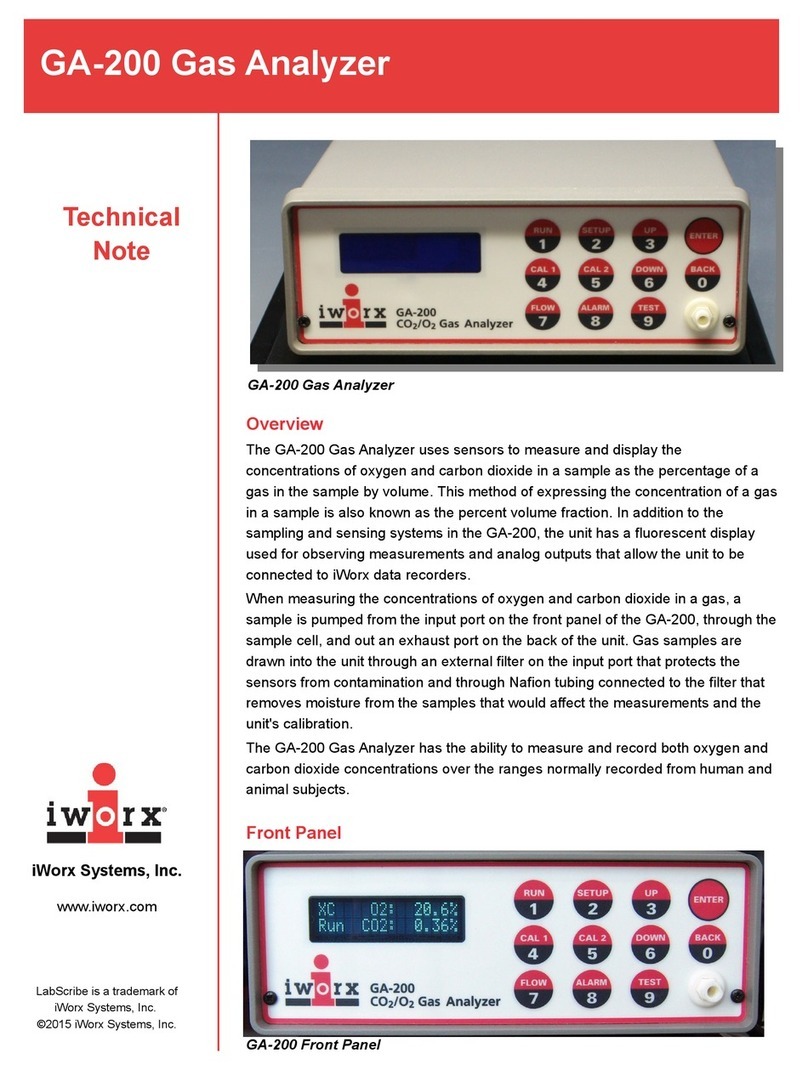

Popular Analytical Instrument manuals by other brands

Fluke

Fluke 434 user manual

Teledyne

Teledyne T802 Operation manual

iWorX

iWorX GA-200 Series Technical note

Enotec

Enotec OXITEC 5000 Series Installation and operation manual

ANALOX

ANALOX O2 Portable Operator's manual

Bühler technologies

Bühler technologies GAS 222.31 Ex2 Installation and operation instruction