Tetra Pak CAP 30/Flex ScrewCap User manual

TechPub_2614345_0105 - IM_CAP30_0103fro.fm

CAP 30/Flex

662950-0100

ScrewCap

Installation Manual

IM

Doc. No. IM-2852922-0103

WARNING

Read and follow all safety precaution instructions throughout this

manual and on safety signs attached to this equipment.

Failure to follow all safety precaution instructions could result in death or

serious injury.

TechPub_2614345_0105 - IM_CAP30_0103fro.fm

Copyright © 2007 Tetra Pak Group

All rights reserved. No part of this document may be reproduced or copied in any form or by any means

without written permission from Tetra Pak Packaging Solutions.

and all Tetra Pak products are trademarks belonging to the Tetra Pak Group.

The content of this manual is in accordance with the design and construction of the machine or

equipment at the time of publishing. Tetra Pak reserves the right to introduce design modifications

without prior notice.

The English version of this document is the original language version.

This document was produced by:

Tetra Pak Packaging Solutions

Via Delfini 1

41100 Modena

Italy

Additional copies can be ordered from Tetra Pak. When ordering additional copies, always provide the

document number.

Doc. No. IM-2852922-0103

Issue 2007-10

This manual is valid for:

Series No./ Machine No. Sign.

IM

Installation Manual

TechPub_2614345_0105 - IM_CAP30_0103fro.fm

CAP 30/FlexScrewCap

Issue 2007-10

Doc. No. IM-2852922-0103

Tetra Pak Packaging Solutions

i Introduction

ii Safety Precautions

1 Technical Data and

Drawings

2 Preparation

3 Moving and Unpacking

the Equipment

4 Positioning, Assembly

and Connections

5 Final Installation Check

6 Preparation for

Commissioning

7 Disassembly and

Removal

Machine or equipment configurationsthat

this manual is valid for are described on

the next page.

TechPub_2614345_0105 - IM_CAP30_0103fro.fm

Valid for:

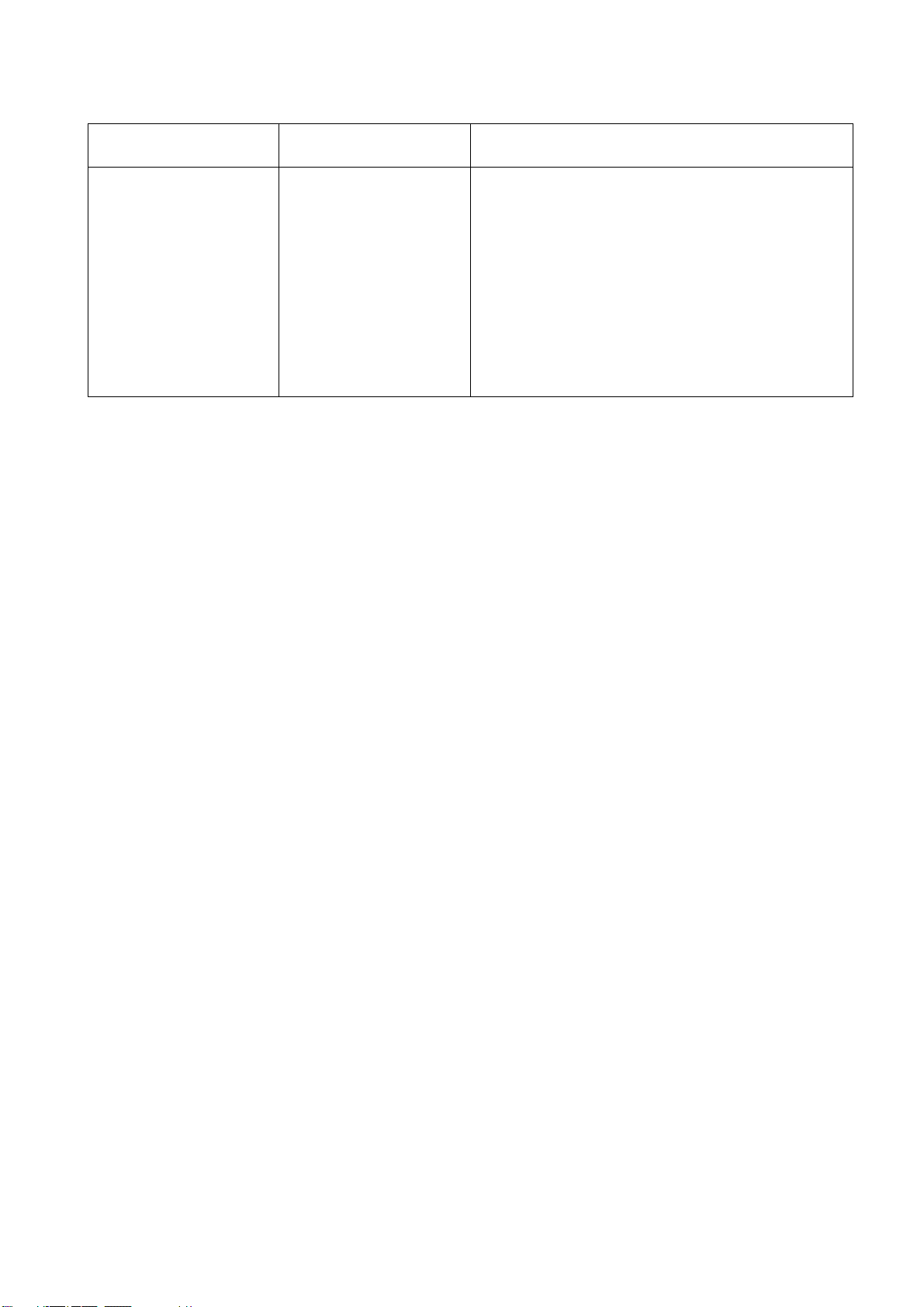

Name Drawing Specification

and Development Step Additional Information

CAP 30/Flex ScrewCap 662950-0100 TBA 500 Sq StreamCap 1000

TBA 1000 Sq StreamCap 1000

TBA 1000 S SlimCap 1000

TBA 1500 S SlimCap 1000

TBA 1890 S SlimCap 2000

TBA 2000 S SlimCap 2000

TGA 500 Sq StreamCap 1000

TGA 750 Sq StreamCap 1000

TGA 1000 Sq StreamCap 1000

TPA 750 Sq StreamCap 1000

TPA 1000 Sq StreamCap 1000

i - 1 (14)

Doc. No. IM-2852922-0103

TechPub_2614345_0105 - IM_CAP30_0103int.fm

i Introduction

i - 2 (14) Doc. No. IM-2852922-0103

i Introduction

TechPub_2614345_0105 - IM_CAP30_0103int.fm

About the Introduction Chapter

This chapter contains basic information about this manual and the related

Tetra Pak equipment.

Table of Contents

i - 3 (14)

Doc. No. IM-2852922-0103

TechPub_2614345_0105 - IM_CAP30_0103int.fm

i Introduction

Abbreviations and Terminology. . . . . . . . . . . . . . i - 5

Manual Information . . . . . . . . . . . . . . . . . . . . . . . . i - 7

Delivered Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . i - 7

Page Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i - 8

Page Numbering. . . . . . . . . . . . . . . . . . . . . . . . . . . . i - 9

Typographical Conventions . . . . . . . . . . . . . . . . . . i - 9

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i - 9

Machine Introduction . . . . . . . . . . . . . . . . . . . . . i - 10

Intended Use of the Equipment . . . . . . . . . . . . . . i - 10

Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i - 10

Support and Feedback . . . . . . . . . . . . . . . . . . . . . i - 10

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . i - 11

CE Classification . . . . . . . . . . . . . . . . . . . . . . . . . . i - 11

Machine Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . i - 11

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i - 12

Hygiene. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i - 13

Packaging Material. . . . . . . . . . . . . . . . . . . . . . . . . i - 13

i - 4 (14) Doc. No. IM-2852922-0103

i Introduction

TechPub_2614345_0105 - IM_CAP30_0103int.fm

This page intentionally left blank

i - 5 (14)

Doc. No. IM-2852922-0103

TechPub_2614345_0105 - IM_CAP30_0103int.fm

i Introduction Abbreviations and Terminology

Abbreviations and Terminology

(Cont'd)

Abbreviation/

Terminology Meaning Translation

AAmpere

ANSI American National

Standards Institute

B Base (package shape)

CAP Cap Applicator

CE Communautés

Européennes/European

Communities

Cont’d Continued

dB Decibel

DE Distribution Equipment

Deg. Degree

Doc. Document

EEA European Economic Area

EM Electrical Manual

ft Foot / feet

Hz Hertz

kg kilogram

kPa kilopascal

lbs Pounds

IM Installation Manual

in. Inch

ISO International Organization

for Standardization

Max Maximum

mMetre

mm Millimetre

MM Maintenance Manual

min Minimum

N Neutral

Nl/min The flow in litres per minute

No. Number

OE Optional Equipment

OM Operation Manual

Abbreviations and Terminology

i - 6 (14) Doc. No. IM-2852922-0103

i Introduction

TechPub_2614345_0105 - IM_CAP30_0103int.fm

(Cont'd)

Abbreviation/

Terminology Meaning Translation

PE Positive Earth

PLC Programmable Logic

Controller

PLMS Packaging Line

Monitoring System

Pos Position

psi Pound per square inch

PVC Polyvinyl chloride

S Slim (package shape)

sec. Second

SPC Spare Parts Catalogue

Sq Square (package shape)

TBA Tetra Brik Aseptic

TeM Technical Manual

TP Tetra Pak

TPA Tetra Prisma Aseptic

VVolt

i - 7 (14)

Doc. No. IM-2852922-0103

TechPub_2614345_0105 - IM_CAP30_0103int.fm

i Introduction Manual Information

Manual Information

Tetra Pak recommends reading all delivered manuals carefully. Make sure

that the delivered manuals are available to personnel who operate or

maintain the equipment.

It is important to keep this manual for the lifetime of the equipment and to

pass the manual on to any subsequent holder or user.

Tetra Pak will not be held responsible for any damage to the equipment

caused by not following the instructions given in this manual.

Delivered Manuals

Manuals delivered with this equipment:

• The Conversion Manual (CM) provides technicians with information on

converting the equipment between different production modes.

• The Electrical Manual (EM) provides technicians with information

about the equipment’s electrical system.

• The Installation Manual (IM) provides technicians with information

required to safely install the equipment.

• The Maintenance Manual (MM) provides technicians with information

on maintaining the equipment.

• The Operation Manual (OM) manual provides the operator with

information on handling and operating the equipment before, during, and

after production.

• The Spare Parts Catalogue (SPC) provides the information necessary to

order spare parts from Tetra Pak

• The Technical Manual (TeM)

– provides technicians with information required to safely install the

equipment

– provides technicians with information on maintaining the equipment

– provides technicians with information about the machine’s/

equipment’s electrical system

– provides the information necessary to order spare parts from

Tetra Pak.

Manual Information

i - 8 (14) Doc. No. IM-2852922-0103

i Introduction

TechPub_2614345_0105 - IM_CAP30_0103int.fm

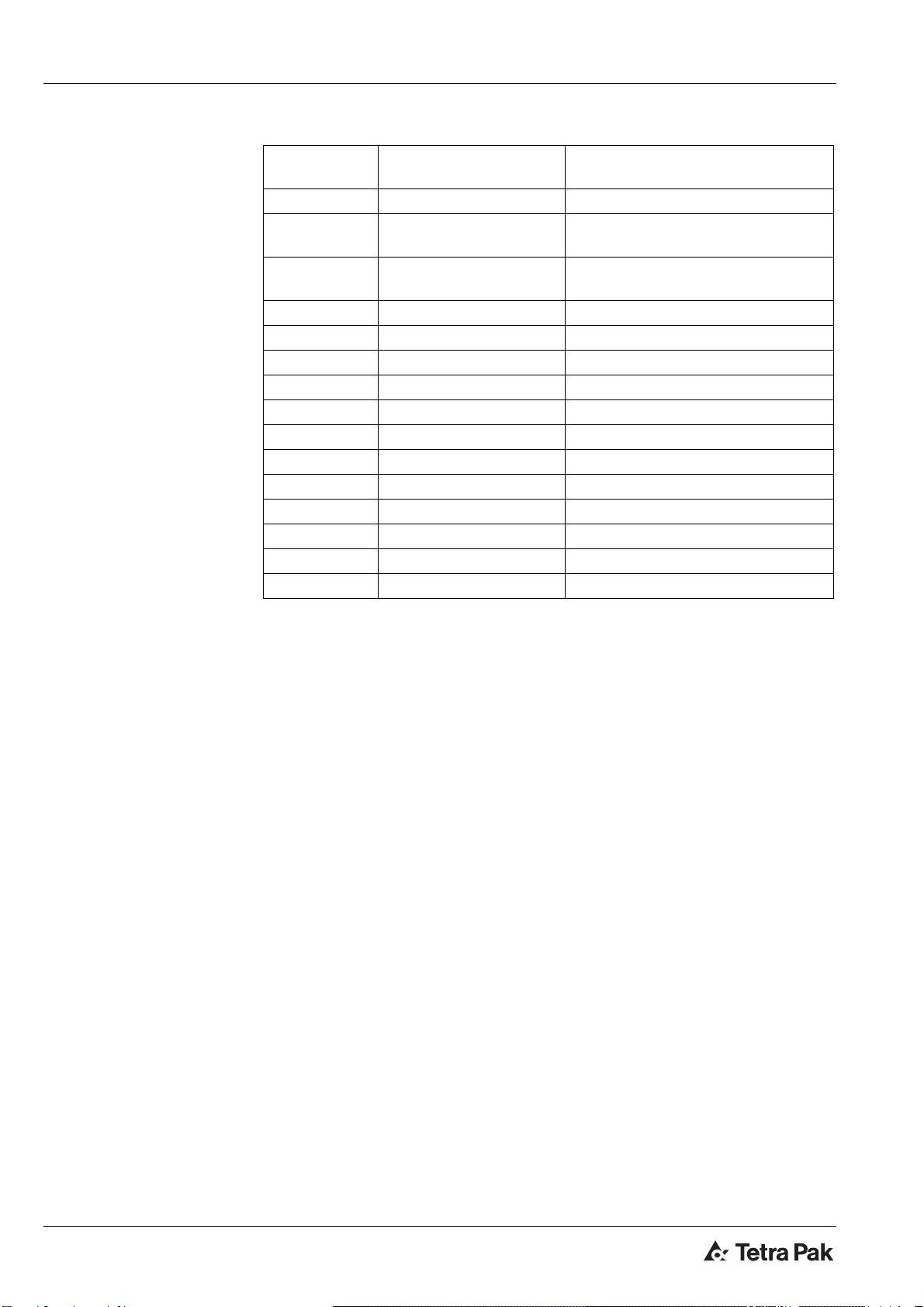

Page Layout

Every main page in a manual contains a header and a footer. The page header

contains the chapter name (1) and the section name (2). The page footer

contains the page number (3), and the document number (4). See also the

Page Numbering section.

9 - 41 (60)

Doc. No. MM-2730517-0103

9 General

9.2 Technical Data

1 2

34

1 Chapter name

2 Section name

3 Page number

4 Document number

i - 9 (14)

Doc. No. IM-2852922-0103

TechPub_2614345_0105 - IM_CAP30_0103int.fm

i Introduction Manual Information

Page Numbering

A page number has three parts:

• chapter number (1)

• consecutive page number (2) within the chapter

• total number of pages (3) in the chapter.

Typographical Conventions

Controls on the operator panel, emergency stop devices, and program steps

are printed in CAPITAL LETTERS.

Cross-references are underlined.

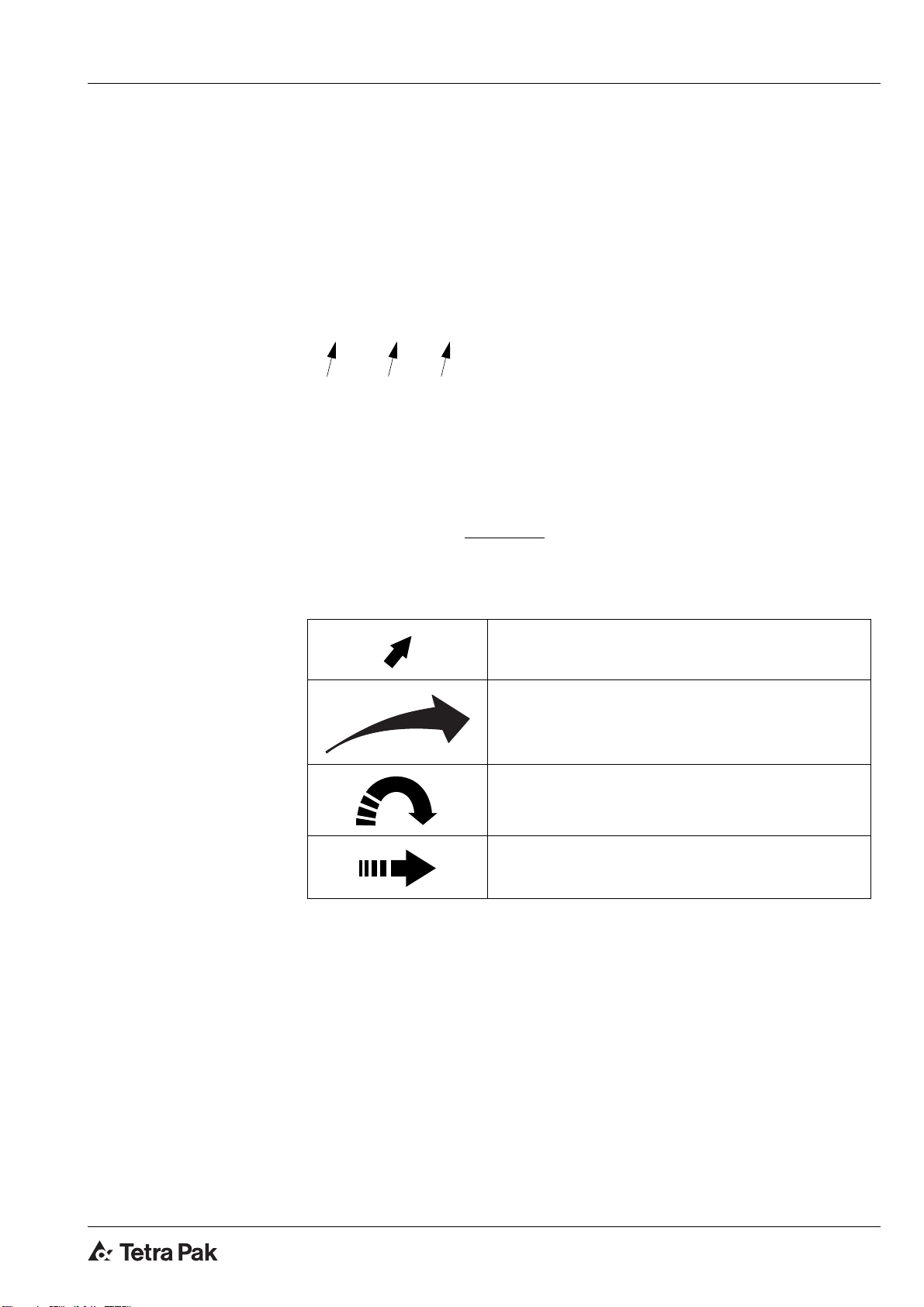

Symbols

Symbols used in illustrations.

A pointer arrow indicates the position of an object.

A zoom arrow indicates that an object view is

enlarged. The arrow points towards the enlarged view

of the object.

A rotation movement arrow indicates rotational

movement of an object. The arrow points in the

direction of rotation.

A straight movement arrow indicates movement of an

object.

The arrow points in the direction of movement.

4 - 11

(18)

321

1 Chapter number

2 Consecutive page number

3 Total number of pages

Machine Introduction

i - 10 (14) Doc. No. IM-2852922-0103

i Introduction

TechPub_2614345_0105 - IM_CAP30_0103int.fm

Machine Introduction

Intended Use of the Equipment

The intended use of this Tetra Pak equipment is to apply a closure onto a

package.

Tetra Brik Aseptic Slim packages with SlimCaps or ReCaps must have

opening tabs. The opening tabs are applied by a PullTab unit which is

incorporated in to the filling machine. Packages with StreamCaps must have

pre-laminated holes.

All other use is prohibited. Tetra Pak will not be held responsible for injury

or damage if the equipment is used for any other purpose.

Manufacturer

This Tetra Pak equipment has been manufactured by:

Tetra Pak Packaging Solutions

Ruben Rausings gata

SE-221 86 Lund

Sweden

Support and Feedback

If you encounter problems when operating this equipment or have other

inquiries, comments, or suggestions for improvement, contact Tetra Pak.

i - 11 (14)

Doc. No. IM-2852922-0103

TechPub_2614345_0105 - IM_CAP30_0103int.fm

i Introduction Identification

Identification

CE Classification

This equipment complies with the basic health and safety regulations of

the European Economic Area (EEA).

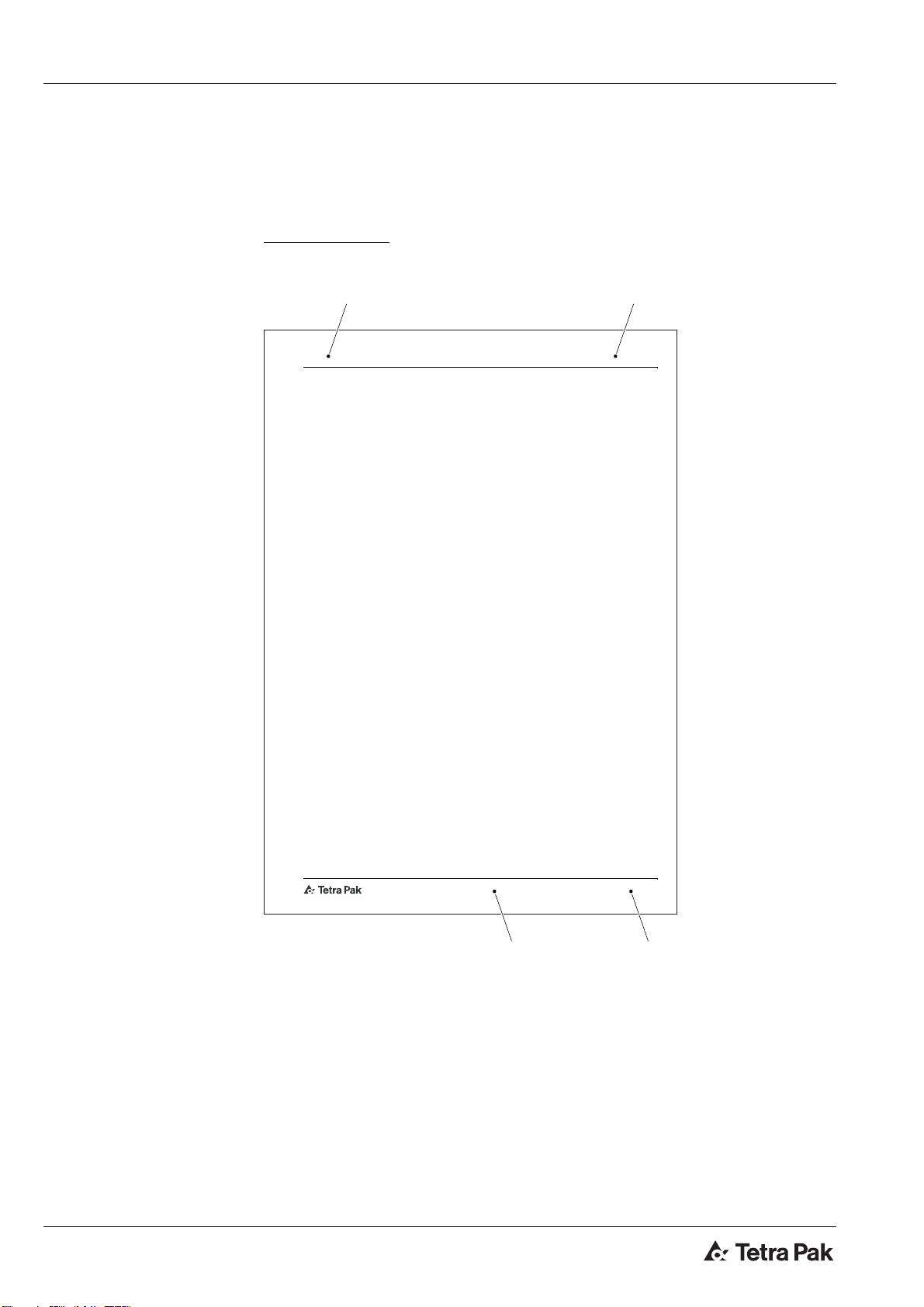

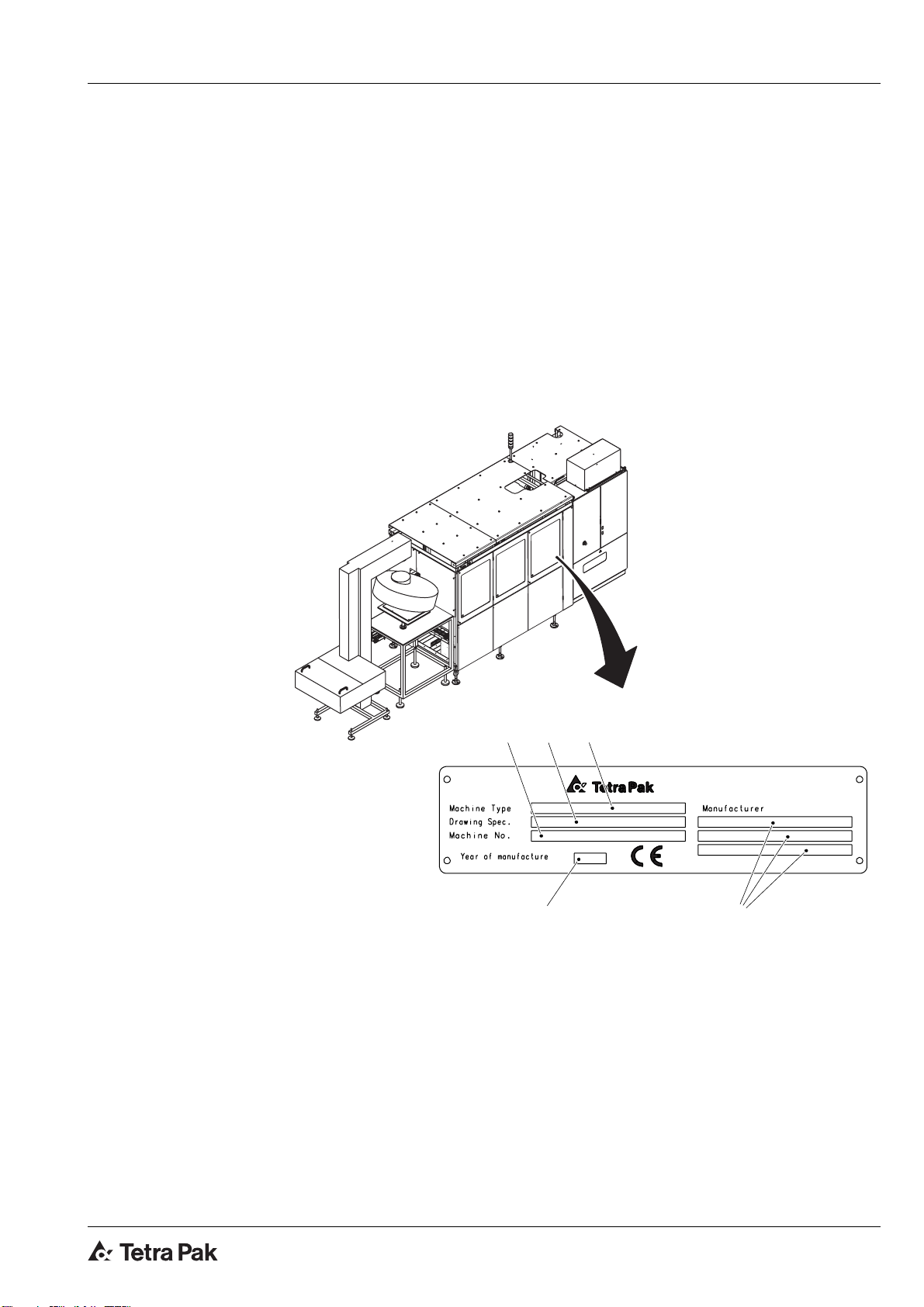

Machine Plate

The illustration below shows an example of the machine plate and its

location on the equipment. The machine plate carries data needed when

contacting Tetra Pak concerning this specific equipment.

Make sure that the equipment data in the front pages of this manual

corresponds to the machine plate data and the machine specification.

5

1 2 3

4

1 Machine Number

2 Drawing Specification

3 Machine Type

4 Manufacture

5 Year of Manufacture

Orientation

i - 12 (14) Doc. No. IM-2852922-0103

i Introduction

TechPub_2614345_0105 - IM_CAP30_0103int.fm

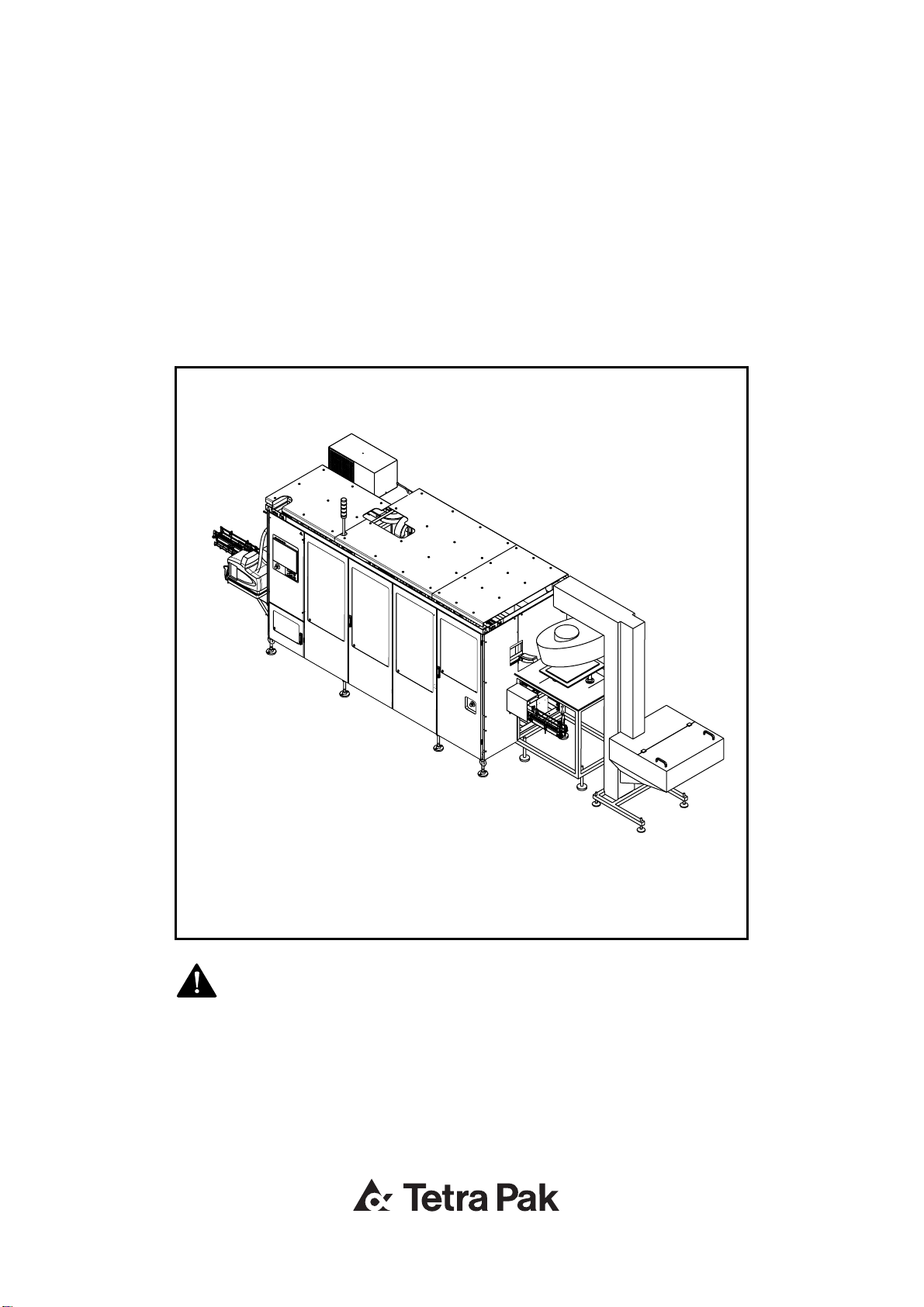

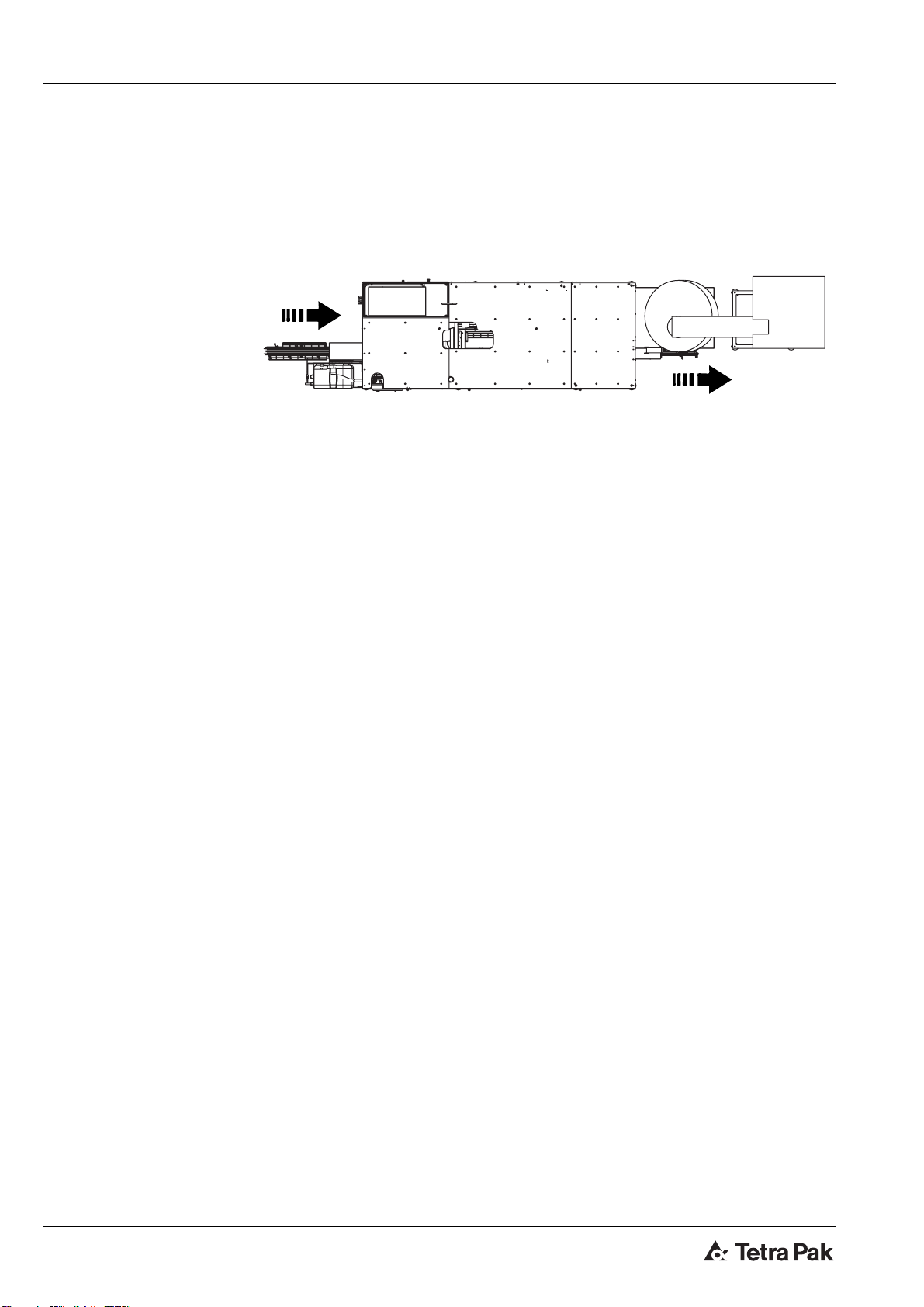

Orientation

The illustration below shows the orientation of the equipment. This

orientation information will be used throughout this manual. The arrows

indicate the flow of material.

AFront

BBack

C Left

DRight

EInfeed

FOutfeed

B

C

DA

E

F

i - 13 (14)

Doc. No. IM-2852922-0103

TechPub_2614345_0105 - IM_CAP30_0103int.fm

i Introduction Hygiene

Hygiene

Packaging Material

Avoid microbiological contamination of the packaging material:

• Always protect your packaging material against contamination. Do not

let the caps come into contact with contaminated areas. Only use caps

direct from their packaging material.

• Except when filling the cap sorter with caps, always keep the cap-sorter

magazine door closed. Keep the transparent door panels clean.

• Always keep the doors to the applicator room (area) closed. To prevent

contamination via air streams, never open a window when the machine is

in production.

• Never clean the floors or the machine in the applicator room (area) when

the machine is in production.

• Compressed air used for cleaning purposes is to be used only for

cleaning filters and should only be used outside of the applicator room

(area).

• Disinfect your hands before touching anything that may come into

contact with the product. Use code H disinfectant. See the Technical

Data chapter in the Maintenance Manual.

• Keep your hands clean.

• Always wear some type of hair protection (cap or hairnet) and clean

clothes (preferably white).

• Do not wear a watch, ring, necklace, earrings, or any other exposed

jewellery.

Hygiene

i - 14 (14) Doc. No. IM-2852922-0103

i Introduction

TechPub_2614345_0105 - IM_CAP30_0103int.fm

This page intentionally left blank

ii - 1 (30)

Doc. No. IM-2852922-0103

TechPub_2614345_0105 - IM_CAP30_0103sp.fm

ii Safety Precautions

ii - 2 (30) Doc. No. IM-2852922-0103

ii Safety Precautions

TechPub_2614345_0105 - IM_CAP30_0103sp.fm

Safety Precaution Instructions

WARNING

Read all safety precaution instructions throughout this manual and on

safety signs attached to this equipment.

Failure to follow all safety precaution instructions could result in death or

serious injury.

Definition of Lockout Procedure

A lockout procedure is a procedure to put each necessary energy isolating

device in its safe position to prevent the energisation of the equipment, such

as when a maintenance procedure should be carried out.

A lockout is the use of a device, for example, a padlock, to make sure that an

energy isolating device cannot be operated.

An energy isolating device is a mechanical device that physically prevents

transmission or release of energy, such as a power supply disconnector.

Table of contents

Other Tetra Pak Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

CULITEK

CULITEK MRSL-1D instruction manual

Vulcan-Hart

Vulcan-Hart PRECIPAN VPP28 Operation manual

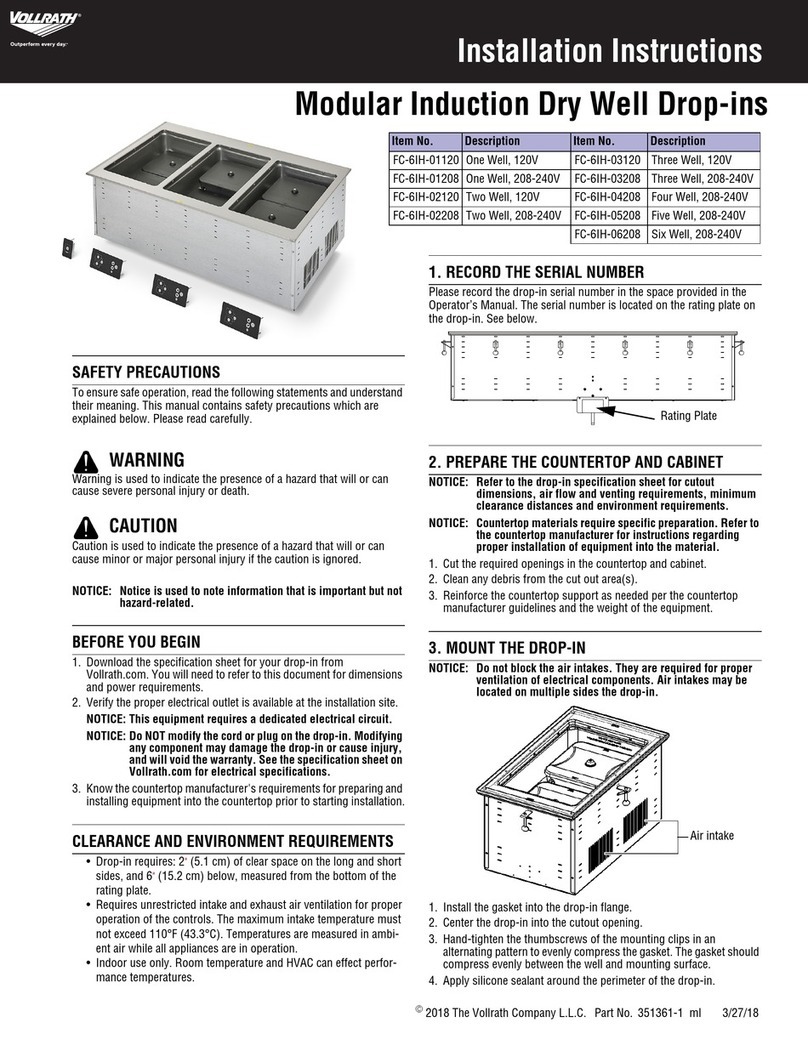

Vollrath

Vollrath FC-6IH-01120 installation instructions

Hussmann

Hussmann ISLA IM-FR Installation & operation manual

Gastrodomus

Gastrodomus Minitemper manual

B+S

B+S GMK10686 Installation, operating and servicing instruction manual