Tetra Pak HOYER FRUIT FEEDER 2000 User manual

Tetra Pak

Hoyer

Tetra Pak Hoyer A/S Tetra Pak Hoyer Inc. Tetra Pak Hoyer S.p.A.

Soeren Nymarks Vej, 13 753 Geneva Parkway Via Monferrato, 52

DK 8270Hoejbjerg P.O. Box 280 20098 San Giuliano Milanese (Milano)

Denmark Lake Geneva, WI 53147 Italy

Telephone + 45 89 393939 U.S.A. Telephone +39 2 98292.1

Telefax + 45 86 292200 Telephone + 1 414 249 7400 Telefax +39 2 9880171

Telex 68770 Alhoy DK Telefax + 1 414 249 7500

FF903B

Wehopethattheinformationcontainedinthismanual

will be helpful. It is based on data and is correct to

thebestofour knowledge.

Readthecontentsofthemanualcarefully,including

therecommendationsandsuggestions.Alsoread the

salesconditions,includingthosethatlimitthewarranty.

Nopart of this manualmaybereproducedorpassed

on to third parties without advance permission in

writingfrom TetraPakHoyerS.p.A.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Macchina HOYERFRUITFEEDER2000

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

No.Matricola

PREVIOUS PAGE

RETURN TO PM

HOYER FRUIT FEEDER 2000

FF711bA1-1

Tetra Pak

Hoyer

Index

1 - MACHINE IDENTIFICATION DATA

1.1 Introduction.............................................................................................................. 1-2

1.2 Identification plate .................................................................................................... 1-2

1.3 Service centres.......................................................................................................... 1-3

RETURN TO PM

FF711BA1-2

Tetra Pak

Hoyer

1.2 Identificationplate

Fig.1.1-Targhettadiidentificazione

1.1 Introduction

MODEL

SERIAL N.:

YEAR OF CONSTRUCTION:

ELECTRICAL SUPPLY:

PNEUMATIC SUPPLY:

REFRIGERANT:

HEATING GAS:

THERMAL CAPACITY:

kW

Kg.

Kcal/h

Via Monferrato, 52 - 20098 San Giuliano Milanese

( MI ) Italia - Tel. 02-982921 - Fax 02-9880171 Made in Italy

Tetra Pak

Hoyer

V

bar Nlt/min.

ph Hz

Type

Thankyouforchoosingamachinemanufactured

byTetraPakHoyerS.p.A.

Werecommendyoutoreadthismanualcarefully

asitisindispensable fortheinstallation,checking

andmaintenanceoperationsrequiredtokeep

yourmachineinperfectworkingorder.

Wewillbepleasedtoreceiveyoursuggestions

shouldyoufindthatanyexplanationhasbeen

omittedorisnotexhaustive.Wewilltakethem

intothegratestconsiderationinaneffortto

improvethemanual.

Formantenanceandoverhauloperationsnot

coveredbythismanualandforalltechnical

problems,ourServiceDepartmentisatyour

completedisposal toprovideinformation

informationandtocoordinatethenecessary

action.

WhencallingourServiceDepartment,please

quotethedatashownontheidentificaitonpalte

affixed tothemachineandshowninFig.1.1.

RETURN TO PM

FF711BA 1-3

Tetra Pak

Hoyer

1.3 Services Centres

For any need or problem requiring our help,

please contact one of the following centres

authorisedto carry outtechnicalassistance under

warranty or maintenance to machines

manufactured by Tetra Pak Hoyer S.p.A.

EUMEA

Tetra Pak Hoyer ApS

Soeren Nymarks Vej 13

DK-8270 Hoejbjerg

Phone: +45 89 39 39 39

Fax: +45 86 29 22 00

Tlx: 6 87 70 alhoy dk

Att.: Mr. Hans Malling

ASIA/PACIFIC:

Tetra Pak Hoyer Shanghai

Shanghai Overseas Chinese

Mansion

Room 2105-2107

No. 129, Yan'an Xi Lu

200040 Shanghai

P.R. China

Phone: +86 21 6249 0860

Fax: +86 21 6249 9064

Att.: Mr. Simon Zhang

NORTH AMERICA

Tetra Pak Hoyer Inc.

7711 95th Street

P.O. Box 0902

PleasantPrairie,WI 53158-0902

USA

Phone: +1 414 947 9100

Fax: +1 414 947 9190

Att.: Mr. Henning Agergaard

FRANCE

Tetra Pak Hoyer France

c/o Tetra Laval Service SARL

R.C.S. Versailles B403 276 223

P.O. Box 56

F-78340 Les Clayes-Sous-Bois

France

Phone: +33 1 30818184

Fax: +33 1 30818120

Att.: Mr. Michel Viglietta

Tetra Pak Hoyer Service

3rd Floor, Molace Building

2231 Pasong Tamo Street

Makati, Metro Manila

Philippines

Phone: +63 2 8132848

Fax: +63 2 8132866

Att.: Mr. Niels Nordestgaard

SOUTH AMERICA

Tetra Pak Hoyer Industria e

Comércio Ltda.

Rua Napoleao de Barros, 1038

Cep04024-003 Sao Paulo-SP

Brazil

Phone: +55 11 573 9422

Fax: +55 11 549 5420

Att.: Mr. Jörg Roberth

C.I.S.

Tetra Pak Hoyer A/O

4th Rostovsky peureulok

Dom 1, stroenie 1

R-11921 Moscow

C.I.S.

Phone: +7 502 2242160

Fax: +7 502 2242162

Att.: Mr. Johnny Schaleck

SOUTH KOREA

Hoyer Ltd.

4fl. Dookyong Bldg.

66-1/9 Hannam-Dong

Yong San-Ku

140-210 Seoul

South Korea

Phone: +82 2 796 0362

Fax: +82 2 796 0365

Att.: Mr. K.S. Lee

THAILAND

Tetra Pak Hoyer (Thai) Ltd.

1042Soi Poosin, SukhumvitSoi

66/1

Bangchak, Prakanong

Thailand

Phone: +66 2 3611680

Fax: +66 2 3612310

Att.:

Mr. Somchoke Chartsiriwattana

RETURN TO PM

HOYER FRUIT FEEDER 2000

FF711BB2-1

Tetra Pak

Hoyer

Index

2 - GENERAL

2.1 Declaration of confirmity.......................................................................................... 2-2

2.2 Preliminary observations........................................................................................... 2-2

2.3 General safety precautions........................................................................................ 2-2

2.4 Warning and special notices...................................................................................... 2-3

2.5 Environmental working restrictions.......................................................................... 2-3

RETURN TO PM

FF711BB2-2

Tetra Pak

Hoyer

2.1 Declaration of confirmity

This machine has been manufactured in

accordance with international standards and

hygieneand sanitary legislation applicabletofood

machinery.InparticularTetraPakHoyer certifies,

through the Declaration of Conformity supplied

together with the machine, that the HOYER

FRUITFEEDER2000machine is designed and

manufactured in accordance with the provisions

of Directive 89/392/EEC and with the above-

mentionedstandards applicable tothisDirective.

• Theillustrationsand drawings of the machine

are intended purely for general reference and

are not necessarily accurate in every detail.

• The machine dimensions and specifications

given in this manual are not binding and may

be changed without advance warning.

• The drawings and all other documents

provided with this machine remain the

property of Tetra Pak Hoyer S.p.A. and may

not be passed on to third parties without

written authorisation from Tetra Pak

Hoyer S.p.A.

• Themanualincludes instructions covering all

accessoriesmounted on the standard machine.

•The machine is covered by warranty as

specifiedin thepurchasecontract. During

the warranty period, any repair work not

authorised by Tetra Pak Hoyer will

automatically invalidate the warranty.

2.2 Preliminaryobservations

2.3 General safety precautions

• THESE SAFETY PRECAUTIONS HAVE

BEEN DRAWN UP IN YOUR

INTERESTS. Follow the guidelines strictly

in order to reduce the risk of accident both to

you and to others.

• Do NOT attempt to move, install or operate

the machine without having read and

understood this manual. If in doubt, ask your

superior.

• Ensure that all guards and safety covers are

in position BEFORE starting the machine.

• NEVERleave tools, mechanical parts or other

extraneousmaterial on orinsidethe machine.

• Press the emergency button in the event of a

product blockage.

• NEVERPUT YOUR HANDSINSIDE THE

MACHINE WHILE IT IS RUNNING;

• Take great care even when the main switch is

inthe“OFF” position, since thepower supply

cables are still live.

• Turn off the air supply before disconnecting

any pneumatic part of the machine.

• Make sure that all guards and protective

covers are correctly installed BEFORE

restarting the production cycle after

maintenance or repair operations.

• Always work with the greatest care and

remember that you are responsible for your

own safety and for that of your colleagues.

• When moving or lifting the machine, ensure

that relevant standards for these operations

are followed.

RETURN TO PM

FF711BB 2-3

Tetra Pak

Hoyer

• The personnel operating this machine must

be aware of and observe strictly the general

safety precautions. Failure to observe the

precautions may result in injury to personnel

or damage to machine components.

• Maintenance must be carried out with the

machineturned off.The main switch mustbe

in the “OFF” position, the air valve must be

closed and a “work in progress” notice must

be fixed to the machine.

• The user must ensure that all the instructions

containedin the manualare followed strictly.

• High (Low) temperatures are reached inside

the machine. After turning off the electric

power supply, wait for the machine to cool

(heat) to room temperature before carrying

out work on it.

• Anytamperingwith the safety systemfor any

reason is at the user’s own risk and shall be

hisresponsibility.

• Never attempt to turn off the safety switches

or make them inoperative.

• The safety of machines used in conjunction

with the machine described in this manual, if

not supplied directly by Tetra Pak Hoyer

S.p.A., is the customer’s responsibility.

• Thepressure, speed, temperatureand voltage

limits as well as all other indications given

are indispensable for the correct running of

the machine and must always be observed by

the customer.

• Forthepneumatic components, dehumidified

compressed air must be used at the right

pressure and in the prescribed quantities,

without any trace of oil.

• The environmental conditions of the

installation site must also be taken into

consideration.

• The national laws which govern the use of

thesekinds of machine mustalsoberespected.

The machine is authorized to run within the

followingenvironmentalrestrictions:

• Temperature : from 4°C to 40°C

• Humidity : from 20% to 95%.

F NOTE:

Our company declines all responsibility for

damage caused by failure to heed the above

warnings.

2.4 Warning and special notices

2.5 Environmentalworkingrestrictions

RETURN TO PM

HOYER FRUIT FEEDER 2000

FF711BC3-1

Tetra Pak

Hoyer

Index

3 - DESCRIPTION OF THE MACHINE AND TECHNICAL SPECIFICATIONS

3.1 Description of the machine ....................................................................................... 3-2

3.2 Operation.................................................................................................................. 3-3

3.3 Technical specification.............................................................................................. 3-4

3.4 Control panel ............................................................................................................ 3-5

RETURN TO PM

FF711BC3-2

Tetra Pak

Hoyer

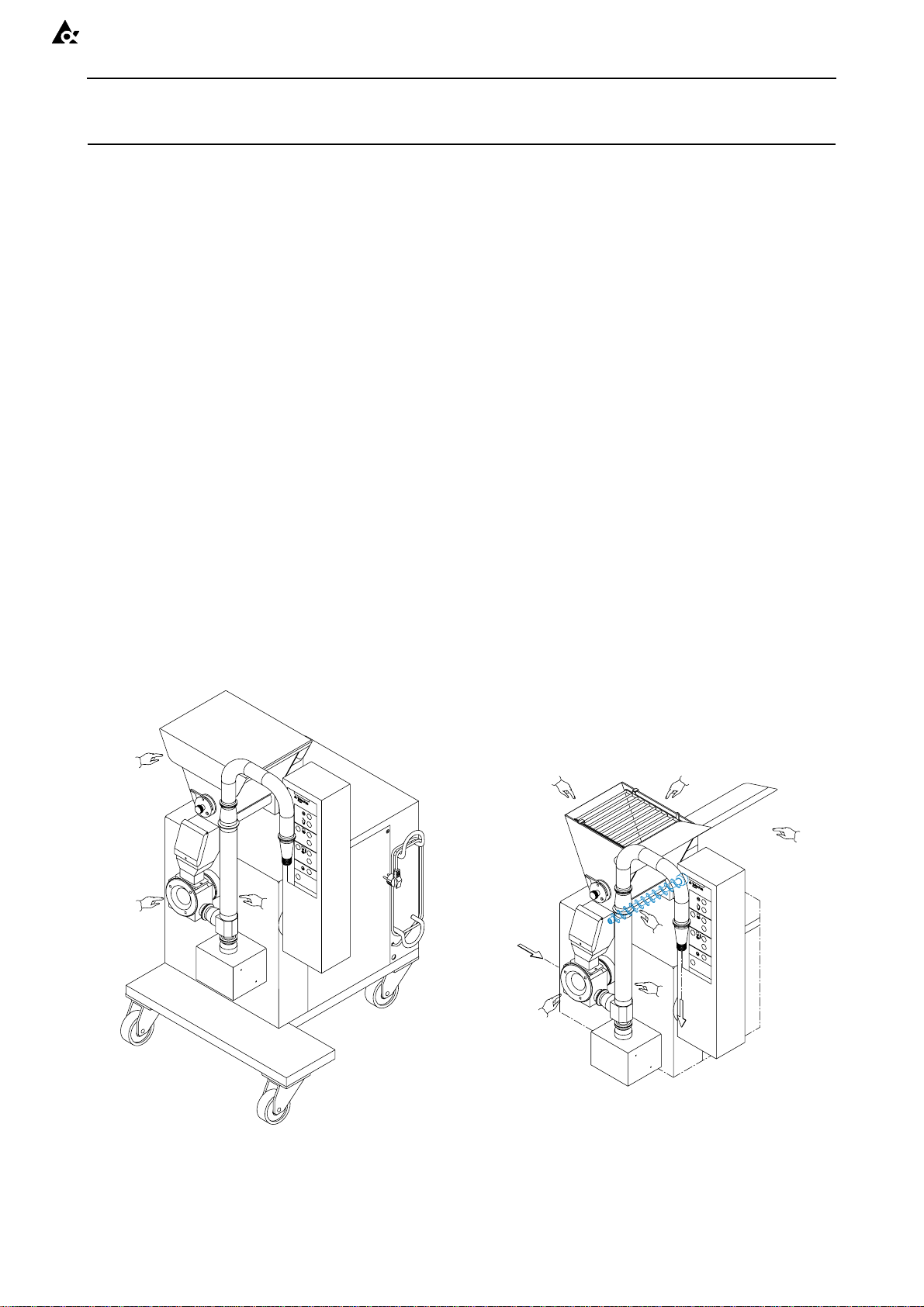

3.1 Description of the machine

Thismachine has beendesigned and constructed

to provide reliability and safety when used for a

wide range of applications.

The automatic machine FRUIT FEEDER2000

iscapable of feeding continuouslypieces offresh

fruit, candied fruit, granular products such as

hazelnutsandnougat, chocolate and awide range

of products normally used for ice-cream

production.

Designed as a stand-alone unit, it is normally

installed on ice-cream production lines between

a continuous freezer and a filler machine.

Toputintoservice, simply hook it up tothe mains

power supply and connect to the freezer and the

filler

machine.

The FRUIT FEEDER 2000 consists of three

mainunits:

1. Adosingunit,consistingessentiallyofa main

hopper, a screw feeder and a secondary

hopper.

The ingredients are fed manually by the

operator into the main hopper and then move

under gravity towards the bottom of the

hopper, where a horizontal-axis screw feeder

is situated. As they descend, the ingredients

are mixed continually by a slow agitator,

which ensures a constant flow of product to

the screw feeder. The screw feeder feeds the

ingredients into the secondary hopper from

where, again under gravity, they are fed to

the pump unit.

2. A pump unit, consisting of a vane pump

(Pos.2, Fig.3.1) which serves to feed the

ingredientsinto the flow ofice-cream coming

from the continuous freezer.

The vane pump consists of a rotor containing

radialvanes which are guidedbyan eccentric

guide machined inside the casing.

The pump also serves a function as a

separating seal between the pressurised ice-

cream line and the external environment so

asto allow a one-wayflowofingredientsfrom

the secondary hopper to the ice-cream.

3. An in-line mixer (Pos.3, Fig.3.1), consisting

ofashaftwithangledbladespositioned inside

the section of pipe downstream of the pump

unit. This unit serves to provide intensive

mixing of the product with thr ice-cream

before it goes on to the filler machine.

Themachine has been constructedtointernational

standards and to health and sanitary regulations

applicable to food machinery. In particular, Te-

tra Pak Hoyer S.p.A. certifies, through the

Declaration of Conformity provided together

with the machine, that the Fruit Feeder 2000

has been designed and constructedin conformity

with the Directive 89/392/EEC (Machinery

Directive) and with the applicable above-

mentioned standards.

The machine has an entirely stainless steel

structure and is mounted on wheels. All parts

directly in contact with the product are made

entirely of stainless or aseptic material and are

polishedinternally.

Inorderto avoid accidental contact betweenparts

of the operator’s body and moving machine

components, the machine is fitted with panels,

guarding and covers fixed by means of screws

and/or systems that in any case require the use of

special tools and deliberate action on the part of

the operator to be removed.

Only the lid of the main hopper can be raised

without the use of special tools to allow the

operator to feed in the ingredients. A safety grid

prevents the operator from accidentally coming

into contact with the slow agitator of the hopper.

Opening the grid activates a microswitch which

causes the machine to stop immediately.

RETURN TO PM

FF711BC 3-3

Tetra Pak

Hoyer

Fig.3.1

The ingredients are fed manually by the operator

into the main hopper (Pos.1, Fig.3.2). Access to

the main hopper is gained by tilting back the lid

(Pos.2,Fig.3.2). Thesafety grid (Pos.3, Fig.3.2)

must only be removed for maintenance work

when the machine is turned off.

The ingredients are kept continually moving by

the slow agitator located in the upper part of the

main hopper; they arethen fed into thesecondary

hopper by means of the screw feeder (Pos.4,

Fig.3.2) located on the bottom of the hopper.

The screw feeder is made of aseptic material and

is available in various versions according to the

type of ingredients to be fed. The speed of the

screw feeder and the slow agitator are variable

and can be regulated by the potentiometer on the

control panel. As a consequence, the flow rate

of ingredients can also be continually varied.

From the secondary hopper the ingredients are

Fig.3.2

3.2 Operation

fed under gravity towards the inlet port of the

vanepump(Pos.5, Fig.3.2) locatedon the bottom

of the secondary hopper.

Theyare then fedinto the cavitycreated between

twoadjacent vanes as a result of thespecialprofile

of the eccentric guide.

Duringrotation the ingredients comeinto contact

with the ice-cream through the discharge port

located on the bottom of the casing. This way

the ingredients are fed into the ice-cream flow.

The rotor is mounted on the reduction gear

output shaft and its speed of rotation can be

regulated from the potentiometer on the control

panel by means of a frequency converter

connected to the gearmotor.

The mix obtained is fed to the vertical mixer

(Pos.6, Fig.3.2), which serves to mix the ice-

cream and the ingredients and hence obtain a

uniform and well-mixed product.

1

23

2

4

6

13

5

RETURN TO PM

FF711BC3-4

Tetra Pak

Hoyer

3.3 Technicalspecifications

Power supply standard: 220 - 380 V / 3 PH / 50-60 Hz

on request: 415 V / 50-60 Hz

Installed power screw feeder: 0,75 kW

mixer: 0,75 kW

pump: 0,75 kW

transfomer: 0,15 kW

Total installed power: 2.4 kW

Net weight: 190 Kg

Pipe diameter In clamp: 2"

Out clamp: 2"

Capacity: the flow of ice cream with standard feeder is 300 ÷ 2000 l/h

(80 ÷528 US Gals/h).

For ingredient capacity see paragraphs 4.4 and 5.2.

Dimensions: A (length) = 932 mm

B (width) = 720 mm

C (height) = 1291 mm

No. Operators: 1

Equivalent A-Weighted Sound Pressure Level at 1 metre: 67.5 dBA

Max. Instantaneous C-Weighted Sound Pressure Level in the Workplace: less than 130 dB/20µPa.

Fig.3.3

B

A

C

RETURN TO PM

FF711BC 3-5

Tetra Pak

Hoyer

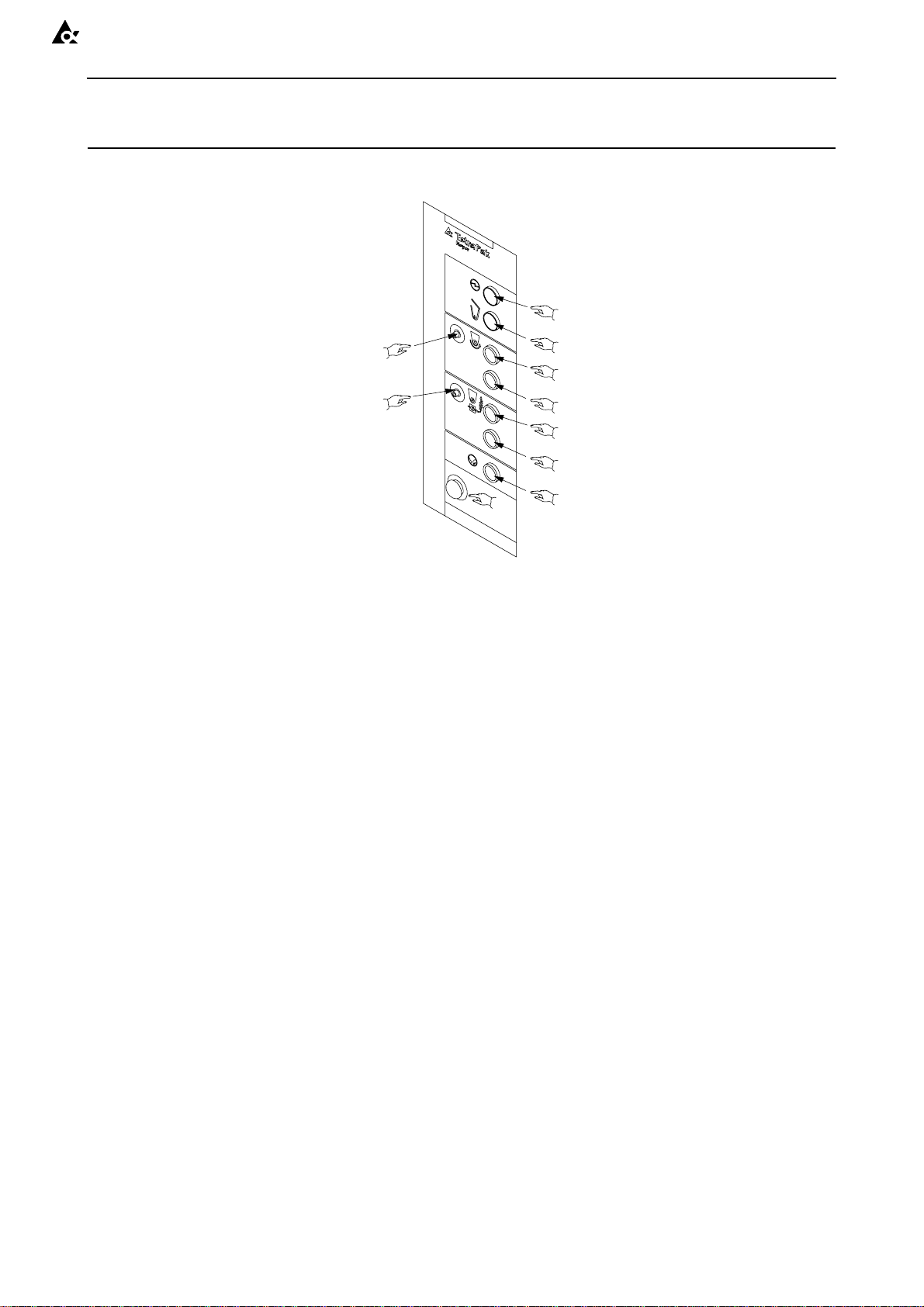

1. Power on (14HL4)

2. Safety device tripped (14HL12)

3. Screw feeder start button (18SB10)

4. Screw feeder stop button (18SB12)

5. Potentiometer to regulate speed of screw feeder unit (9RP8)

6. Slow agitator and vane pump start button (19SB7)

7. Slow agitator and vane pump stop button (19SB8)

8. Potenziometro per la regolazione della velocità della pompa a lamelle (10RP8)

9. Washing cycle selector switch (18SA4)

10. Emergency stop button (15SB13)

Fig.3.4

3.4 Controlpanel

1

5

8

10

2

3

4

6

7

9

RETURN TO PM

HOYER FRUIT FEEDER 2000

FF711BD4-1

Index

Tetra Pak

Hoyer

4.1 Unpacking and delivery checks ................................................................................ 4-2

4.2 Transport and installation ......................................................................................... 4-2

4.3 Functional checks ..................................................................................................... 4-4

4.4 Characteristics of ingredients ................................................................................... 4-5

4 - INSTALLATION

RETURN TO PM

FF711BD4-2

Tetra Pak

Hoyer

4.1 Unpacking and delivery checks

Thesimplest way tohandletheFRUITFEEDER

2000 crate is to use a pallet truck or a lift truck.

The crate must be unloaded as close as possible

to the place of installation.

When the crate has been positioned correctly,

unpack as follows:

a. Unnail the upper lid (Pos. 1 Fig. 4.1) and

remove it. Do the same with the side panels.

Pay particular attention to the wooden spacer

blocks located between the sides of the crate.

b. Remove the spare parts box (Pos. 2 Fig. 4.1)

and the other components.

c. Unnail the wooden blocks that hold the

machineinplaceduring transport and remove

the cellophane sheet.

Fig.4.1

4.2 Transportandinstallation

Asthemachineismountedonwheels(Pos.1,

Fig.4.2),itcanbepusheddirectlybytheoperator,

asshowninFig.4.2.

Alternativelythemachinemaybemovedby

meansofaforklifttruck.Takecaretoposition

theforksundertheadhesivearrowsonthemachine

frame,asshowninFig.4.3.

2

1

d. Check that the contents of the crate

correspond to the description given in the

shipping documents.

e. Checkthat all the covers and panels have been

correctly fitted and that there are no loose

parts.

f. Inspectvisually all theelectrical components

to check that they are not damaged.

g. If any part/component is missing, stop

unpacking and immediately notify Tetra Pak

Hoyer S.p.A.

h. If the machine has been damaged during

transport, notify the Insurance Company

immediately.

Do not proceed beyond unpacking until you

are authorised to do so by the Insurance

Company.

RETURN TO PM

FF711BD 4-3

Tetra Pak

Hoyer

Fig.4.2

TheFRUITFEEDER2000mustbesituatedas

closeaspossibletothefillermachineforthe

followingreasons:

a. The pressure of ice cream reaches its lowest

value at this point.

b. The ingredients fed in tend to be deposited

on the layer of ice-cream in contact with the

pipe. Therefore a smaller distance between

themixer and thefiller machine willgive rise

to a more uniform distribution of the

ingredients in the ice-cream.

Fig.4.3

Fortheinstallationprocedure,ensurethatthe

followinginstructionsarefollowed:

a. Position the machine at the place of

production and check the nameplate data to

ensure that the machine is compatible with

the electrical power supply (Pos.A, Fig.4.4).

b. Connect the ice-cream inlet and outlet pipes

to the pump body (Pos.B, Fig.4.4).

c. Connecttheelectricalcable (3 phases + earth)

bymeans of a wall-mountedswitchfittedwith

a fuse.

Fig.4.4

ATTENTION:

L’interruttore differenziale di protezione deve

essere di classe “A” adatta alla protezione dei

circuiti elettronici di potenza dell’inverter.

1

1

1

MODEL

SERIAL

N.:

YEAR OF CONSTRUCTION:

ELECTRICAL

SUPPLY:

PNEUMATIC SUPPLY:

REFRIGERANT:

HEATING GAS:

THERMAL

CAPACITY:

kW

Kg.

Kcal/h

Via Monferrato, 52 - 20098 San Giuliano Milanese

( MI ) Italia - Tel. 02-982921 - Fax 02-9880171 Made in Italy

Tetra Pak

Hoyer

V

bar Nlt./min.

ph Hz

Type

B

A

B

RETURN TO PM

FF711BD4-4

Tetra Pak

Hoyer

Fig.4.7

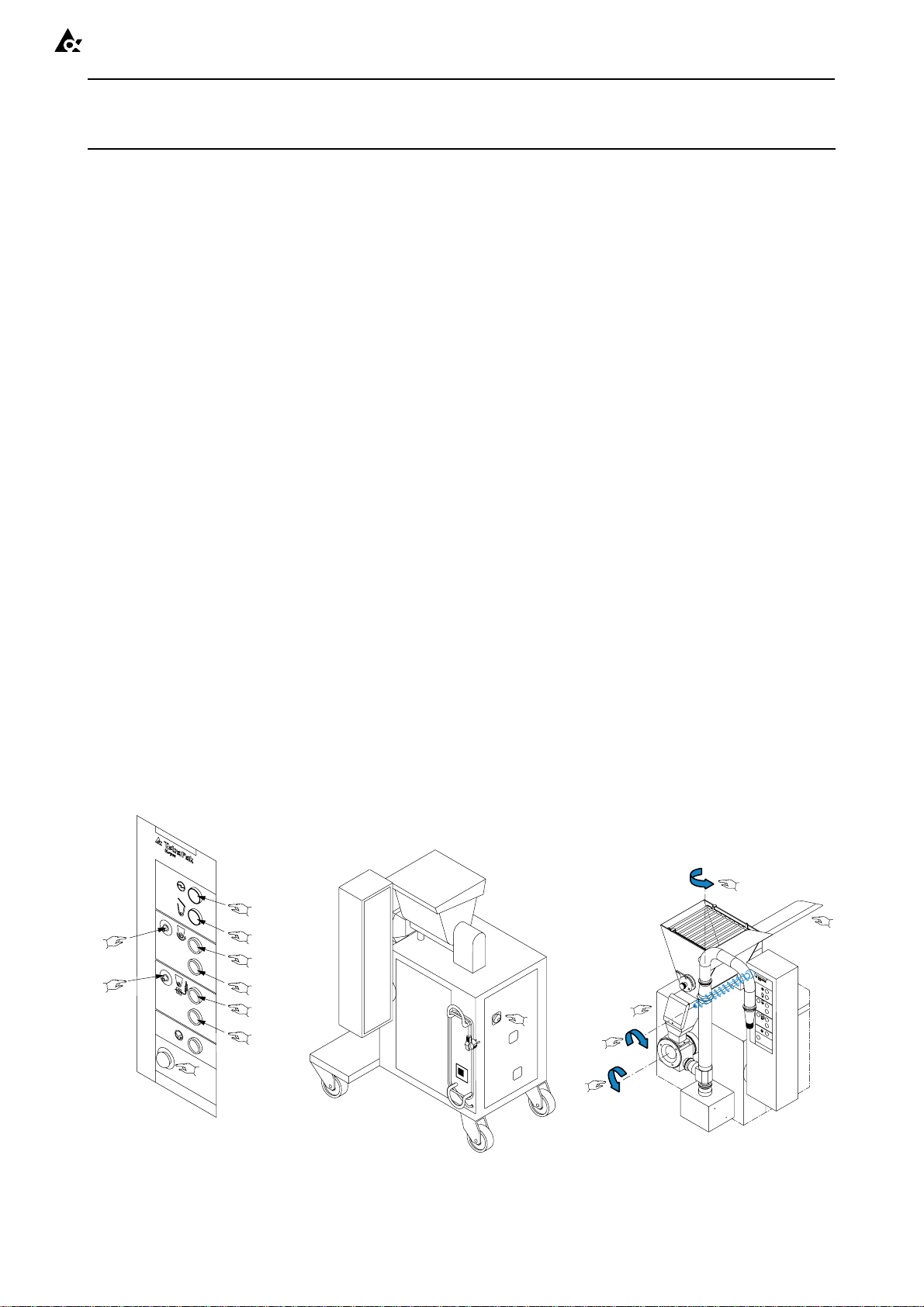

Carryoutthefollowingcheckingprocedures

beforestartingthemachine:

a. Check that the emergency stop button is

released (Pos.9 Fig.4.5).

b. Turn on the main switch located on the rear

panel of the machine (Pos.1 Fig.4.6).

c. Check that the motors work correctly. In

order to avoid damaging the machine, make

sure that all the motors turn in the correct

direction. If they do not, invert the phases.

In particular:

1. Screw feeder motor

Press luminous button (Pos.3 Fig.4.5) to

start the motor. Lift the main hopper lid

(Pos.1, Fig.4.7) and check that the screw

feeder turns clockwise (Pos.2, Fig.4.7).

Pressthe luminous button(Pos.4Fig.4.5)

to stop the motor.

2. Vane pump motor and in-line mixer motor

Pressthe luminous button(Pos.6Fig.4.5)

Fig.4.6

Fig.4.5

4.3 Functionalchecks

to start the motors. Lift the secondary

hopper lid (Pos.3, Fig.4.7) and check that

the vanes turn anticlockwise (Pos.4,

Fig.4.7). Check, by viewing from above,

that the in-line mixer turns anticlockwise

(Pos.5, Fig.4.7). To carry out this check,

disconnect the 2” to 1 1/2” reducer. Be

particularly careful not to crush parts of

your body during rotation of the mixer

baldes. Press the luminous button (Pos.7

Fig.4.5) to stop the motor.

N.B.: Since the vane pump needs to be

lubricated with ice-cream and/or water

during operation, make sure that it does

not run empty by introducing water

directly into the secondary hopper during

this check.

With the motors running, check that the

emergency stop button (Pos.9 Fig.4.5)

works correctly. In the case of a

malfuction, contact one of our Service

Centresimmediately.

1

5

8

9

2

3

4

6

7

1

1

5

2

3

4

RETURN TO PM

FF711BD 4-5

Tetra Pak

Hoyer

4.4 Characteristics of ingredients

Ingredientsthatareviscous,sensitivetohumidity

ortendtosticktogethertoformlumpsarenot

suitablefordosing.

FNOTE:

Some ingredients like raisins must be washed

and dripped before dosing.

The ingredients should have particles of

maximum diameter 15 mm.

This means for example that products such as

wholestrawberriescan be fed into theice-cream

flow without being crushed.

TheFRUITFEEDER2000isdesigned for any

kind of solid and/or highly viscous product.

Liquidsorproductswith low viscosity (e.g. jam,

fruit juice with whole pieces of fruit, etc...)

should not be used in the machine.

In these cases it is advisable to feed in the solid

part using the FRUIT FEEDER 2000 and the

liquid part using a volumetric dosing device for

liquids installed before the in-line mixer.

The machine is supplyed with two standard screw

feeders:

- Screw feeder, code no. 540501205

Pitch 40, Diam. 20 (for high flow)

- Screw feeder, code no. 540501202

Pitch 20, Diam. 20 (for low flow)

As optional the following two screw feeders are

available to optimize the dosing at intermediate

flow:

- Screw feeder, code no. 540501203

Pitch 30, Diam. 20

- Screw feeder, code no. 540501204

Pitch 30, Diam. 24

RETURN TO PM

HOYER FRUIT FEEDER 2000

FF711BE5-1

Tetra Pak

Hoyer

Index

5 - ADJUSTMENT PROCEDURES

5.1 Set-upand adjustments .............................................................................................. 5-2

5.2 Ice-creamsolildingredients ........................................................................................ 5-3

RETURN TO PM

FF711BE5-2

Tetra Pak

Hoyer

5.1 Set-up and adjustments

Beforestartingthemachineandbeginningthe

productioncycle,makesurethatthemachinehas

beencarefullywashedandsterilised.

Afterwashingandsterilisingthemachine,connect

theice-creamoutletpipefromthefreezertothe

pumpuintconnector(Part.1,Fig.5.1);thenconnect

Fig.5.1

Tosetthespeedofthescrewfeedercorrectly,

proceedasfollows:

1. Connectthescrewfeederoutletpipeto rubber

hoseprovided, leaving thesecondaryhoperlid

open (Part.1 Fig.5.2). Place a container of

suitabledimensions under the extension outlet

tocollecttheingredients.

2. Turn on the electrical power supply to the

machinebyturningthemainswitchtothe“ON”

position.

3. Check that the safety grid is lowered into its

safetyposition.

4. Start the screw feeder by pressing button

18SB10 (Pos. 3, Fig. 3.4).

Fig.5.2

thefillermachineice-creaminletpipetotheoutlet

connectoronthein-linemixer(Part.2,Fig.5.1).

Toconnecttwofreezersatthesametime,connecta

Yfitting(Part.3,Fig.5.1)tothepumpunitinlet

connector.

5. Measurethe flowrateovera reasonable period

of time and check that it corresponds to the

desiredvalue.Ifnot,turnthescrewfeederspeed

adjustment knob (PT3) to increase or reduce

the speed according to whether the measured

flowrate is lower or higher than desired.

Repeatthisoperationuntil thedesiredflow rate

isobtained.

6. Turn of the screw feeder motor by pressing

luminousbutton 18SB12 (Pos.4,Fig.3.4)and

turnoffthe powersupplytothemachine.

7. Disconnect the screw feeder outlet pipe

extension.

8. Ifnecessary, cleanandsterilisethe machine.

1

2

3

P

T

1

RETURN TO PM

Table of contents

Other Tetra Pak Ice Cream Maker manuals