Texas International Oilfield Tools, LTD. OM010-C

CONFIDENTIALITY STATEMENT

This document contains confidential information. All rights including copyright, confidential information, trade

secrets and design rights are owned by Texas International Oilfield Tools, LTD (TIOT, Texas International,

and Texas International Oilfield Tools). No use or disclosure is to be made without prior written permission of

Texas International Oilfield Tools, LTD.

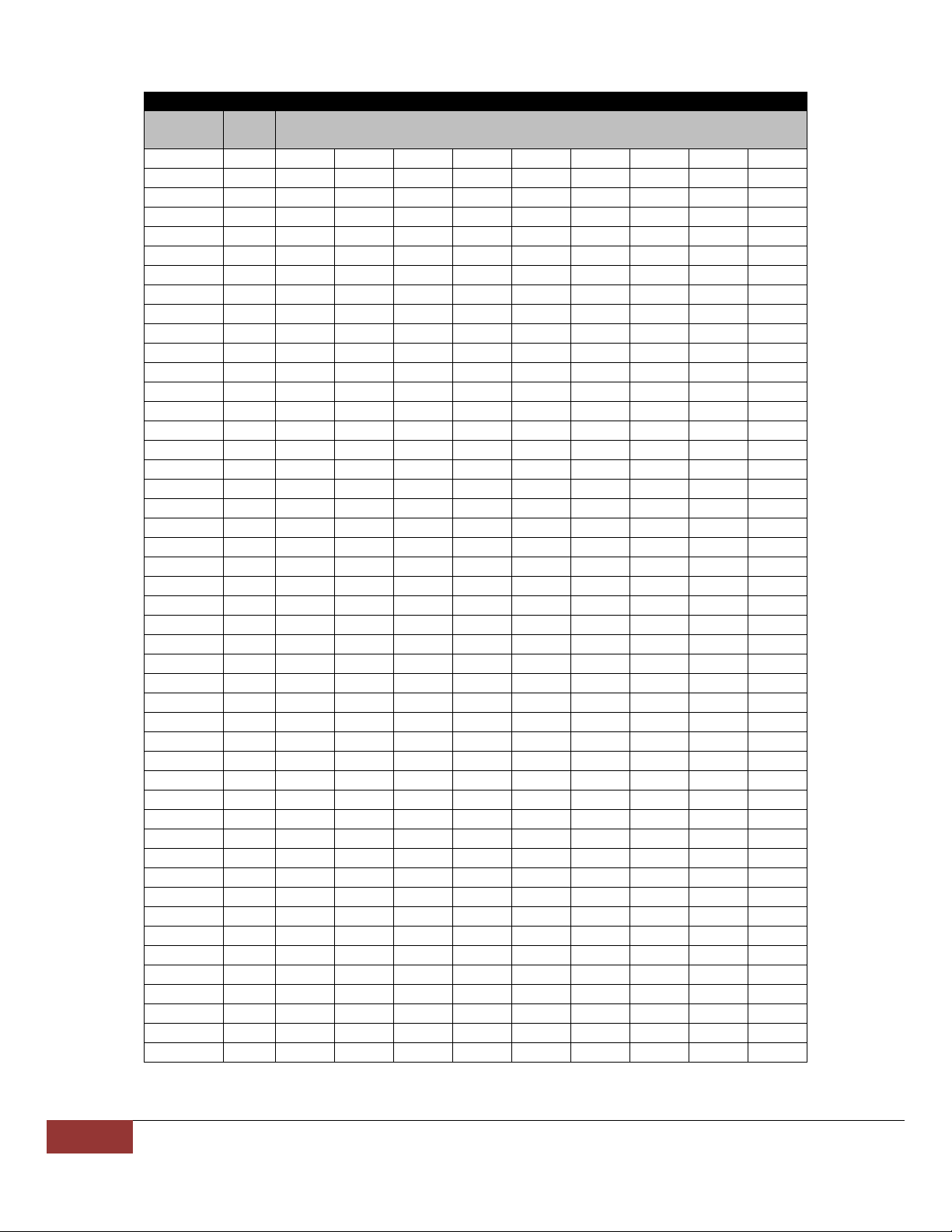

Revision History

Description of Change

Reformatted and added Operation and Troubleshooting sections

Changed max operating pressure from 2500 psi in Table 2. Updated

Table 3. Corrected Figure 4. Revised Table 10 by combining items 8

and 10. In Table 11, item 5 was p/n 060000, 14 is now bought as an

assembly (p/n T17567-16A) – see starred items in BOM, 15 was

040002, 17 was 060005, 20 was 060002, 36 was 030016, 40 was

030015, 42 was 030024, and added item 71. On Table 12, qty of item

7 was 1. Added assembly part numbers where applicable (specifically