©Copyright Task Force Tips LLC 2023 4 LIY-220 August 21, 2023 Rev00

1.0 MEANING OF SAFETY SIGNAL WORDS

A safety related message is identified by a safety alert symbol and a signal word to indicate the level of risk involved with a particular

hazard. Per ANSI Z535.6, the definitions of the four signal words are as follows:

2.0 SAFETY

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION CAUTION indicates a potentially hazardous situation which, if not avoided, could result in minor

or moderate injury.

NOTICE is used to address practices not related to physical injury.

An inadequate supply of pressure and/or flow will cause an ineffective stream and can result

in injury or death. Choose operating conditions to deliver adequate fire suppression. See flow

graphs.

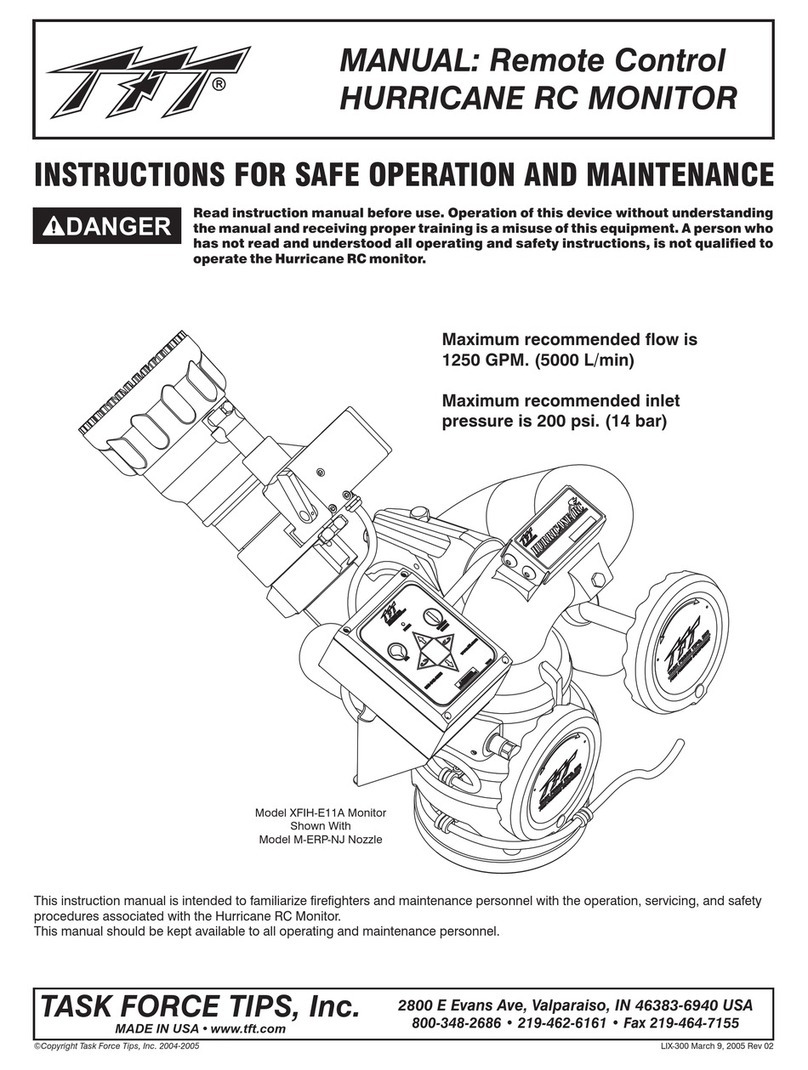

Injury or damage can occur from an inadequately supported monitor. The mounting must be

capable of supporting the nozzle reaction force which can be as high as 1500 lbs.

The stream exiting a nozzle is very powerful and capable of causing injury and property damage.

Make sure the nozzle is securely attached and pointing in a safe direction before water is turned on.

Do not direct water stream to cause injury or damage to persons or property.

Equipment may be damaged if frozen while containing significant amounts of water. Such damage

may be difficult to detect visually. Subsequent pressurization can lead to injury or death. Any time

the equipment is subject to possible damage due to freezing, it must be tested and approved for

use by qualified personnel before being considered safe for use.

On many vehicle installations, the monitor is the highest point on the apparatus. Damage or injury

could occur if there is not sufficient clearance to safely pass under doors or overhead obstructions.

Always check stowed position of the monitor before moving.

CAUTION The electric drives are current limited but may still produce enough force to cause injury. To avoid

injury from moving equipment:

• Be aware that equipment may be remotely operated

• Keep hands and fingers away from pinch points

• Never operate the manual override while electric controls are in operation