Directory

1. Instruction....................................................................................................................................................................1

1.1. Features.............................................................................................................................................................1

1.2. Composition..................................................................................................................................................... 1

1.3. Working Principles............................................................................................................................................1

1.4. Technical Parameters.......................................................................................................................................2

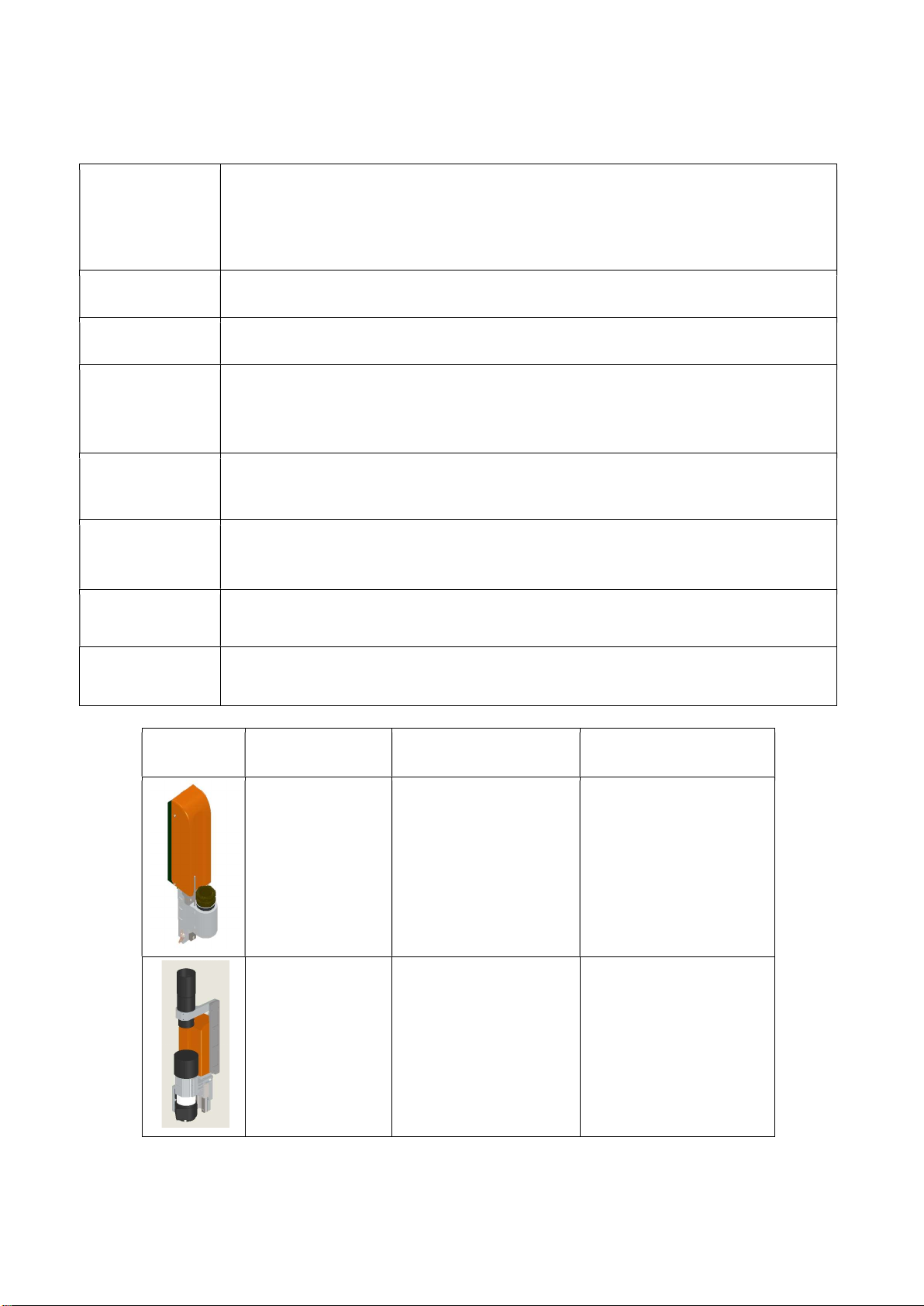

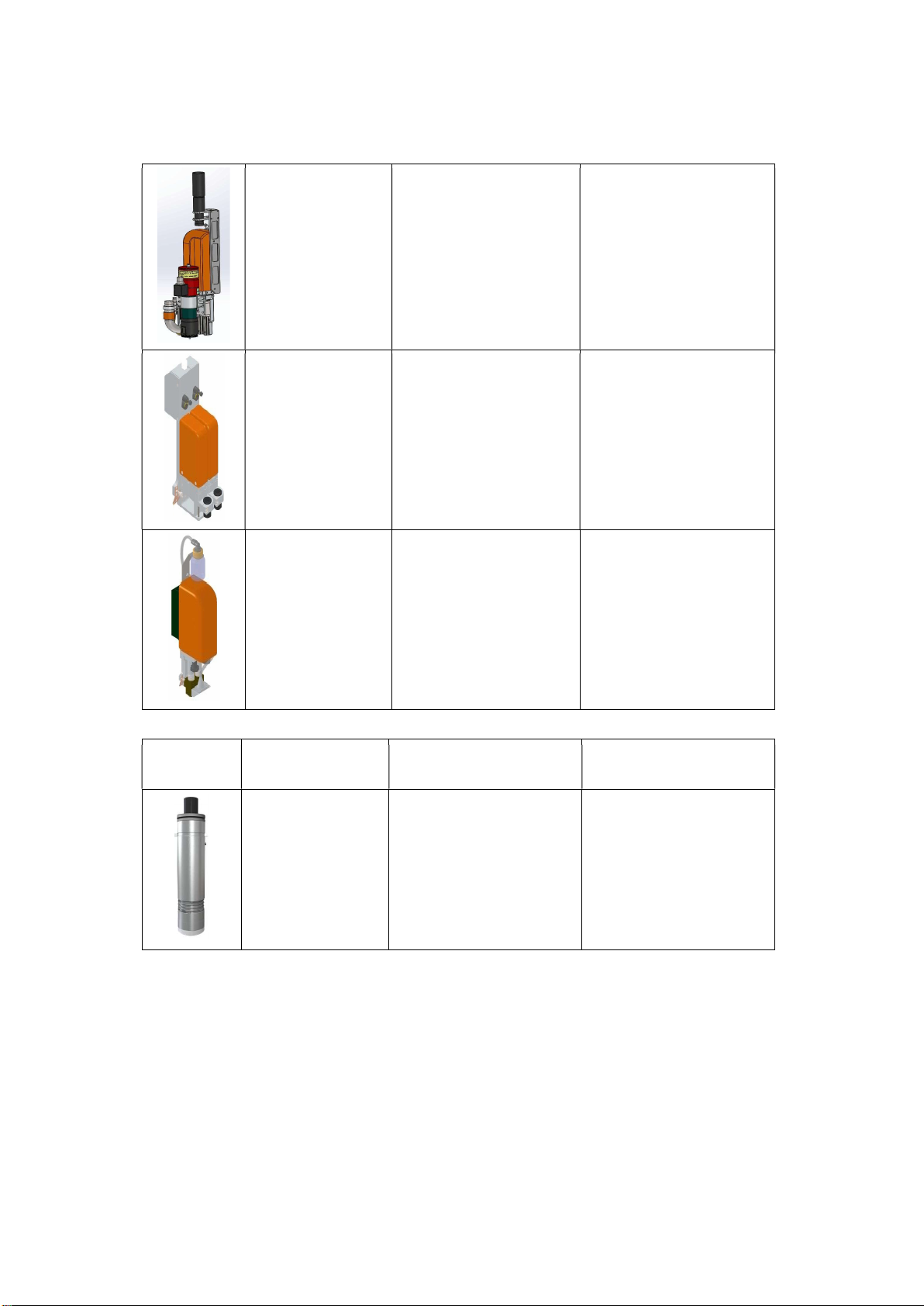

1.5. Cutting modules............................................................................................................................................... 3

1.6. Tools..................................................................................................................................................................4

1.7. Circuit boards....................................................................................................................................................8

1.8. List of tools....................................................................................................................................................... 9

2. Preconditions..............................................................................................................................................................11

2.1. Installation location.........................................................................................................................................11

2.2. Personnel.........................................................................................................................................................11

2.3. Power requirement ( 50HZ / 60HZ Voltage±5% )................................................................................11

2.4. Environmental conditions.............................................................................................................................. 12

2.5. Basic device compressed air.......................................................................................................................... 12

2.6. Flooring Space Requirement...........................................................................................................................13

2.7. Operation Space requirement........................................................................................................................13

3. Installation................................................................................................................................................................. 14

3.1. Opening and inspecting packing crates......................................................................................................... 14

Note:..............................................................................................................................................................14

Note:..............................................................................................................................................................14

3.2. Initial leveling of the base frame.....................................................................................................................15

3.3. Base machine installation...............................................................................................................................16

3.4. Assembling the workstation............................................................................................................................20

3.4.1 Connect the monitor, keyboard and mouse.....................................................................................20

3.4.2 Connecting the PC to the cutter...................................................................................................... 21

3.5. Assemble the Milling support device. ( The total height : 2.8 m)................................................................22

3.5.1 Connect cables in the milling device support...................................................................................24

4. Danger area during initialization...............................................................................................................................25

4.1. Danger area on the module carriage..............................................................................................................25

4.2. Safety device on the machine and PC table....................................................................................................26

5. Power installation and air supply connection........................................................................................................... 27

6. Modules installation.................................................................................................................................................. 28

6.1. Tools installation.............................................................................................................................................30

6.1.1 Tangent tool......................................................................................................................................30