TF Model Apache 600 User manual

Table of contents

Other TF Model Toy manuals

Popular Toy manuals by other brands

Kyosho

Kyosho Calmato Alpha40 Sports instruction manual

Fisher-Price

Fisher-Price CAR-NIVORES M1804 user manual

Faller

Faller 232233 manual

Eduard

Eduard Fw 200 Condor exterior Assembly instructions

LEGO

LEGO 42009 Technic Building instructions

Hasbro

Hasbro Buzz Lightyears Electronic Spaceship 03173 instruction manual

Spirit Halloween

Spirit Halloween Limb Ripper Easy-to-follow Instructions

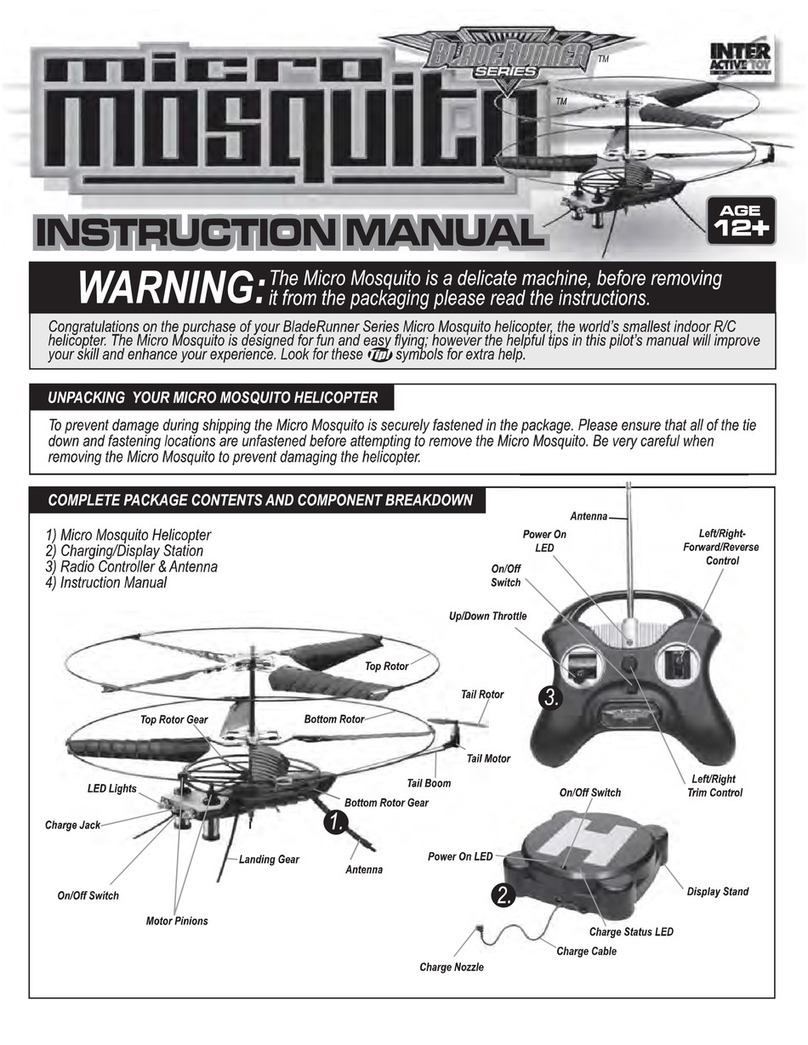

Micro mosquito

Micro mosquito BladeRunner Series instruction manual

Mega Construx

Mega Construx FXW78 quick start guide

BCP

BCP SKY2219 instruction manual

THE WORLD MODELS

THE WORLD MODELS P-47D THUNDERBOLT instruction manual

Viessmann

Viessmann 4502 Operation manual

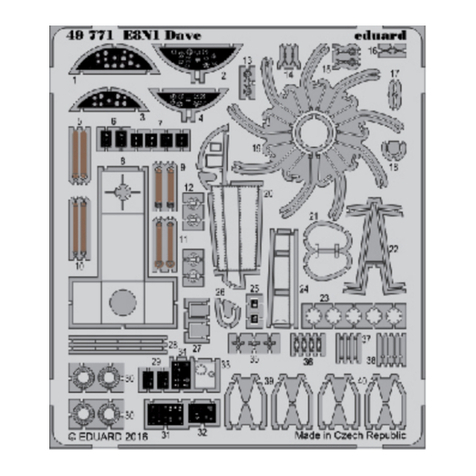

Eduard

Eduard E8N1 Dave quick start guide

KANGKE INDUSTRIAL

KANGKE INDUSTRIAL FUN-50 Assembly manual

Hasbro

Hasbro Vamp 65269/65266 instructions

Multiplex

Multiplex ROXXY Roxxoo 35WP operating instructions

Faller

Faller 180548 quick start guide

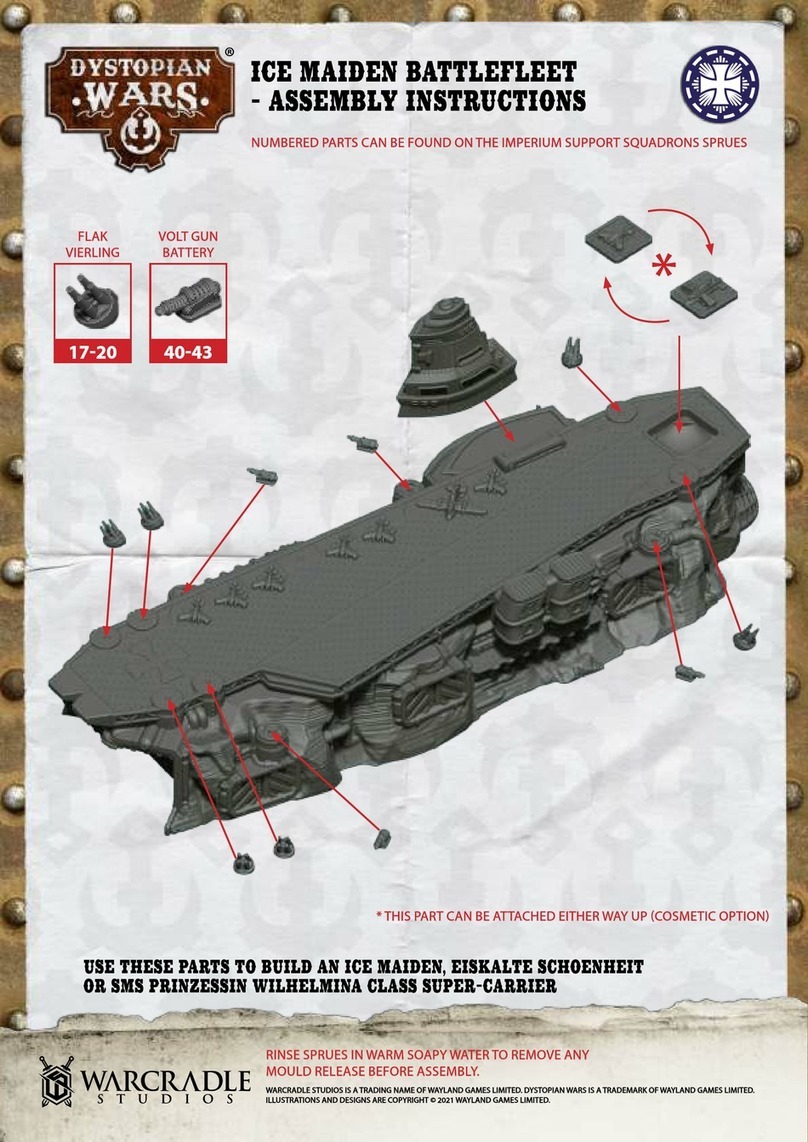

WARCRADLE STUDIOS

WARCRADLE STUDIOS DYSTOPIAN WARS ICE MAIDEN BATTLEFLEET Assembly instructions