Textron Aviation 400T User manual

Aviation Fabricators Inc.

805 North Fourth Street

Clinton, MO. 64735

INSTRUCTIONS FOR CONTINUED AIRWORTHINESS

For

Cabinet Assembly, Toilet and Manual Storage

Document No.: AF-645

Revision “A”

Revision Date: 08/10/20

Applicable to:

Textron Aviation 400T Aircraft

The information in the Instruction for Continued Airworthiness is FAA accepted material and complies with

14 CFR 25.1529, Instructions for Continued Airworthiness. It supersedes or adds to that provided in the

Maintenance Manual for the Textron Aviation 400T aircraft, only where covered in the items contained

herein. For limitations and procedures not contained in the Supplement, consult the Textron 400T

Maintenance Manual, or other approved airplane data.

Aviation Fabricators Inc. ICA Document No.: AF-645

805 North Fourth Street Revision A)

Clinton, MO. 64735 Date: August 10, 2020

Page 2 of 13

REVISION PAGE

Document Title: Instructions for Continued Airworthiness

Prepared By: Nolan Groff

Updates to the ICA will be made by Aviation Fabricators Inc. Updates will be listed in the log of

revisions below.

Per the requirement of Appendix H of 14 CFR Part 25 paragraph H23.1 (c), the changes

made to the ICA by the applicant will be distributed via mail by means of paper copy.

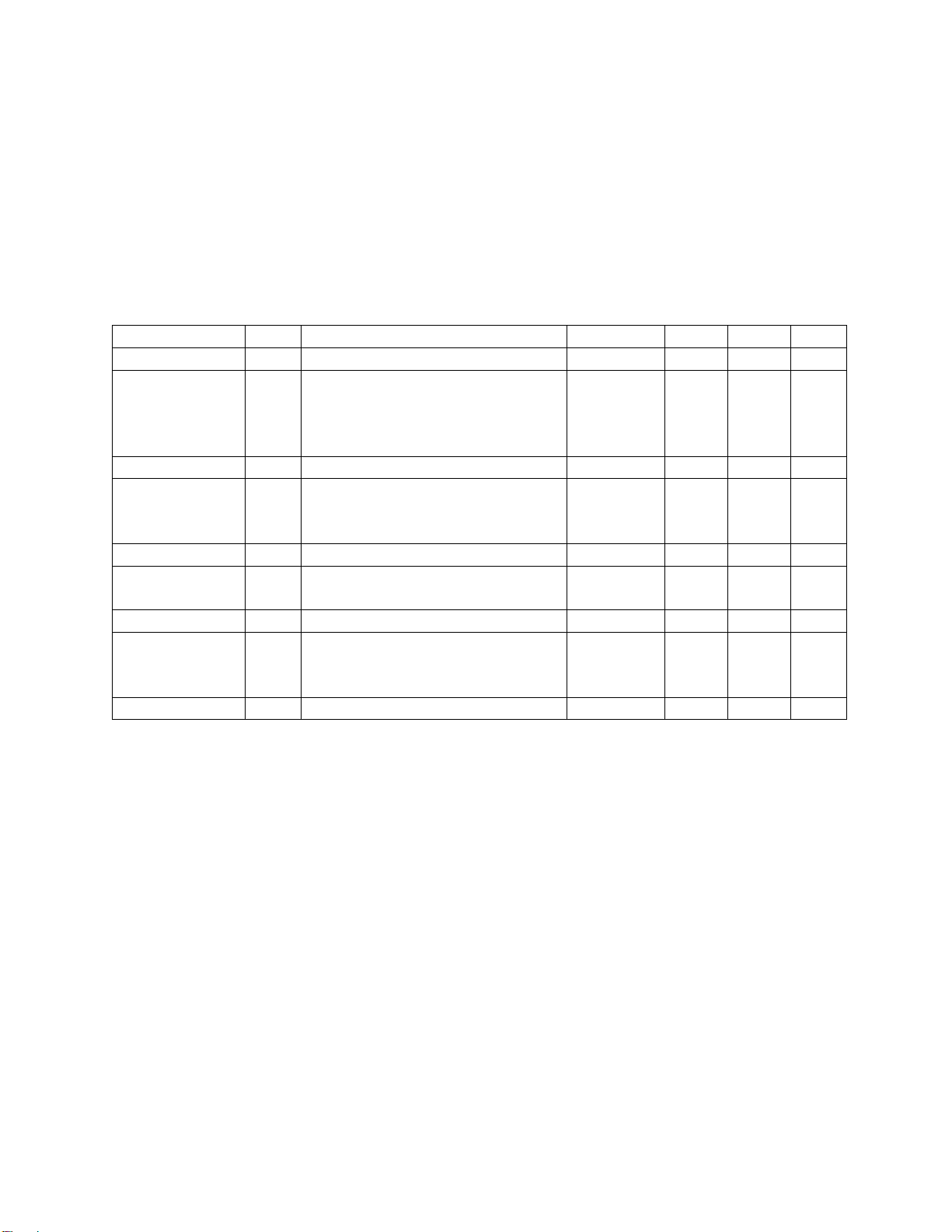

Log of Revisions

REV.

NO.

EFFECTED

PAGE(S)

DESCRIPTION

DATE

APPROVED

BY

Orig.

Issue

All

Initial Release

11/13/18

G.R. Lowe

A

All

*Updated the paragraph at the bottom of page 1 to

say “consult the Textron 400T Maintenance Manual”

from “consult the Component Maintenance Manual

*Updated the Abbreviations and Definitions list on

page 4 to include only those used in the document

*Updated the paragraph on page 5 in Section 1 under

DATA heading to describe the toilet cabinet assembly

with more detail to better comply with 14CFR

G23.3(a)(3)

*Changed “Work Unit Code (WUC)” to “Task Code” in

the inspection table on page 8 and added AFI-XXX

task code #’s

*Updated the inspection table on page 8 to conduct

GVI inspections for task A, B, & C on page 8

*Updated the paragraph under Section 2.2.b to say to

clean any excess water from the tank assembly and

removed reference to drain the entire system, page 8

*In Section 9.C. added items 1, 2, & 3 to describe the

Toilet Cabinet Assembly Removal and Installation

procedures, page 10

*In Section 9.E.1. added procedure to replace the

pump hose, page 12

*In Section 9.E.2., noted the timer location on page 12

*Added “Installation document reference under DATA

heading on page 5

*Added “as defined per supplier instructions” in the

Note concerning the antifreeze mixture in Section

9.D.5 on page 13

08/10/20

G.R. Lowe

Aviation Fabricators Inc. ICA Document No.: AF-645

805 North Fourth Street Revision (A)

Clinton, MO. 64735 Date: August 10, 2020

Page 3 of 13

TABLE OF CONTENTS

DESCRIPTION PAGE

REVISION PAGE..........................................................................................................................................2

TABLE OF CONTENTS................................................................................................................................3

ABBREVIATIONS AND DEFINITIONS.........................................................................................................4

1.0 INTRODUCTION...............................................................................................................................5

2.0 INSPECTION REQUIREMENTS AND OVERHAUL SCHEDULE....................................................8

3.0 DIMENSION AND ACCESS: ............................................................................................................8

4.0 LIFTING AND SHORING..................................................................................................................8

5.0 LEVELING AND WEIGHING ............................................................................................................9

6.0 TOWING AND TAXIING ...................................................................................................................9

7.0 PARKING AND MOORING...............................................................................................................9

8.0 PLACARDS AND MARKINGS..........................................................................................................9

9.0 SERVICE INFORMATION ................................................................................................................9

10.0 AIRWORTHINESS LIMITATIONS..................................................................................................13

Aviation Fabricators Inc. ICA Document No.: AF-645

805 North Fourth Street Revision (A)

Clinton, MO. 64735 Date: August 10, 2020

Page 4 of 13

ABBREVIATIONS AND DEFINITIONS

Abbreviations

Definitions

FAA

Federal Aviation Administration

General Visual

Inspection (GVI)

A visual examination of an interior or exterior area, installation or

assembly to detect obvious damage, failure or irregularity. This level

of inspection is made from within touching distance unless otherwise

specified. A mirror may be necessary to enhance visual access to all

exposed surfaces in the inspection area. This level of inspection is

made under normally available lighting conditions such as daylight,

hangar lighting, flashlight or droplight and may require removal or

opening of access panels or doors. Stands, ladders or platforms

may be required to gain proximity to the area being checked.

ICA

Instructions for Continued Airworthiness

STC

Supplemental Type Certificate

Aviation Fabricators Inc. ICA Document No.: AF-645

805 North Fourth Street Revision (A)

Clinton, MO. 64735 Date: August 10, 2020

Page 5 of 13

1.0 INTRODUCTION

The purpose of this Maintenance Manual Supplement and Instructions for

Continued Airworthiness (ICA) is to provide the maintenance technician with the

information necessary to ensure the continued airworthiness of the Aviation

Fabricators cabinet assembly, toilet and manual storage, part number 32-0531K,

when installed in accordance with Aviation Fabricators design data included on

STC Data List AF-644.

Modification to an aircraft obligates the operator to include the maintenance

information provided by this document into the operator’s aircraft Maintenance

Manual and operator’s aircraft scheduled maintenance program. This document

defines supplementary maintenance operations and frequencies recommended

by Aviation Fabricators Inc., to ensure the aircraft’s airworthiness.

The information contained herein addresses the requirements specified in 14

CFR 25.1529, Instructions for Continued Airworthiness and supplements the

basic Airplane Maintenance Manual only in those areas listed as pertains to the

cabinet assembly, as installed per the Aviation Fabricator STC Data List AF-644.

For limitations and procedures not contained in this supplement, consult the

basic Airplane Maintenance Manual.

DATA

All information to support the continued airworthiness of this modification is

contained in:

STC Data List: AF-644.

Parts: P/N 32-0531, Cabinet Assembly, Toilet and Manual Storage

Refer to respective drawing listed on STC Data List AF-644

Installation: Drawing D-10580

The toilet cabinet assembly is attached to the existing cabin floor track at FS

170.0 +/-1.0 using four track bolts, lock washers, and floor fittings. The toilet

assembly sits on a shelf in the toilet cabinet assembly and is attached to the toilet

cabinet assembly using four bolts. The toilet assembly is connected to the

aircraft electrical system using the existing electrical receptacle.

Once toilet cabinet assembly is installed, the toilet assembly is operated by lifting

the lid assembly and ensuring that the waste container cap is stowed. To active

the toilet press the flush switch which will pump fluid into the reservoir and will

thoroughly rinse the bowl. The flushing reservoir has sufficient capacity for 10-

13 flushes.

Aviation Fabricators Inc. ICA Document No.: AF-645

805 North Fourth Street Revision (A)

Clinton, MO. 64735 Date: August 10, 2020

Page 6 of 13

Design Change Control

All data and changes to the parts and assemblies will be tracked per STC Data

List AF-644 rev IR or later approved revision.

Applicable Aircraft

Textron Aviation 400T Aircraft

Cabinet Assembly, Toilet and Manual Storage

P/N 32-0531

Figure 1.0A

Aviation Fabricators Inc. ICA Document No.: AF-645

805 North Fourth Street Revision (A)

Clinton, MO. 64735 Date: August 10, 2020

Page 7 of 13

Toilet Assembly

P/N 17-0939

Figure 1.0B

Aviation Fabricators Inc. ICA Document No.: AF-645

805 North Fourth Street Revision (A)

Clinton, MO. 64735 Date: August 10, 2020

Page 8 of 13

2.0 INSPECTION REQUIREMENTS AND OVERHAUL SCHEDULE

1. To comply with14 CFR 25.1529, continue the cabinet assembly on the same

inspection and maintenance schedule used per the Beechcraft Maintenance

Manual for Cabinet Assembly, Toilet & Manual Storage, p/n 132-384024-1.

The toilet cabinet assembly requires no service other than a scheduled

inspection at 800 hours or 24 months whichever occurs first.

Task Code

Schedule

Date

Mech

Insp

AFI-100

A.

Conduct a General Visual

Inspection (GVI) of attaching

fittings for damage, security,

and function.

AFI-101

B.

Conduct a GVI of the cabinet

assembly for damage, and

corrosion.

AFI-102

C.

Conduct a GVI of the entire

assembly for fit and function.

AFI-103

D.

Check operation of toilet

assembly.

See Section 9.0.

2. Flushing toilet maintenance schedule:

a. Service and clean after each flight when toilet is used.

b. If the toilet is to remain inactive for an extended period, empty the

water/chemical solution and thoroughly flush the system with fresh water. Be

sure to clean any excess water from the toilet tank using paper towels.

3.0 DIMENSION AND ACCESS:

The installation of the toilet cabinet assembly does not change the dimensions of

the aircraft or alter the access to any existing aircraft system.

4.0 LIFTING AND SHORING

No change.

Aviation Fabricators Inc. ICA Document No.: AF-645

805 North Fourth Street Revision (A)

Clinton, MO. 64735 Date: August 10, 2020

Page 9 of 13

5.0 LEVELING AND WEIGHING

For the toilet, the dry weight plus fluid will be used to conduct the aircraft

weighing procedures for determining the empty weight of the aircraft:

Cabinet weight without toilet = 26.0 lbs

Toilet weight = 11.3 lbs

Flushing fluid reservoir liquid = 5.2 lbs

Waste tank pre-charge = 1.0 lbs

Total = 43.5 lbs

6.0 TOWING AND TAXIING

No change.

7.0 PARKING AND MOORING

No change.

8.0 PLACARDS AND MARKINGS

No change.

9.0 SERVICE INFORMATION

A. Leading Particulars

Waste Tank Capacity

1.25 gallon

Flushing Reservoir Capacity

2 quarts (9-12 flushes)

Operating Voltage

24-28 VDC

Operating Amperage

2 amp

Operating Time

1 second per flush

Aviation Fabricators Inc. ICA Document No.: AF-645

805 North Fourth Street Revision (A)

Clinton, MO. 64735 Date: August 10, 2020

Page 10 of 13

B. Chemicals Needed for Servicing

NOTE: Equivalent substitutes may be utilized in place of the following items:

Germicidal Deodorant

ChemKare of Monogram Sanitation

Disinfectant

Lysol

Anti-Freeze

Ethylene Glycol Solution Containing Anti-Foam Agent

Refer to SDS for chemicals to ensure proper precautions are observed for their

use.

C. Toilet Cabinet Servicing Instructions

1. Remove the Toilet Cabinet Assembly:

a. Open the front door of the cabinet assembly.

b. Loosen attaching bolts at the bottom of the cabinet assembly.

c. Unplug from power supply.

d. Lift cabinet assembly away from seat track.

2. Installation of the Toilet Cabinet Assembly:

a. Locate floor fittings in seat track to for Toilet Cabinet attachment.

b. Plug Toilet assembly into power supply and then set Toilet Cabinet into

place on seat track.

c. Open the front door of the cabinet assembly.

d. Attach Toilet Cabinet to track fittings using track bolt and lock washer.

e. Close front door.

See Figure 1.0A

3. If aircraft is to be operated without the Toilet Cabinet Assembly then the

operator needs to ensure that the existing aircraft wiring is stowed to prevent

damage to it. The operator will need to adjust the aircraft weight & balance

for removed toilet cabinet assembly.

D. Toilet Servicing Instructions

Servicing the waste container:

1. Lift the bowl assembly straight up and rest on lid angle. Secure with strap

assembly.

2. Place cap firmly onto waste container.

3. Grasp both handles and remove container from the cabinet.

4. Dispose of contents in a commode and rinse waste container.

5. Pre-charge container with approximately one pint of water and two ounces of

germicidal deodorant.

Aviation Fabricators Inc. ICA Document No.: AF-645

805 North Fourth Street Revision (A)

Clinton, MO. 64735 Date: August 10, 2020

Page 11 of 13

NOTE: If the aircraft is parked in sub-freezing temperatures, ensure an

appropriate amount of propylene glycol-based antifreeze containing an anti-

foam agent is added to the pre-charge mixture as defined per supplier

instructions.

6. Reinstall waste container in the toilet. Stow waste container cap.

Servicing the flushing reservoir:

1. Lift the bowl assembly straight up and rest on lid angle. Secure with strap

assembly.

2. Fill the reservoir with water to “Fill to Here” line.

3. Add 2 ounces of germicidal deodorant. See note under item 5 in waste

container servicing instructions.

4. Replace the bowl assembly on the cabinet seal. Wipe down the bowl and seat

with disinfectant.

Toilet functional test:

1. Fill reservoir to “Fill to Here” line.

2. Check that pump power wire plug is plugged into socket on rear wall of

cabinet.

3. Check that timer is connected to aircraft power, pump power wire and to flush

switch.

4. Depress and release flush button. Observe that flushing action continues for

approximately 1 second.

E. Toilet Troubleshooting

1. Perform the following procedures to isolate and identify possible problems:

Problem

Probable Cause

Action

Toilet will not cycle

Aircraft power not

operating

Check aircraft power,

fuses, circuit breakers.

Check input power to toilet.

Defective switch or

wiring

Check switch and wire for

continuity.

Defective flushing

pump motor

Return to Aviation

Fabricators or another

Certified Repair Station for

servicing of pump P/N

5250-AS-1

Defective timer

Replace timer (see section

E.2.).

Aviation Fabricators Inc. ICA Document No.: AF-645

805 North Fourth Street Revision (A)

Clinton, MO. 64735 Date: August 10, 2020

Page 12 of 13

Toilet cycles but

little or no flushing

liquid pumps to bowl

Inadequate flushing

fluid in reservoir

Fill reservoir to “Fill to

Here” line.

Broken or loose pump

hose

Replace hose P/N 5000-2-

2DLubricate each end of

the new hose with silicone

grease or petroleum jelly

and install it on the bowl

assembly and to the pump

by pressing straight down

on attachment fittings.

Broken or loose pump

impeller

Return to Aviation

Fabricators or another

Certified Repair Station for

servicing.

NOTE: To determine if the pump is defective, connect a separate power

supply to the pump leads. If the pump does not operate, return to Aviation

Fabricators for servicing. If the pump operates, replace the timer.

2. To replace timer, part number 17-0939-01, unplug the existing timer assembly

from the aircraft, toilet power, and switch and install a new timer in its place.

The timer is velcroed to the back panel inside the toilet cabinet assembly just

outboard of the toilet assembly.

Aviation Fabricators Inc. ICA Document No.: AF-645

805 North Fourth Street Revision (A)

Clinton, MO. 64735 Date: August 10, 2020

Page 13 of 13

10.0 AIRWORTHINESS LIMITATIONS

The information contained herein supplements the basic Maintenance Manuals only in

those areas listed, when the aircraft is modified in accordance with Aviation Fabricators

STC Data List AF-644 revision IR or later approved revision. For limitations and

procedures not contained in this supplement, consult the basic Airplane Maintenance

Manuals.

The Airworthiness Limitations section is FAA approved and specifies maintenance

required under Sec. 43.16 and 91.403 of the Federal Aviation Regulations unless an

alternative program has been FAA approved.

AIRWORTHINESS LIMITATIONS - LOG OF REVISIONS

REV.

EFFECTED

PAGE (s)

DESCRIPTION of REVISION

DATE

(IR)

All

Initial Release

11/13/18

AIRWORTHINESS LIMITATIONS

There are no new Airworthiness Limitations to the aircraft required when the toilet

cabinet assembly is installed.

Table of contents

Other Textron Aviation Aircraft manuals

Textron Aviation

Textron Aviation 680A User manual

Textron Aviation

Textron Aviation Cessna 172R NAV III Skyhawk User manual

Textron Aviation

Textron Aviation Cessna 525B User manual

Textron Aviation

Textron Aviation Cessna 525 User manual

Textron Aviation

Textron Aviation Cessna 172S NAV III Skyhawk SP Quick setup guide

Textron Aviation

Textron Aviation Cessna 525B User manual