1. Safety Caution .......................................................................................................2

2. General Troubleshooting ......................................................................................3

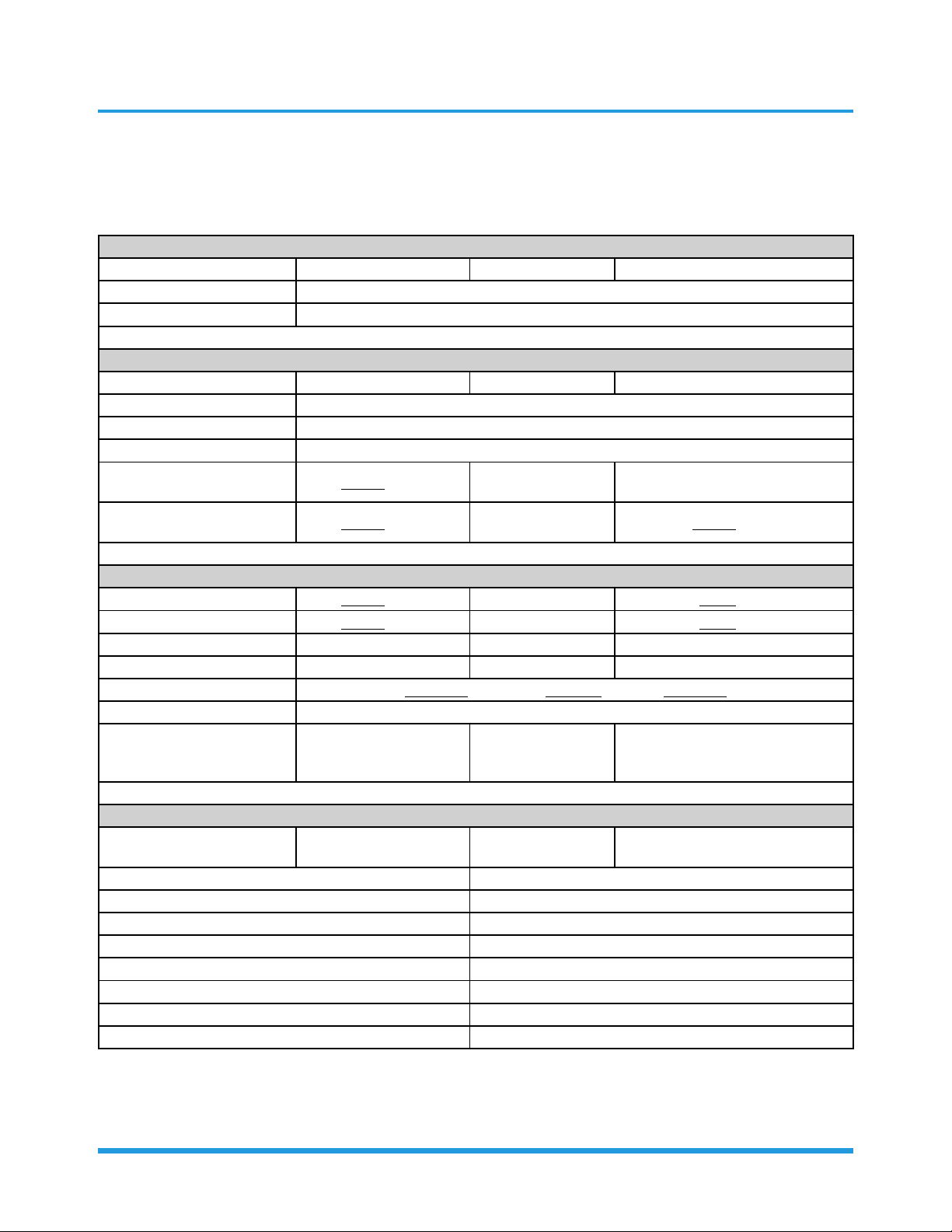

3. Complain Record Form ..........................................................................................4

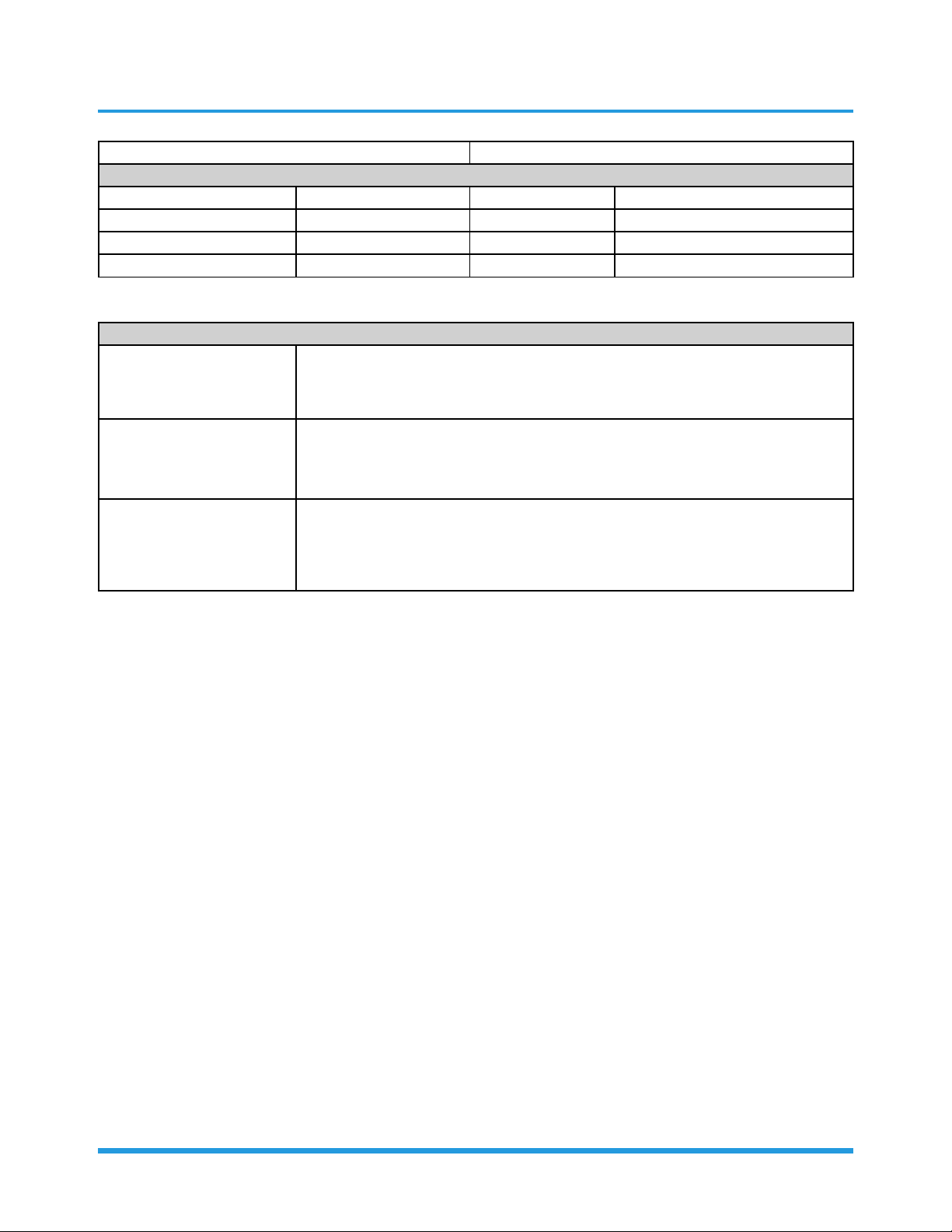

4. Information Inquiry ...............................................................................................6

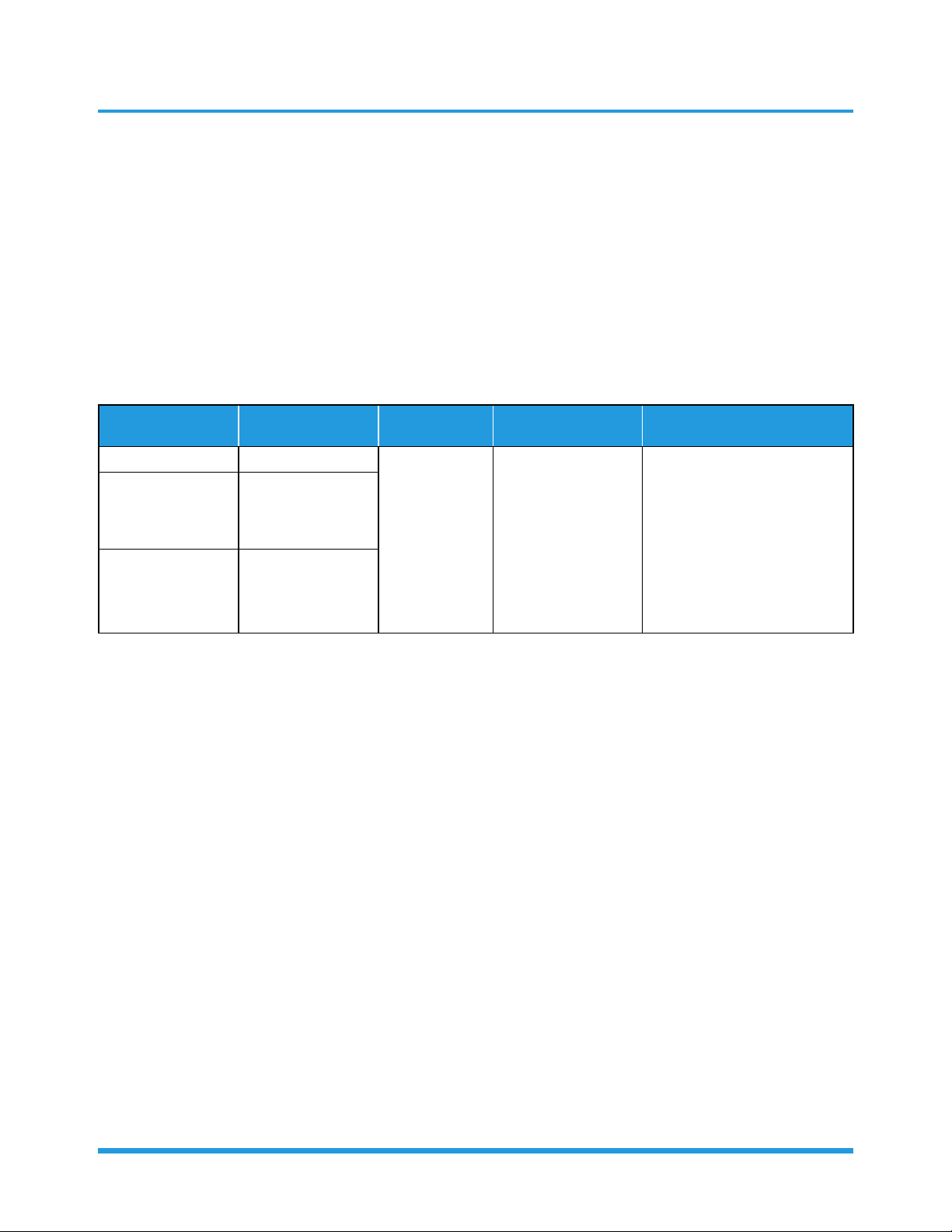

5. Error Diagnosis and Troubleshooting Without Error Code.................................7

5.1 Remote maintenance.....................................................................................7

5.2 Field maintenance .........................................................................................8

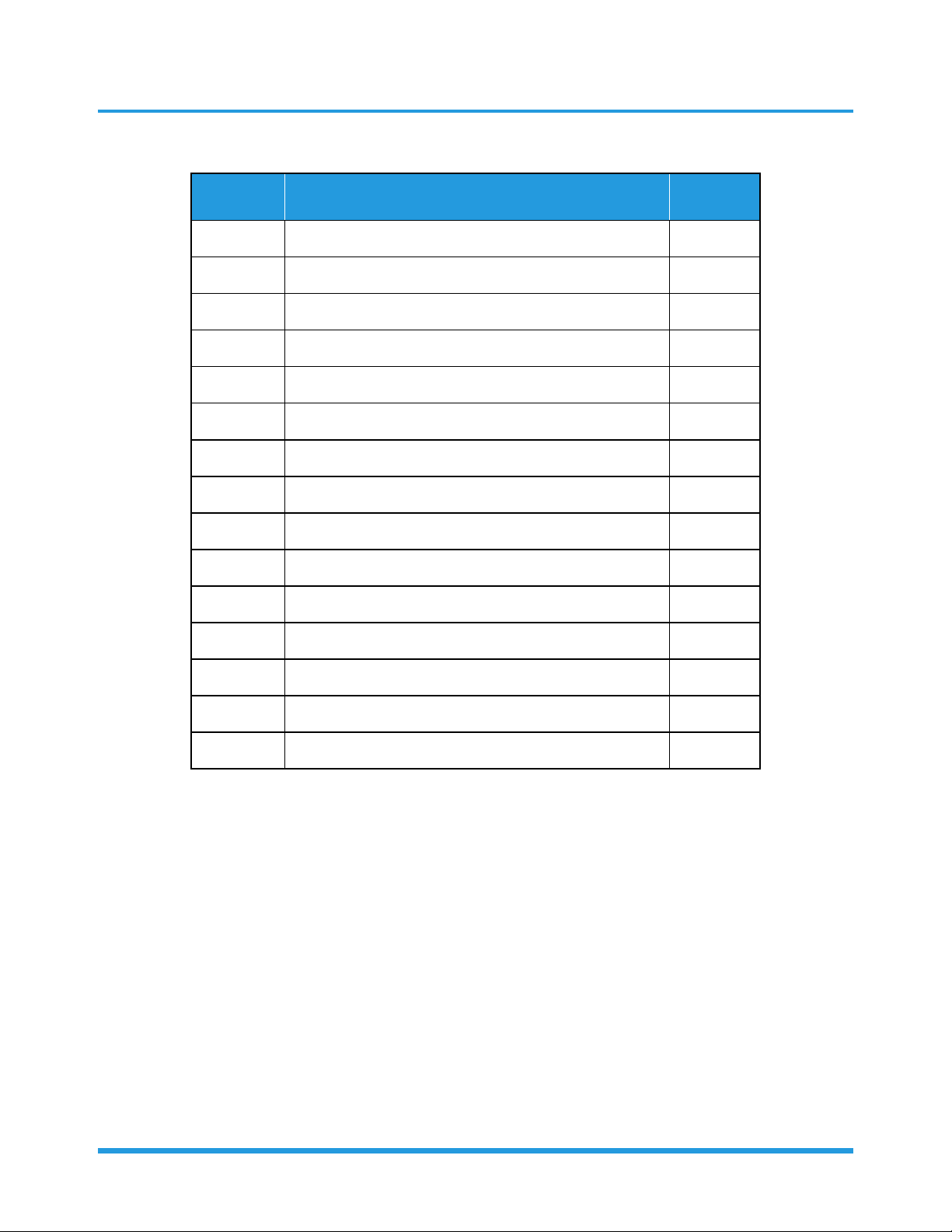

6. Quick Maintenance by Error Code........................................................................9

7. Troubleshooting by Error Code...........................................................................14

7.1 EH 00 (EEPROM parameter error diagnosis and solution) .............................14

7.2 EL 01 (Indoor and outdoor unit communication diagnosis and solution).......15

7.3 EH 02 (Zero-crossing detection error diagnosis and solution)........................17

7.4 EH 03/F5/EC 07 (Fan speed is operating outside of the normal range diagnosis

and solution) ...............................................................................................18

7.5 EH 60/EH 61/EC 52 (Open circuit or short circuit of temperature sensor diagnosis

and solution) ...............................................................................................21

7.6 EH 0b (Indoor PCB/display board communication error diagnosis and solution)22

7.7 EL 0C (Refrigerant leakage detection diagnosis and solution) .......................23

7.8 PC 03 (High pressure protection) .................................................................24

8. Check Procedures.................................................................................................25

Troubleshooting