Tetra Pak HOYER CF2 User manual

Tetra Pak

Hoyer

CF2 03 - 20

B

Tetra Pak Hoyer S.p.A.

Via Monferrato, 54

20098 San Giuliano Milanese (Milano)

Italy

Telephone +39 2 98292.1

Telefax +39 2 9880171

HOYER CF2

We hope that the information will be of help to

you. It is based on concrete data and on the best

of our current knowledge.

Read the contents of the manual carefully,

including the warnings and recommendations.

No part of this manual may be reproduced or

transmitted to third parties without the prior

written permission of Tetra Pak Hoyer.

Tetra Pak

Hoyer

CF2 03 - 20

B

1Machine identification data

2General information

3Description of the machine and technical data

4Installation

5Operator panel

6Operating procedures

7Cleaning and maintenance

Spare parts list

Tetra Pak

Hoyer

1-1

HOYER CF2

Contents

CF2 03 A 20B

1 - MACHINE IDENTIFICATION DATA

1.1 Introduction .............................................................................................................. 1-2

1.2 Identification plate.................................................................................................... 1-2

1.3 Service centres ......................................................................................................... 1-3

Tetra Pak

Hoyer

1-2 CF2 03 A 20B

MODEL

SERIAL N.:

YEAR OF CONSTRUCTION:

ELECTRICAL SUPPLY:

PNEUMATIC SUPPLY:

REFRIGERANT:

HEATING GAS:

THERMAL CAPACITY:

kW

Kg.

Kcal/h

Via Monferrato, 52 - 20098 San Giuliano Milanese

( MI ) Italia - Tel. 02-982921 - Fax 02-9880171 Made in Italy

Tetra Pak

Hoyer

V

bar Nlt/min.

ph Hz

Type

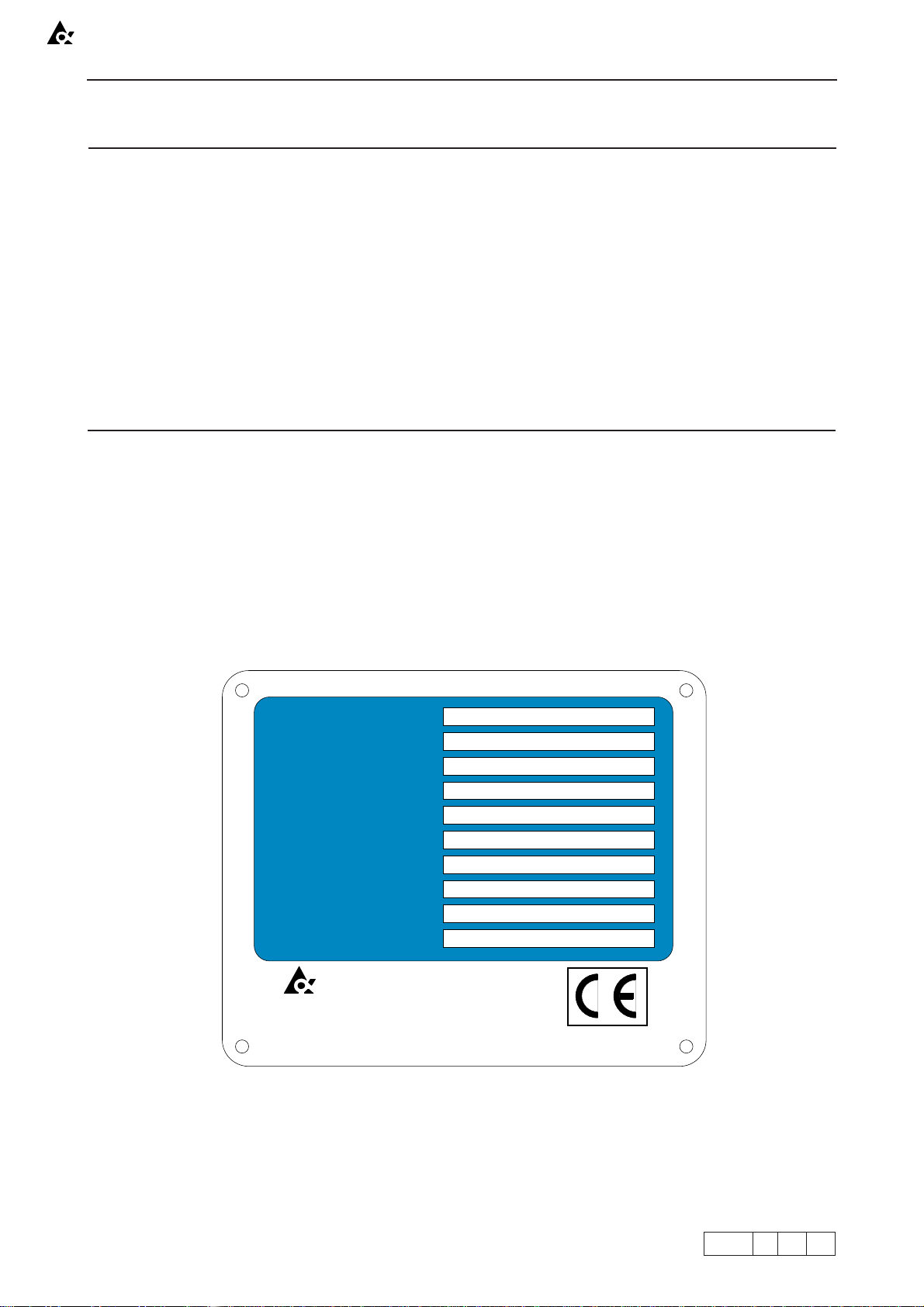

1.2 Identification plate

For maintenance and overhaul operations not

covered by this manual and for all technical

problems, our Service Department will be happy

to supply any information required and to agree

Fig. 1.1 - Identification plate

1.1 Introduction

Thank you for choosing a machine manufactured

by Tetra Pak Hoyer S.p.A.

We recommend that you read this manual

carefully as it is indispensable for the installation,

checking and maintenance operations required

to keep your machine in perfect working order.

Themanualincludestables,figuresandschemes

in order to let you familiarize with the machine

in all its details.

We will be pleased to receive your suggestions

should you find that any explanation has been

omitted or is not exhaustive.

We will take them into the gratest consideration

in an effort to improve the manual.

the necessary course of action.

When calling our Service Department, please

quote the data shown on the identification plate

affixed to the machine and shown in Fig. 1.1.

Tetra Pak

Hoyer

1-3

CF2 03 A 20B

1.3 Service Centres

For any assistance you may require, please

contact one of the following Tetra Pak Hoyer

authorised service centres:

EUROPE and

MIDDLE EAST:

Tetra Pak Hoyer ApS

Soeren Nymarks Vej 13

DK-8270 Hoejbjerg

Denmark

Phone: +45 89 39 39 39

Fax: +45 86 29 22 00

Tlx: 6 87 70 alhoy dk

Tetra Pak Hoyer S.p.A.

Via Monferrato, 52

I - 20098 San Giuliano Mila-

nese

(Milan)

Italy

Phone: + 39 2 98 29 21

Fax: + 39 2 98 80 171

Tetra Pak Hoyer France

c/o Tetra Laval Service SARL

R.C.S. Versailles B403 276 223

P.O. Box 56

F-78340 Les Clayes-Sous-Bois

France

Phone: +33 1 30818184

Fax: +33 1 30818120

NORTH AMERICA:

Tetra Pak Hoyer Inc.

7711 95th Street

P.O. Box 0902

Pleasant Prairie, WI 53158-0902

USA

Phone: +1 414 947 9100

Fax: +1 414 947 9190

SOUTH AMERICA:

Tetra Pak Hoyer Industria e

Comércio Ltda.

Rua Napoleao de Barros, 1038

Cep04024-003 Sao Paulo-SP

Brazil

Phone: +55 11 573 9422

Fax: +55 11 549 5420

ASIA/PACIFIC:

Tetra Pak Hoyer Shanghai

Shanghai Overseas Chinese

Mansion

Room 2105-2107

No. 129, Yan'an Xi Lu

200040 Shanghai

P.R. China

Phone: +86 21 6249 0860

Fax: +86 21 6249 9064

Tetra Pak Hoyer Service

3rd Floor, Molace Building

2231 Pasong Tamo Street

Makati, Metro Manila

Philippines

Phone: +63 2 8132848

SOUTH KOREA:

Hoyer Ltd.

4fl. Dookyong Bldg.

66-1/9 Hannam-Dong

Yong San-Ku

140-210 Seoul

South Korea

Phone: +82 2 796 0362

Fax: +82 2 796 0365

THAILAND:

Tetra Pak Hoyer (Thai) Ltd.

1042 Soi Poosin, Sukhumvit Soi

66/1

Bangchak, Prakanong

Thailand

Phone: +66 2 3611680

Fax: +66 2 3612310

C.I.S.:

Tetra Pak Hoyer A/O

4th Rostovsky peureulok

Dom 1, stroenie 1

R-11921 Moscow

C.I.S.

Phone: +7 502 2242160

Fax: +7 502 2242162

Tetra Pak

Hoyer

2-1

Contents

BCF2 03 B 20

HOYER CF2

2 - GENERAL INFORMATION

2.1 Declaration of conformity ........................................................................................ 2-2

2.2 Preliminary points .................................................................................................... 2-2

2.3 General safety rules .................................................................................................. 2-2

2.4 Special warnings ...................................................................................................... 2-3

2.5 Ambient operating limits ......................................................................................... 2-3

Tetra Pak

Hoyer

2-2 B

CF2 03 B 20

2.1 Declaration of conformity

This machine has been manufactured in

accordance with international standards and

hygiene and sanitary legislation applicable to

food machinery.

In particular Tetra Pak Hoyer certifies, through

the Declaration of Conformity supplied with the

machine, that the HOYER CF2 machine is

designed and manufactured in accordance with

the provisions of Directive 98/37/CE (Machinery

Directive) and with the above-mentioned

standards.

•The illustrations and drawings of the machine

are intended for general reference only and

are not necessarily accurate in every detail;

•The machine dimensions and specifications

given in this manual are not binding and may

be changed without prior notice;

•The drawings and all other documents

provided as a part this machine remain the

property of Tetra Pak Hoyer and must not

be passed on to third parties without the

written permission of Tetra Pak Hoyer.

•The manual includes instructions for all

accessories mounted on the standard

machine.

•The machine is covered by warranty as

laid down in the purchase contract. Any

repair work not authorised by Tetra Pak

Hoyer carried out during the warranty

period will automatically invalidate the

warranty.

2.2 Preliminary observations

2.3 General safety rules

•THESE SAFETY RULES HAVE BEEN

DRAWN UP IN YOUR INTEREST. Strict

observance will reduce the risk of accident

to yourself ot to others.

•DO NOT attempt to move, install or operate

the machine before reading and assimilating

the contents of this manual. Ask your superior

in case of doubt;

•make sure that all guards and safety covers

are in place BEFORE starting the machine;

•NEVER leave tools, mechanical parts or

other foreign materials on or inside the

machine;

•in the event of a malfunction, press the

emergency stop button.

•NEVER PUT YOUR HANDS INSIDE THE

MACHINE WHEN IT IS IN OPERATION;

•exercise caution even when the main switch

located on the tunnel is in the “OFF” position,

as the supply conductors will still be live;

•shut off the compressed air supply before

disconnecting any pneumatic component;

•make sure that all guards and safety covers

are correctly in place BEFORE restarting the

production cycle subsequent to maintenance

or repair operations;

•proceed with caution at all times. Remember

that you are responsible for your own safety

and for that of your colleagues;

•make sure that applicable regulations are

observed when moving or lifting the

machine.

Tetra Pak

Hoyer

2-3

B

CF2 03 B 20

• All personnel operating the machine must be

familiar with the general safety rules and

must observe them strictly. Failure to follow

these rules may result in personal injury

ordamage to machine components;

• maintenance work must be performed with

the machine turned off. The main switch must

be in the “OFF” position, the air valve closed

and a “ work in progress” sign affixed to the

machine;

• the user must make sure that all the

instructions given in the manual are

scrupulously observed;

• users will be solely responsible for risks

caused by tampering with the safety system;

• The safety of machines used in conjunction

with this machine, if not supplied directly by

tetra Pak Hoyer, is the responsibility of the

customer.

• The pressure, speed, temperature and voltage

limits and all instructions given are

indispensable for correct operation of the

machine and must always be complied with

by the customer.

• Ambient conditions must be taken into

consideration during installation.

• National legislation governing this type of

machine be observed.

The machine is suitable for operation in the

following ambient conditions:

• Temperature : from 4°C to 40°C

• Humidity : from 20% to 95%.

NOTE:

Tetra Pak Hoyer will accept no responsibility for

damage or injury caused by failure to comply

with the above warnings.

2.4 Special warnings

2.5 Ambient operating limits

Tetra Pak

Hoyer

HOYER CF2

3-1

Contents

3 - DESCRIPTION OF THE MACHINE AND TECHNICAL DATA

3.1 Description of the machine ...................................................................................... 3-2

3.2 Technical data ........................................................................................................... 3-2

3.3 Improprer use ........................................................................................................... 3-3

3.4 Demolition and disposal........................................................................................... 3-3

3.5 Control panel ............................................................................................................ 3-4

Tetra Pak

Hoyer

3-2

Fig. 3.1

3.1 Description of the machine

The machine has been planned and built to fill

containers (tubs) using a timed doser.

The filler is made of:

-Steelsupportstructure(Position1–Figure

3.1)

-Control panel (Position 2 – Figure 3.1)

-Shelf with regulatable height for the tubs’

support (Position 3 – Figure 3.1)

-Rolling doser (Position 4 – Figure 3.1)

activated by a pneumatic actuator (Position

6 – Figure 3.1)

-Pneumatic slide (Position 5 – Figure 3.1)

for the doser’s raising and descending

Alltheabovementionedequipmentisassembled

on a robust and compact structure made entirely

of stainless steel.

4

5

3

2

1

Tetra Pak

Hoyer

3-3

Fig. 3.2

AB

C

D

3.3. Improper use

Though the machine is equipped with a number of

safety systems, operators must be very careful to

make sure that no situations arise which could

potentially put them or others in danger.

Themachine is designed and built exclusively for

theusedescribedinchapter3.1.Anyotherusemust

be considered improper and unreasonable. The

manufacturershallnot beheldresponsoblefor any

damage caused by improper, erroneous or

unreasonable use.

Everyone who works on the machine must be

adequately trained in the correct working methods

and informed of the nature and functioning of

safety devices.

Dimensions and weight (Fig.3.2):

A (mm) 700

B (mm) 700

C (mm) 1400

D (mm) 850

Net weight: 95 Kg

Gross weight: : 110 Kg

Installed power:

Total installed power: 0.3 kW

Compressed air

Inlet pressure: 6 bar (87 psi)

Consumption: 55 Nl/min

Inlet pipe diameter: 1/4”

Maximum dimension of the container: 320 x

140 x115

Maximum volume of the container: 5lt.

Noise

EquivalentlevelofweightedacousticpressureA

at 1 meter: 67.5 dBA

Max.pressureofinstantaneousweightedacoustic

pressure C in workstations: below 130 dB/

20uPa..

No. of operators: 1

3.2 Technical specifications

Tetra Pak

Hoyer

3-4

Reset Up-Down

Dosing time Dosing

Main switch Emergency

Fig. 3.3

Reset: Key that resets the machine operations when the machine is started or after

an emergency.

Up-down: Position selector (up-down) of the doser.

Dosing time: Timer which sets the dosing time.

Doser: This activates the automatic cycle dosing operation.

Main switch: Main switch.

Emergency: Emergency key.

3.5 Control panel

3.4. Demolition and disposal

Information of use for disposal of the machine

and its components.

Themachinemustbedemolishedby specialised

personnel wearing appropriate safety garments

and working in compliance with safety and

environmental legislation.

Construction materials:

- steel, stainless steel, aluminium, cast iron

- copper, silver in electrical components

- rubber, nylon, PVC, resins and fibres.

No component is toxic or harmful.

Dispose of reduction gears carefully as they are

full of oil.

do not abandon these components or dispose of

them with regular waste.

WARNING! When finished using

machines and components, dispose of them in

accordancewiththelawsineffectinyourcountry.

Tetra Pak

Hoyer

HOYER CF2

4-1

Contents

4.1 Unpacking, shipment checks and transportation...................................................... 4-2

4.2 Installation ................................................................................................................ 4-3

4.3 Electrical connection ................................................................................................ 4-4

4.4 Pneumatic connection .............................................................................................. 4-4

4 - INSTALLATION

Tetra Pak

Hoyer

4-2

Fig. 4.1 Fig. 4.2

The machine and the various operating statons

are transported in special containers, generally

wooden crates. Unpacking must be done near to

thefinalinstallationpositionofthemachine.The

crates can be esily transported by a lift truck.

When the crate has been positioned correctly,

unpack as follows:

a. Unnail the lid and remove it. Do the same

thing with the side panels. Pay particular

attention to the wooden spacer blocks located

between the sides of the crate.

b. Remove the spare parts box and other

components from the crate.

c. Unnail the woodwn blocks that the hold the

machine in place during transport and remove

the cellophane sheet.

d. Check that the contents of the crate

correspond to the description given in the

shipping documents.

e. Check that all the covers and panels have

been correctly fitted and that there are no

loose parts.

f. Visually inspect all the electrical components

to make sure that they are not damaged.

g. If any part/component is missing, stop

unpacking and immediately notify Tetra Pak

Hoyer.

h. If the machine has been damaged during

transit, notify the insurance company

imediately. Do not proceed beyond

unpacking until you are authorised to do so

by the nsurance company.

4.1 Unpacking and delivery checks

Position the machine at the place of production.

Move the machine using a fork lift truck of

suitable capacity.

Tetra Pak

Hoyer

4-3

Fig. 4.3

The machine is completely validated and

regulated by producing ice-cream for about an

hour before shipment to the customer.

Consequently to install it, only the connections

with the mixture entrance and ice-cream exit,

compressed air pipes and the electric power need

to be carried out. No machine internal regulation

is needed and we strongly advise the regulations

carried out in the factory are not altered.

The installation procedure is carried out by the

following operations:

a. Position the machine in the place of

production, checking the dataplate data to

assure yourself that the machine is

compatible with the existing electric

powering

b. Connect the ice-cream entrance pipes to the

production freezer (Position 1, Figure 4.3)

c. Connect the compressed air pipe

d. Connect the machine to earth and to the

electrical powering.

4.2 Installation

1

Tetra Pak

Hoyer

4-4

Fig. 4.4

MODEL

SERIAL N.:

YEAR OF CONSTRUCTION:

ELECTRICAL SUPPLY:

PNEUMATIC SUPPLY:

REFRIGERANT:

HEATING GAS:

THERMAL CAPACITY:

kW

Kg.

Kcal/h

Via Monferrato, 52 - 20098 San Giuliano Milanese

( MI ) Italia - Tel. 02-982921 - Fax 02-9880171 Made in Italy

Tetra Pak

Hoyer

V

bar Nlt/min.

ph Hz

Type

Themachine’selectricalsystemhasbeenfactory

checked by Tetra Pak Hoyer engineers.

The machine’s components are electrically

protected against short-circuits.

WARNING:

The connection must be made exclusively by

competent technicians familiar with accident

prevention legislation.

It is recommended that the power is taken from

a master switch fitted with thermal overload

cutoutandultra-rapidfusesofadequateamperage.

WARNING:

The differential cutout switch must be class ”A”

and suitable for protecting inverter electronic

power circuits.

• Check the data on the identification plate

(Fig.4.2) to ensure that the factory voltage.

• Connect the three phases to terminals in the

electronic panel.

For the minimum sections of the power supply

cable, refer to the voltage and power values

reported on the identification plate (Fig.4.2) and

the standards in force in the country of

installation.

4.3 Electrical connection

4.4 Pneumatic connection

Connectthemachinetothecomprssedairsupply.

The minimum working pressure is 6 bar.

If the pressure is less than 4 bar, a factory-set

pressure awitch will disable the machine’s

functions.

Refert to CHAPTER 3 - DESCRIPTION OF

THE MACHINE AND TECHNICAL

CHARACTERISTICSforairconsumptionand

pipe sizes.

Tetra Pak

Hoyer

HOYER CF 2

5-1

Contents

5 - ADJUSTMENT PROCEDURES

5.1 Adjustments ............................................................................................................. 5-2

Tetra Pak

Hoyer

5-2

Fig. 5.1

Dosing adjustment

Use the timer (Position 1, Figure 5.1) (doser

time) to adjust the dosing time and the breaks

Doser height adjustment

- Loosen the screws fixing the doser to the

pneumatic slide.

- Adjust the doser height using the support

axles (Position 2, figure 5.1).

- Tighten the doser fixing screws.

Adjustment of the height of the tub support

shelf

- Position a tub on the shelf.

- Release the shelf from the rack (Position 3,

figure 5.1)

- Hook the shelf back up to the rack (Position

3,Fig. 5.1).

Tub centring adjustment

- Position a container on the shelf.

- Loosen the cursor’s locking knobs (Position

4, figure 5.1)

- Position the centring cursors to the edge of

container.

- Tighten the locking knobs.

5.1 Adjustments

1

2

3

4

3

HOYER CF2

6-1

Tetra Pak

Hoyer

CF2 03 FC 20

Contents

6 - OPERATING PROCEDURE

6.1 Preliminary checks ................................................................................................... 6-2

6.2 Start of production ................................................................................................... 6-2

6.3 End of production cleaning ...................................................................................... 6-3

6.4 Recommended products ........................................................................................... 6-3

6-2

Tetra Pak

Hoyer

CF2 03 FC 20

Fig. 6.1

Reset Up-Down

Dosing time Dosing

Main switch Emergency

6.1 Preliminary checks

Before starting the production, it is advisable to

carry out the following checks:

a. a. Ensure that the machine has been

previously made hygienic.

b. Ensure that the main switch has been

activated

c. Ensure that the valves for the pneumatic

powering are open.

d. Ensure that the emergency key is released.

e. Check the correct tightening of the clamp

connections.

f. Verify the correct connection of the freezer

pipes.

6.2 Start of production

a. Wait until the ice-cream has reached the

required density.

b. Set the dosing time on the timer (Dosing

time).

c. Set the dosing time break (1 or 2 seconds)

on the timer (Dosing time).

d. Turn the selector (Dosing). After the few

seconds (dosing break time), the doser carries

out the work cycle according to the set

dosing.

e. Turning the selector (up-down) to “Up”, the

doser starts the automatic work cycle with

the raised position far from the container.

Turing the selector (Up-down) to “Down”,

the doser starts the automatic work cycle in

the following sequence:

- vertical nearing to the container to be filled

using the pneumatic slide;

- doser opening and re-raising phase start

after the set dosing time;

- the doser goes away vertically;

- doser closing which can be advanced or

delayed using a regulatable height limit on

the pneumatic slide;

- doser rest in the “Up” position for the set

time.

f. Insert the tub under the doser and start the

production.

Other Tetra Pak Freezer manuals