A.M. MFG. CO. MASTER MODEL:

DIV. OF ATWOOD CORP. S500

©1996

S500_7.DOC 7 1/96

OPERATING INSTRUCTIONS

WARNING:

UNIT MUST BE PROPERLY OPERATED AND MAINTAINED TO PREVENT MACHINE DAMAGE OR PERSONAL INJURY. REVIEW

INSTRUCTIONS WITH ALL EMPLOYEES BEFORE USE.

I. PRELIMINARY START UP DIVIDER

A. REMOVE SMALL INSPECTION DOOR.

B. REMOVE PACKING, PACKING SLIPS, DOCUMENTS

AND OTHER OBSTRUCTIONS FROM HOPPER.

C. PLUG POWER CORD INTO PROPER RECEPTACLE.

D. PUSH DIVIDER START BUTTON AND TEST BUTTON

SIMULTANEOUSLY AND HOLD.

E. CAUTION (THIS WILL START DIVIDER ONLY)

F. CHECK ROTATION OF DIVIDER BY LOOKING

THROUGH SMALL INSPECTION DOOR. LARGE

GEAR FOR DIVIDER SHOULD BE TURNING (C.W.)

CLOCK-WISE.

G. IF THE GEAR IS TURNING IN THE (C.C.W.) COUNTER

CLOCK-WISES DIRECTION, CONSULT A PROPERLY

TRAINED ELECTRICIAN.

H. IF ROTATION IS CORRECT, YOU ARE READY TO

CONTINUE INSPECTION OF THE ROUNDER

CONVEYOR.

I. REINSTALL SMALL INSPECTION DOOR.

J. SHUT OFF DIVIDER.

II. PRELIMINARY START-UP

ROUNDER

A. MAKE SURE CONVEYOR IS SECURELY FASTENED

TO CABINET.

B. INSTALL GEAR MOTOR BREATHER (OIL VENT)

C. BE SURE CONVEYOR IS CLEAR AND NOT

OBSTRUCTED.

D. CHECK ROUNDER MOTOR CORD CONNECTION TO

CABINET RECEPTACLE.

E. TURN ON LARGE CONVEYOR POWER SWITCH.

THIS WILL START CONVEYOR MECHANISM.

F. CHECK CONVEYOR BELT, CONVEYOR BELT

SHOULD BE RUNNING FORWARD, OUT FROM

MACHINE.

G. IF CONVEYOR BELT IS RUNNING BACKWARDS,

INTO MACHINE, CONSULT A PROPERLY TRAINED

ELECTRICIAN.

H. SHUT OFF DIVIDER.

III. OPERATION OF DIVIDER

A. FILL THE OIL RESERVOIR WITH LIGHT WEIGHT

MINERAL OIL.

B. WITH THE SQUIRT BOTTLE SUPPLIED, APPLY A

SMALL AMOUNT OF MINERAL OIL TO THE INSIDE

WALLS OF THE DOUGH HOPPER.

C. OPEN THE VALVE LOCATED ON THE TOP GIB BAR

APPROXIMATELY 1/8 OF A TURN.

D. REMOVE BACK CABINET DOOR.

E. OPEN THE CYLINDER VALVE APPROXIMATELY 1/8

OF A TURN. THIS VALVE IS LOCATED ON THE OIL

PUMP INSIDE OF THE REAR DOOR.

F. REINSTALL THE BACK CABINET DOOR.

G. FILL THE HOPPER WITH DOUGH.

H. SET HOPPER COVER ON TOP OF DOUGH.

I. SWITCH LARGE CONVEYOR SWITCH TO THE “ON”

POSITION.

J. SWITCH SMALL CONVEYOR SWITCH TO THE “ON”

POSITION.

K. PRESS DIVIDER BUTTON.

L. HOPPER SHOULD BE OILED EVERY TIME NEW

DOUGH IS PLACED IN HOPPER.

IV. DIVIDING THE DOUGH

A. DOUGH IS PORTIONED IN THE MEASURING CUP

LOCATED ON THE DIVIDER SLIDE.

B. TO ADJUST THE WEIGHT, STOP THE

MACHINE.

C. LOOSEN THE STAR KNOB NUT (529MS-2D) AND

TURN THE SMALL HANDLE ON THE TOP OF THE

MEASURING CUP. NOTE: ALWAYS LOOSEN STAR

KNOB PRIOR TO ADJUSTING MEASURING CUP.

FAILURE TO DO SO CAN RESULT IN DAMAGE TO

CUP.

D. BY TURNING THE HANDLE, THE STOP COVER OF

THE CUP WILL MOVE UP OR DOWN. THE “UP”

(C.C.W.) MOTION WILL INCREASE THE DOUGH

WEIGHT. THE “DOWN” (C.W.) MOTION DECREASES

THE DOUGH WEIGHT.

E. FIND YOUR DESIRED DOUGH WEIGHT BY

WEIGHING THE DOUGH PIECES.

F. ONCE YOU HAVE ACHIEVED THIS, LOCK THE STAR

KNOB (529MS-2D) ON THE SIDE OF THE

MEASURING CUP TO KEEP SCALING ACCURATE.

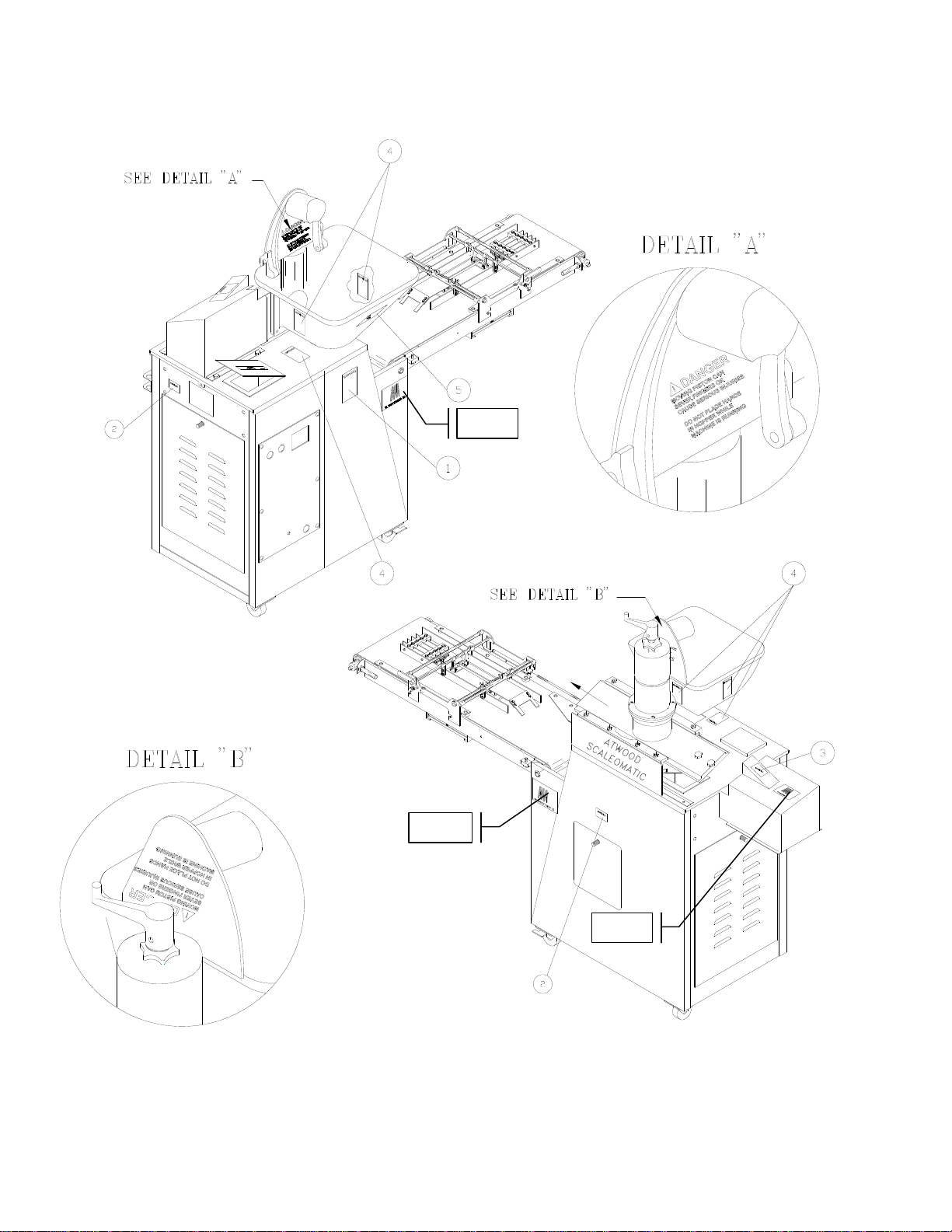

V. SECOND STAGE DIVIDER

AFTER THE DOUGH HAS BEEN DIVIDED, IT WILL TRANSFER

FROM THE SMALL DROP CONVEYOR TO THE LARGE

CONVEYOR AND CONTINUE THROUGH THE SECOND STAGE

DIVIDER. IT IS THEN DIVIDED AGAIN AUTOMATICALLY INTO 3, 4

OR 5 EQUAL PIECES, ACCORDING TO THE SIZE REQUIRED.

A. THE SECOND STAGE DIVIDER HAS BEEN PRE-

ADJUSTED AT THE FACTORY. THE PRESSURE

PLATE HAS BEEN SECURED FOR SHIPPING

PURPOSES. VERIFY ADJUSTMENT PRIOR TO USE.

B. TO OPERATE THE SECOND STAGE DIVIDER YOU

MUST FIRST BE CERTAIN IT IS DISCONNECTED

FROM THE POWER SOURCE. NEXT RAISE THE

PRESSURE PLATE APPROXIMATELY 1 1/2” FROM

THE CONVEYOR BELT. THIS IS ACCOMPLISHED BY

LOOSENING THE WING BOLT (PART NO.F0604WB)

AND THEN RAISING THE HANDLE (PART NO.MPP15)

TO THE DESIRED HEIGHT.

C. LOCK THE PRESSURE PLATE IN PLACE BY

TIGHTENING THE WING BOLTS (PART

NO.F0604WB). RECONNECT POWER SOURCE.

D. SWITCH THE LARGE CONVEYOR TO THE “ON”

POSITION.

E. SWITCH THE SMALL CONVEYOR TO THE “ON”

POSITION.

F. PUSH THE DIVIDER START BUTTON. AFTER

CHECKING TO BE SURE THE CONVEYORS ARE

CLEAR.

G. AFTER DOUGH IS DIVIDED, DOUGH PIECES

SHOULD BE SPREAD INTO A STRAIGHT EVEN

SHAPE AFTER IT COMES OUT OF PRESSURE

PLATE. AN INCONSISTENT SHAPE WILL CAUSE

INCONSISTENT PIECES OUT OF THE SECOND

STAGE DIVIDER

NOTE: TO MUCH PRESSURE ON THE DOUGH PIECE GOING

THROUGH THE PRESSURE PLATE WILL CAUSE THE PIECE TO

ARCH FORWARD IN THE CENTER THIS CAN CAUSE THE MIDDLE

PIECES FROM THE SECOND STAGE DIVIDER TO BE HEAVIER

THAN THE END PIECES. TOO LITTLE PRESSURE WILL NOT GIVE

AN EVEN SPREAD CAUSING DOUGH PIECES TO BE HEAVY ON

ONE SIDE.

A. IF DESIRED RESULTS ARE NOT ACHIEVED.

STOP MACHINE.

B. REPEAT STEPS 2 THROUGH 6.

C. AFTER ACHIEVING DESIRED RESULT, MAKE A

NOTE OF THE SETTING OF THE PRESSURE PLATE

BY USING THE NUMBER LOCATED ABOVE THE

ADJUSTING HANDLE.