TF Model COBRA AH-1S 600 User manual

Required items for finishing this product

1. A comprehensive set of tools

2. CA glue

3. 30 minute epoxy glue

4. Trex 600 type mechanic, belt version

dry fitting of all the parts before assembly.

TF Model AH-1S 600

Thank you for purchasing TF Model's product, please read all

instructions carefully before proceeding with the actual assembly.

Some steps are required to be done first, so please do a complete

Recommended items for use in this product

1. TF Model 600 Slim tail gear box.

Wood Formers Assembly

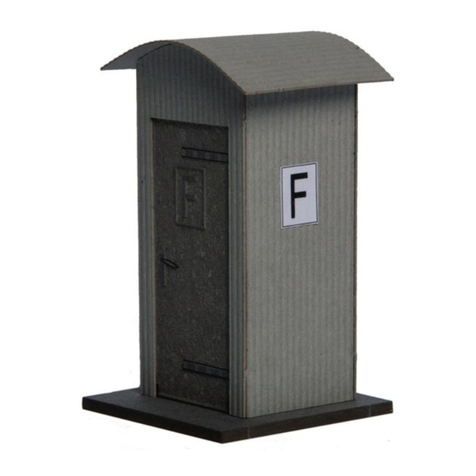

4.Dry fit formers F-4A and F-4B halves into the

fuselage to the premarked line. Make sure the

formers fit flush and square to the

fuselage.The formers should sit behind the

rear landing gear hole. Once the formers are

aligned correctly, tack glue in place with a few

drops of CA glue.Use epoxy and securely glue

the former to the fuselage.

2.First glue the former F5 into the fuselage at

the tail joint location. Use photo for

reference.Once the former is glued in remove

the top section marked out by the cut lines.

1.Locate all the wood formers for the main

fuselage shown in the photo.

3.Glue former F3 to the front of the fuselage

as in the photo.

5.Another view of the formers F-4A and F-4B

6.Slide both landing gear cross memebers

through the fuselage holes.Now centre the

cross memember and tack glue in place with

CA glue.Use the predrilled holes in the cross

member as template and mark the 2 holes

onto the shims, do both the front and back

cross members.Drill 2mm diameter holes

through to the outside of the fuselage.Secure

the cross members with supplied 2 mm dia

screws and nuts.Insert the screw from the

bottom and the nuts on the inside for a flush

finish.

7.Once the screws are installed, epoxy the

landing gear cross member to the fuselage.

Do the front and rear corss members.Photo

shows the rear cross member.

8.Photo shows the front cross member.

9.Landing gear cross member screws. Screw

from the outside in for a flush finish on the

exterior.

10.Insert the landing gear plastic "T"s onto the

cross members' ends and insert the landing

skids through them. Once the landing gear is

squared, tack glue the skids and cross

members to the plastic "T". Drill 1 mm holes at

the location shown in the photo and secure

the landing gear skids with screws.

Rudder Sevo Mount Assembly

11.Locate the wood rudder mount and glue

them together as in the photo.

12.Glue the servo mount into the position

shown in the photo.Do this before joining the

fuselage halves for ease of assembly.You can

install the rudder servo at this time as well.

THE FOLLOWING STEPS FOR TREX 600 VERSION ONLY

13.The rudder servo mounting location viewed

from the inside.

14.Locate the fuselage wing area doubler in

the photo.

15.Next locate the wing stub outer

reinforcement ring and glue it to the outside

fuselage. The ring should align with the stub

wing outline. Once the glue has dried, use a

Dremel to open up the wing stub hole until

flush with the inside of the wood wing stub

reinforcement ring.The 4 circles are magnets

holding the former in place for gluing only.

16.Now glue the wing area doubler to the

inside of the main fuselage. Note the location

of the reinforcement panel in the photo. The

wing hole in the fuselage should sit inside the

doubler hole on all sides.If the doubler

interferes with the rear landing gear cross

member,trim the doubler's corner until it

fits.Do both sides of the fuselage insides.

17.Fit the mechanics inside the fuselage, take

off the rotor head and fit the top cover onto

the fuselage temporarily. Move the mechanics

until the main shaft is centered in the hole.

Mark the location of the 4 mounting holes and

drill the 4 3mm dia. holes on the fuselsage

bottom.

18.Use the holes for reference and glue the

wood mechanics shims onto the fuselage

bottom, covering the mounting holes. Use 3

shims for both the front and rear mounting

points.After the glue has set drill through the

wood shims from the outside bottom of the

fuselage, using the already drilled holes as

template.Use of 3 shims will put the main gear

centered in the wing hole on the sides of the

fuselage. Adjust height further by using

washers if needed.Spin the main gear to make

sure that it does not rub against the sides of

the fuselage.Once all is correct install the

mechanic into the fuselage using 4 bolts and

lock nuts.

19.Photo shows the completed front and back

mechanic shims.

20.Now join the front and rear fuselage halves

using epoxy glue. Align the joint line

accurately before gluing.

Wire Mesh Assembly

21.Cut the supplied wire mesh slightly larger

than the openings circled in the photo and

glue the mesh from the inside with epoxy.

Also glue in the exhaust cone into the rear

opening at this time.

Once all the shims and mechanic mounting holes are done, install the mechanic into the

fuselage.Due to the scale proportion of the Cobra, the fuselage is slim to scale and when

installing the mechanic you need to carefully spread the sides of the fuselage in order to

allow the mechanic to slip into the fuselage.

Once the mechanics is fitted inside, secure the mechanic using bolts screwed in

from the bottom and secured with nuts on the inside.

Installing the Mechanic

Elbow Gear Box Assembly

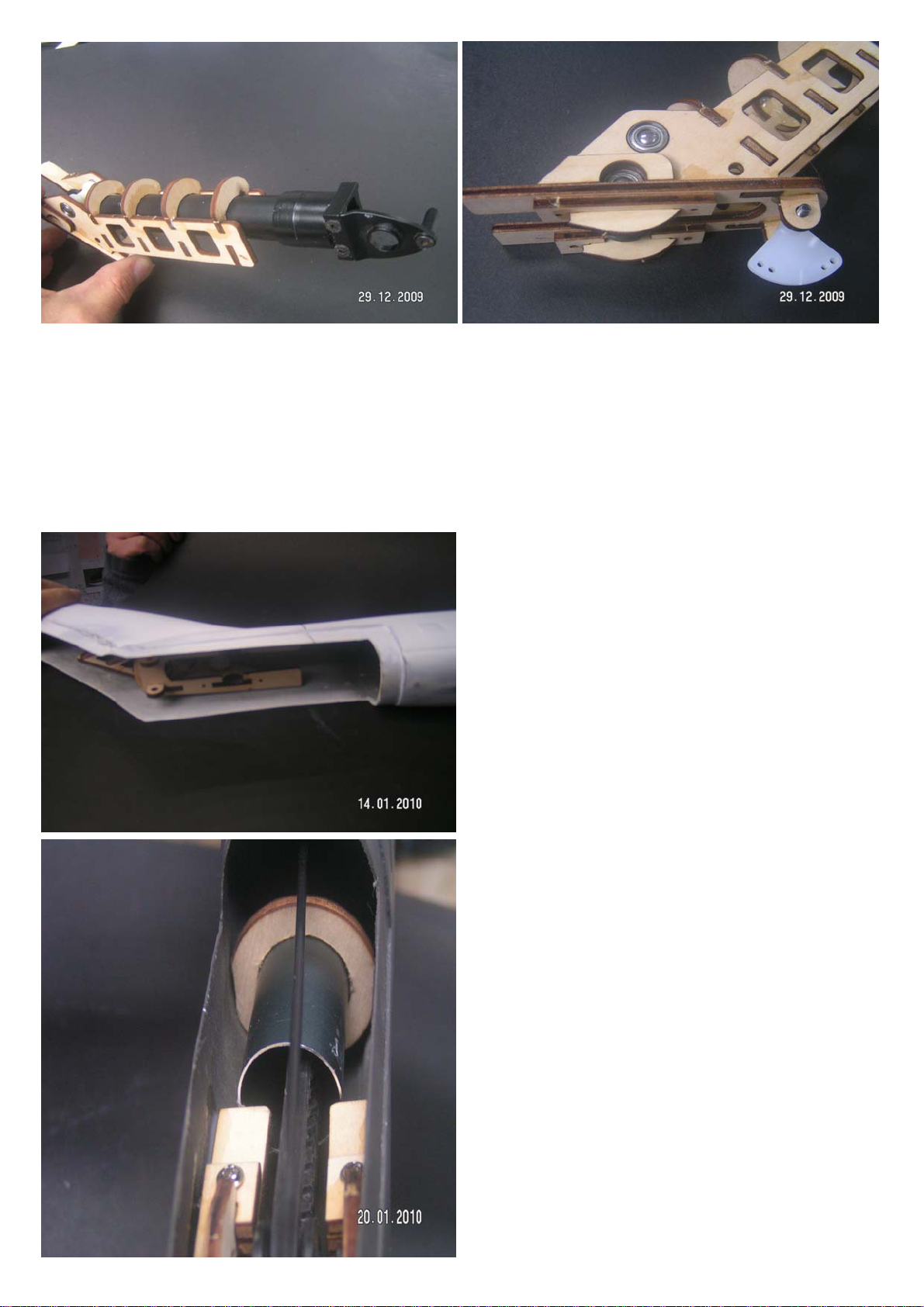

22.Locate the parts for the elbow bear box in

the photos.

23.Glue the pulley wheel doubler onto the

outside of the elbow gearbox side frames.

Align the circular cut out as in the photo. Do

both sides.Photo shows the outside face of

the elbow gear box side frame.

24.Install the bearing for the tension wheel

and insert the tension wheel into the bearing.

Also glue in the rear wood cross members at

this time.Use epoxy glue for this.

25.Glue the other side frame onto the cross

members and glue on the elbow gear box

base. Then glue the rudder bell crank support

onto the base. Use photo for reference while

assembling.Use epoxy glue for this.Assemble

the pulley wheel and its bearings and

assemble the bearing brackets. Again use

photo as reference. Dry fit the pulley wheel

assembly into the bearing slot,use supplied

plastic spacer to shim the pulley wheel and

the bearings for a snug fit in the bearing slot.

26.Install the rudder bell crank to the bell

crank support at the base board. Make sure

that the bell crank can turn smoothly and

freely. Adjust the bell crank smoothness by

the tightness of the screw.

27.Insert the pully wheel assembly into the

bearing slot and screw in the bearing brackets

to hold the pulley wheel assembly in place

temporarily.

31.After cutting the tail tube to length and

lining up the tail tube with the elow gear box

base board, slip the wood tail tube fixing

former onto the tail tube and slide it up the tail

tube. Trim the wood fixing if necessary for

centering the tail tube. The tail tube does not

have to touch the base board.After the

location of the wood tail tube is correct, glue

the former to the fuselage ONLY. DO NOT

GLUE THE TAIL TUBE TO THE FORMER AT

ANY TIME.Now slide the vertical tail tube into

the elbow gear box assembly, do not glue the

tube yet, and glue the elbow gear box aood

frame to the fuselage using epoxy.

28.Temporarily insert the supplied tail tube

against the rear cross member and use it as a

jig for gluing the front cross memebers. Tacky

glue the front cross members in place,

remove the tail tube, then glue with epoxy.

29.Photo shows the completed assembly

before inserting into the fuselage tail.

Elbow Gear Box Insertion.

30.Slide the elbow gear box assembly into the

tail fin for dry fitting. Install the mechancis

with tail tube. Note the length of the tail tube

to cut off to allow fitting of the elbow gear

box.Try to line up the elbow gear box base

with the tail tube centre line. Please pay

attention to the following photo for better

understanding of the relationship of the elbow

gear box and the tail tube.

32.Remove the pulley wheel bracket and

remove the pulley from the elbow gear box

assembly base board. Pull the timing belt

through, note the direction of the belt. Install

the pulley wheel through the belt and back

into the base board,and reinstall the pulley

wheel brackets and screw them in place.Pull

the belt through the vertical tail tube. Again

note the orientation of the belt.

33.Disassemble the tail gear box and slip the

locking collar part of the tail gear box onto the

vertical tail tube. Pull the belt through.Install

one side of the tail gear box side frame and

pull tight on the belt with your finger.

Estimate the approximate location of the tail

rotor shaft and mark the corresponding

location on the tail for removal of parts of the

tail area to fit the tail rotor and rudder pitch

bell crank. Patiently remove material for a

nice snug fit, checking the fit frequently and

removing material little at a time.Be sure to

allow for tension adjustment of the tail gear

box after the first flight.Please refer to the

following group of photos for reference.

34.After completing the above step, you can

now glue the tail tiube to the elbow gear box

wood frame using epoxy.

Now install 2 ball links to the bell crank in the photo and connect the push rod

forwards to the rudder servo and backwards, up along the vertical tail tube to

the rudder pitch bell crank at the tail gear box. Refer to the following group of

photos.

37.After checking that the bell crank and

rudder is operating smoothly and correctly, fit

the tail cover on and drill 1 mm diameter

holes for the fixing screws on both sides.

35.We recommend that you glue a push rod

support at the location indicated.

36.Connect the push rod to the rudder servo.

Before connecting please power up the

receiver and transmitter and centre the rudder

servo.

38.After installing the mechanics inside the

fuselage, dry fit formers F2 in front of the front

landing gear making sure that it does not

interfere with the mechanic and anchillary

equipments. Once the location is determined,

glue formers F2 (both left and right sides) into

place.

Now locate the tail rotor cover and trim it to fit the tail rotor location as in the

following group of photos. Once the fitting is correct, glue into place.

Front Cross Member Former Assembly

39.Locate cross brace former F7 and the

fuselage stays anchors. Use bolts and nuts to

attach the cross brace to formers F2.

40.Carefully study the installation of the cross

brace and the mounting of the fuselage stays

in the photo, using it as reference.

41.Now proceed to gluing the battery tray to

the floor on the front part of the fuselage in

front of formers F2.

Upper Front Cover Assembly

Fit the upper front cover onto the main fuselage and use clamps to achieve a

flush fit on all sides. Once flush fit is achieved mark and drill 4 fixing holes

on both inside lips. Glue 4 pegs on the upper front cover and fit in on to the

upper main fuselage. Trim the 4 holes on the main fuselage section to again

achieve a flush fit. After a flush fit of the 2 parts are achieved use screws to fix

the 2 parts together.Refer to the following group of photos.

42.4 fixing pegs.

43.4 corresponding holes for the fixing pegs

on the main fuselage section.

Canopy and Cockpit Assembly

44.Use screws to fix the 2 parts.

Glue the supplied canopy lock on the rear inside of the canopy frame.

Dry fit the clear windows onto the canopy frame and glue them

on the inside using silicone glue or canopy glue.

Tack glue the cockpit support frame to the inside of the canopy frame first,

fit the canopy frame onto the fuselage and check for a flush fit. If the cockpit

frame is too low in the canopy framethe canopy frame will not sit flush with

the fuselage.Adjust the height of the cockpit support frame to achieve a

flush fit. Glue the cockpit support frame to the canopy frame

glue in the fixing tongue as well.

canopy lock.Now glue in the front canopy frame wood support and also

Trim the cockpit little at a time for a flush fit. Once a flush fit is achieved,

cockpit and slide it in between the canopy frame and cockpit support.

With the cockpit support frame glued in, trim the black vacuum formed

with epoxy once the correct height is set.

glue the cockpit to the support frame.Remember to trim the cockpit for the

45.Glue in canopy lock. Remember to centre

it.

46.Cockpit support frame.

47.View of cockpit support frame side.

48.Cockpit support frame and cockpit fitting.

49.Cockpit cut out for canopy lock.

50.Front canopy frame wood former and

fixingtongue.

51.You might need to glue a wood shim

indicated in the photo for the canopy lock to

work properly.

52.Canopy lock once assembled correctly.

53.Completed canopy.

Table of contents

Other TF Model Toy manuals