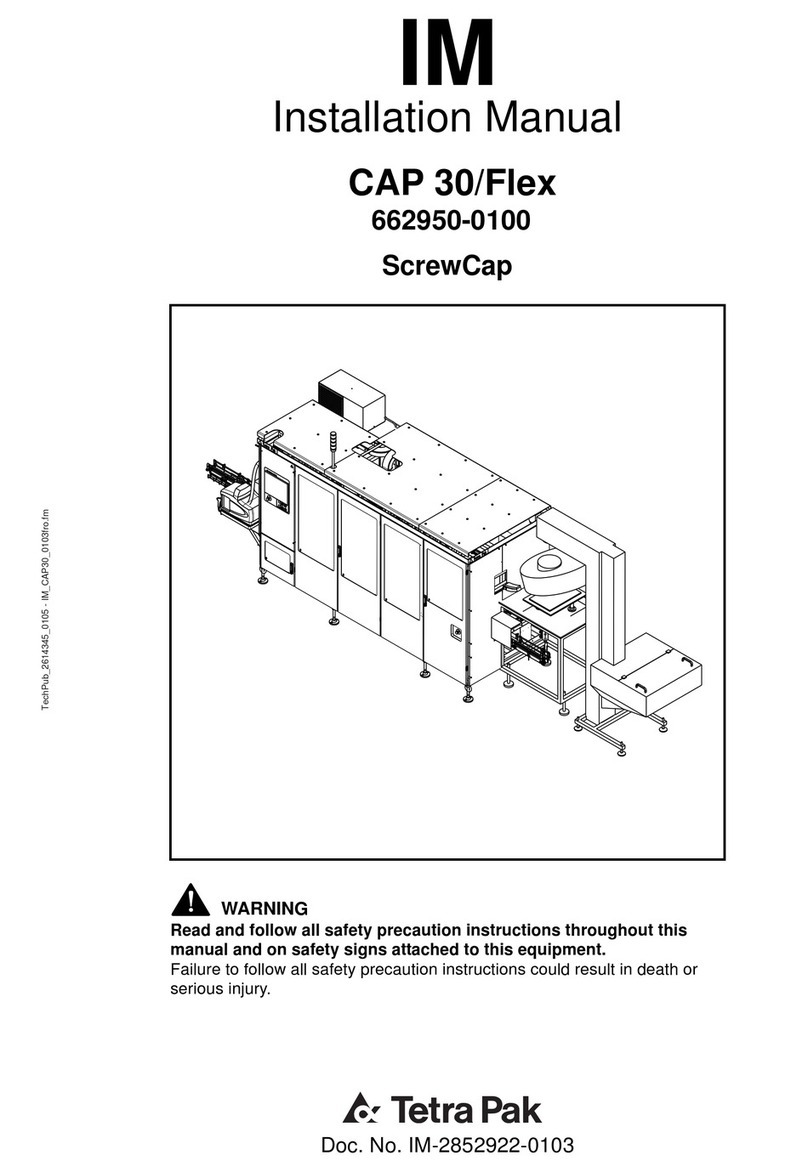

Tetra Pak HOYER COMET N User manual

CN901A

Tetra Pak

Hoyer

Tetra Pak Hoyer A/S Tetra Pak Hoyer Inc. Tetra Pak Hoyer S.p.A.

Soeren Nymarks Vej, 13 753 Geneva Parkway Via Monferrato, 52

DK 8270 Hoejbjerg P.O. Box 280 20098 San Giuliano Milanese (Milano)

Denmark Lake Geneva, WI 53147 Italy

Telephone + 45 89 393939 U.S.A. Telephone +39 2 98292.1

Telefax + 45 86 292200 Telephone +1 414 2497400 Telefax +39 2 9880171

Telex 68770 Alhoy DK Telefax +1 414 2497500

Wehopethattheinformationwillbeofhelptoyou.It

isbasedonconcretedataandonthebestofour

currentknowledge.

Readthecontentsofthemanualcarefully,including

thewarningsandrecommendations.Alsoreadthe

conditionsofsale,includingthosegoverningthe

warranty.

Nopartofthismanualmaybereproducedor

transmittedtothirdpartieswithoutthepriorwritten

permission of TETRAPAKHOYER.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Machine HOYER COMET N

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Serial Number

CN901A

Tetra Pak

Hoyer

F

1Machine identification data

2General

3Description of the machine and technical data

4Installation

5Set-up procedures

6Operating procedures

7Cleaning and maintenance

8Troubleshooting

9Parts catalogue

NOTE:

Allthedrawingsshowthemachineandstationsforproductiononsixlanes.

HOYER COMET N

CN901AA1-1

Tetra Pak

Hoyer

Contents

1 - MACHINE IDENTIFICATION DATA

1.1 Introduction .............................................................................................................. 1-2

1.2 Identification plate ................................................................................................... 1-2

1.3 Service centres ......................................................................................................... 1-3

CN901AA1-2

Tetra Pak

Hoyer

MODEL

SERIAL N.:

YEAR OF CONSTRUCTION:

ELECTRICAL SUPPLY:

PNEUMATIC SUPPLY:

REFRIGERANT:

HEATING GAS:

THERMAL CAPACITY:

kW

Kg.

Kcal/h

Via Monferrato, 52 - 20098 San Giuliano Milanese

( MI ) Italia - Tel. 02-982921 - Fax 02-9880171 Made in Italy

Tetra Pak

Hoyer

V

bar Nlt/min.

ph Hz

Type

1.2 Identification plate

For maintenance and service operations not

describedin this manual or forany other problem

of a technical nature, our Service Department is

at your complete disposal for information or to

Fig. 1.1 - Identification plate

1.1 Introduction

Thank you for having chosen a Tetra Pax Hoyer

machine.

We recommend that you read this manual

carefully as it contains essential information

regarding the installation, checking and

maintenance operations required to keep your

Themanualcontainstables,drawingsanddiagrams

whichwillallowyoutofamiliariseyourselfwithall

partsof themachine.

Please let us know if any information is missing

or is not sufficiently detailed. Your comments

will be used to improve this manual.

arrangeforthe necessary measures to be taken.

Whencontacting our Service Department, please

quote the data given on the identification plate

affixed to the machine and shown in Fig.1.1.

CN901AA 1-3

Tetra Pak

Hoyer

1.3 Service centres

Ifyouhaveanyrequirementorproblemthatrequires

ourassistance, please contact one of the following

service centres, which are authorised to perform

maintenanceand provide technicalservice under

warrantyfor Tetra Pak Hoyermachines.

EUROPEand

MiDDLEEAST:

TetraPak HoyerApS

SoerenNymarks Vej 13

DK-8270Hoejbjerg

Denmark

Phone: +45 89 39 39 39

Fax: +45 86 29 22 00

Tlx:687 70 alhoy dk

TetraPak HoyerS.p.A.

Via Monferrato, 52

I- 20098 San GiulianoMilanese

(Milan)

Italy

Phone: + 39 2 98 29 21

Fax: + 39 2 98 80 171

TetraPak HoyerFrance

c/oTetraLavalServiceSARL

R.C.S.Versailles B403 276 223

P.O. Box 56

F-78340Les Clayes-Sous-Bois

France

Phone: +33 1 30818184

Fax: +33 1 30818120

NORTHAMERICA:

Tetra PakHoyer Inc.

7711 95th Street

P.O. Box 0902

PleasantPrairie,WI 53158-0902

USA

Phone: +1 414 947 9100

Fax: +1 414 947 9190

SOUTHAMERICA:

Tetra Pak Hoyer Industria e

ComércioLtda.

Rua Napoleao de Barros, 1038

Cep04024-003 Sao Paulo-SP

Brazil

Phone: +55 11 573 9422

Fax: +55 11 549 5420

ASIA/PACIFIC:

Tetra PakHoyerShanghai

Shanghai Overseas Chinese

Mansion

Room 2105-2107

No.129, Yan'anXiLu

200040Shanghai

P.R.China

Phone: +86 21 6249 0860

Fax: +86 21 6249 9064

Tetra Pak Hoyer Service

3rdFloor,Molace Building

2231Pasong Tamo Street

Makati,Metro Manila

Philippines

Phone: +63 2 8132848

Fax: +63 2 8132866

SOUTHKOREA:

HoyerLtd.

4fl.DookyongBldg.

66-1/9Hannam-Dong

Yong San-Ku

140-210 Seoul

SouthKorea

Phone: +82 2 796 0362

Fax: +82 2 796 0365

THAILAND:

Tetra PakHoyer(Thai)Ltd.

1042Soi Poosin, SukhumvitSoi

66/1

Bangchak,Prakanong

Thailand

Phone: +66 2 3611680

Fax: +66 2 3612310

C.I.S.:

Tetra PakHoyer A/O

4thRostovskypeureulok

Dom1,stroenie1

R-11921 Moscow

C.I.S.

Phone: +7 502 2242160

Fax: +7 502 2242162

HOYER COMET N

CN901AB2-1

Tetra Pak

Hoyer

Contents

2 - GENERAL

2.1 Declaration of conformity ........................................................................................ 2-2

2.2 Preliminary points .................................................................................................... 2-2

2.3 General safety rules.................................................................................................. 2-2

2.4 Special warnings ...................................................................................................... 2-3

2.5 Ambient operating limits ......................................................................................... 2-3

CN901AB2-2

Tetra Pak

Hoyer

2.1 Declaration of conformity

Thismachinehasbeenmanufacturedinaccordance

withinternationalstandardsandhygieneandsanitary

legislationapplicabletofoodmachinery.

Inparticular Tetra Pak Hoyercertifies,through the

Declaration of Conformity supplied with the

machine,thattheHOYERCOMET Nmachineis

designedandmanufacturedinaccordancewiththe

provisions of Directive 89/392/EC (Machinery

Directive)andwiththeabove-mentionedstandards.

•Theillustrationsand drawings of the machine

are intended for general reference only and

are not necessarily accurate in every detail;

•The machine dimensions and specifications

given in this manual are not binding and may

be changed without prior notice;

•The drawings and all other documents

provided as a part of this machine remain the

property of Tetra Pak Hoyer and must not be

passed on to third parties without the written

permission of Tetra Pak Hoyer.

•The manual includes instructions for all

accessories mounted on the standard

machine.

•The machine is covered by warranty as

laid down in the purchase contract. Any

repair work not authorised by Tetra Pak

Hoyer carried out during the warranty

period will automatically invalidate the

warranty.

2.2 Preliminary points

2.3 General safety rules

•THESE SAFETY RULES HAVE BEEN

DRAWN UP IN YOUR INTEREST. Strict

observance will reduce the risk of accident

to yourself or to others.

•DO NOT attempt to move, install or operate

the machine before reading and assimilating

thecontentsofthismanual.Askyoursuperior

in case of doubt;

•make sure that all guards and safety covers

are in place BEFORE starting the machine;

•NEVER leave tools, mechanical parts or

other foreign materials on or inside the

machine;

•in the event of a malfunction, press the

emergency stop button.

•NEVERPUT YOUR HANDSINSIDE THE

MACHINE WHEN IT IS IN OPERATION;

•exercise caution even when the main switch

locatedonthe tunnel is in the"OFF"position,

as the supply conductors will still be live;

•shut off the compressed air supply before

disconnecting any pneumatic component;

•make sure that all guards and safety covers

are correctly in place BEFORE restarting the

production cycle subsequent to maintenance

or repair operations;

•proceed with caution at all times. Remember

that you are responsible for your own safety

and for that of your colleagues;

•make sure that applicable regulations are

observed when moving or lifting the

machine.

Ι

CN901AB 2-3

Tetra Pak

Hoyer

• All personnel operating the machine must be

familiar with the general safety rules and

must observe them strictly. Failure to follow

these rules may result in personal injury or

damage to machine components;

• maintenance work must be performed with

themachineturnedoff.The main switch must

be in the "OFF" position, the tunnel air val-

ve closed and a “work in progress” sign

affixed to the machine;

• the user must make sure that all the

instructions given in the manual are

scrupulously observed;

• users will be solely responsible for risks

caused by tampering with the safety system;

• Thesafetyof otherplantusedtogetherwiththis

machine,unless supplied directly byTetraPak

Hoyer,istheresponsibilityofthecustomer.

• Thepressure, speed, temperatureand voltage

limits and all instructions given are

indispensable for correct operation of the

machine and must always be complied with

by the customer.

• Ambient conditions must be taken into

consideration during installation.

• National legislation governing this type of

machinemust beobserved.

The machine is suitable for operation in the

following ambient conditions:

• Temperature : from 4°C to 40°C

• Humidity : from 20% to 95%.

FNOTE:

Tetra Pak Hoyer will accept no responsibility for

damage or injury caused by failure to comply

with the above warnings.

2.4 Special warnings

2.5 Ambient operating limits

HOYER COMET N

CN901AC3-1

Tetra Pak

Hoyer

Contents

3 - DESCRIPTION OF THE MACHINE AND TECHNICAL DATA

3.1 Description of the machine ...................................................................................... 3-2

3.2 Operation.................................................................................................................. 3-2

3.3 Technical data........................................................................................................... 3-3

3.4 Programming and control panel ............................................................................... 3-4

CN901AC3-2

Tetra Pak

Hoyer

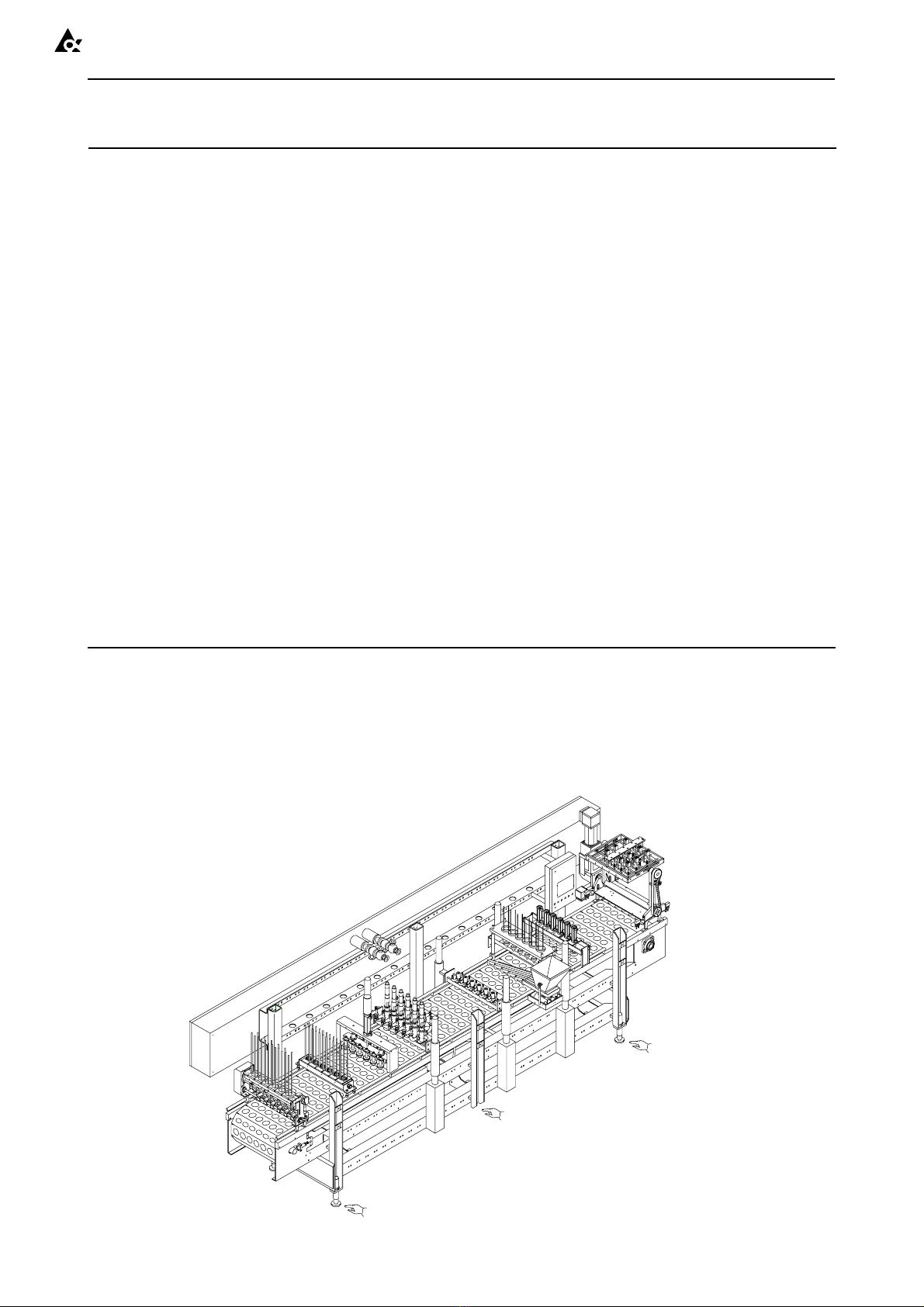

Fig.3.1

2

1

3

3

4

6

5

TheHOYERCOMETNisamachineusedfor

fillingavarietyofice-creamcontainers.

Thestructureofthemachine,themechanical

componentsandthecommercialcomponents

areallfabricatedinstainlesssteelorcorrosion

proofmaterials.Allthepartsdirectlyincontact

withtheproductareincorrosionproofmaterial

orothermaterialsapprovedforuseinthefood

industry.

Inordertopreventaccidentalcontactbetween

partsofthebodyandanymovingpartsinthe

machine,themachineitselfhasbeenfittedwith

protectivepanelsandshields,screw-downcovers

and/orsystemsrequiringspecialtoolsandthe

deliberateactionoftheoperatortoremovethem.

Themachineconsistsof:

1. Steel structure with adjustable feet (Part.1

3.1 Description of the machine

Fig.3.1).

2. Mechanical transmission system driven by

an electric motor fitted with an inverter.

3. Indexing gear unit for jog feed.

4. Set of lamellas with slots (Part.2 Fig.3.1)

specifically designed to hold the type of

container in production. The lamellas are

supported by two members which guide the

chains driven by the gear wheels..

5. Vacuum generator.

6. Pneumatic system.

7. Control panel with operator interface

program (Part.3 Fig.3.1).

- A stack of empty containers and a stack of

covers are placed manually in the relative

magazines (Part.4 and Part. 6, Fig.3.1).

- The lamellas, with the appropriate slots

(Part.2 Fig.3.1), move forward with a jog-

ging action. During the standstill period, an

empty container per line is placed in the slot.

- The lamella (Part.2 Fig.3.1) with the empty

containers is jogged forward once (a number

of times) and stops under the dosing stations

(Part.5Fig.3.1). Thedosers fillthe containers

with the required quantity of ice-cream,

3.2 Operation

chocolate and granules.

- The lamella with the full containers is jogged

forward once (a number of times) and stops

under the lid feed station (Part.6 Fig.3.2),

Onelid per lane ispositionedoverthecontain-

ers.Atthenextstation,the lidsarepressedonto

thecontainer.(An ink-jetdatestampingstation

isalso available onrequest.).

- At the end of the conveyor, the sealed con-

tainers are ejected by an electrically powered

combined lifting, extraction and transfer

system.

CN901AC 3-3

Tetra Pak

Hoyer

Fig.3.2

A

B

C

Standardpowersupply:

220-440V /3Ph/50-60Hz

Installedpower

Mainmotor: 2,2 kW

Beltmotor: 0,37kW

Totalinstalledpower: 9 kW

Netweight: 3500Kg

Grossweight: 4000Kg

Compressedair

Inletpressure: 6 barminimum

Consumption: 1300Nl/min

Inletpipediameter:1/2"gas

Dimensions

A(length) =5750mm

B(width) =1475mm

C(height) =2000mm

No.ofoperators:2

EquivalentA-weightedsoundpressurelevelat1

metre:67.5dBA

MaximuminstantaneousC-weightedsoundpres-

surelevelattheworkstations:lowerthan130

dB/20uPa.

3.3 Technical data

FNOTE:

Fig. 3.2 shows a machine for the production of

conesor cups.

CN901AC3-4

Tetra Pak

Hoyer

Fig.3.3

8

y

z

+

A1 A2

1

Enter

pdown

pdup

7

w

w

x9

*

/

=

5

p

q

r

4

m

n

o6

s

t

u

2

g

h

i3

j

k

l

1

d

e

f

0

c

b

a

shift

alarm clr

help print

2

3

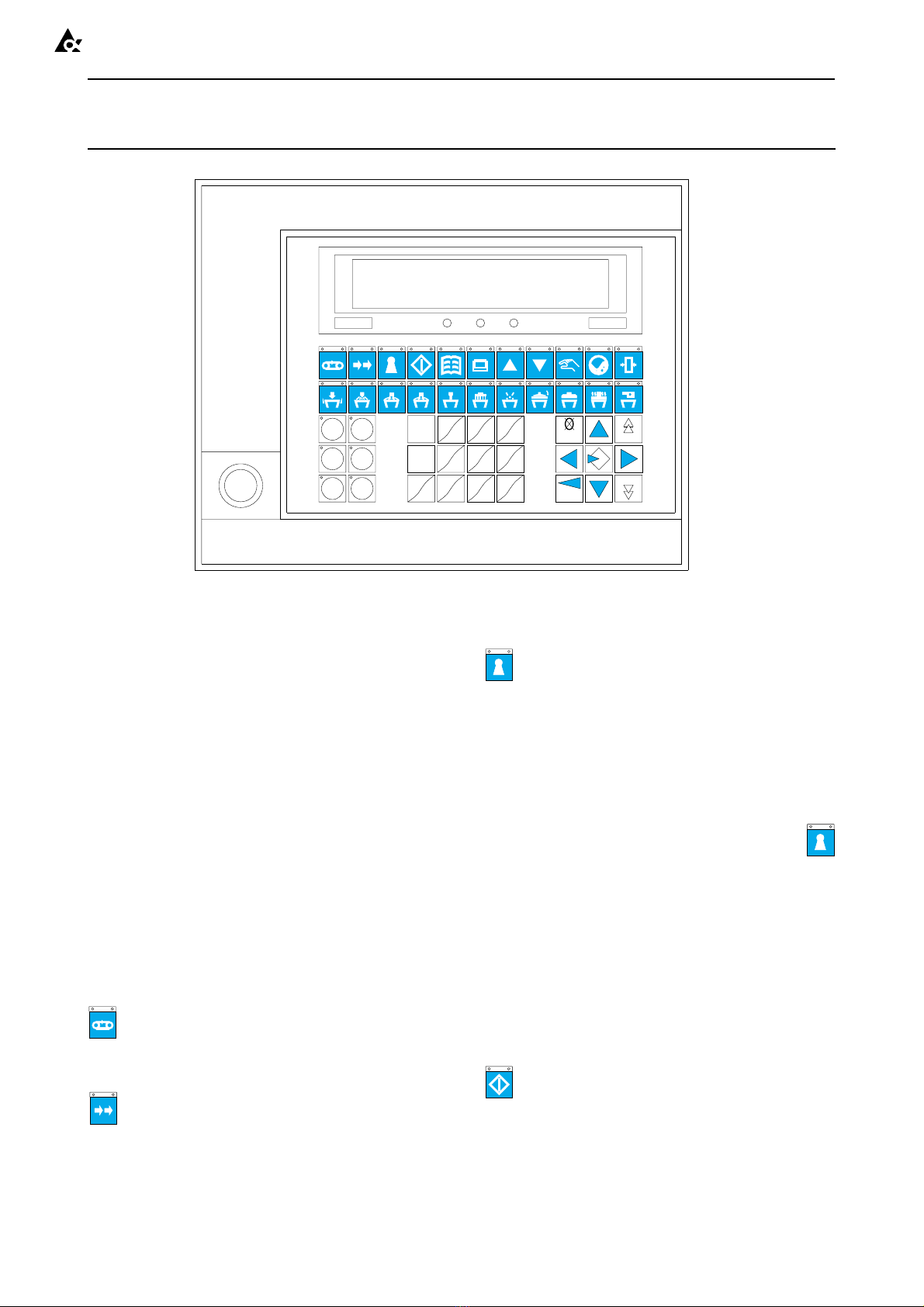

3.4 Programming and control panel

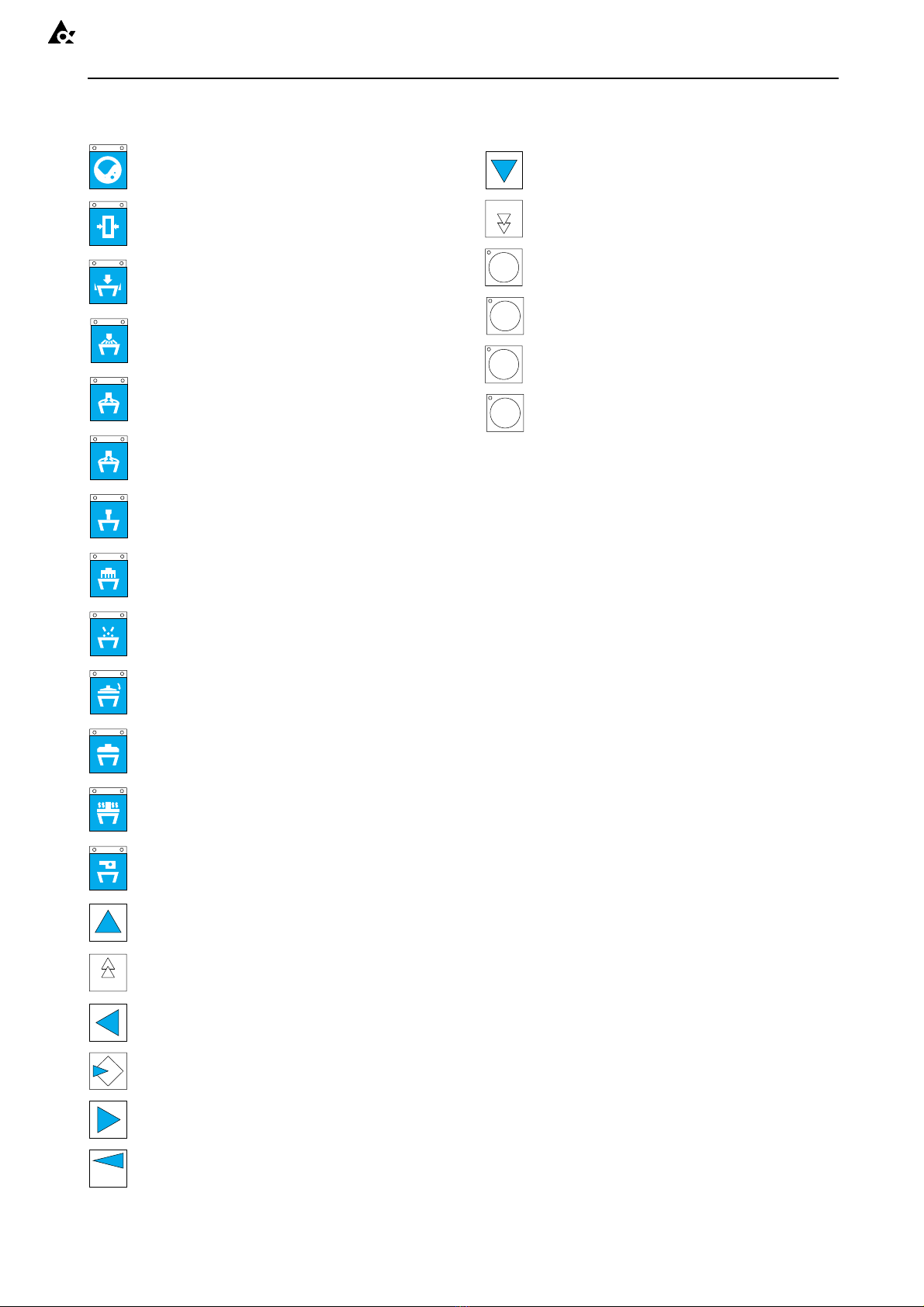

Start/Stop main motor

Jog main motor

Selectproduction cycle Auto/Manual

Start/Stop stations and C.I.P. cycle

Data settings

Select format

Save data

Apply data

Position station (for automatic start-up

of the production cycle), password “1 2

3 4”

CN901AC 3-5

Tetra Pak

Hoyer

Set C.I.P. data

Reset

Start/Stop loading cones-cups

Start/Stop spraying chocolate

Start/Stop doser 1

Start/Stop doser 2

Start/Sop pencil filler

Start/Stop topping

Start/Stop granule

Start/Stop loading lids

Start/Stop pressing lids

Start/Stop sealing head pressing

Start/Stop date stamp

Shift to the previous paragraph

pdup

Go to the previous page

Shift on the left

Activate value modification

Shift on the right

Enter

Confirm data

Shift to the next paragraph

pdown

Go to the next page

alarm

Display alarm messages

clr

Clear

help

Display help

print

Print

A1: Chocolate tank heaters

A2: Ice cream by-pass

Pos.1: Emergency push-button

Pos. 2:Alphanumeric keyboard

Pos. 3:Display

HOYER COMET N

CN901AD4-1

Tetra Pak

Hoyer

Contents

4.1 Unpacking and delivery checks ............................................................................... 4-2

4.2 Transport and installation......................................................................................... 4-2

4.3 Electrical connection................................................................................................ 4-3

4.4 Pneumatic connection .............................................................................................. 4-3

4.5 Checking direction of rotation ................................................................................. 4-4

4.6 Freezer connections.................................................................................................. 4-4

4 - INSTALLATION

CN901AD4-2

Tetra Pak

Hoyer

Fig.4.1

2

2

1

TheHOYERCOMETNmachineandthevarious

operatingstationsaretransportedinspecialcon-

tainers,generallywoodencrates.Unpackingmust

be done near to the final installation position of

themachine.Thecratescanbeeasilytransported

by a lift truck.

When the crate has been positioned correctly,

unpack as follows:

a. Unnail the lid and remove it. Do the same

thing with the side panels. Pay particular

attentionto the wooden spacer blockslocated

between the sides of the crate.

b. Remove the spare parts box and other com-

ponents from the crate.

c. Unnail the wooden blocks that hold the ma-

chine in place during transport and remove

the cellophane sheet.

d. Check that the contents of the crate corre-

spondto the description givenin the shipping

documents.

e. Check that all the covers and panels have

been correctly fitted and that there are no

loose parts.

f. Visually inspectallthe electrical components

to make sure that they are not damaged.

g. If any part/component is missing, stop un-

packing and immediately notify Tetra Pak

Hoyer.

h. If the machine has been damaged during

transit, notify the insurance company

immediately. Do not proceed beyond

unpacking until you are authorised to do so

by the insurance company.

4.1 Unpacking and delivery checks

4.2 Transport and installation

The following measures must be adopted during

the installation of the machine:

a. Position the machine at the place of

production. Move the machine using a fork

lift truck of suitable capacity (Part.1 Fig.4.1

fork positions), checking that there is

sufficient space to remove the guards and

allow ease of access to the internal machine

parts.

b. Adjust the feet (Part.2 Fig.4.1) until the ma-

chine is perfectly level both longitudinally

and transversally.

CN901AD 4-3

Tetra Pak

Hoyer

MODEL

SERIAL N.:

YEAR OF CONSTRUCTION:

ELECTRICAL SUPPLY:

PNEUMATIC SUPPLY:

REFRIGERANT:

HEATING GAS:

THERMAL CAPACITY:

kW

Kg.

Kcal/h

Via Monferrato, 52 - 20098 San Giuliano Milanese

( MI ) Italia - Tel. 02-982921 - Fax 02-9880171 Made in Italy

Tetra Pak

Hoyer

V

bar Nlt/min.

ph Hz

Type

Fig.4.2

4.3 Electrical connection

4.4 Pneumatic connection

Themachine’selectricalsystemhasbeenfactory

checked by Tetra Pak Hoyer engineers.

The machine’s components are electrically pro-

tected against short-circuits.

WARNING:

The connection must be made exclusively by

competent technicians familiar with accident

prevention legislation.

It is recommended that the power is taken from

a master switch fitted with thermal overload

cutoutandultra-rapidfusesofadequateamperage.

WARNING:

The differential cutout switch must be class “A”

and suitable for protecting inverter electronic

power circuits.

• Check the data on the identification plate

(Fig.4.2) to ensure that the machine is com-

patible with the factory voltage.

• Connect the three phases to terminals R S T

and the earth wire to the earth terminals in

the electric panel.

For the minimum sections of the power supply

cable, refer to the voltage and power values

reported on the identification plate (Fig.4.2) and

the standards in force in the country of

installation.

Connectthemachinetothecompressedairsupply.

The minimum working pressure is 6 bar.

If the pressure is less than 4 bar, a factory-set

pressure switch will disable the machine’s

functions.

Refer to CHAPTER 3 - DESCRIPTION OF

THE MACHINE AND TECHNICAL

CHARACTERISTICS for air consumption

and pipe sizes.

CN901AD4-4

Tetra Pak

Hoyer

Fig.4.3

2

3

1

Make sure that the ice-cream pipes from the

bypass valve (Part.2 Fig.4.3) to the dosers

(Part.3 Fig.4.3) are connected as required.

Connecttheice-creampipes fromthefreezersto

the ice-cream dosers through the bypass valves

(Part.2 Fig.4.3) located above the pneumatic

panel.

After having made the electrical and pneumatic

connections, check the direction of rotation of

the machine as follows:

• Make sure that there are no foreign bodies

which may prevent the machine from

operating.

• Release the emergency stop button.

• Rotate the main switch.

• Slowly turn on the air supply.

• Press the jog button and check that the

lamellas move from left to right (Part.1

Fig.4.3) when looking at the machine from

4.5 Checking the direction of rotation

4.6 Freezer connection

the operator’s side.

• Press the stop to stop the chain.

WARNING:

Ifthe direction of rotationis incorrect, invert the

two phases at the terminal board.

This operation must be carried out exclusively

by competent technicians familiar with accident

prevention legislation.

Before starting-up the freezers connected to the

machine, place a container under the ice-cream

bypassoutletpipeandanotherunder theproduct

collection chute.

HOYER COMET N

CN901AE5-1

Tetra Pak

Hoyer

Contents

5.1 Control panel adjustments........................................................................................5–2

5.2 Product change .........................................................................................................5–8

5.3 Mechanical and pneumatic adjustments................................................................... 5-9

5.3.1 Cone feed station adjustment .......................................................................... 5-9

5.3.2 Cup feed station adjustment............................................................................ 5-9

5.3.3 Tube feed and tube gauge station adjustment ............................................... 5-10

5.3.4 Gauging - chocolate spray station adjustment .............................................. 5-10

5.3.5 Ice cream doser station adjustment............................................................... 5-11

5.3.6 Volumetric dosing station adjustment ........................................................... 5-11

5.3.7 Pencil filler station adjustment ...................................................................... 5-12

5.3.8 Chewing gum doser station adjustment ........................................................ 5-12

5.3.9 Topping station adjustment ........................................................................... 5-13

5.3.10 Granule station adjustment............................................................................ 5-13

5.3.11 Lid feed station adjustment ........................................................................... 5-14

5.3.12 Cone lid closure station adjustment .............................................................. 5-14

5.3.13 Cup lid closure station adjustment ................................................................ 5-15

5.3.14 Lid sealing station adjustment ....................................................................... 5-15

5 - ADJUSTMENT AND FORMAT CHANGE PROCEDURES

CN901AE5-2

Tetra Pak

Hoyer

Fig.5.1

8

y

z

+

A1 A2

Enter

pdown

pdup

7

w

w

x9

*

/

=

5

p

q

r

4

m

n

o6

s

t

u

2

g

h

i3

j

k

l

1

d

e

f

0

c

b

a

shift

alarm clr

help print

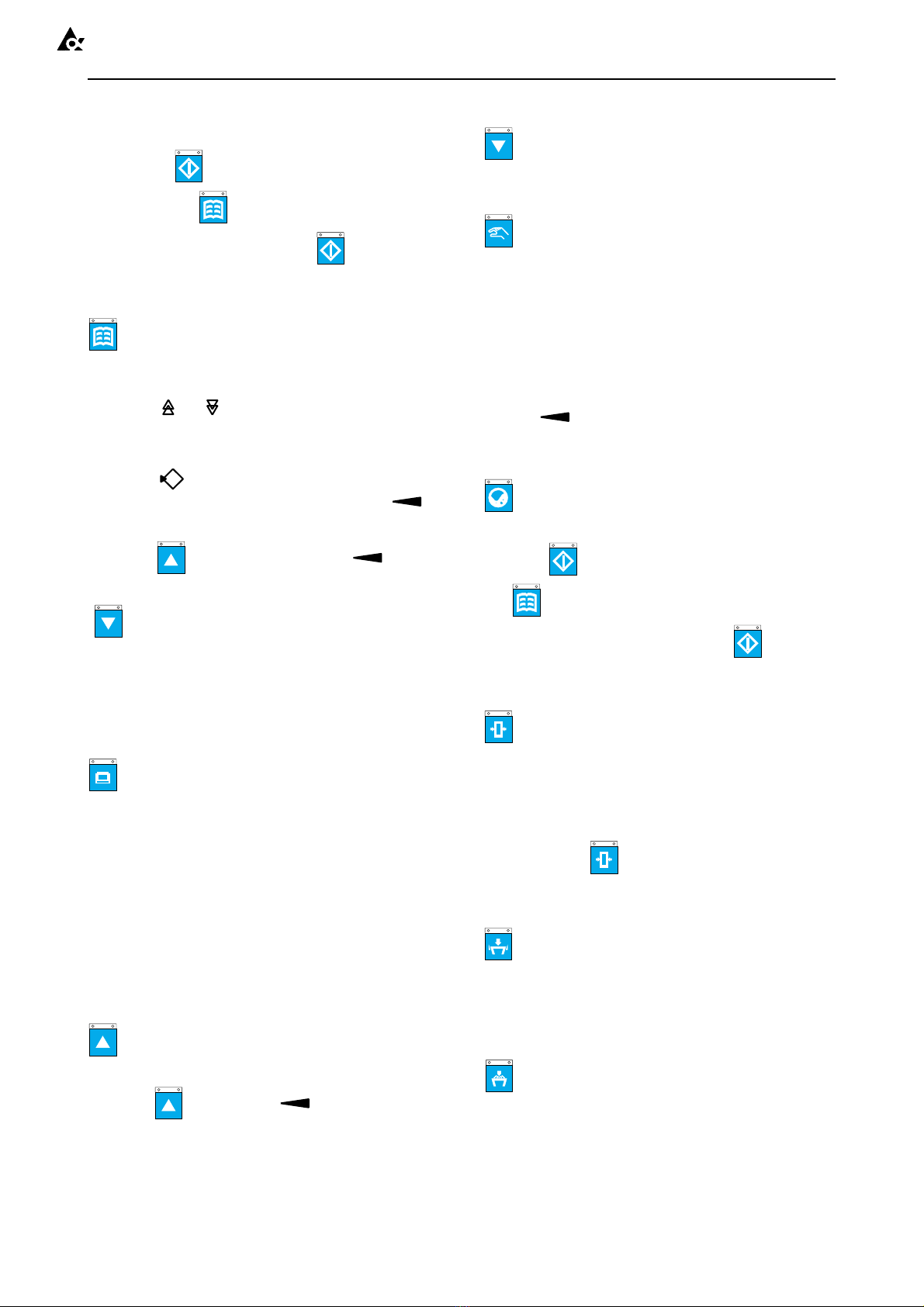

5.1 Control panel adjustments

5.1.1 PLCsettings

The various functions of the production line are

controlled by a PLC. Use the keypad (Fig. 5.1)

to programme the PLC as described below.

FNOTE:

The programme is set in the factory. Every time

the control panel is turned on, the main screen

with the text COMET N, the encoder degrees

and machine status will be displayed.

Twoled’scome on: the “POWER”led indicating

that the power is on and the “BATTERY” led

which will come on when the battery is low. The

“XO” led willflash if there isno communication

between the keypad and the PLC.

: START/STOP MAIN MOTOR

Starts or stops main motor.

: JOG MAIN MOTOR

Jogs or stops the step-by-step chain.

: SELECT PRODUCTION CYCLE

AUTO/MANUAL

When the power is on, the led on the keypad

display will flash if the machine is in manual

mode.

Press this key to display the machine’s current

status on the display.

Toputthe machine in automatic mode,press

; the led will stay on without flashing and the

display will indicate that the machine is in

automatic mode.

FNOTE:

The keys at the top (F1 through F11) are for

functions to be added to the machine.

: START/STOP STATIONS AND CIP

CYCLE

Turns stations F12 through F22 on and off. This

key is also used for the CIP washing cycle at the

end of production.

CN901AE 5-3

Tetra Pak

Hoyer

To perform CIP washing, stop the stations by

pressingthe key,then enter the required wash

time using the key.

After setting the duration press key to begin

washing.

: DATA SETTINGS

Press this key to display a series of video pages

on all the stations on the machine.

Use the P

g

up

P

g

dn

keys to reach the station you

wish to edit or enable.

Press the key to enable data editing. When

you have finished editing data, press

Enter

to

confirm.

Press the key “Savedata” and

Enter

to save

the format in the operator panel and then press

key: “Apply data” to transfer the format

to the PLC.

Press CLR to go back to the first page of the

display, indicating encoder degrees and machine

status.

: SELECT FORMAT

Press this key to call up a video page containing

formats provided by Tetra Pak Hoyer and those

entered by the customer for production.

The following example will appear on the next

page of the video:

CODE: 1

DESCRIPTION: STANDARD CONE

: SAVE DATA

After entering the required format, save it by

pressing and then

Enter

; next press to

transfer the format to the PLC.

: APPLY DATA

Transfers data to the PLC.

: POSITION STATIONS (for automatic

start-up of the production cycle); password

“1 2 3 4”

Enter the password “1 2 3 4” to view the video

page containing all the stations installed on the

machine. Enter the progressive number of steps

from the first to last station, and when you have

finished entering the steps of the last station,

press

Enter

to store the production cycle in

memory automatically.

: SET C.I.P. DATA

To perform CIP washing, stop the stations by

pressing ,then enter wash time settingsusing

the key.

After setting wash time, press to begin

washing.

: RESET

Resets alarms, broken microswitches, inverter

malfunctions, etc.

When an alarm is displayed, the technician must

check and repair the problem as necessary.

Press RESET on the display to remove the

alarm from the display.

: START/STOP LOADING CONES/

CUPS

Startsorstops loading of cones orcupsif enabled

by the current format.

: START/STOP SPRAYING

CHOCOLATE

Starts or stops the chocolate spray device if

enabled by the current format.

Other manuals for HOYER COMET N

1

Table of contents

Other Tetra Pak Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use