Tetra Pak Hoyer Dino C User manual

DIN806B

Wehopetheinformationcontainedinthismanualwill

beofusetoyou.Itisbasedonconcretedataandon

the best of our current knowledge. Please read this

manual carefully, including all warnings and

recommendations. No part of this manual may be

reproduced or transmitted to a third party without

thepriorwrittenpermissionofTETRAPAKHOYER.

Tetra Pak

Hoyer

Tetra Pak Hoyer ApS Tetra Pak Hoyer Inc. Tetra Pak Hoyer S.p.A.

Soeren Nymarks Vej, 13 7711 95th Street Via Monferrato, 52

DK 8270Hoejbjerg P.O. Box 0902 20098 San Giuliano Milanese (Milano)

Denmark Pleasant Prairie, WI 53158-092 Italy

Telephone + 45 89 393939 U.S.A. Telephone +39 2 98292.1

Telefax + 45 86 292200 Telephone + 414 9479100 Telefax +39 2 9880171

Telex 68770 Alhoy DK Telefax + 414 9479190

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Machine HOYER DINO C

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Serialnumber

RETURN TO PM

PREVIOUS PAGE

HOYER DINO C

DIN806BA1-1

Tetra Pak

Hoyer

Contents

1 - IDENTIFICATION OF THE MACHINE

1.1 Introduction ............................................................................................................... 1-2

1.2 Identificationplate ...................................................................................................... 1-2

1.3 ServiceCentres.......................................................................................................... 1-3

RETURN TO PM

DIN806BA1-2

Tetra Pak

Hoyer

1.2 Identification plate

For maintenance and service operations not

describedinthismanualorforanyotherproblemof

atechnicalnature,ourServiceDepartmentisatyour

completedisposalforinformationortoarrangefor

thenecessarymeasurestobetaken.

Fig.1.1-Identificationplate

1.1 Introduction

Thank you for having chosen a Tetra Pak Hoyer

machine. We recommend you read this manual

carefully,asitcontainsessentialinformationregarding

theinstallation,checkingandmaintenanceoperations

requiredtokeepyourmachineinperfectcondition.

Themanualcontainstables,drawingsanddiagrams

whichwillallowyoutofamiliariseyourselfwithall

partsofthemachine.

Pleaseletusnowifanyinformationismissingoris

notsufficientlydetailed.Yourcommentswillbeused

toimprovethismanual.

MODEL

SERIAL N.:

YEAR OF CONSTRUCTION:

ELECTRICAL SUPPLY:

PNEUMATIC SUPPLY:

REFRIGERANT:

HEATING GAS:

THERMAL CAPACITY:

kW

Kg.

Kcal/h

Via Monferrato, 52 - 20098 San Giuliano Milanese

( MI ) Italia - Tel. 02-982921 - Fax 02-9880171 Made in Italy

Tetra Pak

Hoyer

V

bar Nlt/min.

ph Hz

Type

WhencontactingourServiceDepartment,please

quotethedatagivenontheidentificationplateaffixed

tothemachineandshowninFig.1.1.

RETURN TO PM

DIN806BA 1-3

Tetra Pak

Hoyer

1.3 Service Centres

If you have any requirement or problem that requires our

assistance,please contactoneof thefollowingservice centres,

which are authorised to perform maintenance and provide

technicalserviceunderwarrantyforTetraPakHoyermachines.

EUROPEand

MIDDLEEAST:

Tetra PakHoyerApS

SoerenNymarksVej13

DK-8270Hoejbjerg

Denmark

Phone: +45 89 39 39 39

Fax: +45 86 29 22 00

Tlx:68770 alhoy dk

Tetra PakHoyerS.p.A.

ViaMonferrato, 52

I- 20098 SanGiulianoMilanese

(Milan)

Italy

Phone: + 39 2 98 29 21

Fax: + 39 2 98 80 171

Tetra PakHoyerFrance

c/oTetraLaval Service SARL

R.C.S.VersaillesB403 276223

P.O. Box 56

F-78340LesClayes-Sous-Bois

France

Phone: +33 1 30818184

Fax: +33 1 30818120

NORTH AMERICA:

Tetra PakHoyerInc.

7711 95th Street

P.O. Box 0902

PleasantPrairie,WI53158-0902

USA

Phone: +1 414 947 9100

Fax: +1 414 947 9190

SOUTHAMERICA:

Tetra Pak Hoyer Industria e

ComércioLtda.

Rua Napoleao de Barros, 1038

Cep04024-003 Sao Paulo-SP

Brazil

Phone: +55 11 573 9422

Fax: +55 11 549 5420

ASIA/PACIFIC:

Tetra PakHoyer Shanghai

Shanghai Overseas Chinese

Mansion

Room 2105-2107

No.129, Yan'an Xi Lu

200040Shanghai

P.R.China

Phone: +86 21 6249 0860

Fax: +86 21 6249 9064

Tetra Pak Hoyer Service

3rdFloor, MolaceBuilding

2231PasongTamoStreet

Makati,Metro Manila

Philippines

Phone: +63 2 8132848

Fax: +63 2 8132866

SOUTHKOREA:

HoyerLtd.

4fl.DookyongBldg.

66-1/9Hannam-Dong

YongSan-Ku

140-210Seoul

SouthKorea

Phone: +82 2 796 0362

Fax: +82 2 796 0365

THAILAND:

TetraPakHoyer(Thai)Ltd.

1042Soi Poosin, Sukhumvit Soi

66/1

Bangchak,Prakanong

Thailand

Phone: +66 2 3611680

Fax: +66 2 3612310

C.I.S.:

Tetra PakHoyerA/O

4thRostovskypeureulok

Dom1,stroenie1

R-11921 Moscow

C.I.S.

Phone: +7 502 2242160

Fax: +7 502 2242162

RETURN TO PM

HOYER DINO C

DIN806BB2-1

Tetra Pak

Hoyer

Contents

2 - GENERAL INFORMATION

2.1Declarationofconformity...........................................................................................2-2

2.2Preliminarycomments.................................................................................................2-2

2.3Generalsafetyrules....................................................................................................2-2

2.4Specialwarnings..........................................................................................................2-3

2.5Ambientoperatinglimits.............................................................................................2-3

RETURN TO PM

DIN806BB2-2

Tetra Pak

Hoyer

2.1 Declaration of conformity

Thismachinehasbeenmanufacturedinaccordance

withinternationalstandardsandhygieneandsanitary

legislationapplicabletofoodprocessingmachinery.

IntheDeclarationofConformitysuppliedwiththe

machine,TetraPakHoyerspecificallycertifiesthat

•Theillustrationsand drawings of the machine

areintendedforgeneralreferenceuseonly,and

arenot necessarilyaccurate ineverydetail;

•Themachinedimensionsandspecificationsgiven

in this Manual are not binding and may be

changedwithoutprior notice;

•Thedrawingsandallotherdocumentssupplied

withthis machine remaintheproperty ofTetra

Pak Hoyer and must not be passed on to third

partieswithout the writtenpermissionof Tetra

PakHoyer.

•The manual includes instructions for all

accessoriesmounted onthestandard machine.

• This machine is covered by a warranty as

laid down in the purchase contract. Any

repair work not authorised by Tetra Pak

Hoyer carried out during the warranty

period will automatically invalidate the

warranty.

2.2 Preliminary comments

2.3 General safety rules

•THESE SAFETY RULES HAVE BEEN

DRAWN UP IN YOUR INTEREST. Strict

observance will reduce the risk of injury to

yourselfor to others.

•DO NOT attempt to move, install or operate

themachinebeforereadingandassimilatingthe

contents of this manual. Ask your superior in

caseof doubt.

•Makesure thatallguards andsafetycovers are

inpositionBEFOREstartingthemachine.

•NEVERleave tools,mechanicalparts or other

foreignmaterialonorinsidethemachine.

•In the event of a malfunction, press the

emergencystop button.

•NEVERPUT YOUR HANDS INSIDE THE

MACHINE WHEN IT IS IN OPERATION.

•Beverycarefulevenwhenthegeneralswitchis

set to “OFF”, because there is still voltage in

thepowersupply cables.

•Shut off the compressed air supply before

disconnectinganypneumaticcomponent.

•BEFORE starting up production again after

maintenanceor repair work,makesure thatall

guardsandprotectivecovershavebeenreplaced

correctly.

•Proceed with caution at all times. Remember

thatyouareresponsibleforyourownsafetyand

forthatofyour colleagues.

•Make sure that applicable regulations are

observedwhenmovingorliftingthemachine.

Ι

the HOYER DINO C machine is designed and

manufacturedinaccordancewith theprovisions of

Directive89/392/EC(MachineryDirective)andwith

above-mentionedstandards.

RETURN TO PM

DIN806BB 2-3

Tetra Pak

Hoyer

• All personnel operating the machine must be

familiarwith the generalsafetyrules andmust

observe them strictly. Failure to follow these

rulesmayresultinpersonalinjuryordamageto

machinecomponents.

• Maintenanceworkmustbeperformedwiththe

machineturnedoff.Thegeneralswitchmustbe

setto“OFF”, the air valve closed anda“work

isinprogress” signaffixedtothemachine.

• Theusermustmakesurethatallinstructionsgiven

inthismanualareobservedstrictly.

• Userswillbesolelyresponsibleforriskscaused

bytamperingwith thesafetysystem.

• Thesafetyofmachinesusedinconjunctionwith

thismachine, if not supplied directly by Tetra

PakHoyer,istheresponsibilityofthecustomer.

• Thepressure,speed, temperature, and voltage

limits and all other instructions given are

indispensable for correct operation of the

machineand mustalways becompliedwithby

thecustomer.

• Ambient conditions must be taken into

considerationduringinstallation.

• National legislation governing this type of

machinemust beobserved.

Themachineissuitableforoperationinthefollowing

ambientconditions:

• Temperature : from 4°C to40°C

• Humidity : from20%to95%.

FNOTE:

Tetra Pak Hoyer will accept no responsibility for

damageor injurycausedby failure tocomplywith

theabovewarnings.

2.4 Special warnings

2.5 Ambient operating limits

RETURN TO PM

HOYER DINO C

DIN806BC3-1

Tetra Pak

Hoyer

Contents

3 - DESCRIPTION OF THE MACHINE AND TECHNICAL DATA

3.1 Descriptionofthemachine.......................................................................................... 3-2

3.2 Operation .................................................................................................................. 3-2

3.3 Technicaldata ............................................................................................................ 3-4

3.4 Programmingandcontrolpanel ................................................................................... 3-5

RETURN TO PM

DIN806BC3-2

Tetra Pak

Hoyer

The Hoyer Dino C multiple row pick-up system

may be used with a wide range of products

(productsonstickhandles,ballcones,wafercups

andproductswithoutsticks).

TheHoyerDinoCpick-upmachineiscomposed

ofthe followingmaincomponents:

Product pick-up unit with a series of

interchangeable grippers (Pos.1,Fig. 3.1).

Product transport with interchangeable rollers

(Pos. 2, Fig. 3.1).

3.1 Description of the machine

Chocolatecoatingtankforproductsonsticksand

ball cones (Pos.3,Fig.3.1).

Setoftanksforcoatingproductsonstickswithfruit

juice.

Setofinterchangeablegrippers(Pos.4,Fig.3.1)

forreleasingproductsonsticksandballconesonto

abeltsynchronisedbyaHoyerChartasinglerow

wrappingunit.

Smoothbeltforconveyingproductswithoutsticks

(Pos. 5, Fig. 3.1).

Electrical cabinet (Pos. 6, Fig. 3.1).

Pneumatic cabinet (Pos. 7, Fig. 3.1).

Operator interface panel (Pos. 8, Fig. 3.1).

Fig.3.1

The pick-up unit, which is constructed with a

rotatingarm(Pos.9,Fig.3.1)holdingthegrippers,

picksuphardenedproductsfromtheworktableat

thetunnelexit.

The grippers are opened and closed to pick up

products by pneumatic cylinders integrated and

controlledinparallelbyasinglepneumaticvalve

locatedinsidethepneumaticcabinet.Movement

issynchronisedbyanencoderundertheworktable

and the PLC programmer located inside the

electricalcabinet,whichinterfaceswiththemain

tunnelprogramme.

3.2 Operation

Before the grippers close, the arm follows the

movementoftheproductsontothetrays(Pos.10,

Fig. 3.1).

Once the products have been gripped, a hammer

positioned underneath the trays detaches the

productsfromthetrays.

The set of products that has been picked up is

positionedontherollersasthearmrotates(Pos.9,

Fig. 3.1).

Therotationofthearmanditsmovementfollowing

theproductstobepickeduparecontrolledbytwo

servomotors ((Pos. 11, Fig. 3.1) to ensure

1

2

3

4

5

7

6

9

10

12

11

8

RETURN TO PM

DIN806BC 3-3

Tetra Pak

Hoyer

synchronisation no matter what the production

speed in the SL C tunnel.

Products are supported and transported to the

coating station on stainless steel rollers (Pos. 2,

Fig.3.1).Eachrollercarriesninesetsofproducts

pickeduptogether.

A sufficient number of rollers is provided to

permit a one-minute drying and hardening time

forchocolateatthemaximumspeedofthetunnel.

Therollersarehookeduptoachainpositionedon

either side of the body of the machine.

The stainless steel chain has a 70 mm step, is

extensibleanddoesnotrequirelubrication.

The roller conveyor motor (Pos. 12, Fig. 3.1) is

positioned to one side of the machine and

connected to the serrated wheels through an

intermitter;it is driveninstep withtheline.

A proximity sensor makes the motor stop.

The optional coating station (Pos. 3, Fig. 3.1)

consistsofasetoftanksassembledonwheelssothat

they can easily be removed for washing and

maintenance.

Levelcontrolis not automatic and so thelevelin

thetanksmustbetoppedupmanuallyfromtimeto

timeduringproduction.

Thetankunitconsistsofastationarybodymadeof

stainless steel surrounded by a space which is

filled with water to keep the chocolate at the

correcttemperatureandatankwithraising/lowering

motion to contain the chocolate for coating the

products.

Thewateriskeptatthecorrecttemperaturebyan

immersedelectricalresistor.

A pump designed on the principle of the

Archimedeanscrewcarrieschocolateandnutbits

(ifany)fromthestationarytanktothemobiletank.

Thelevelofchocolateinthemobiletankismaintained

byallowingchocolatetooverflowoutofthemobile

tankintothestationarytankbelowit.

Theshapeofthetankpermitscollectionofdropsof

chocolatewhichfallofproductsduringthefirst20

seconds of drying.

The raising and lowering motion is created by a

pneumatic cylinder connected to the pick-up

machineprogramme,whichraisesthetankwhenthe

rollerispositionedabovethemobiletankandlowers

itbeforetherollermovesonforthenextcycle.

TheHoyerDinoCmultiplerowpick-upmachine

may also be equipped with a fruit juice coating

station, which consists of a product pre-cooling

area in which the first three rows of products are

immersed in liquid nitrogen while the two rows

behindthemareimmersedinfruitjuice.Afterthe

four stages involved in hardening the juice, the

lasttworowsareimmersedintheliquidnitrogen.

Themaximumthicknessofthefruitjuicelayeris

1 to 1.5 mm.

Thelaststationinthemultiplerowpick-upmachine

isthe product rejection station(Pos. 8, Fig. 3.1),

with automatic step conveyance on a belt with

lamellaswhichissynchronisedwiththeline.

The operator interface panel on the door of the

electricalcabinet(Pos.3,Fig.3.1)maybeusedto

selectaworkingprogrammeandmodifythefactory

settings to optimise operation of the machine

under actual operating conditions, which may

varyinaccordancewiththetypeofproductbeing

made.

The pick-up machine is run by a PLC with a

programme capable of synchronising the belts

that travel through the cooling tunnel of the line

for coating products without sticks. When

producing products without sticks, such as bars,

anoptionalsmoothbelt(Pos.5,Fig.3.1).mustbe

positioned on top of the roller for removal and

conveyanceofproductsarrivingfromthepick-up

stationtotheHoyerHoyrobe350coatingmachine.

Thespeedofthe evacuation belt is controlled by

an inverter which is set automatically by the

tunnelprogramme;whentheoperatoradjuststhe

speed of production in the tunnel, the belt speed

and following movement are automatically

adjusted.

RETURN TO PM

DIN806BC3-4

Tetra Pak

Hoyer

Standard power supply:

220-440V /3Ph/50-60Hz

Installedpower

Totalinstalledpower: 9 kW

Netweight: ???? Kg

Grossweight: ???? Kg

Compressedair

Pressureofair supply: min. 6 Bar

Consumption: 1300Nl/min

Diameterofairhose: 3/4"gas

Dimensions

A(length) = 1800mm

B(width) = 2640mm

C(height) = 2160mm

Number of operators: 1

EquivalentWeightedNoiseLevelAatadistance

of 1 metre: 67.5 dBA

Max. Instantaneous Weighted Noise Level C in

the workplace: less than 130 dB/20uPa.

3.3 Technical data

Fig.3.2

AB

C

RETURN TO PM

DIN806BC 3-5

Tetra Pak

Hoyer

3.4 Programming and control panel

Fig.3.3

F1 F2 F3 F4 F5

F12 F13 F14 F15 F16

F6

F17

F7

F18

F8

F19

F9

F20

F10

F21

F11

F22

A1 A2

F1 Chaindrive

F2 Jog(continuouschaincontrol)

F3 Selectionofautomatic/manualcycle

F4 Start/stopof automaticcycle

F5 Editrecipe

F6 Activaterecipe

F7 Saverecipe

F8 Send recipe to PLC

F9

F10

F11 Reset

F12 Coating

F13 Coatingresistance

F14 Coatingpump

F15 Nitrogencontrol

F16

F17 Startpick-upmovement

F18

F19

F20

F21

F22

A1: By-passrelease

A2: Overlaying

RETURN TO PM

HOYER DINO C

DIN806BD4-1

Contents

Tetra Pak

Hoyer

4.1 Unpacking and checking the contents ....................................................................... 4-2

4.2 Positioningand installation........................................................................................ 4-2

4.3 Electricalconnection ................................................................................................. 4-3

4.4 Pneumaticconnection ............................................................................................... 4-3

4.5 Checking direction of rotation................................................................................... 4-4

4.6 Positioningaccessories .............................................................................................. 4-4

4 - INSTALLATION

RETURN TO PM

DIN806BD4-2

Tetra Pak

Hoyer

The HOYER Dino C pick-up machine and its

various components are delivered in special

packaging,normallyinawoodencrate.The crate

should be unpacked as close to the location of

installationas possible; itmaybetransported with

a forklift.

When the crate has been positioned correctly,

proceed with unpacking as follows:

a. Extract the nails from the top of the crate and

remove the top. Repeat this operation for the

sides of the crate. Watch out for the wooden

spacers positioned between the sides of the

crate.

b. Remove the box of spare parts and other

components from the crate.

c. Extractthenails from thewoodenblocksused

to secure the machine in transit and remove

the protective cellophane.

d. Check that the contents of the packages

correspond to the items indicated in the

shippingdocuments.

e. Checkthatthetopandsidepanelsofthecrate

were correctly fixed and that no parts have

come loose in transit.

f. Visually inspect all electrical components,

looking for signs of damage.

g. Ifa part/componentis missing,stopunpacking

the machine and notify Tetra Pak Hoyer

immediately.

h. If the machine has been damaged in transit,

notifytheinsurancecompanyimmediatelyand

do not proceed further with unpacking until

authorisedtodo so by theinsurancecompany.

4.1 Unpacking and checking the contents

4.2 Positioning and installation

Theinstallationprocedurerequires the following

steps:

a. Position the machine at the production

location(refer to the annexed layout), using a

forklift of adequate capacity to move it (Pos.

1, Fig.4.1 illustrates correct insertion of

forks). Make sure that thereissufficient space

to permit removal of protection and allow

access to components inside the machine.

b. Adjust the adjustable feet (Pos. 3, Fig. 4.2)

so that the machine is perfectly level both

lengthwaysandcrossways.

c. Connect the pick-up machine to the tunnel,

fastening it using the tie rods provided (Pos.

3, Fig. 4.1).

d. Check that the roller surface is at the right

height.

RETURN TO PM

DIN806BD 4-3

Tetra Pak

Hoyer

Fig.4.1

4.3 Electrical connection

Themachine’selectricalsystemhasbeenfactory

tested by Tetra Pak Hoyer technicians.

Themachinecomponentsareelectricallyprotected

fromshort circuits:

WARNING:

Electricalconnectionmustbeperformedbyskilled

technicianswhoarefamiliarwithsafetylegislation.

Itisrecommendedthatpowerbeobtainedfroma

box containing a main switch with thermal

protection and ultra-rapid fuses of adequate

amperage.

For information on connections, refer to the

annexedwiringdiagram.

WARNING:

The differential protection switch must be class

“A”, suitable for protection of the inverter’s

electronicpowercircuits.

• Check the identification plate (Fig. 4.2) to

makesure that themachineis compatiblewith

localvoltage.

• Connect the three phases to the R S T

terminals and the ground wire to the ground

terminals in the electrical panel.

Forthe minimum sectionofthepower cable, refer

to the voltage and power reported on the

identification plate (Fig. 4.2) in relation to the

regulations in effect in the place where the

machineisinstalled.

2

2

2

1

1

3

4

RETURN TO PM

DIN806BD4-4

Tetra Pak

Hoyer

Afterelectricalandpneumaticconnection,check

themachine’sdirectionof rotation as follows:

• First make sure that there are no foreign

materialsinthemachine which might impede

itsmovement.

• Release the emergency stop button.

• Turn the main switch.

• Turn on the air supply.

• Press the intermittent operation push button

and make sure that the rollers move from left

4.5 Checking the direction of rotation

to right (Pos. 1, Fig. 4.3) when looking at the

machine from the operator’s side.

• Press the stop button to stop the chain.

WARNING:

If the machine rotates in the wrong direction,

invert the two phases in the terminal board.

This operation must be carried out by trained

technicianswhoarefamiliarwithsafetylegislation.

4.4 Pneumatic connection

Connectthemachinetothecompressedairsupply.

The minimum operating pressure is 6 bar.

The machine is equipped with a safety pressure

switchwhichwillstoppneumaticoperationsifthe

supply pressure falls below 4 bar.

For figures on air consumption and air supply

hose dimensions, refer to CHAPTER 3 –

DESCRIPTION OF THE MACHINE AND

TECHNICAL DATA.

MODEL

SERIAL N.:

YEAR OF CONSTRUCTION:

ELECTRICAL SUPPLY:

PNEUMATIC SUPPLY:

REFRIGERANT:

HEATING GAS:

THERMAL CAPACITY:

kW

Kg.

Kcal/h

Via Monferrato, 52 - 20098 San Giuliano Milanese

( MI ) Italia - Tel. 02-982921 - Fax 02-9880171 Made in Italy

Tetra Pak

Hoyer

V

bar Nlt/min.

ph Hz

Type

Fig. 4.2

RETURN TO PM

DIN806BD 4-5

Tetra Pak

Hoyer

Fig.4.3

• Positionthecoatingtankassembledonitswheels

(Pos. 2, Fig. 4.3) in the correct position

underneath the pick-up machine.

• Positionthe smooth belt for products without

sticks(Pos. 3, Fig. 4.3) inthecorrect position

on top of the pick-up machine.

Connect the coating tank (Pos. 1, Fig. 4.4)to

thecontrol panel ofthepick-upmachine (Pos.

4.6 Positioning accessories

1

2

2

3

Fig.4.4

2, Fig.4.4) using themultipleconnectioncable

provided.

• Connectthecoatingtanktothepneumaticpanel

ofthepick-upmachine.

• Connect the smooth belt (Pos.3, Fig. 4.4) to

thecontrolpanel of thepick-upmachine(Pos.

4, Fig. 4.4) using the multiple connection

cable provided.

2

1

4

3

RETURN TO PM

HOYER DINO C

DIN806BE5-1

Contents

Tetra Pak

Hoyer

5.1 Productchange .......................................................................................................... 5-2

5.1.1 Coatedproducts............................................................................................... 5-2

5.1.2 Productsonsticks............................................................................................. 5-3

5.1.3 Ballcones and wafercups................................................................................. 5-4

5.1.4 Productswithoutsticks ..................................................................................... 5-4

5.2 Adjustmentfromthe controlpanel .............................................................................. 5-5

5 -ADJUSTMENT AND FORMAT CHANGE PROCEDURES

RETURN TO PM

DIN806BE5-2

Tetra Pak

Hoyer

TheHoyerDinoCmultiplerowpick-upmachine

maybeusedwithawiderangeofproducts(products

withstickhandles,ballcones,wafercupsandproducts

withoutsticks).

5.1 Product change

Fig. 5.1

Formatchangesinvolvereplacementof:

- pick-up tools (Pos. 1, Fig. 5.1);

- conveyorrollers(Pos.2,Fig.5.1);

- release tools (Pos.3, Fig. 5.1).

• Positionthe coatingtankassembled onwheels

(Pos. 1, Fig. 5.2) in the correct position

underneaththepick-upmachine.

• Connect the coating tank (Pos. 1, Fig. 5.2) to

thecontrolpanel of thepick-upmachine(Pos.

2,Fig.5.2)usingthemultipleconnectioncable

provided.

• Connectthecoatingtanktothepneumaticpanel

ofthe pick-upmachine.

• Adjust the rise of the mobile coating tank so

thatthe productisimmersedcorrectly.

5.1.1 Coatedproducts

3

1

2

RETURN TO PM

Table of contents

Other Tetra Pak Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Moduline

Moduline HSH E Series Service manual

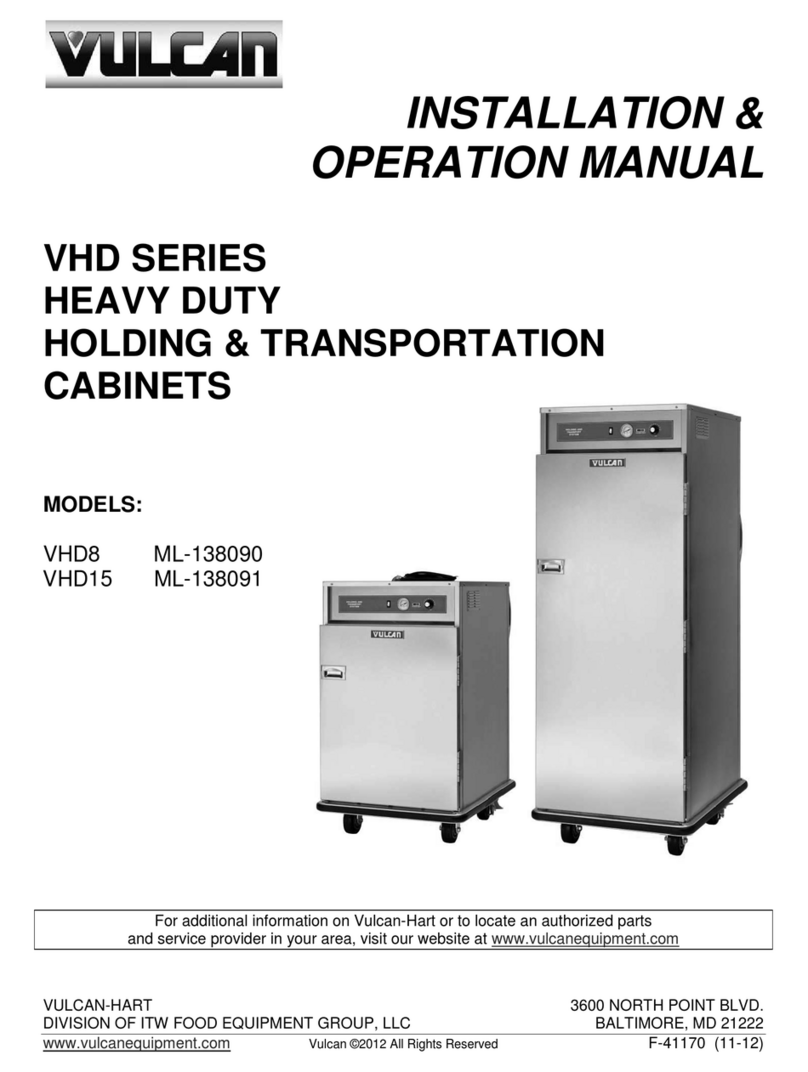

Vulcan-Hart

Vulcan-Hart VHD Series Installation & operation manual

CombiSteel

CombiSteel Wesley user manual

LIVERYMAN

LIVERYMAN BLACK BEAUTY Instructions for use

Univex

Univex VS9 Operator's manual

Broaster

Broaster Perfect Hold Installation & operating manual

BD

BD 5513E Instructions for use

Henny Penny

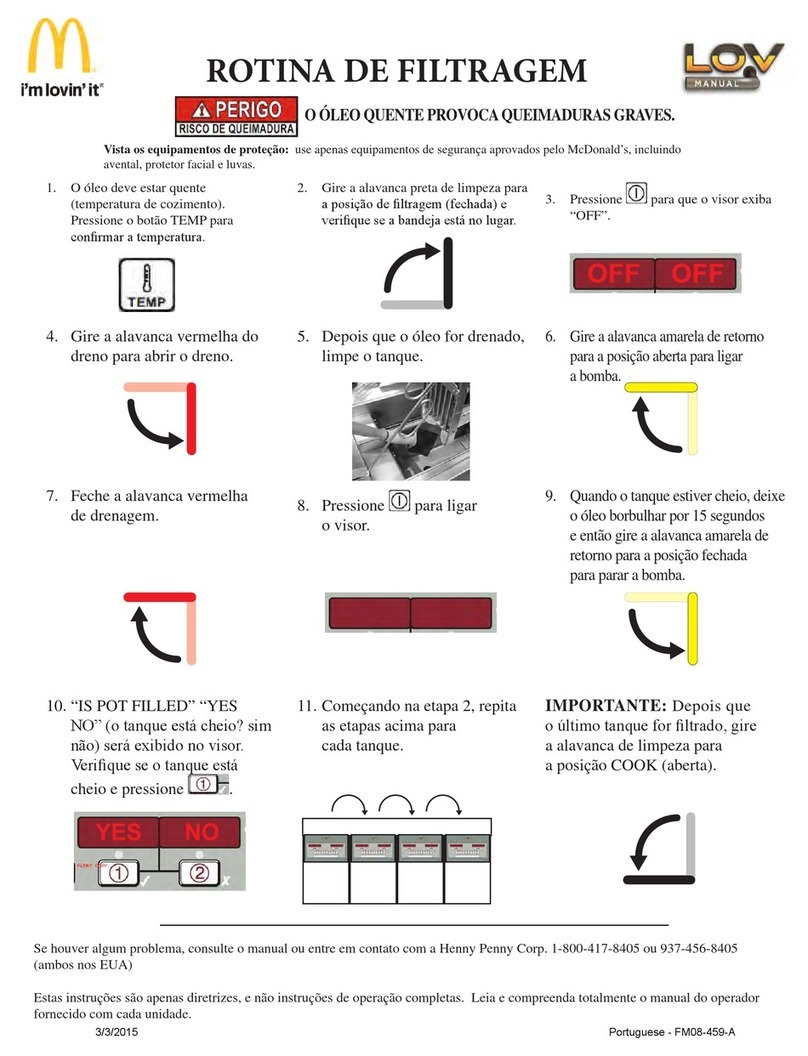

Henny Penny McDonald's LOV MVE 07X Electric Series quick start guide

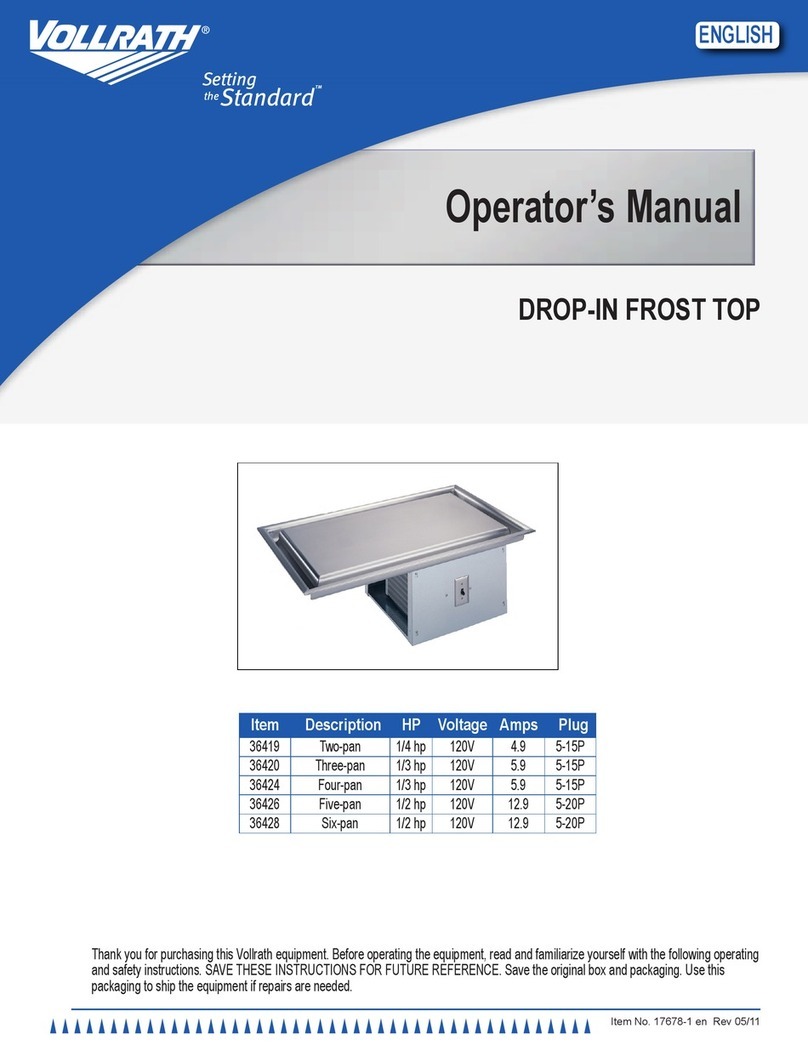

Vollrath

Vollrath 36419 Operator's manual

Unified Brands

Unified Brands Groen EE Series Operators & service manual

APW Wyott

APW Wyott COLDWELLS CW-13 Installation and operating instructions