Tetra Pak Hoyer Frigus 600 User manual

Tetra Pak

Hoyer

B

F60 03 - 04

Hoyer Frigus 600

Tetra Pak Hoyer S.p.A.

Via Monferrato, 54

20098 San Giuliano Milanese (Milano)

Italy

Telephone +39 2 98292.1

Telefax +39 2 9880171

We hope that the information will be of help to

you. It is based on concrete data and on the best

of our current knowledge.

Read the contents of the manual carefully,

including the warnings and recommendations.

No part of this manual may be reproduced or

transmitted to third parties without the prior

written permission of Tetra Pak Hoyer.

Tetra Pak

Hoyer

B

F60 03 - 04

1Machine identification data

2General information

3Description of the machine and technical data

4Installation

5Operator panel

6Operating procedures

7Cleaning and maintenance

8Troubleshooting

9Spare parts list

10 Index of attachments

Tetra Pak

Hoyer

1-1

Contents

B

F60 03 A 04

HOYER FRIGUS 600

1 - MACHINE IDENTIFICATION DATA

1.1 Introduction .............................................................................................................. 1-2

1.2 Identification plate.................................................................................................... 1-2

1.3 Service centres ......................................................................................................... 1-3

Tetra Pak

Hoyer

1-2 B

F60 03 A 04

MODEL

SERIAL N.:

YEAR OF CONSTRUCTION:

ELECTRICAL SUPPLY:

PNEUMATIC SUPPLY:

REFRIGERANT:

HEATING GAS:

THERMAL CAPACITY:

kW

Kg.

Kcal/h

Via Monferrato, 52 - 20098 San Giuliano Milanese

( MI ) Italia - Tel. 02-982921 - Fax 02-9880171 Made in Italy

Tetra Pak

Hoyer

V

bar Nlt/min.

ph Hz

Type

1.2 Identification plate

For maintenance and overhaul operations not

covered by this manual and for all technical

problems, our Service Department will be happy

to supply any information required and to agree

Fig. 1.1 - Identification plate

1.1 Introduction

Thank you for choosing a machine manufactured

by Tetra Pak Hoyer S.p.A.

We recommend that you read this manual

carefully as it is indispensable for the

installation, checking and maintenance

operations required to keep your machine in

perfect working order.

Il manuale contiene tavole, disegni e schemi che

Vi permetteranno di familiarizzare con la mac-

china in tutti i suoi dettagli.

Vi preghiamo di segnalarci le Vostre osserva-

zioni nel caso qualche spiegazione sia stata

omessa o non sia esauriente. Ne terremo conto

per migliorare il carattere funzionale di questo

manuale.

the necessary course of action.

When calling our Service Department, please

quote the data shown on the identification plate

affixed to the machine and shown in Fig. 1.1.

Tetra Pak

Hoyer

1-3

B

F60 03 A 04

1.3 Service Centres

For any assistance you may require, please

contact one of the following Tetra Pak Hoyer

authorised service centres:

EUROPE and

MIDDLE EAST:

Tetra Pak Hoyer ApS

Soeren Nymarks Vej 13

DK-8270 Hoejbjerg

Denmark

Phone: +45 89 39 39 39

Fax: +45 86 29 22 00

Tlx: 6 87 70 alhoy dk

Tetra Pak Hoyer S.p.A.

Via Monferrato, 52

I - 20098 San Giuliano Mila-

nese

(Milan)

Italy

Phone: + 39 2 98 29 21

Fax: + 39 2 98 80 171

Tetra Pak Hoyer France

c/o Tetra Laval Service SARL

R.C.S. Versailles B403 276 223

P.O. Box 56

F-78340 Les Clayes-Sous-Bois

France

Phone: +33 1 30818184

Fax: +33 1 30818120

NORTH AMERICA:

Tetra Pak Hoyer Inc.

7711 95th Street

P.O. Box 0902

Pleasant Prairie, WI 53158-0902

USA

Phone: +1 414 947 9100

Fax: +1 414 947 9190

SOUTH AMERICA:

Tetra Pak Hoyer Industria e

Comércio Ltda.

Rua Napoleao de Barros, 1038

Cep04024-003 Sao Paulo-SP

Brazil

Phone: +55 11 573 9422

Fax: +55 11 549 5420

ASIA/PACIFIC:

Tetra Pak Hoyer Shanghai

Shanghai Overseas Chinese

Mansion

Room 2105-2107

No. 129, Yan'an Xi Lu

200040 Shanghai

P.R. China

Phone: +86 21 6249 0860

Fax: +86 21 6249 9064

Tetra Pak Hoyer Service

3rd Floor, Molace Building

2231 Pasong Tamo Street

Makati, Metro Manila

Philippines

Phone: +63 2 8132848

SOUTH KOREA:

Hoyer Ltd.

4fl. Dookyong Bldg.

66-1/9 Hannam-Dong

Yong San-Ku

140-210 Seoul

South Korea

Phone: +82 2 796 0362

Fax: +82 2 796 0365

THAILAND:

Tetra Pak Hoyer (Thai) Ltd.

1042 Soi Poosin, Sukhumvit Soi

66/1

Bangchak, Prakanong

Thailand

Phone: +66 2 3611680

Fax: +66 2 3612310

C.I.S.:

Tetra Pak Hoyer A/O

4th Rostovsky peureulok

Dom 1, stroenie 1

R-11921 Moscow

C.I.S.

Phone: +7 502 2242160

Fax: +7 502 2242162

Tetra Pak

Hoyer

2-4

Contents

BF60 03 B 04

HOYER FRIGUS 600

2 - GENERAL INFORMATION

2.1 Declaration of conformity ........................................................................................ 2-2

2.2 Preliminary points .................................................................................................... 2-2

2.3 General safety rules .................................................................................................. 2-2

2.4 Special warnings ...................................................................................................... 2-3

2.5 Ambient operating limits ......................................................................................... 2-3

2.6 Residual risks ........................................................................................................... 2-3

Tetra Pak

Hoyer

2-5

B

F60 03 B 04

2.1 Declaration of conformity

This machine has been manufactured in

accordance with international standards and

hygiene and sanitary legislation applicable to

food machinery.

In particular Tetra Pak Hoyer certifies, through

the Declaration of Conformity supplied with the

machine, that the HOYER FRIGUS machine

is designed and manufactured in accordance with

the provisions of Directive 98/37/CE (Machinery

Directive) and with the above-mentioned

standards.

•The illustrations and drawings of the machine

are intended for general reference only and

are not necessarily accurate in every detail;

•The machine dimensions and specifications

given in this manual are not binding and may

be changed without prior notice;

•The drawings and all other documents

provided as a part this machine remain the

property of Tetra Pak Hoyer and must not

be passed on to third parties without the

written permission of Tetra Pak Hoyer.

•The manual includes instructions for all

accessories mounted on the standard

machine.

•The machine is covered by warranty as

laid down in the purchase contract. Any

repair work not authorised by Tetra Pak

Hoyer carried out during the warranty

period will automatically invalidate the

warranty.

2.2 Preliminary observations

2.3 General safety rules

•THESE SAFETY RULES HAVE BEEN

DRAWN UP IN YOUR INTEREST. Strict

observance will reduce the risk of accident

to yourself ot to others.

•DO NOT attempt to move, install or operate

the machine before reading and assimilating

the contents of this manual. Ask your superior

in case of doubt;

•make sure that all guards and safety covers

are in place BEFORE starting the machine;

•NEVER leave tools, mechanical parts or

other foreign materials on or inside the

machine;

•in the event of a malfunction, press the

emergency stop button.

•NEVER PUT YOUR HANDS INSIDE THE

MACHINE WHEN IT IS IN OPERATION;

•exercise caution even when the main switch

located on the tunnel is in the “OFF” position,

as the supply conductors will still be live;

•shut off the compressed air supply before

disconnecting any pneumatic component;

•make sure that all guards and safety covers

are correctly in place BEFORE restarting the

production cycle subsequent to maintenance

or repair operations;

•proceed with caution at all times. Remember

that you are responsible for your own safety

and for that of your colleagues;

•make sure that applicable regulations are

observed when moving or lifting the

machine.

Tetra Pak

Hoyer

2-6 B

F60 03 B 04

•All personnel operating the machine must be

familiar with the general safety rules and

must observe them strictly. Failure to follow

these rules may result in personal injury

ordamage to machine components;

•maintenance work must be performed with

the machine turned off. The main switch must

be in the “OFF” position, the air valve closed

and a “ work in progress” sign affixed to the

machine;

•the user must make sure that all the

instructions given in the manual are

scrupulously observed;

•users will be solely responsible for risks

caused by tampering with the safety system;

•The safety of machines used in conjunction

with this machine, if not supplied directly by

tetra Pak Hoyer, is the responsibility of the

customer.

•The pressure, speed, temperature and voltage

limits and all instructions given are

indispensable for correct operation of the

machine and must always be complied with

by the customer.

•Ambient conditions must be taken into

consideration during installation.

•National legislation governing this type of

machine be observed.

The machine is suitable for operation in the

following ambient conditions:

•Temperature : from 4°C to 40°C

•Humidity : from 20% to 95%.

NOTE:

Tetra Pak Hoyer will accept no responsibility for

damage or injury caused by failure to comply

with the above warnings.

2.4 Special warnings

2.5 Ambient operating limits

2.6 Residual risks

The Frigus maker is used for combining ice-

cream mixture with sanitary air in fixed

quantities and, subsequently, for forming the

ice-cream with the addition of cold generated

by a refrigeration cycle.

The mixture of ice-cream and sanitary air is

blended inside a manifold by means of the

pressure of a rotating pump and the injection of

compressed air which is then pushed to the

cylindrical evaporator of a refrigerating system

for the treatment of ice-cream.

Several issues arise when adapting the pre-

printer to suit the needs of man: more precisely,

centralizing the controls on a single instrument

panel for the functions of adjustment and control.

The top lid of the freezing cylinder is interfaced

with a safety microswitch. The machine will stop

if the lid is removed.

All the transmission parts, the kinematic motions

and the refrigerating system are protected by

fixed boards.

Dismantling side panels (anchored in place with

screws) permits contact with moving parts.

This residual risk is referred to in section 3.5

Prohibition and hazard signs and with a sign

indicating moving parts positioned on the

panels.

A signal of danger is placed on the flap of the

electric box to indicate live equipment.

For additional safety, the remaining risk is

recalled in paragraph 3.5 Instructions on ban

and danger signals.

Tetra Pak

Hoyer

3-7

Contents

BF60 03 C 04

HOYER FRIGUS 600

3 - DESCRIPTION OF THE MACHINE AND TECHNICAL DATA

3.1 Description of the machine ...................................................................................... 3-2

3.1.1 Filter set .......................................................................................................... 3-2

3.1.2 Mix pump ....................................................................................................... 3-3

3.1.3 Freezing cylinder ............................................................................................ 3-3

3.1.4 Refrigerating plant .......................................................................................... 3-4

3.1.5 Electrical system ............................................................................................. 3-4

3.1.6 Control panel .................................................................................................. 3-5

3.2 Technical data........................................................................................................... 3-6

3.3 Improper use ............................................................................................................ 3-7

3.4 Demolition and disposal........................................................................................... 3-7

3.5 Warnings, prohibition and danger signs ................................................................... 3-7

Tetra Pak

Hoyer

3-8 B

F60 03 C 04

Fig. 3.1

Fig. 3.2

1

4

2

5

3

3.1 Description of the machine

The machine mixes sanitised air into ice cream

mix to obtain the desired overrun, cools and agi-

tate the mix with air incorporated in it to create

the viscous product known as ice cream, and

supplies sufficient pressure to convey the ice

cream to its destination through a pipe.

In order to carry out these functions the machine

incorporates the following components:

-aset of filters which sanitise air coming from

the compressed air supply.

-apump which receives mix from ageing vats,

and sends the product to the freezing cylinder.

-freezing cylinder with a dasher and blades,

inside which air is uniformly blended into

the mix and the product is cooled until it takes

on a thick consistency.

-arefrigerating plant connected to the outside

wall of the freezing cylinder to cool it down.

The shop’s compressed air (the machine does

not have an air compressor of its own) passes

through a pressure reducer (1) and a mesh filter

(2) to separate out any large particles; these are

followed by a microfilter for oil vapours (3) and

an active carbon filter (4) to eliminate odours.

Finally, the clean air goes through a (sterilisable)

Teflon (5) membrane filter with microscopic

pores specifically intended to stop the passage

of bacteria.

The sanitised air thus obtained is let in between

the first and second stage of the mixing pump at

a rate of flow which may be controlled by the

operator using the control panel; changes in the

rate of flow permit variation of ice cream volu-

me.

3.1.1 Filter set (3.2)

-an electrical system for command and control

of all machine functions.

All these items of equipment are assembled on a

strong, compact stainless steel frame.

Tetra Pak

Hoyer

3-9

B

F60 03 C 04

Fig. 3.3

Fig. 3.4

1

3

2

32

1

It is a two-stage pump constructed with two

pistons of different sizes; the first (1) receives

and batches a quantity of mix determined by the

operator on the basis of the desired hourly

production; the second stage (2) receives mix

dispensed by the first stage and sanitised air let

in between the two stages and puts it all into the

freezer cylinder.

As the difference in volume between the first

and the second stage (a result of the size of the

pistons) does not change under different pump

pressure and speed conditions, the quantity of

air let in per mixing unit is also constant and

depends on the rate of flow of the air. By

adjusting the flow of sanitised air, the operator

therefore controls the increase in volume, which

remains constant throughout the production

cycle.

The pump is driven by an electric motor

commanded by an inverter (for speed changes)

3.1.2 Mix pump

This is the most important part of the machine:

an upright pipe with a chrome coating on its

inside walls, surrounded by a jacket in which

coolant fluid flows to cool down the cylinder. A

dasher (1) with three blades rotates inside it,

scraping the chrome-plated inside surface to

ensure that frozen ice cream does not build up

on the walls. The top (2) and bottom (3) ends of

the cylinder are closed by two covers, which in-

corporate the mix feed pipe (bottom) (3) and the

ice cream exit valve (top) (2).

Mix blended with sanitary air coming from the

pump flows into the bottom part of the cylinder

(3); on its way to the top it is whisked by the

dasher (1) and cooled by contact with the walls

of the cylinder, kept cold by the refrigerating

plant. The ice cream forms and then flows out

of the ice cream outlet valve (2), which is

controlled pneumatically to regulate the pressure

of ice cream in the cylinder.

In order to make sure the machine operates

correctly, it is important to be very careful not to

damage the cylinder, always making sure that

3.1.3 Freezing cylinder

the scraper blades are in perfect condition and

have been assembled correctly.

and incorporates a pneumatically driven by pass

(optional) for CIP washing. It works properly at

relatively high pressures, so that no extraction

pump is needed coming off the machine.

Tetra Pak

Hoyer

3-10 B

F60 03 C 04

Composed of the freezing cylinder (evaporator),

a Scroll Compliant rotary compressor, a high

efficiency condenser, an economiser, a

thermostatic valve and a number of minor

accessories. All these components are designed

specifically for operation at low temperatures

using R404A coolant gas.

Cooling is carried out by steam compression: the

compressor pumps gas into the condenser, where

it is cooled and liquefied, and the liquid gas then

passes through the thermostatic valve and is

vaporized in the freezer cylinder (transforming

into gaseous state once more) before returning

to the compressor and starting the cycle again.

Vaporization of gas in the freezing cylinder

removes heat from the ice cream mix, which

3.1.4 Refrigerating plant

The electrical system consists of the operator

panel and the electrical panel which covers all

of the rear of the machine. The operator panel

may be used to activate or deactivate all machine

functions, adjust functions and indicate

anomalies. The electrical box at the rear contains

the main switch and all control and power

devices.

3.1.5 Electrical system

cools down; the heat is then disposed of in the

condenser, where it is transferred to the water

coming from the cooling tower (or well), heating

it.

A pressure switch valve assembled on the

condenser water circuit keeps condensation

pressure constant, independently of water tem-

perature.

The system mounted on the Frigus 600 is a

particularly efficient one which makes use of a

dependable, low maintenance Scroll compressor

which acts as a two-stage compressor with an

economiser to obtain considerable cooling

capacity and improved dependability.

Tetra Pak

Hoyer

3-11

B

F60 03 C 04

Hoyer

Frigus

4

1

6

14

9

11

10

2

13

15

17

12

Fig. 3.5

3

5

7

8

18

16

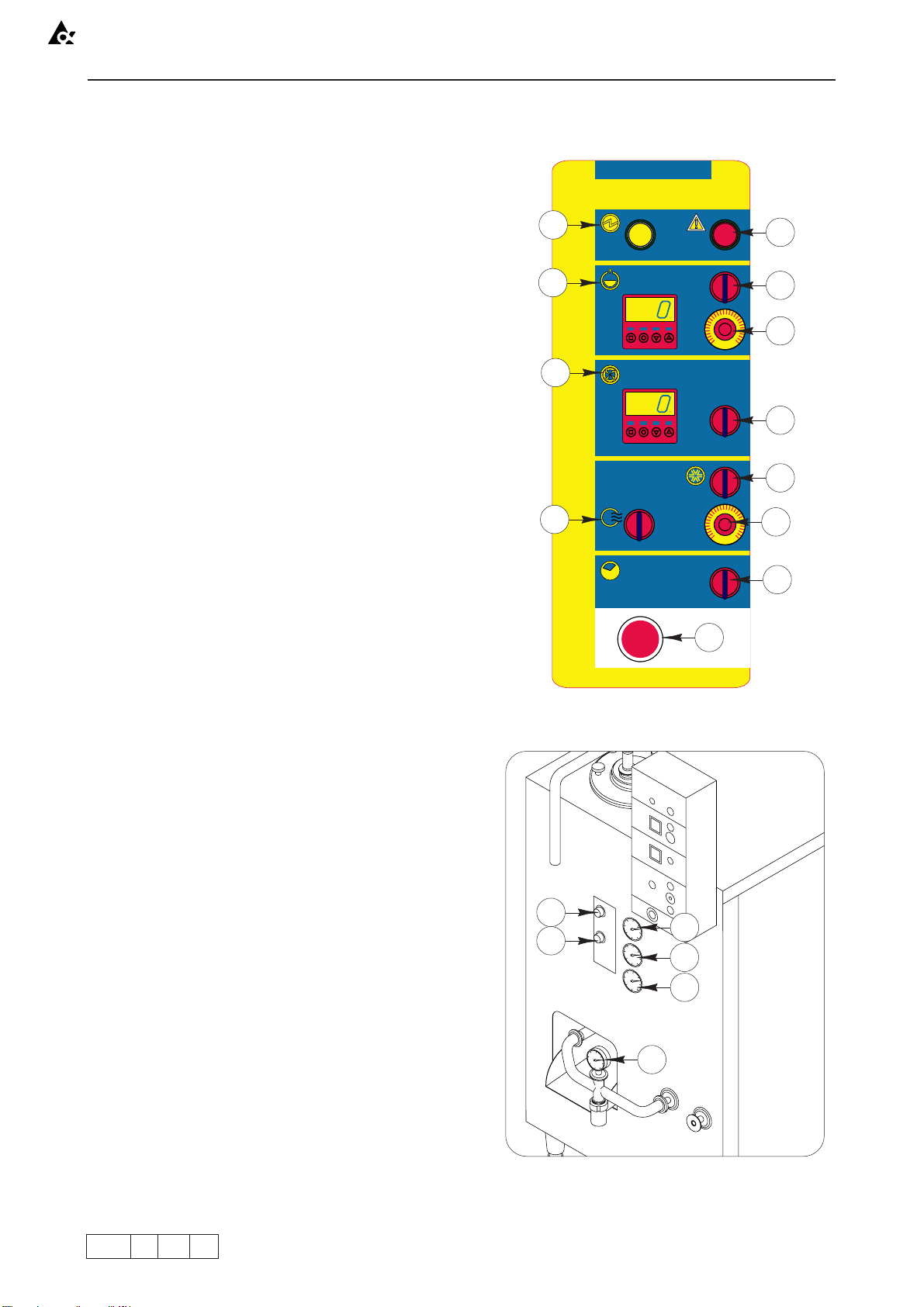

3.1.6 Control panel

1White power indicator lamp

2Red thermal switch indicator light

3Pump start/stop switch

4Litre counter

5Pump potentiometer

6Dasher motor ammeter

7Dasher start/stop selector

8Compressor start/stop switch

9Overrun air ON/OFF switch

10 Hot gas control potentiometer

11 C.I.P washing switch.

12 Emergency stop pushbutton

13 Overrun pressure indicator

14 Overrun pressure regulator

15 Cylinder outlet valve pressure indicator

16 Cylinder outlet valve pressure control

17 Coolant evaporation pressure gauge

18 Dasher pressure indicator

Tetra Pak

Hoyer

3-12 B

F60 03 C 04

A

B

C

Fig. 3.6

3.2 Technical data

Dimensions and weights:

Dimensions

A = 1330 mm

B = 755 mm

C = 1665 ±25 mm

Net weight: 525 Kg

Gross weight: 725 Kg

Volume (with packaging): 2.96 m3

(1,60x0,95x1,95h metres)

Rated capacity in standard conditions:

from 200 to litres/hour of ice cream at –5.5ºC

Standard conditions:

Mix input temperature: + 4°C

Overrun: 100%

Neutral mix with 38% solids content

Electrical specifications:

Dasher motor: kW

Pump motor: kW

Refrigerator compressor: kW

Auxiliaries: kW

Total installed power: kW

Compressed air:

Operating pressure: 6-10 bar

Consumption (max): 10 Nl/min

Filtering degree: A0

Connector: 1/2” female

Refrigerating plant:

Coolant gas: R404A

Quantity: 2.8 Kg

Condensation water:

a) dwell water + 5°C 600 l/h

b) mains water +15°C1300 l/h

c) tower water +28°C3600 l/h

Water inlet connector: 1” gas female

Water outlet connector:1” gas female

Noise:

A-weighted equivalent sound pressure level at

1 metre:

Leq(A) = 70.5 dB(A)

Max. C-weighted instantaneous sound pressure

level at working positions:

Less than 130 dB/20uPa

Max. non-weighted sound pressure level at

working positions:

Less than 140 dB/20uPa

Electromagnetic compatibility:

Conforms to VDE 0843/IEC801; wiring in

accordance with EN55011

Number of operators: 1

600

5.5

0,75

9,5

0,85

16,6

Tetra Pak

Hoyer

3-13

B

F60 03 C 04

3.3. Improper use

Though the machine is equipped with a number of

safety systems, operators must be very careful to

make sure that no situations arise which could

potentionally put them or others in danger.

The machine is designed and built exclusively for

the use described in chapter 3.1. Any other use must

be considered improper and unreasonable. The

manufacturer shall not be held responsible for any

damage caused by improper, erroneous or

unreasonable use.

Everyone who works on the machine must be

adequately trained in thecorrect working methods

and informed of the nature and functioning of

safety devices.

3.4. Demolition and disposal

Information of use for disposal of the machine

and its components.

The machine must be demolished by specialised

personnel wearing appropriate safety garments

and working in compliance with safety and

environmental legilation.

Construction materials:

- steel, stainless steel, aluminium, cast iron

- copper, silver in electrical components

- rubber, nylon, PVC, resins and fibres.

No component is toxic or harmful.

Dispose of reducting gears carefully as they are

full of oil.

Do not abandon these components or dispose of

them with regular waste.

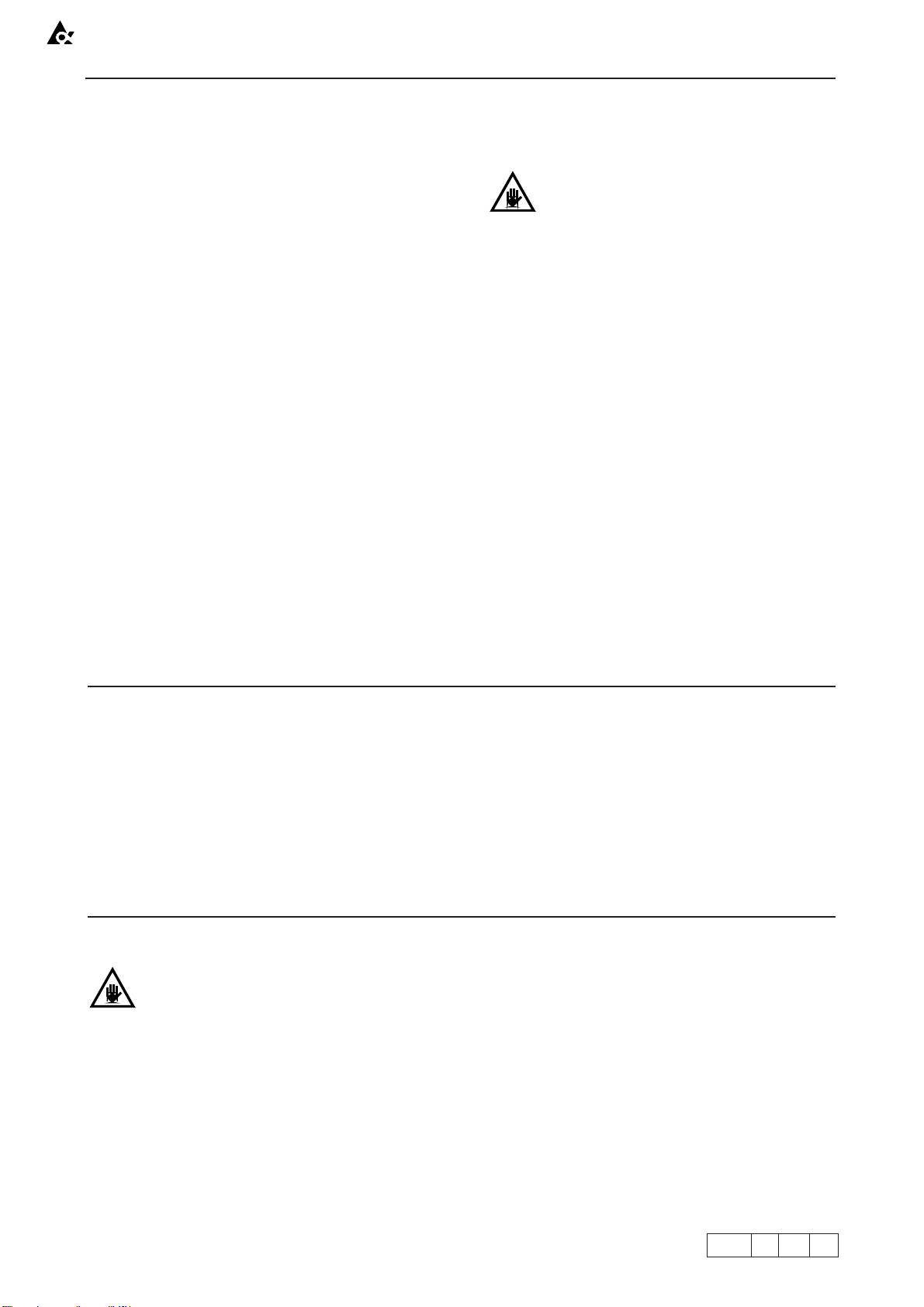

WARNING! When finished using

machines and components, dispose of them in

accordance with the laws in effect in your country.

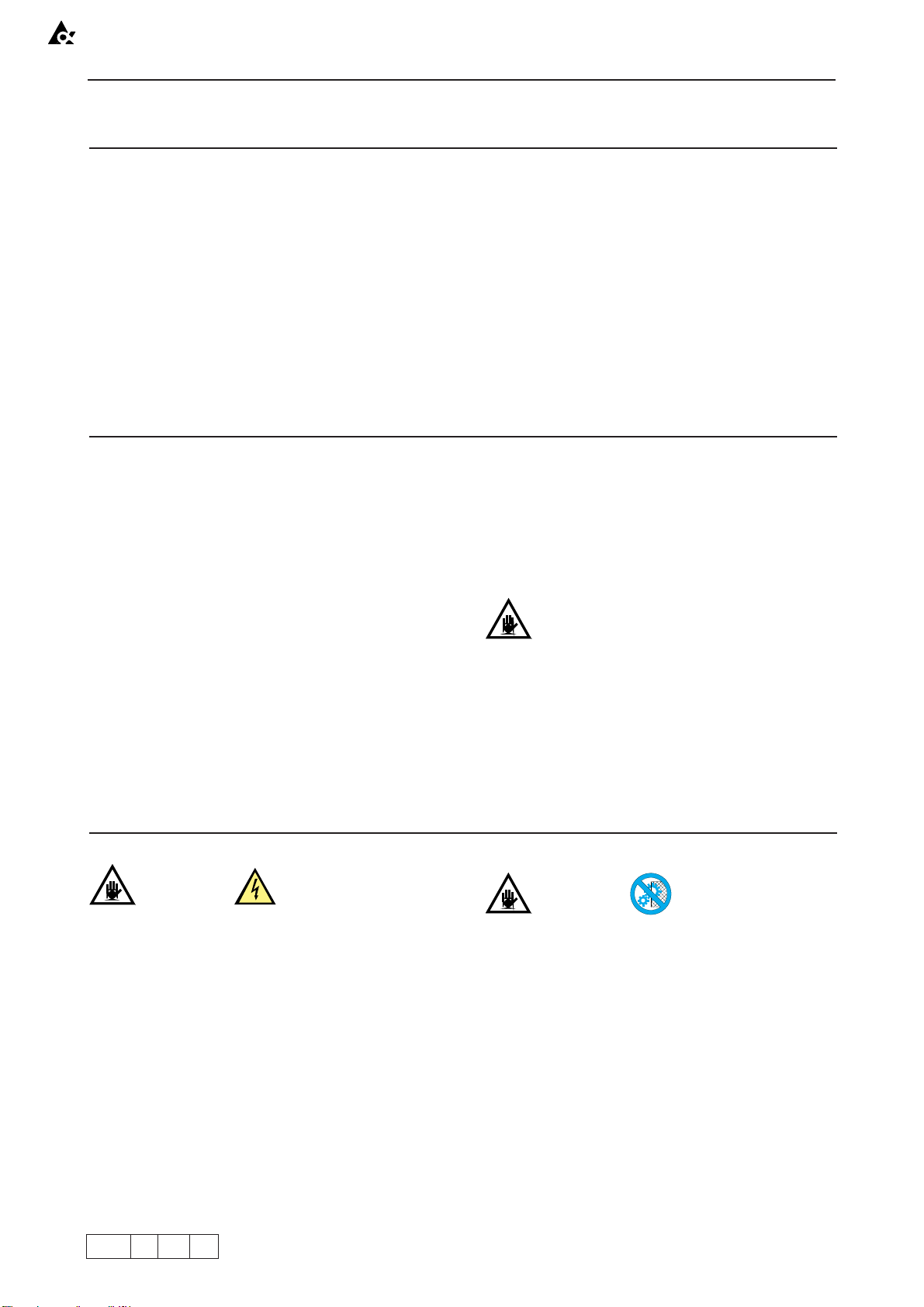

3.5 Warnings, prohibition and danger signs

WARNING :

Dismantling side panels (anchored in place with

screws) permits contact with moving parts.

A moving parts sign must be positioned on the

panels.

WARNING :

The doors of the electric board can be opened

using the tools supplied with the machine.

The opening of the doors disconnects the

components downstream from the main swutch.

Some components may continue to be powered

by residual current for a specific interval of time.

After opening the machine, avoid touching the

internal parts for at least 5 minutes.

A sign indicating the presence of powered parts

is placed on the door.

Tetra Pak

Hoyer

4-14

Contents

B

HOYER FRIGUS 600

F60 03 D 04

4.1 Unpacking, delivery checks and transport ............................................................... 4-2

4.2 Installation ............................................................................................................... 4-3

4.2.1 Cooling water connection (tower water) ........................................................ 4-4

4.2.2 Ice cream intake and outlet connection .......................................................... 4-5

4.2.3 Compressed air connection ............................................................................ 4-5

4.2.4 Electrical connection ..................................................................................... 4-5

4.3 Installation check .................................................................................................... 4-6

4 - INSTALLATION

Tetra Pak

Hoyer

4-15

B

F60 03 D 04

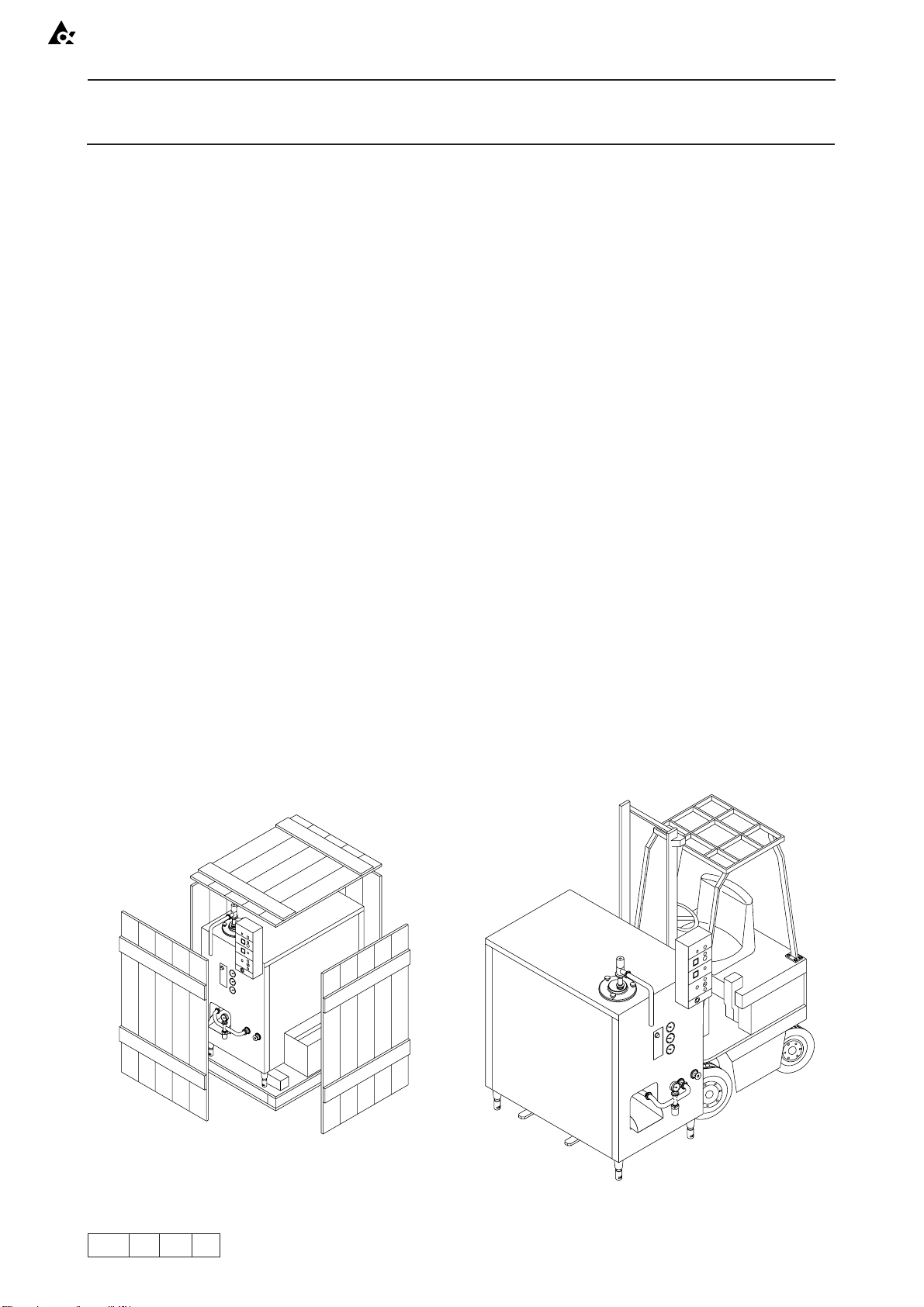

Fig. 4.1 Fig. 4.2

The machine is packed in wooden crates.

Unpacking must be done close to the installation

position. The cases may be easily transported

by a lift truck.

If the crate has been damaged during transport,

notify the insurance company immediately and

do not proceed with removal of packaging until

authorised by the insurance company.

When the crate is positioned in the place of

installation, proceed to remove the machine from

its packaging as follows:

a. Unnail the top cover and remove it. Do the

same with the side panels. Take care with

the wooden spacers between the walls of the

crate.

b. Remove the box containing spare parts and

the other components from the crate.

c. Unnail the wooden blocks that hold the

machine in place during transport and

remove the protective cellophane.

d. Check that the content of the package

corresponds to the shipping documents.

e. Make sure that all covers and panels are

correctly fastened in place and there are no

loose parts.

f. Visually inspect all electrical components to

make sure they are in perfect condition.

g. If any part or component is missing, notify

Tetra Pak Hoyer immediately.

The machine may be moved using a fork lift

truck, taking care to position the forks so that

the machine’s weight is evenly distributed.

4.1 Unpacking, delivery checks and transport

Tetra Pak

Hoyer

4-16 B

F60 03 D 04

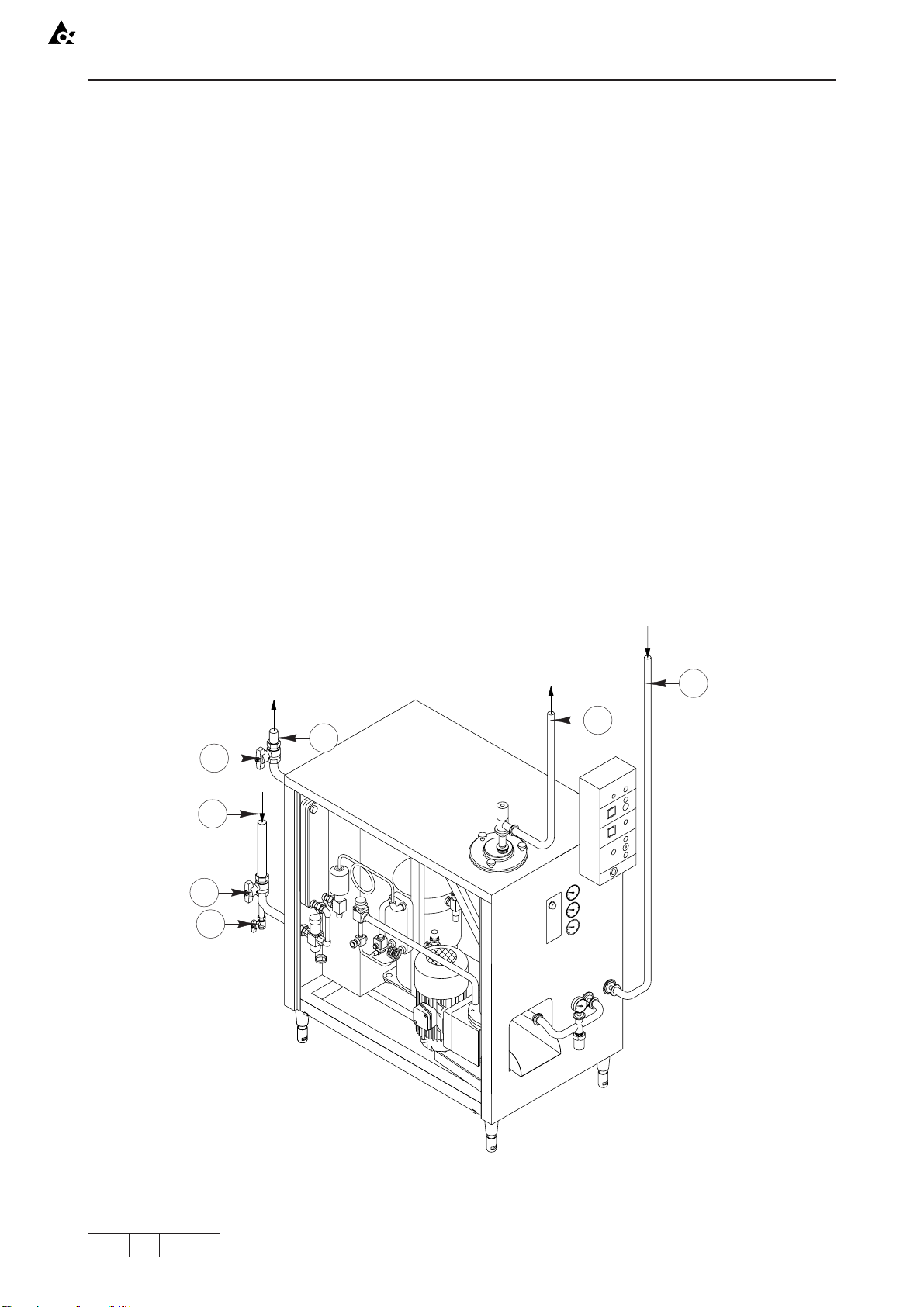

Fig. 4.3

The machine is fully tested and regulated in the

factory with about one hour of ice cream

production prior to shipment to the customer.

Installation simply involves connecting up the

pipes for the condenser cooling water supply, ice

cream mix intake and outlet, compressed air

supply and electric power supply. There is no

need for internal adjustments to the machine; we

recommend that factory settings not be changed.

Proceed with the installation procedure as

follows:

a. Position the machine in its operating position

and check the plate data to make sure that

the machine is compatible with the site’s

electrical power supply, and compressed air

supply.

b. Level the machine with a spirit level by

means of the adjustable feet.

The plates provided may be applied

underneath the feet.

c. Connect up the condenser cooling water

pipes (1) (2). If tower water (+28°C) is used

for cooling, use inlet (7) and shut off inlet

(2).

d. Connect up the ice cream mix intake (3) and

outlet (4) pipes to the production line.

e. Connect up the compressed air pipe (5).

f. Connect the machine to the ground and to

the electrical power supply (6).

4.2 Installation

195

443

50 1070

1005 280

1530

443

580 696

30 600 120

3

156 2

5

6

1

2

44

3

750

82

7

Tetra Pak

Hoyer

4-17

B

F60 03 D 04

Fig. 4.4

4.2.1 Cooling water connection (tower water)

Connect up the supply of condenser cooling

water, taking care to get the direction of water

flow correct: water must flow in through the

connection at the bottom (1) and out through the

connection at the top (2). It is recommended that

two on/off taps (3) (4) be installed close to the

machine, as well as a small drain tap (5) close to

the bottom connection; it is also a good idea to

connect up these two taps with the machine

through two pipe unions (three-piece connectors)

to make it easy to separate the freezer from the

installation.

The machine is fitted with a pressure valve which

controls the flow of water in inverse proportion

to its temperature to obtain constant cooling

(constant condensation pressure on the coolant

side); this makes it possible to use water supplies

with widely varying temperatures for cooling the

condenser. The water flow varies as a result, from

about 600 litres/hour at 5ºC to 3600 litres/hour

at 28ºC (average values for machine in operation

at maximum production rate).

Pipe diameter depends on pipe length and the

pumps available, and must never be less than

the diameter of the connections, which is 1” gas.

It is essential to wash out the pipes BEFORE

connecting them to the machine by flushing them

with water to eliminate any particles or dirt. If

the water that flows out of the pipes continues

to be dirty, it will be necessary to install a filter

with a filtering capacity and size appropriate to

the type and amount of dirt conveyed at the intake

(1) (the bottom connection). In any case, it is

recommended that you install the filter to redu-

ce soiling of the condenser.

See Chapter CLEANING AND

MAINTENANCE .

6

3

7

2

4

5

1

Tetra Pak

Hoyer

4-18 B

F60 03 D 04

4.2.2 Ice cream intake and outlet connection

Connect the mix supply pipe to the mix pump

inlet connection (6) on the front of the machine.

The machine has a CIP washing programme

permitting thorough, safe washing of the machine

without dismantling its parts; it will therefore be

necessary to prepare the required connections

between the CIP washing pump and solutions and

the mix pipe.

Make sure that the mix flows “spontaneously”

to the machine connection (6), and does not need

to be suctioned by the freezer pump; this may be

done by simply positioning the aging vats higher

than the freezer (check that the spontaneously

flowing supply is sufficient even when the mix

level in the containers is low), or by installing a

suitable centrifugal pump close to the vats. Take

care to ensure that there is no air getting into the

pipes, which could pollute the product and result

in fluctuation of ice cream overrun.

CAUTION:

Pipes must be dismantled and washed

thoroughly after completing this procedure

to ensure that no hard solid particles are

conveyed toward the freezer mix pump. This

is very important as solid particles such as

metal burr or welding residues could severely

damage the freezer pump and will invalidate

the guarantee.

Connect up the ice cream outlet (7) to the utility.

Use the shortest possible pipe, with as few

curves as possible, and use a pipe which is shiny

inside; the pipe does not need to be insulated.

Make sure that ice cream pressure in the

cylinders does not exceed 12 bar (the absolute

maximum permitted value); if this should occur,

move the freezer closer to the ice cream utility

and/or use hot gas to produce softer ice cream.

Connect the compressed air supply pipe to the

connection on the rear of the machine; it is

recommended that an easily removable tap and

connection be assembled close to the machine

connection.

The supply pressure measured on the machine

4.2.3 Compressed air connection

must never drop below 6 bar. It is strongly

recommended that the compressed air supply

in the place of installation be fitted with an air

drying system and A0 filters to remove oil

vapours and residual fine particles.

CAUTION:

Electrical connection must be made

exclusively by competent technicians who are

familiar with safety legislation and authorised

to perform and certify electrical installations.

Check the identification plate to make sure that

the machine is compatible with the site’s power

supply. Connect the machine’s power supply to

the site’s distribution panel and protect it with a

4.2.4 Electrical connection

suitable device, complying with all regulations

for correct electrical installation in effect in the

place of installation.

We recommend installing an automatic circuit

breaker on the distribution panel, complying

with local regulations.

Table of contents

Other Tetra Pak Ice Cream Maker manuals