Tetra Pak Hoyer Frigus 400 User manual

Tetra Pak

Hoyer

TetraPakHoyerS.p.A.

ViaMonferrato,54

20098SanGiulianoMilanese(Milano)

Italy

Telephone +39 2 98292.1

Telefax +39 2 9880171

We hope that the information will be of help to

you. It is based on concrete data and on the best

of our current knowledge.

Readthecontentsofthemanualcarefully,including

the warnings and recommendations.

No part of this manual may be reproduced or

transmitted to third parties without the prior

written permission of Tetra Pak Hoyer.

F40 03 -B 00

Hoyer Frigus 400

Tetra Pak

Hoyer

F40 03 -B 00

1Machine identification data

2Generalinformation

3Description of the machine and technical data

4Installation

5Set-up

6Operatingprocedures

7Cleaningandmaintenance

8Troubleshooting

9Spare parts list

Enclosures

HOYER FRIGUS 400

1-1

Tetra Pak

Hoyer

Contents

F40 03 AB 00

1 - MACHINE IDENTIFICATION DATA

1.1 Introduction ............................................................................................................... 1-2

1.2 Identificationplate ..................................................................................................... 1-2

1.3 Servicecentres........................................................................................................... 1-3

1-2

Tetra Pak

Hoyer

F40 03 AB 00

MODEL

SERIAL N.:

YEAR OF CONSTRUCTION:

ELECTRICAL SUPPLY:

PNEUMATIC SUPPLY:

REFRIGERANT:

HEATING GAS:

THERMAL CAPACITY:

kW

Kg.

Kcal/h

Via Monferrato, 52 - 20098 San Giuliano Milanese

( MI ) Italia - Tel. 02-982921 - Fax 02-9880171 Made in Italy

Tetra Pak

Hoyer

V

bar Nlt/min.

ph Hz

Type

1.2 Identification plate

For maintenance and service operations not

describedinthismanualorforanyotherproblemof

atechnicalnature,ourServiceDepartmentisatyour

completedisposalforinformationortoarrangefor

Fig.1.1 -Identificationplate

1.1 Introduction

Thank you for having chosen a Tetra Pak Hoyer

machine.

Werecommendthatyoureadthismanualcarefully

asitcontainsessentialinformationregardingthe

installation,checkingandmaintenanceoperations

requiredtokeepyourmacineinperfectcondition.

Themanualcontainstables,drawingsanddiagrams

whichwillallowyoutofamiliariseyourselfwithall

partsofthemachine.

Pleaseletusknowifanyinformationismissingoris

notsufficientlydetailed.Yourcommentswillbeused

toimprovethismanual.

thenecessarymeasurestobetaken.

WhencontactingourServiceDepartment,please

quotethedatagivenontheidentificationplateaffixed

tothemachineandshowninFig.1.1.

1-3

Tetra Pak

Hoyer

F40 03 AB 00

If you have requirement or problem that requires

ourassistance,pleasecontactone of the following

service centres, which are authorised to perform

maintenanceandprovidetechnicalserviceforTetra

PakHoyermachines.

EUMEA:

Tetra Pak HoyerApS

SoerenNymarksVej13

DK-8270Hoejbjerg

Denmark

Phone: +45 89 39 39 39

Fax: +45 86 29 22 00

Tlx:6 87 70alhoy dk

TetraPakHoyerS.p.A.

Via Monferrato, 54

I-20098 SanGiulianoMilanese

(Milan)

Italy

Phone: + 39 2 98 29 21

Fax: + 39 2 98 80 171

TetraPakHoyerFrance

c/oTetraLavalService SARL

R.C.S.VersaillesB403276 223

P.O. Box 56

F-78340Les Clayes-Sous-Bois

France

Phone: +33 1 30818184

Fax: +33 1 30818120

NORTH AMERICA:

TetraPakHoyerInc.

7711 95th Street

P.O. Box 0902

PleasantPrairie, WI 53158-0902

USA

Phone: +1 414 947 9100

Fax: +1 414 947 9190

SOUTHAMERICA:

Tetra Pak Hoyer Industria e

ComércioLtda.

Rua Napoleao de Barros, 1038

Cep04024-003 Sao Paulo-SP

Brazil

Phone: +55 11 573 9422

Fax: +55 11 549 5420

ASIA/PACIFIC:

TetraPak HoyerShanghai

Shanghai Overseas Chinese

Mansion

Room 2105-2107

No. 129,Yan'an Xi Lu

200040Shanghai

P.R.China

Phone: +86 21 6249 0860

Fax: +86 21 6249 9064

Tetra Pak Hoyer Service

3rdFloor,MolaceBuilding

2231PasongTamo Street

Makati,MetroManila

Philippines

Phone: +63 2 8132848

Fax: +63 2 8132866

SOUTH KOREA:

HoyerLtd.

4fl.DookyongBldg.

66-1/9Hannam-Dong

Yong San-Ku

140-210 Seoul

SouthKorea

Phone: +82 2 796 0362

Fax: +82 2 796 0365

THAILAND:

TetraPak Hoyer(Thai)Ltd.

1042Soi Poosin, Sukhumvit Soi

66/1

Bangchak,Prakanong

Thailand

Phone: +66 2 3611680

Fax: +66 2 3612310

C.I.S.:

TetraPakHoyerA/O

4thRostovskypeureulok

Dom1, stroenie 1

R-11921 Moscow

C.I.S.

Phone: +7 502 2242160

Fax: +7 502 2242162

1.3 Service centres

HOYER FRIGUS 400

2-1

Tetra Pak

Hoyer

Contents

F40 03 BB 00

2 - GENERAL INFORMATION

2.1 Declarationofconformity ........................................................................................... 2-2

2.2 Preliminarypoints ....................................................................................................... 2-2

2.3 Generalsafetyrules .................................................................................................... 2-2

2.4 Specialwarnings ........................................................................................................ 2-3

2.5 Residualrisks ............................................................................................................. 2-3

2.6 Ambientoperatinglimits ............................................................................................. 2-3

2-2

Tetra Pak

Hoyer

F40 03 BB 00

2.1 Declaration of conformity

Thismachinehasbeenmanufacturedinaccordance

withinternationalstandardsandhygieneandsanitary

legislationapplicabletofoodmachinery.

InparticularTetraPakHoyercertifies,throughthe

Declaration of Conformity supplied with the

machine,thattheHOYERFRIGUS400machine

isdesigned and manufactured in accordancewith

theprovisionsofDirective89/392/CE(Machinery

Directive)andwiththeabove-mentionedstandards.

•Theillustrations and drawingsof the machine

areintendedforgeneralreferenceonlyand are

notnecessarilyaccurateineverydetail;

•Themachinedimensionsandspecificationsgiven

in this manual are not binding and may be

changedwithoutpriornotice;

•Thedrawingsandallotherdocumentsprovided

as a part this machine remain the property of

TetraPak Hoyer and mustnot bepassed onto

thirdparties without thewrittenpermission of

Tetra Pak Hoyer.

•The manual includes instructions for all

accessoriesmountedonthestandardmachine.

•Themachineiscoveredbywarrantyaslaid

downin thepurchasecontract.Anyrepair

work not authorised by Tetra Pak Hoyer

carriedoutduringthewarrantyperiodwill

automaticallyinvalidatethewarranty.

2.2 Preliminary observations

2.3 General safety rules

•THESE SAFETY RULES HAVE BEEN

DRAWN UP IN YOUR INTEREST. Strict

observance will reduce the risk of accident to

yourselfottoothers.

•DO NOT attempt to move, install or operate

themachinebeforereadingandassimilatingthe

contents of this manual.Ask your superior in

caseof doubt;

•makesurethatall guards and safetycoversare

inplaceBEFOREstarting themachine;

•NEVERleavetools,mechanicalparts or other

foreignmaterialson orinsidethemachine;

•intheeventofamalfunction,presstheemergency

stopbutton.

•NEVER PUTYOUR HANDS INSIDE THE

MACHINE WHEN ITIS IN OPERATION;

•exercise caution even when the main switch

locatedon the tunnelis in the“OFF” position,

asthesupplyconductorswillstillbelive;

•shut off the compressed air supply before

disconnectinganypneumaticcomponent;

•makesurethatall guards and safetycoversare

correctly in place BEFORE restarting the

productioncyclesubsequenttomaintenance or

repairoperations;

•proceedwithcautionatalltimes.Rememberthat

youareresponsibleforyourown safetyandfor

thatofyourcolleagues;

•make sure that applicable regulations are

observedwhenmovingorliftingthemachine.

Ι

2-3

Tetra Pak

Hoyer

F40 03 BB 00

• All personnel operating the machine must be

familiarwiththegeneralsafety rules and must

observethemstrictly.Failuretofollowtheserules

may result in personal injury ordamage to

machinecomponents;

• maintenanceworkmustbeperformedwiththe

machineturnedoff.Themainswitchmustbein

the“OFF” position, the air valve closed and a

“workinprogress”signaffixedtothemachine;

• theusermustmakesurethatalltheinstructions

giveninthemanualarescrupulouslyobserved;

• userswillbesolely responsibleforriskscaused

bytamperingwiththesafetysystem;

• Thesafetyofmachinesusedinconjunctionwith

thismachine,ifnotsupplieddirectlybytetraPak

Hoyer,istheresponsibilityofthecustomer.

• Thepressure, speed, temperature and voltage

limitsandallinstructionsgivenareindispensable

forcorrect operation of the machine and must

alwaysbecompliedwithbythecustomer.

• Ambient conditions must be taken into

considerationduringinstallation.

• National legislation governing this type of

machinebeobserved.

Themachineissuitableforoperationinthefollowing

ambientconditions:

• Temperaturae : from 4°C to 40°C

• Humidity : from20%to95%.

FNOTE:

Tetra Pak Hoyer will accept no responsibility for

damageorinjurycausedbyfailuretocomplywith

theabovewarnings.

2.4 Special warnings

2.6 Ambient operating limits

The Frigus 400 maker is used for combining ice-

creammixturewith sanitary air infixedquantities

and, subsequently,forformingtheice-creamwith

the addition of cold generated by a refrigeration

cycle.

Themixtureofice-creamandsanitaryairisblended

inside a manifold by means of the pressure of a

rotatingpump and the injectionof compressed air

whichisthen pushed tothecylindrical evaporator

of a refrigerating system for the treatment of ice-

cream.

Severalissuesarise when adaptingthe pre-printer

tosuittheneedsof man:moreprecisely,centralizing

the controls on a single instrument panel for the

functionsofadjustmentand control.

Allthetransmissionparts,thekinematicmotionsand

the refrigerating system are protected by fixed

boards.

Asignalofdangerisplacedontheflapoftheelectric

boxtoindicatelive equipment.

Foradditionalsafety,theremainingriskisrecalled

inparagraph3.5Instructionsonbananddanger

signals.

2.5 Residual Risks

HOYER FRIGUS 400

2-1

Tetra Pak

Hoyer

Contents

F40 03 CB 00

3 - DESCRIPTION OF THE MACHINE AND TECHNICAL DATA

3.1 Descriptionofthemachine.......................................................................................... 3-2

3.1.1 Filterset ........................................................................................................... 3-3

3.1.2 Mixpump ......................................................................................................... 3-3

3.1.3 Freezingcylinder ............................................................................................... 3-3

3.1.4 Refrigeratingplant ............................................................................................. 3-3

3.1.5 Electricalsystem ............................................................................................... 3-4

3.1.6 Controlpanel.................................................................................................... 3-5

3.2 Technicaldata ............................................................................................................ 3-6

3.3 Improperuse ............................................................................................................. 3-7

3.4 Demolitionanddisposal.............................................................................................. 3-7

3.5 Warnings,prohibitionanddangersigns........................................................................ 3-7

2-2

Tetra Pak

Hoyer

F40 03 CB 00

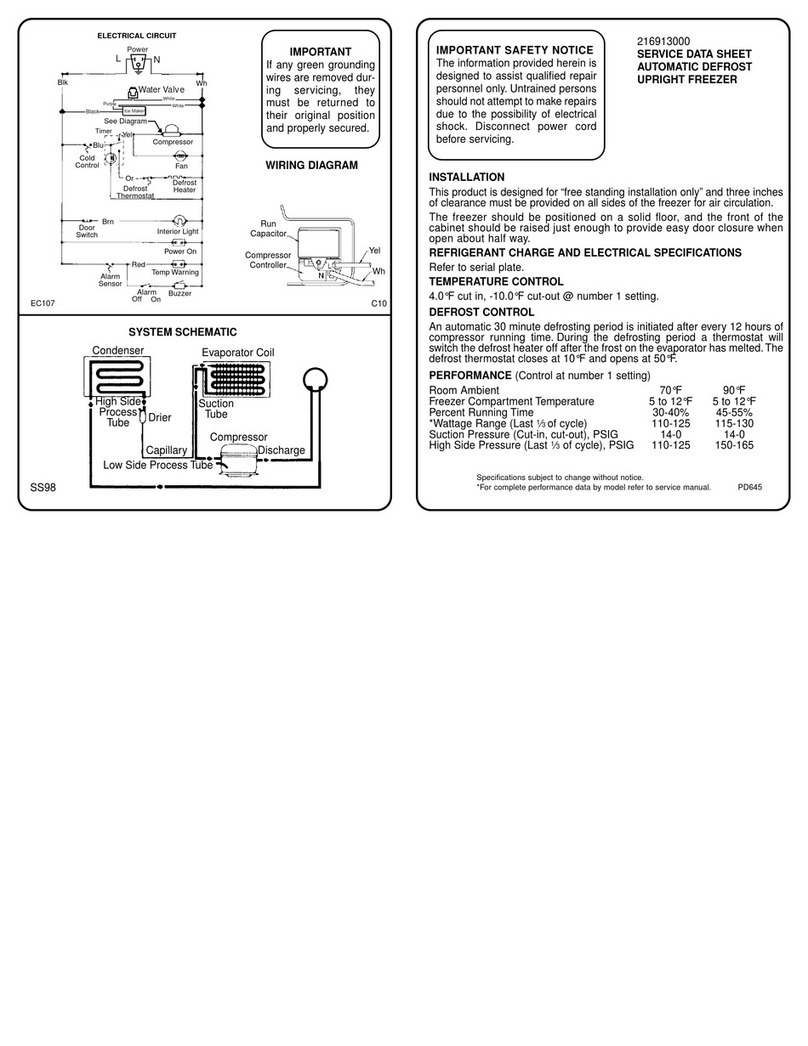

Fig.3.1

Fig.3.2

4

2

3

5

1

3.1 Description of the machine

TheFRIGUS6000mixessanitisedairintoicecream

mixtoobtainthedesiredoverrun,coolsmixwithair

incorporated in it to create the viscous product

knownasicecream,andsuppliessufficientpressure

toconveytheicecreamtoitsdestinationthrougha

pipe.

In order to carry out these functions the machine

incorporatesthefollowingcomponents:

- asetoffilterswhichsanitiseaircomingfromthe

compressedairsupply;

- apump whichreceives mixfrom ageingvats,

addssanitised air, andsendsthe product tothe

freezingcylinder;

- freezingcylinderwithadasherandblades,inside

whichairisuniformlyblendedintothemixand

the product is cooled until it takes on a thick

consistency;

- arefrigeratingplantconnectedtotheoutsidewall

ofthefreezingcylindertocoolit down;

- anelectrical system for command andcontrol

ofallmachinefunctions.

Thecompressed air supply(the machine does not

includeanaircompressor)travelsthroughapressure

reducer (1) and a mesh filter (2) which separates

outanylargeparticles;itthengoesthroughamicro-

filter for removal of oil vapours (3) and an active

carbonfilter(4) which eliminatesodours. Finally,

thecleanairgoesthroughasterilisableTeflonmem-

branefilter(5)withmicroscopicporesspecifically

intendedto stop thepassage of bacteria.

The sanitised air thus obtained is let into the mix

betweenthefirstandsecondstageofthemixpump,

under a pressure which may be controlled by the

operator with a command on the control panel;

pressure may be adjusted to increase ice cream

volume.

3.1.1 Filterset

All these items of equipment are assembled on a

strong,compactstainlesssteelframe.

2-3

Tetra Pak

Hoyer

F40 03 CB 00

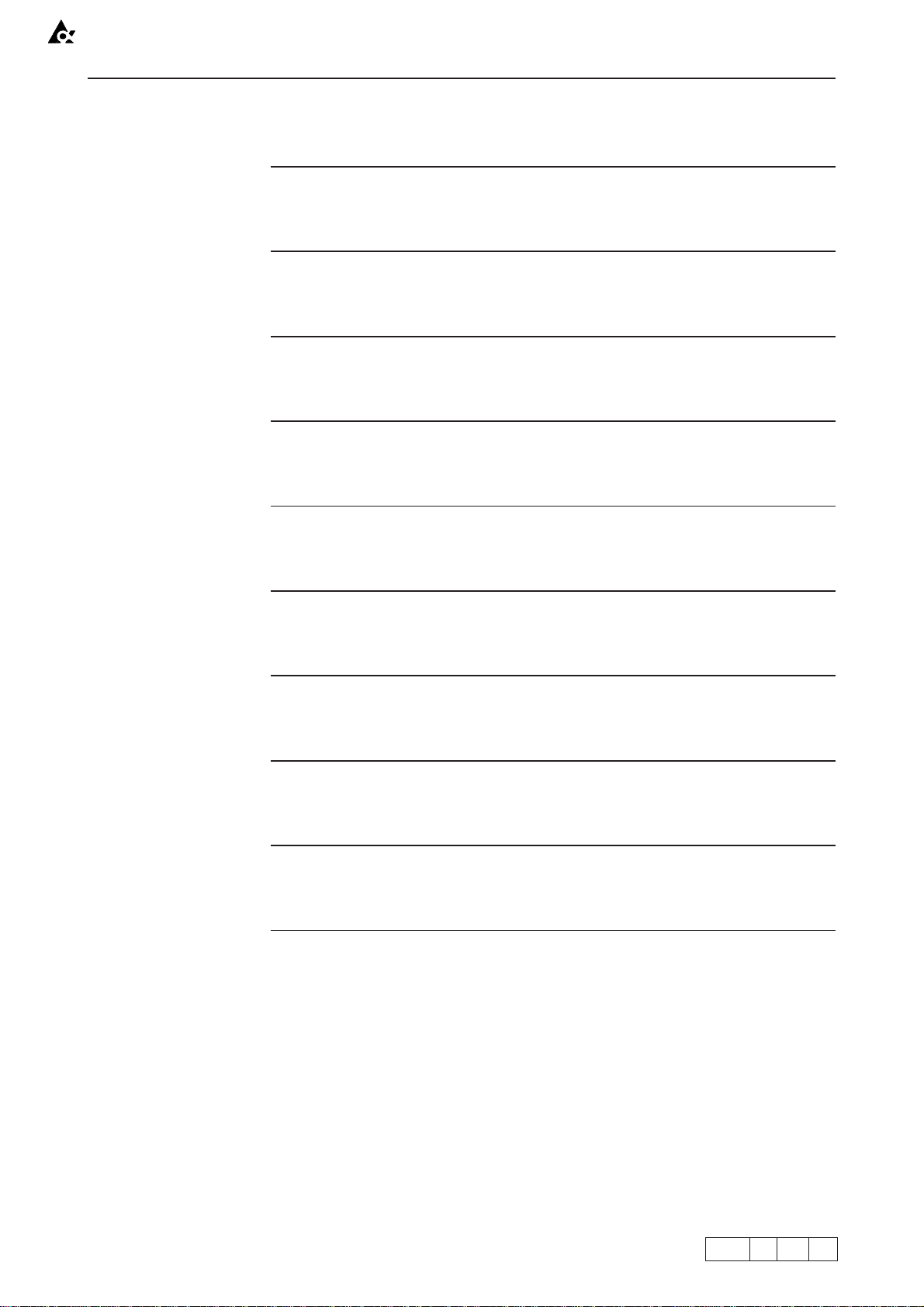

Fig.3.3

Fig.3.4

2

1

3

2

1

3

4

This is a two stage pump constructed with two

pistonsofdifferentsizes.Thefirststage(1)receives

andmetersthequantityofmixsetbytheoperatorin

accordancewiththehourlyproductionrequired;the

secondstage(2)receives mixdispensedbythefirst

withsanitisedairletinbetweenthe two stages and

sendsitallto thefreezingcylinder.

Asthe differencein volume between the first and

thesecond stage (determinedby pistonsize) does

notchangedependingoncylinderpressureandpump

speed, the quantity of air let in per unit of mix is

constantanddependsonairpressure.Byadjusting

thepressureofsanitisedair,theoperatortherefore

controls the increase in volume, which remains

constantthroughouttheproductioncycle.

Thepumpisdrivenbyanelectricmotorcommanded

byaninverter(for speedchanges)andincorporates

apneumaticallydrivenbypass(3) forCIPwashing.

It works properly at relatively high pressures, so

3.1.2 Mixpump

thatno extraction pump is needed coming off the

machine.

Thisis the mostimportant part ofthe machine: an

uprightpipewithachromecoatingonitsinsidewalls,

surroundedbya jacket in whichcoolantgas flows

tocool downthe cylinder.Adasher (1) with three

bladesrotatesinsideit,scrapingthechrome-plated

insidesurfacetoensurethat frozen ice creamdoes

not build up on the walls. The top (2) and bottom

(3) ends of the cylinder are closed by two covers,

whichincorporate the mix feed pipe (bottom) (3)

andtheice cream exitvalve(top) (4).

Mixblendedwithsanitaryaircomingfromthepump

flowsintothebottom partofthecylinder(3);onits

way to the top it is whisked by the dasher (1) and

cooledbycontactwiththewallsofthecylinder,kept

coldbytherefrigeratingplant.Theicecreamforms

andthenflowsoutoftheicecreamoutletvalve(4)

,whichiscontrolled pneumatically to regulatethe

pressureoficecreaminthecylinder.

In order to make sure the machine operates

correctly, it is important to be very careful not to

damagethe cylinder, always making sure that the

3.1.3 Freezingcylinder

scraperbladesareinperfectconditionandhavebeen

assembledcorrectly.

2-4

Tetra Pak

Hoyer

F40 03 CB 00

Composedofthefreezingcylinder (evaporator), a

Copeland Scroll Compliant rotary compressor, a

high efficiency condenser, an economiser, a

thermostatvalveandanumberofminoraccessories.

Allthesecomponentsaredesignedspecificallyfor

operationatlowtemperatures usingR22orR404A

coolantgases.

Cooling is carried out by steam compression: the

compressorpumpsgasintothecondenser,whereit

iscooledandliquefied,andtheliquidgasthenpasses

throughthethermostatvalveandisvaporisedinthe

freezercylinder(transformingintogaseousstateonce

more) before returning to the compressor and

startingthe cycle again.Vaporisationofgasin the

freezingcylinderremovesheatfromtheicecream

mix,whichcoolsdown;theheatisthendisposedof

3.1.4 Refrigeratingplant

Theelectricalsystemconsistsof the operatorpanel

andtheelectricalpanelwhichcoversalloftherear

ofthemachine.Theoperatorpanelmaybeused to

activateordeactivateallmachinefunctions,adjust

functionsandindicateanomalies.Theelectricalbox

attherearcontains the main switchandall control

andpower devices.

3.1.5 Electricalsystem

inthecondenser,whereitistransferred tothewater

inthetower(orwell),heatingit.

Apressureswitchvalveassembledonthecondenser

watercircuitkeepscondensationpressureconstant,

independentlyofwatertemperature.

The system mounted on the Frigus 600 is a

particularly efficient one which makes use of a

dependable, low maintenance Scroll Copeland

compressorwhichacts as atwo-stagecompressor

withaneconomisertoobtainconsiderablecooling

capacityandimproveddependability.

2-5

Tetra Pak

Hoyer

F40 03 CB 00

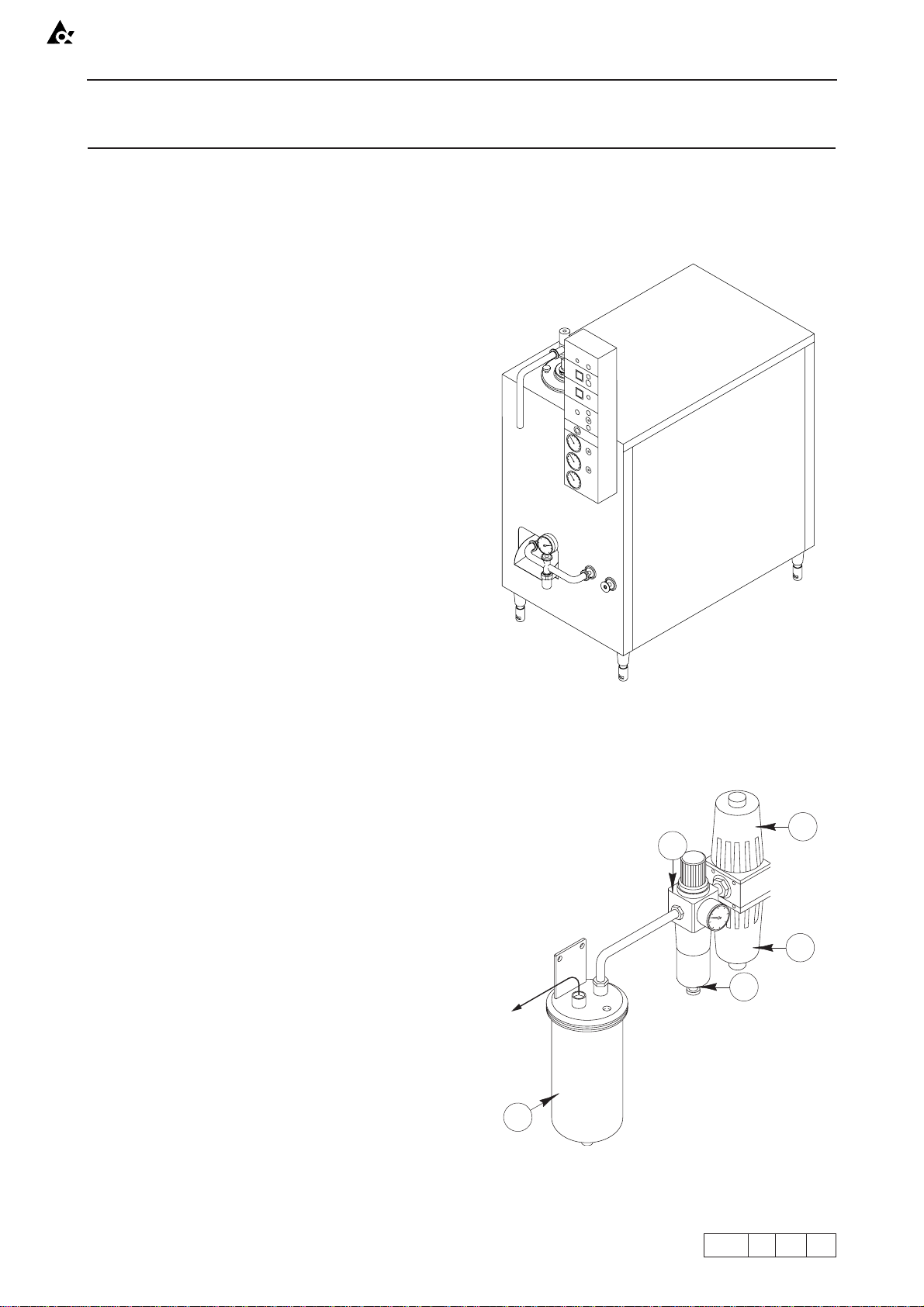

Fig.3.5

Hoyer

Frigus

21

4

3

5

67

1

0

8

11

9

14

12

13

1615

17

18

1Whitepowerindicatorlamp(L1)

2Redthermalswitchindicatorlight(L2)

3Pumpstart/stopswitch(SL1)

4Litrecounter(D1)

5Pumppotentiometer(P1)

6Dashmotorammeter(D2)

7Dasherstart/stopselector (SL2)

8Compressorstart/stopswitch (SL3)

9Overrunair ON/OFF switch(SL4)

10 Hotgascontrolpotentiometer (P2)

11 C.I.P.washingswitch(SL5)

12 Emergencystoppushbutton

13 Overrunpressuregauge(M1)

14 Overrunpressureregulator(P3)

15 Cylinderoutletvalvepressureindicator(M2)

16 Cylinderoutletvalvepressurecontrol(P3)

17 Coolantevaporationpressuregauge

18Gaugefordetection of ice cream pressureincylinder

3.1.6 Controlpanel

2-6

Tetra Pak

Hoyer

F40 03 CB 00

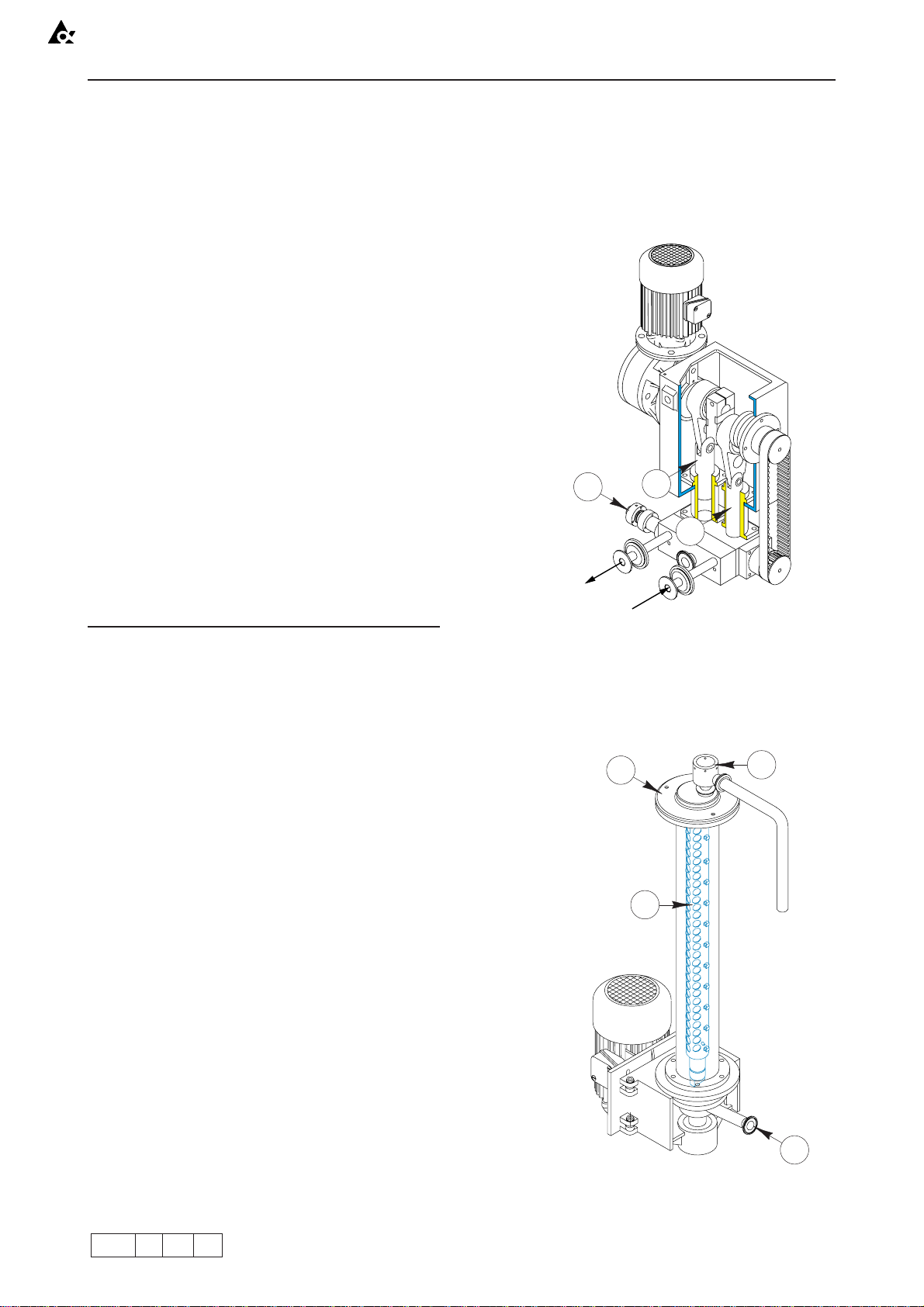

A

B

C

Fig.3.6

3.2 Technical data

Dimensionsandweights:

Dimensions A = 1330

mm B = 755

mm C = 1665 ±25

mm

Netweight: 525

Kg

Grossweight: 725 Kg

Volume(withpackaging): 2.96 m³

(1.6 x 0.95 x 1.95 h metres)

Ratedcapacity:

from100 to 400litres/hour of icecream at –5.5ºC

Standardconditions:

Mixinputtemperature: + 4°C

Overrun:

100%

Neutralmixwith38%solids content

Nominalcapacityinstandardconditions:

200 to 600 l/h ice cream at –5.5ºC

Electricalspecifications:

Dashermotor : 4 kW

Pumpmotor: 0.75 kW

Refrigeratorcompressor: 6 kW

Auxiliaries: 0.85 kW

Totalinstalledpower: 11.6 kW

Compressedair:

Operatingpressure: 6÷10 bar

Consumption(max.): 10 Nl/min

Filteringdegree A0

Connector: 1/2”

female

Refrigeratingplant:

Coolantgas: R404A

Quantity: 2.8 Kg

Condensationwater:

a) dwellwater @ + 5°C 600 l/h

b) mainswater@ +15°C 1100l/h

c) tower water@ +28°C 3300l/h

Waterinletconnector: 1”gasfemale

Wateroutletconnector: 1”gasfemale

Noise:

A-weighted equivalent sound pressure level at 1

metre: Leq(A) = 69.9 dB(A)

Max. C-weighted instantaneous sound pressure

levelatworkingpositions:

Lessthan 130 dB/20uPa

Max.non-weightedsoundpressurelevelatworking

positions: Lessthan 140 dB/20uPa

Electromagneticcompatibility:

Conforms to VDE 0843/IEC801; wiring in

accordancewith EN55011

2-7

Tetra Pak

Hoyer

F40 03 CB 00

3.5 Warnings, prohibition and danger signs

WARNING:

Thedoorsoftheelectricboardcanbeopenedusing

thetoolssuppliedwiththemachine.

The opening of the doors disconnects the

componentsdownstreamfromthemain swutch.

Somecomponentsmaycontinuetobepoweredby

residualcurrentfora specificintervaloftime.

After opening the machine, avoid touching the

internalpartsforatleast5minutes.

Asignindicatingthepresenceofpoweredpartsis

placedon the door.

Nocomponentistoxicorharmful.

Disposeofreductinggearscarefullyastheyarefull

ofoil.

Do not abandon these components or dispose of

themwithregularwaste.

WARNING!Whenfinishedusingmachines

and components, dispose of them in accordance

withthelawsineffectinyourcountry.

Informationofusefordisposalofthemachineandits

components.

Themachine must bedemolished by specialised

personnelwearingappropriatesafetygarmentsand

workingincompliancewithsafetyandenvironmental

legilation.

Constructionmaterials:

-steel,stainlesssteel,aluminium,castiron

-copper,silverinelectricalcomponents

-rUbber,nylon,PVC,resinsandfibres.

Thoughthemachineisequippedwithanumberofsafety

systems,operatorsmustbeverycarefultomakesure

thatnosituationsarisewhichcouldpotentionallyput

themorothersindanger.

Themachineisdesignedandbuiltexclusivelyfortheuse

described in chapter 3.1. Any other use must be

considered improper and unreasonable. The

manufacturer shall not be held responsible for any

damagecausedbyimproper,erroneousorunreasonable

use.

Everyonewhoworksonthemachinemustbeadequately

trainedinthecorrectworkingmethodsandinformedof

thenatureandfunctioningofsafetydevices.

3.3 Improper use

3.4 Demolition and disposal

Tetra Pak

Hoyer

HOYER FRIGUS 400

4-1 F40 03 DB 00

Contents

4.1 Unpacking, delivery checks and transport ............................................................... 4-2

4.2 Installation............................................................................................................... 4-3

4.2.1 Cooling water connection ............................................................................... 4-4

4.2.2 Ice cream intake and outlet connection........................................................... 4-4

4.2.3 Compressed air connection............................................................................ 4-5

4.2.4 Electrical connection ..................................................................................... 4-4

4.3 Installation check .................................................................................................... 4-6

4 - INSTALLATION

Tetra Pak

Hoyer

4-2 F40 03 DB 00

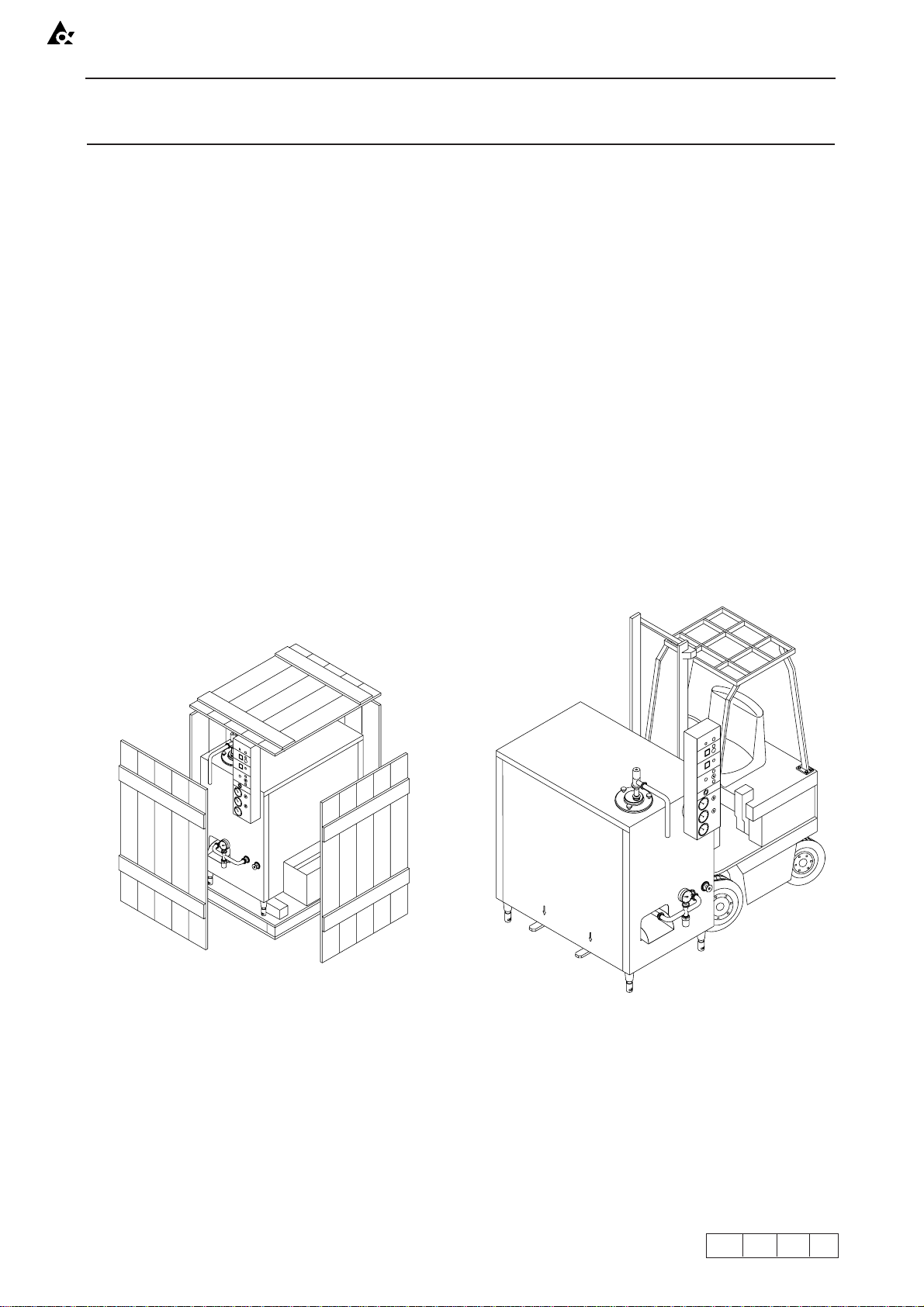

Fig. 4.1 Fig. 4.2

The machine is packed in wooden crates.

Unpacking must be done close to the installation

position. The cases may be easily transported by

a lift truck.

If the crate has been damaged during transport,

notify the insurance company immediately and

do not proceed with removal of packaging until

authorised by the insurance company.

When the crate is positioned in the place of

installation,proceed to removethe machine from

its packaging as follows:

a. Unnail the top cover and remove it. Do the

same with the side panels. Take care with

the wooden spacers between the walls of the

crate.

b. Remove the box containing spare parts and

the other components from the crate.

c. Unnail the wooden blocks that hold the

machine in place during transport and

remove the protective cellophane.

d. Check that the content of the package

corresponds to the shipping documents.

e. Make sure that all covers and panels are

correctly fastened in place and there are no

loose parts.

f. Visually inspect all electrical components to

make sure they are in perfect condition.

g. If any part or component is missing, notify

Tetra Pak Hoyer immediately.

4.1 Unpacking, delivery checks and transport

The machine may be moved using a fork lift

truck, taking care to position the forks so that

the machine’s weight is evenly distributed.

Tetra Pak

Hoyer

4-3

F40 03 DB 00

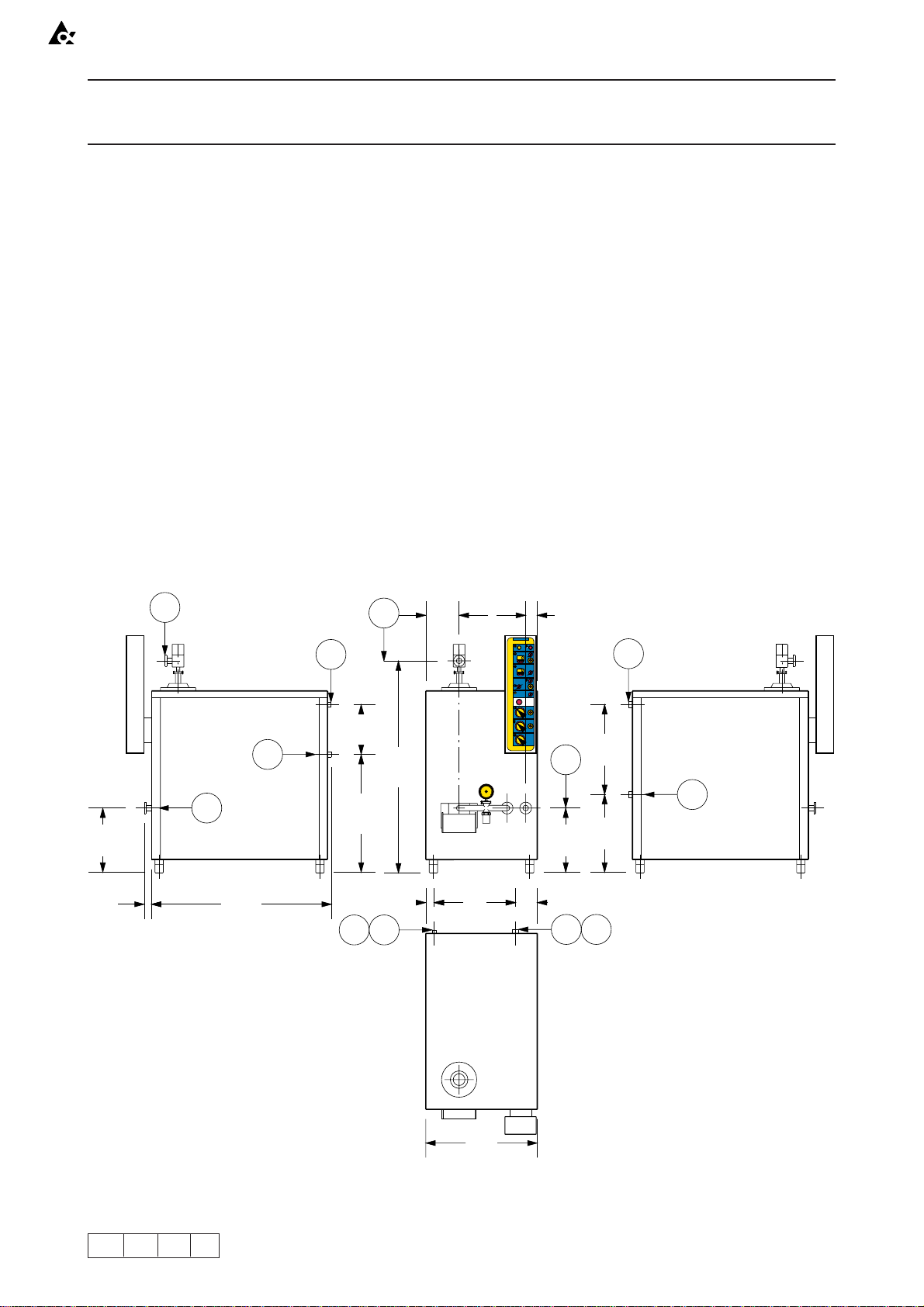

Fig. 4.3

195

443

50 1070

1005 280

1530

443

580 696

82

30 600 120

24

222021 23

20

21

22

23

25 25

24

750

The machine is fully tested and regulated in the

factory with about one hour of ice cream

production prior to shipment to the customer.

Installation simply involves connecting up the

pipes for the condenser cooling water supply, ice

cream mix intake and outlet, compressed air

supply and electric power supply. There is no

need for internal adjustments to the machine; we

recommend that factory settings not be changed.

Proceed with the installation procedure as

follows:

a. Positionthe machine in its operating position

and check the plate data to make sure that

the machine is compatible with the site’s

electrical power supply.

b. Level the machine with a spirit level by

means of the adjustable feet. The plates

provided may be applied underneath the feet.

c. Connect up the condenser cooling water

pipes. (1) (2).

d. Connect up the ice cream mix intake (3) and

outlet(4_pipestothe production line.

e. Connectup the compressed air pipe(5).

f. Connect the machine to the earth and to the

electricalpowersupply(6).

4.2 Installation

Tetra Pak

Hoyer

4-4 F40 03 DB 00

Fig. 4.4

4.2.1 Cooling water connection

Connect up the supply of condenser cooling

water, taking care to get the direction of water

flow correct: water must flow in through the

connection at the bottom (2) and out through the

connection at the top (1) . It is recommended that

two on/off taps (3) (4) be installed close to the

machine,aswellasasmalldraintap(5)closetothe

bottomconnection;itisalsoa goodideatoconnect

upthesetwotapswiththemachinethroughtwopipe

unions(three-piece connectors) to makeit easy to

separatethefreezerfromthe installation.

Themachine is fittedwith a pressure valve which

controls the flow of water in inverse proportion

to its temperature to obtain constant cooling

(constant condensation pressure on the coolant

side); this makes it possible to use water supplies

withwidely varyingtemperatures forcooling the

condenser.Thewaterflow varies asa result, from

about 600 litres/hour at 5ºC to 3600 litres/hour

at 28ºC (average values for machine in operation

at maximum production rate).

Pipe diameter depends on pipe length and the

pumps available, and must never be less than

the diameter of the connections, which is 1” gas.

It is essential to wash out the pipes BEFORE

connectingthem to themachine by flushing them

with water to eliminate any particles or dirt. If

the water that flows out of the pipes continues to

bedirty,it will be necessary to install a filter with

a filtering capacity and size appropriate to the

typeandamountof dirt conveyed attheintake (1)

(thebottomconnection).

76

2

3

1

4

5

Tetra Pak

Hoyer

4-5

F40 03 DB 00

4.2.2 Ice cream intake and outlet connection

Connect the mix supply pipe to the mix pump

inletconnection (24) on the front of themachine.

The machine has a CIP washing programme

permittingthorough,safe washing of themachine

without dismantling its parts; it will therefore

be necessary to prepare the required connections

between the CIP washing pump and solutions

and the mix pipe.

Make sure that the mix flows spontaneously to

the machine connection (24) , and does not need

to be suctioned by the freezer pump; this may be

done by simply positioning the aging vats higher

than the freezer (check that the spontaneously

flowing supply is sufficient even when the mix

level in the containers is low), or by installing a

suitable centrifugal pump close to the vats. Take

care to ensure that there is no air getting into the

pipes, which could pollute the product and result

in fluctuation of ice cream overrun.

CAUTION:

Pipes must be dismantled and washed

thoroughly after completing this procedure

to ensure that no hard solid particles are

conveyedtoward the freezermix pump.This

is very important as solid particles such as

metalburrorweldingresiduescouldseverely

damagethefreezer pump and will invalidate

the guarantee.

Connect up the ice cream outlet to the utility.

Use the shortest possible pipe, with as few

curves as possible, and use a pipe which is shiny

inside; the pipe does not need to be insulated.

Make sure that ice cream pressure in the

cylinders does not exceed 12 bar (the absolute

maximumpermitted value); if this should occur,

move the freezer closer to the ice cream utility

and/or use hot gas to produce softer ice cream.

Connect the compressed air supply pipe to the

connection on the rear of the machine; it is

recommended that an easily removable tap and

connection be assembled close to the machine

connection.

The supply pressure measured on the machine

4.2.3 Compressed air connection

must never drop below 6 bar. It is strongly

recommended that the compressed air supply in

the place of installation be fitted with an air

drying system and A0 filters to remove oil

vapours and residual fine particles.

CAUTION:

Electrical connection must be made

exclusivelyby competent technicianswhoare

familiarwithsafetylegislationand authorised

toperform and certifyelectrical installations.

Check the identification plate to make sure that

the machine is compatible with the site’s power

supply. Connect the machine’s power supply to

the site’s distribution panel and protect it with a

4.2.4 Electrical connection

suitable device, complying with all regulations

for correct electrical installation in effect in the

place of installation.

We recommend installing an automatic circuit

breaker on the distribution panel, complying

with local regulations. Great care must be taken

to ensure correct connection with the earth, as

incorrectconnection couldcause severedamage

to the machine’s electronic parts and injury or

death to the operator.

The section of the power supply cable must be

determinedon the basis of its length and the grid

Table of contents

Other Tetra Pak Freezer manuals