Thaijetboard Jetboard 2011 User manual

2011

Jetboard

Jetkayak

1

USER'S MANUAL

2

Your new powered surf board or kayak rides very low on the water compared to other vessels.

Steer clear of other boats, under speed or idle.

when operating your powerboard never assume another boater has seen you

Keep this USER’S MANUAL in a waterproof bag with the Powerboard at all times

even if it is transferred to a new owner.

• Your powered surfboard or kayak is unlike any other powered watercraft you may have riden before.

E-wave recommands running your new watercraft at slow speed and avoid aggressive maneuver until

you are completely familiar with the operation and steering your watercraft

WARNING

• Read this safety notice completely before enjoying your powerboard

• Does not have a reverse gear or breaking device

• Always approach land, docks, swimmers or hazards slowly and with caution to avoid collision or injury

to the rider

• Failure to do so can result in SEVERE INJURY OR DEATH..

WARNING

• Always check 360 degrees (especially behind you) for other boats before executing a turn.

WARNING

WARNING

• This vessel uses and stores flammable gasoline on board

• Always use caution against fire

• Do not smoke on or near the vessel

• Open engine cover while refueling to avoid build up of gas fumes

• Check fuel cap is securly fastened

WARNING

• Engine Break-in to prevent excessive wear and damage to your engine

• Operate your new powerboard at lower RPM's for the first 4~6hours to break in the engine

• However brief acceleration and speed variations contribute to a good break-in

• The scheduled oil change during the breaking period is also required

• Check all fluid levels and filters after each ride during the break-in period

!

!

!

!

!

3

Table of contents

Section 1 Safety information

Section 2 Powerboard information

Section 4 Maintenance and care

Section 5 Trouble shooting

Section 3 Operation

4

Section 1

Safety information

The owner of the watercraft is responsible for the watercraft’s safe operation.

Jetboard and jetKayak Models :

Recommended Maximum Load:

91 kg (200 lb)

Load is the total weight of operator and cargo.

JetKayak GT Model :

Recommended Maximum Load:

114 kg (250 lb)

Load is the total weight of operator and cargo.

FUELING

TO WEAR

HELMET

5

The owner of the watercraft is responsible for the watercraft’s safe operation. The owner also has

the responsibility to require that all operators read and understand this User’s Manual and the

on-product warning/caution labels before operating the watercraft. Failure to follow this safety

information and safe boating rules could result in injury, including the possibility of death to you,

the people you lend your watercraft to, or other water users.

The safe use and operation of this watercraft is dependent upon the use of proper riding techniques,

as well as upon the common sense, good judgment, and expertise of the operator. The performance

and function of this watercraft may be significantly different and exceed that of other craft you may

have operated. Make sure to become completely familiar with the controls and operation of the

watercraft before embarking on your first trip. If you have not had the opportunity to do so, practice

driving solo in a suitable traffic free area and feel the response of each control. Be fully familiar with

all controls before accelerating above idle speed.

BOAT CAPACITY AND OPERATION LIMITATION

E-WAVE recommends a minimum operator age of 16 years old. A boating safety course is

recommended and may be required in your province or state.

Boarding in deep water can be strenuous. Practice in chest-deep water before operating or embarking

your watercraft in deep water.

explained in the Operator’s Guide. Make sure engine is off before rolling over the watercraft.

WARNING

When fueling, follow the safe boating fueling instructions explicitly, as provided in your User’s Manual

and those given to you at the marina. Always verify fuel level before use and during the ride.

•Always stop the engine before refueling.

•Fuel is flammable and explosive under certain conditions.

•Always work in a well ventilated area. Do not smoke or allow open flames or sparks in the vicinity.

•Fuel tank may be pressurized, turn cap slowly when opening.

•When fueling, keep watercraft level.

•Do not overfill or top off the fuel tank and leave watercraft in the sun. As temperature increases, fuel

expands and might overflow.

• Always wipe off any fuel spillage from the watercraft. Periodically verify fuel system.

Always stop the engine before fueling and never allow anyone to remain on the watercraft while fueling.

Always remember that fuel is flammable and explosive under certain conditions.

Do not smoke or allow open flames or sparks in the vicinity.

Some Important Considerations Helmets are designed to offer some degree of protection in case of

impact to the head.

In most motorized sports, the benefits of wearing a helmet clearly outweigh the drawbacks. However, in

the case of motorized watersports such as riding Powerboard, this is not necessarily true as there are

some particular risks associated with the water.

The operator must wear a Coast Guard approved Personal Flotation Device (PFD) that is suitable for

Powerboard use.

!

GEARS AND EQUIPMENTS

BEFORE RIDING

Check local and federal boating laws applicable to the waterways where you intend to use your watercraft.

A Powerboard is not designed to operate in rough water or inclement weather.

SAFE RIDING

keep a safe distance from all other craft, people and objects.

Always keep a constant lookout for other water users, other boats or objects, especially when turning.

Unless in an emergency, do not negotiate sharp, high speed turns.

this Powerboard has no brake.

Ride within your limits and level of riding ability.

Do not engage in stunts or jumps as they could lead to serious injuries or even death.

In shallow water, proceed with caution and at very low speeds. Grounding or abrupt stops may result in injury.

Powerboards are not designed for night-time operation.

AFTER RIDING

6

Stopping distance will vary depending on initial speed, load, wind, and water conditions. Practice

stopping and docking in a safe,

•jetSurf is not designed for surfing like a regular surf board.

•Do not jump waves or wakes.

•Usage on rough water may result in SEVERE INJURY OR DEATH.

WARNING

RISKS- On the other hand, in some situations when falling off the watercraft, helmets have a tendency

to catch the water, like a “bucket”, and put severe stresses on the neck or spine. This could result in

choking, severe or permanent neck or spine injury, or death. Helmets may also interfere with peripheral

vision and hearing, or increase fatigue, which could contribute to increase the risk of a collision. You

must decide whether to wear a helmet or not based on your particular situation, the particular

environment you will be riding in, as well as other factors such as personal experience. If you decide to

wear a helmet, you must then decide what type is the most appropriate for the circumstances. Look for

helmets that meet DOT or Snell standards, and if possible, choose one designed for motorized

watersports.

Always carry the regulatory safety items and have them conveniently on board available for use.

Check the local regulations or consult your authorized Aquanami dealer. Such required safety items

usually include, without limitation, a sound signaling device such as a whistle, a watertight flashlight or

approved flares, a buoyant heaving line and rope. A cellular telephone in a waterproof bag or container

has also been found to be beneficial to boaters when in distress or just for contacting someone on

shore.

Keep the engine shut-off cord (safety lanyard) attached to the operator’s wrist or PFD at all times so

that engine stops

When riding a jetKayak model, always keep in mind that as the throttle lever is released to idle position,

less directional control is available, and as the engine is off, directional control is lost.

Do not start or operate the watercraft if anyone is behind or nearby the jet.

Water and/or debris exiting jet thrust nozzle can cause severe injury.

Keep away from intake grate while engine is on. Items such as long hair, loose clothing,

or PFD straps can become entangled in moving parts resulting in severe injury or drowning.

To prevent accidental starting, always detach the safety lanyard from the watercraft during removal of

any weeds

After riding, remove the safety lanyard from Powerboard to avoid unauthorized use by children or others.

If operator falls off the watercraft and safety lanyard is not pulled off from its post, the watercraft will not

stop.

Leave the safety lanyard on its post will drain battery dead slowly.

Read and understand all safety instructions on your Powerboard, and all other safety documents before

operating

always perform “Daily Pre-Operation Checks” as specified in your User’s Manual before operating your

watercraft.

BENEFITS-

A helmet helps to reduce the risk of injury in case of a head impact against a hard surface such as

Do not wake or wave jump, You may misjudge the ability of the watercraft or your own riding skills and

strike a boat or person.

It should be remembered that sun, wind, alcohol, drugs, fatigue and illness, may impair your judgment

and reaction time.

!

7

Section 2

Product information

JETBOARD

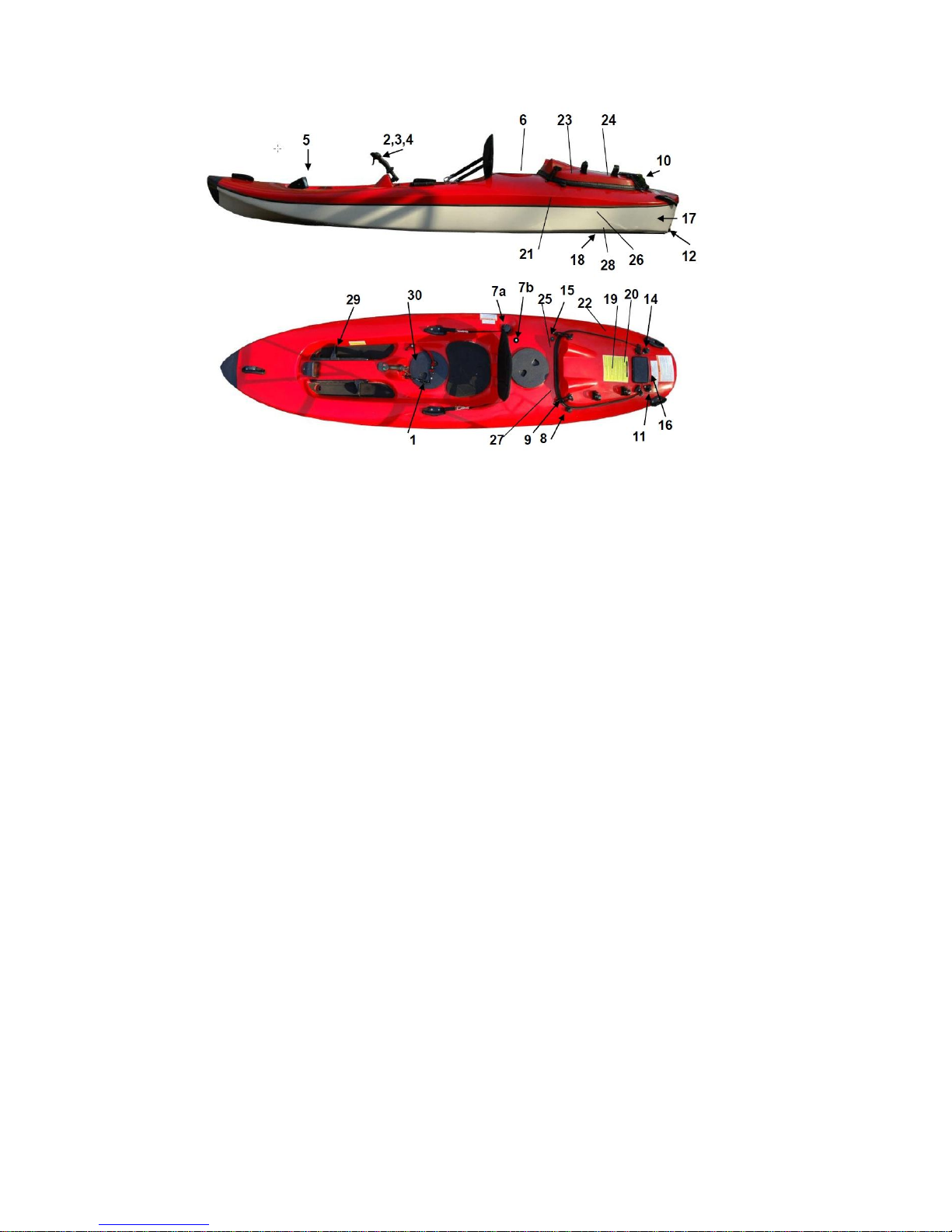

1. Safety Lanyard (engine cut-off cord) 15. Bilge Pump Switch

2. Throttle Lever 16. Exhaust By-Pass

3. Engine Start/Stop Button 17. Jet Pump Nozzle

4. Control Handle 18.Jet Pump Water Intake

5. Armpole 18a. Adjustable Fin box

6. Fire extinguisher area 18b. Removable Fin

7a. Fuel Tank Cap 19. Control Box

7b. Fuel primer bulb 20. Battery

8. Fuel Tank Vent 21. Oil Fill Cap

9. Engine Compartment Cover Latch 22. Bilge Pump and Water Sensor

10. Air Intake Opening 23. Coolant Fill/Pressure Valve Cap

11. Exhaust Flushing Connector 24. Coolant Expansion Tank Cap

12. Bilge Drain Plugs 25. Engine Breathing Oil Retainer

26. Carburetor Drain Screw

14. Bilge Pump Water Outlet 27. Fuel Water Separator

28. Automatic Vacuum Siphon Pump

8

13. Oil Drain Plug (Bottom Of Hull Beneath Engine)

JETKAYAK

1. Safety Lanyard (engine cut-off cord) 16. Exhaust By-Pass

2. Throttle Lever 17. Jet Pump Nozzle & Steering Nozzle

3. Engine Start/Stop Button 18. Jet Pump Water Intake

4. Steering Handle 19. Control Box

5. Information meter 20. Battery

6. Fire extinguish area 21. Oil Fill Cap

7a. Fuel Tank Cap 22. Bilge Pump and Water Sensor

7b. Fuel Primer Bulb 23. Coolant Fill/Pressure Valve Cap

8. Fuel Tank Vent 24. Coolant Expansion Tank Cap

9. Engine Compartment Cover Latch 25. Engine Breathing Oil Retainer

10. Air Intake Opening 26. Carburetor Drain Screw

11. Exhaust Flushing Connector 27. Fuel Water Separator

12. Bilge Drain Plugs 28. Automatic Vacuum Siphon Pump

29. Foot Brace

14. Bilge Pump Water Outlet 30. Dry Compartment

15. Bilge Pump Switch

9

13. Oil Drain Plug (Bottom of Hull Beneath Engine)

POWERBOARD AND MAIN COMPONENTS

1). Safety Lanyard (Engine Shut-off Cord)

Leaving the safety lanyard on its post when engine is not running will slowly discharge the battery.

2). Throttle Lever

When the throttle lever is squeezed, the watercraft accelerates.

3). Engine Start and Stop Button

To start engine, depress and hold the start button. Release immediately after engine is started.

4). Control Handle for jetSurf and Steering Handle for jetKayak

5. Armpole for jetSurf and Information Meter for jetKayak

Armpole links control handle to board, and provides support to operator

When safety Lanyard is plugged in and the start button is depressed once,

the information meter reads engine RPM, engine temperature, fuel level, and battery life.

6). Fire Extinguisher Area

Use Fire Extinguisher Area to store an approved fire extinguisher (sold separately).

7a). Fuel Tank Cap

Unscrew the cap counterclockwise. After fueling, reinstall cap and fully tighten.

7b). Fuel Primer Bulb

8). Fuel Tank Vent

Vent air out from fuel tank when pressure builds up in the tank as temperature increases.

9). Engine Compartment Cover Latch

Close and secure the engine compartment cover to keep engine compartment dry.

Ensure the cover is well position, and water tight.

10

Attach the engine Safety Lanyard (Engine Shut-off Cord) to operator’s life vest or wrist so that the

engine stops if the operator falls off.

To stop engine, fully release throttle lever then depress the stop button. Remember to disconnect safety

lanyard from its post.

When operating the watercraft first time or after long period of non-usage, press the fuel primer bulb 4

times to pump fuel to carburetor.

•Components inside engine compartment may be hot.

•When starting or operating the engine, do not touch any electrical part.

•Never leave any object, rag, tool, etc., in the engine compartment or in the bilge.

WARNING

•The fuel level indicator may provide false reading if the craft is not leveled.

•Always remove safety Lanyard when the engine is not running. Leave safety lanyard on its post will drain

battery dead when engine is not running.

WARNING

This is a one way path only.

It lets air out, no air/water gets in. The fuel tank breathing in check valve is inside the engine

When fully released, engine automatically slows down to idle speed and watercraft is gradually stopped

by water drag.

Operator grasps the control handle to keep balance and operates safety lanyard, throttle lever, start and

stop buttons.

Always disconnect safety lanyard when watercraft is not in operation in order to prevent accidental

engine starting or to avoid unauthorized use by children or others or theft.

The steering handle controls the direction of the watercraft.

Turning the steering handle to the right steers the watercraft to the right and inversely.

•Check steering handle and corresponding steering nozzle operation before starting.

WARNING

!

!

!

10). Air Intake

Opening

Allows air into the bilge for ventilation purposes and engine supply.

The snorkel valve inside the intake opening will be closed when the craft submerges in water or the craft is capsized

11). Exhaust Flushing Connector

A convenient

connector is

Refer to POST-OPERATION CARE section for proper use.

Ensure to close the connector with the cap after flushing. Otherwise the cooling water from jet will flow out here,

and the exhaust system will not be cooled, which will damage the exhaust system.

12). Bilge Drain Plugs

13). Oil Drain Plug

Oil drain plug is located at the bottom of hull beneath engine.

14). Bilge Pump Water Outlet

The outlet exits the water in bilge by the electric bilge pump inside the engine compartment.

15). Bilge Pump Switch

16). Exhaust By-Pass

Small exit of engine exhaust for easier engine start and smooth idle speed.

17). Jet Pump Nozzle And Steering Nozzle

18). Jet Pump Water Intake And Intake Grate

19). Control Box

Control Box. It holds CDI and all other electronic components.

20). Battery

The battery is located in the engine compartment. Ensure to connect the battery with correct “+” and “-” terminals.

21). Engine Oil Filling Cap And Oil Dipstick

Located in engine compartment.

It allows adding oil in the engine when required. Dipstick indicates the engine oil level. Refer to LIQUIDS for more details.

22). Bilge Pump and Water Level Sensor

23). Coolant Fill/Pressure Cap

CAUTION:

Slowly add coolant until it is full. Adding coolant after the first time use.

24). Expansion Tank Cap

Located in engine compartment. Refer to LIQUIDS for more details.

11

However it is not water proof. If the air intake opening is kept under water, water may get inside the bilge

under certain circumstances.

Always take the watercraft out of the water prior to open drain plugs.

Make sure the drain plugs are properly secured prior to launching the watercraft in the water.

WARNING

Should water be found in the bilge, it can be easily drained by opening the drain plugs when engine is

off and watercraft is out of the water.

Make sure the drain plug is properly secured after oil change and the access window is properly sealed

with “O” ring and properly secured. No water leak!

It is a push button switch to turn on the electric bilge pump manually located inside engine

compartment, to evacuate water from the bilge.

Water exits from the jet pump nozzle. jetKayak models are equipped with a steering nozzle. Steering

nozzle turns left and right by operating steering handle.

The water is drawn in by the impeller through this opening. The water intake grate minimizes the entry of

foreign objects into the propulsion system.

Located in engine compartment. Bilge pump draws water out when water level sensor detects water or

when the bilge pump switch is pressed.

Located in engine compartment. It regulates engine coolant pressure and provides access to add

coolant. Refer to LIQUIDS for more details.

WARNING

!

!

25). Engine Breathing Oil Retainer

Located in engine compartment. Retain oil mist and oil from engine breathing path.

Check the bottle periodically and clean any oil residue to keep engine breathing freely and engine compartment clean.

26). Carburetor Drain Screw

27). Fuel Water Separator

28). Automatic Vacuum Siphon Pump

Located in engine compartment. Evacuate water in bilge by the low pressure generated in jet pump.

29). Foot Brace

Provide foot support.

30). Dry Storage Compartment

Convenient storage space.

LIQUIDS

Engine Oil

This watercraft is equipped with a 4-stroke engine that requires 4-stroke motor oil for internal engine lubrication.

Oil Level

Check oil level frequently and refill if necessary. Do not overfill. it would make the engine smoke and reduce its power.

Operating the engine with an improper oil level may severely damage engine.

CAUTION:

Every time oil is added in engine, do following steps to ensure correct oil level:

(1). Start engine, idling for 20 seconds, then stop engine.

(2). Wait for 1 minute then, rechecking the oil level.

Change Engine Oil

•After First 10 Hours Operation, According To Maintenance Schedule In Section 4

•After Your Powerboard Capsize A Couple Of Times

•When Water Gets Into Engine Through Carburetor, Exhaust System Or Engine Breathing Hose.

STEPS TO CHANGE ENGINE OIL:

6)Drain dirty oil completely.

7)Clean oil filter screen and magnet.

8)Re-install back magnet, filter screen, washer and oil drain plug.

9)Close the access window cover. Make sure the “O” ring is in good condition and fit into the cover.

10) Fill new engine oil to the right oil level.

Engine Coolant

12

4)Use the special wrench tool (supplied) to open the access window to engine oil drain plug at bottom

of hull. Keep the “O” ring for later use.

5)Use a 17mm socket wrench to open oil drain plug. There is a washer, a spring, oil filter screen and a

magnet came out with the oil drain plug. Put oil filter screen and magnet in a cleaning container.

Located at the bottom of the carburetor in engine compartment. Use a Philip screw driver to drain water

or contaminated fuel in carburetor bowl. Ensure to close the drain screw after cleaning.

Located inside engine compartment. Retain water or contaminated fuel. Check the bottle periodically

and drain water or contaminated fuel to keep engine run with clean fuel.

Cooling system must be filled with water and antifreeze solution (50% demineralized water, 50%

antifreeze), or premixed coolant with freezing protection.

Always use ethylene-glycol antifreeze containing corrosion inhibitors specifically for internal combustion

aluminum engines.

1)Oil drain plug is located at the bottom of hull beneath engine. Make sure that engine is off and warm,

but NOT HOT.

To prevent antifreeze deterioration, always use the same brand. Never mix different brands unless

cooling system is completely flushed and refilled.

Before checking the oil level on this engine, watercraft must be level. Check oil level either with

watercraft in water or out of water. Engine should be warm. Start engine for 20 seconds to warm up oil if

Use a funnel to add oil. You may find it is helpful to attach 12MM (½ in) ID hose of 6 inches long to the

funnel for filling oil. Add the recommended oil to the proper level. Do not overfill.

2)Place your watercraft on a trailer or a lifting equipment so that you can access to the bottom of hull.

Make sure the engine is leveled.

3)Use a proper oil pan to collect used oil to protect environment. Place it under the access window to

the engine oil drain plug.

13

WARNING

•Always stop the engine before refueling.

•Fuel is flammable and explosive under certain conditions.

•Always work in a well ventilated area. Do not smoke or allow open flames or sparks in the vicinity.

•Fuel tank may be pressurized, turn cap slowly when opening.

•When fueling, keep watercraft level.

•Do not overfill or top off the fuel tank and leave watercraft in the sun. As temperature increases, fuel

expands and might overflow.

•Always wipe off any fuel spillage from the watercraft. Periodically verify fuel system.

•RECOMMEND PREMIUM UNLEADED

GASOLINE 91 PUMP OCTANE OR HIGHER

•MINIMUM UNLEADED GASOLINE 86

PUMP OCTANE OR HIGHER

NOTE: Do not mix oil with fuel.

!

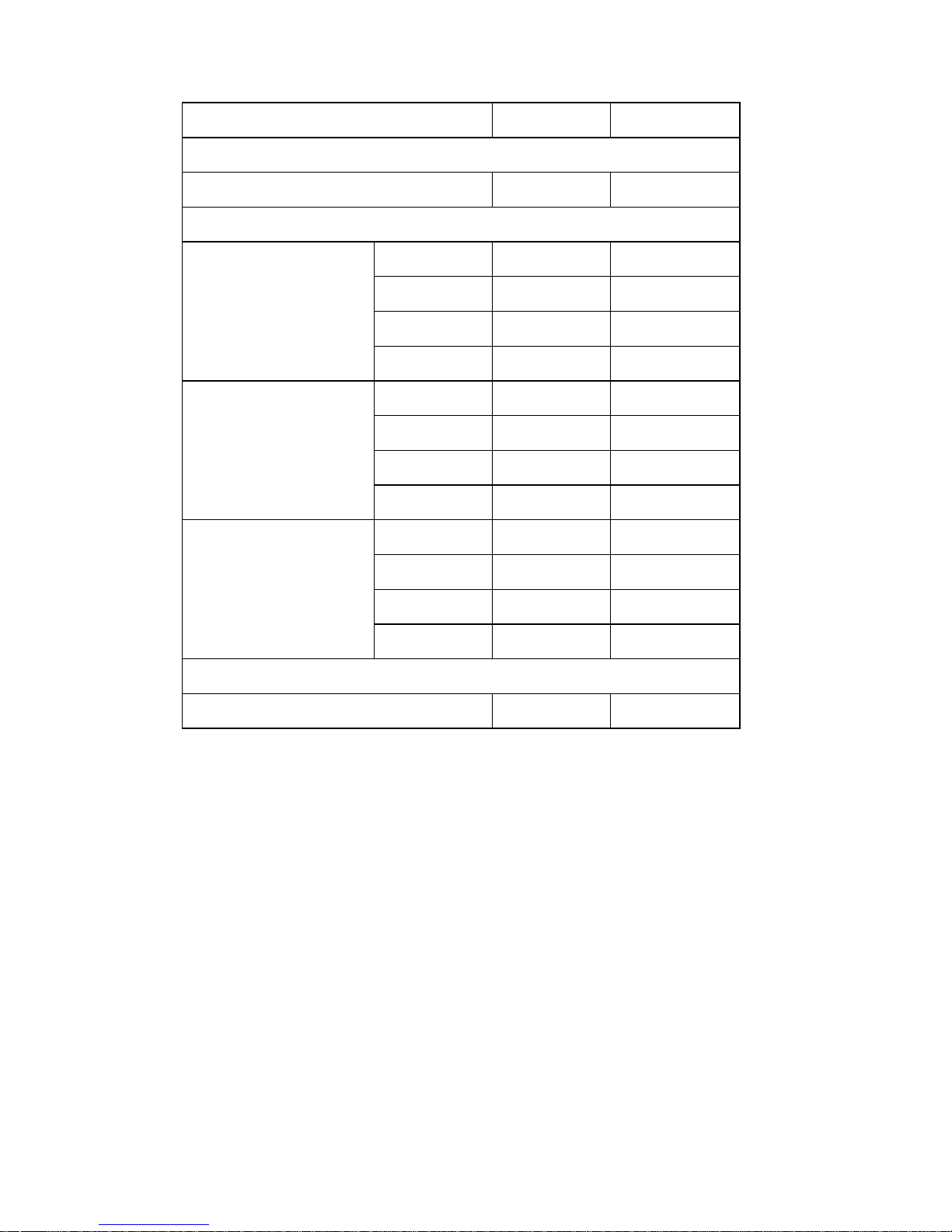

UNIT DATA

Number of People 1

Length cm(in) 254(100)

Width cm(in) 70 (27.5)

Dry weight kg(lb) 50(110)

Recommended

max load

kg(lb) 91(200)

Length cm(in) 264(104)

Width cm(in) 72(28.5)

Dry weight kg(lb) 58(128)

Recommended

max load

kg(lb) 91(200)

Length cm(in) 291(115)

Width cm(in) 74(29)

Dry weight kg(lb) 65(143)

Recommended

max load

kg(lb) 114(250)

km/h (mph) 40(25)

13

Performance

Dimensions, weights and recommended maximum loads

JetBoard

JetKayak

2011 POWERBOARD SPECIFICATIONS

ITEM

Maximum people

Capacity

JetKayak GT

Max speed

ITEM UNIT DATA

Type 4 stroke

Max power Kw(hp) 7(9.5)

Number of cylinders 1

Displacement

cm3(cu in) 149.6(9.2)

Bore mm (in) 57.4

Stroke mm (in) 57.8

Compression ratio 10.5 : 1

Start Electric start

Ignition type CDI

Spark plug NGK DPR7EA-9

Spark plug gap mm (in)

0.6~0.7

(0.024~0.028)

Intake mm (in) 0.03 (0.0012)

Exhaust mm (in) 0.05 (0.0020)

Engine cooling type

Closed loop water

cooling. Refer to

Liquids section for

Exhaust cooling type

Inject water cool.

Direct flow from

propulsion unit

Lubrication type

Oil sump. Refer to

liquids

Product Unit Data

Fuel tank capacity L (US gal) 7 (1.8)

Play time at full throttle hours 2

Jet pump

Aluminum/composit

e, axial flow, single

stage

Transmission

Direct drive,

forward/reverse (if

equipped)

Impeller Aluminum alloy

14

2011 POWERBOARD SPECIFICATION (Continued)

Propulsion system

Engine

Valve clearance (Cold)

Cooling system

Lubrication system

Fuel system

15

Section 3

OPERATION

BREAK-IN PERIOD

CAUTION:

STEPS TO CHANGE ENGINE OIL:

6)Drain dirty oil completely.

7)Clean oil filter screen and magnet.

8)Re-install back magnet, filter screen, washer and oil drain plug.

9)Close the access window cover. Make sure the “O” ring is in good condition and fit into the cover.

10) Fill new engine oil to the right oil level.

CAUTION:

10-Hour Inspection

16

WARNING

Your craft is equipped with a 4 stroke closed loop water cooled engine. Having a breaking-in period

is crucial to its proper performance and the product life. The engine break-in period allows various

components of the engine to wear and polish themselves to the correct operation clearances and

conditions. The scheduled oil change during the break-in period is also required. It will prevent

excessive wear and damage to the components. Failure to perform the required break-in period may

significantly handicap your craft performance, shorten the product life. In certain circumstances, it

may void your craft warranty.

Before operating your Powerboard, read this User’s Manual thoroughly, fully understand how the craft

works, become familiar with all controls and functions. Consult your Aquanami Dealer for any

questions about control and operation you may have. Failure to do so could cause damage to your

watercraft and an accident!

2)Place your watercraft on a trailer or a lifting equipment so that you can access to the bottom of

hull. Make sure the engine is leveled.

1)Oil drain plug is located at the bottom of hull beneath engine. Make sure that engine is off and

warm, but NOT HOT.

It is highly recommended that after the first 10 hours of operation, the watercraft be checked by an

authorized Aquanami dealer. This inspection will also provide the opportunity to discuss the

unanswered questions you may have encountered during the first hours of operation.

•Make sure the drain plug is properly secured after oil change. No oil leak!

•Make sure the access window is properly sealed with “O” ring and properly secured. No water leak!

•Explicitly follow the instructions of this section. Failure to do so may reduce the engine’s life and/or

performance. With the 4 stroke closed loop water cooled engine, a break-in period of 10 hours is

required before continuous operation at full throttle. To achieve a good break-in, throttle lever should

not be depressed more than 3/4, however, brief acceleration and speed variations contribute to a

good break-in.

•Continued wide open throttle runs and prolonged cruising without speed variations should be

avoided, this can cause engine damage during the break-in period.

YOU MUST CHANGE ENGINE OIL, REPLACE OR CLEAN OIL FILTER AND MAGNET

AFTER FIRST 10 HOURS OPERATION BY AN AUTHORIZED AQUANAMI DEALER!

4)Use the special wrench tool (supplied) to open the access window to engine oil drain plug at

bottom of hull. Keep the “O” ring for later use.

5)Use a 17mm socket wrench to open oil drain plug. There is a washer, a spring, oil filter screen and

a magnet came out with the oil drain plug. Put oil filter screen and magnet in a cleaning container.

3)Use a proper oil pan to collect used oil to protect environment. Place it under the access window to

the engine oil drain plug.

!

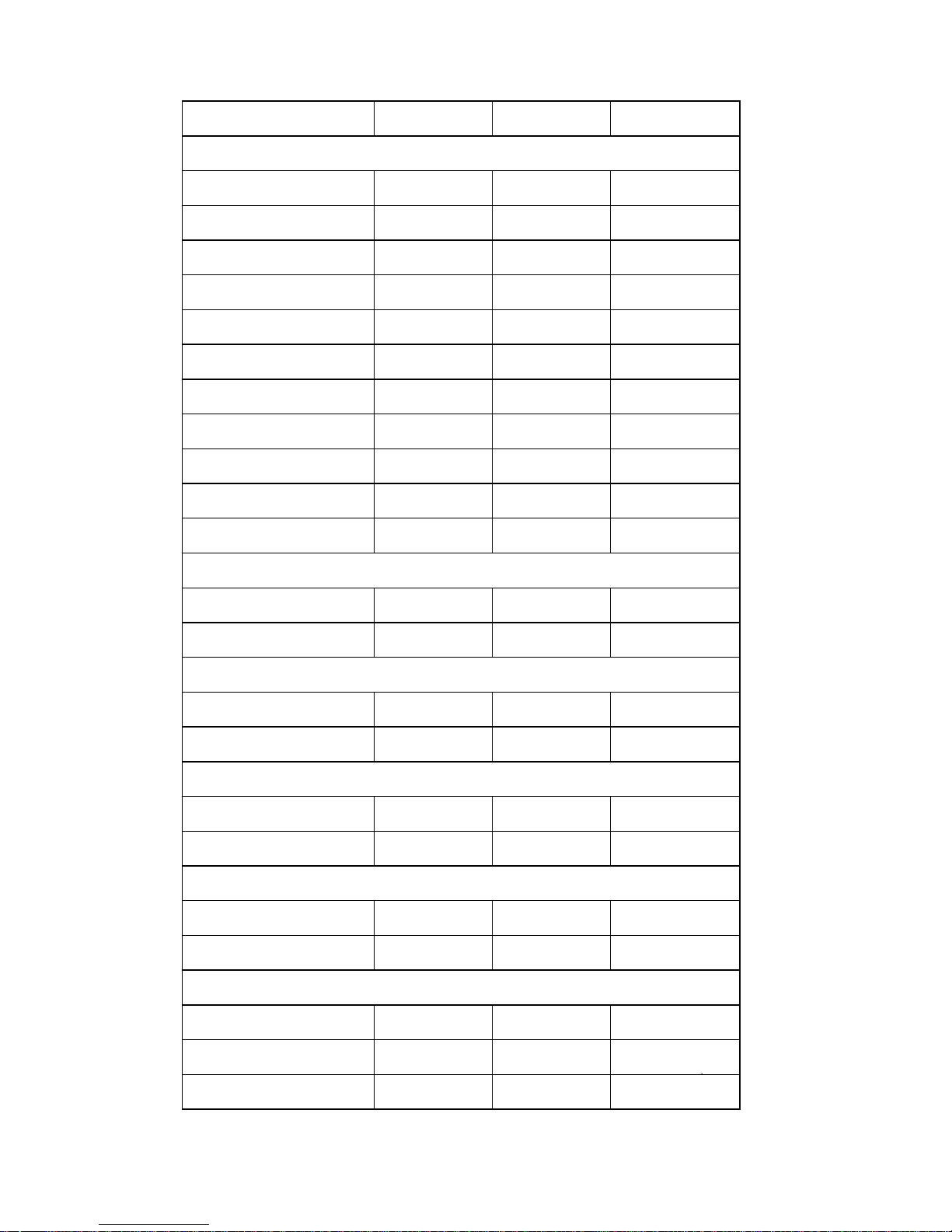

PRE-OPERATION CHECKS

PRE-OPERATION CHECK LIST

17

Periodically drain the engine breathing oil

retainer bottle to clean oil/water residue.

Inspect/clean.

Inspect any damage or leak.

Check the access window is properly sealed

and secured. No water leak.

Inspect.

Ensure they are closed and properly sealed.

Check/refill.

Check if any water exists.

Check if any signs of water leak.

Check fuel line connections for tightness.

Verify for any fuel leak/odor as well as oil

and coolant leaks.

Check/refill.

Check/refill.

Periodically drain water or contaminated fuel

from the carburetor bowl by loosening the

carburetor drain screw. Use a cup to collect

the drained liquids. Ensure the drain screw

closed after cleaning.

Fuel water separator bottle

Periodically drain water or contaminated

Periodically drain water or contaminated fuel

from the bottle.

Hull

Dry storage compartment covers

Safety Lanyard

Throttle

Steering system

Armpole

Exhaust pipe cooling

Bilge plugs

Carburetor

Fuel water separator bottle

Exhaust flush cap

Battery

Fuel tank

Engine compartment

Engine oil level

Engine coolant

Ensure the cap is installed.

Inspect cables and retaining fasteners.

Ensure good condition and fully charged.

Engine breathing oil retainer

Jet pump water intake

Jet pump water intake seal

Access window to oil drain plug

Check by-pass outlet. Water mist/drops

should come out exhaust by-pass outlet.

WARNING

Check operation.

Check operation.

Check operation.

•The pre-operation check is very important prior to operating the watercraft. Always check the proper

operation of critical controls, safety features and mechanical components, before starting as listed

hereinafter. If not done as specified here, severe injury or death might occur.

•Bring all safety equipment required by local laws. Some of the following items may not have been

previously covered in this Manual, however they will be described in the MAINTENANCE or SPECIAL

PROCEDURES sections. Please refer to these sections to have more detailed information.

WARNING

ITEM

TO DO

•Engine should be off and the safety Lanyard should always be removed from its post prior to do any

of the following check. Leave safety lanyard on its post will drain battery dead when engine is not

running.

•Start your craft only after all items have been checked and operate properly.

Start and Stop buttons

Check operation.

Check operation.

Ensure plugs are secured.

!

!

Engine Start/Stop Button and Safety Lanyard

Make sure that both switches operate properly. Start engine and stop it using each switch individually.

Throttle

Steering System For jetKayak

Armpole for jetSurf

CAUTION:

Damage to the Armpole, Armpole housing and/or the handle can result in SEVERE INJURY OR DEATH.

Exhaust Pipe Cooling

CAUTION

CAUTION

CAUTION

CAUTION

18

To ensure it is properly working, check by-pass outlet. Water mist/drops should come out exhaust

by-pass outlet. If the exhaust from the by-pass is not wet, stop engine and consult your Aquanami

Dealer.

Never run the engine without supplying water to the exhaust cooling system when watercraft is out of

water. If out of water, level the craft. Install a garden hose to the flushing connector. Refer to POST-

OPERATION CARE and follow the procedure.

Failure to flush exhaust cooling system, when engine is out of water, may severely damage the

Never run engine longer than 1 minute when watercraft is out of water. Drive line seal has no cooling

when watercraft is out of water.

•The exhaust pipe is cooled by the water from the jet pump. If the water flow from jet pump to

exhaust pipe is blocked, the exhaust pipe and connecting components could be damaged.

•Close and tight the exhaust flush cap (garden hose connector cap) after flushing exhaust system.

•Exhaust system will be burned, damaged or caught fire if the exhaust flush cap left open!

Lanyard could be securely attached to the kill switch post. It shuts electric system and engine off

when being pulled off its post.

Check the throttle lever for free and smooth operation. It should return to its initial position

immediately after it is released.

Armpole provides support to operator during operation. It also houses control cables and electric

wires. Having a damage free and fully functioning Armpole is important to your safety as well as other

waterway users.

Check the Armpole housing looking for cuts, tears or any other kind of damage. Ensure that the

Armpole housing is securely connected to the housing anchor and the handle. The Armpole should

remain securely attached to the jetSurf when the handle is pulled. Additionally ensure that there are

no loose and/or missing screws.

WARNING

WARNING

WARNING

WARNING

•Should the stop/start button not work properly, refer to an authorized Aquanami dealer immediately.

Fail to do so may result in SEVERE INJURY OR DEATH.

•Should the safety lanyard be loose or not work properly, replace it immediately in order to avoid

unsafe use.

Check throttle lever operation before starting the engine.

check steering operation for free movement with the assistance of another person. When the steering

handle is in the center position, the jet pump nozzle should be in the straight ahead position. Ensure

the jet pump nozzle pivot easily.

•Check steering handle and corresponding steering nozzle operation before starting the engine.

•Never turn steering handle while someone is nearby the rear of the watercraft. Keep away from

steering moving parts.

WARNING

!

!

!

!

!

Bilge Plugs

Exhaust Flush Cap (Garden Hose Connector Cap)

Battery

Fuel Tank

Engine Compartment

Engine Oil Level

Engine Coolant

Check Carburetor

Check Fuel Water Separator Bottle

Clean Engine Breathing Oil Retainer

Jet Pump Water Intake

19

Periodically drain water or contaminated fuel from the separator bottle. Use a cup to collect the

drained liquids. To drain the contaminated fuel in the separator bottle, simply pull off the hose from

the middle nozzle of the bottle, and let the contaminated fuel drain out from the bottom nozzle

through the hose to a cup. Ensure reconnect the drain hose back to the middle nozzle of the

Check the bottle periodically and clean any oil residue to keep engine breathing freely. To drain the

oil/water in the retainer bottle, simply pull off the hose from the middle nozzle of the bottle, and let

the water/oil drain out from the bottom nozzle through the hose to a cup. Ensure reconnect the drain

hose back the middle nozzle of the oil retainer bottle.

Check the seal between the jet pump intake and the ride plate. A damaged seal will let air get into the

jet pump. The jet looses its propulsion force.

Although the jet pump is equipped with weed cutter. It is still recommended that check jet pump.

Remove weeds, shells, debris or anything else that could restrict the flow of water and damage

cooling system or propulsion unit. Clean as necessary. If any obstruction can not be removed, refer

to an authorized Aquanami dealer for servicing.

Inspect leading edges of the impeller, if they have nicks or bends performance will be greatly

reduced.

Do not inspect the water intake or intake grate without removing the lanyard from the post.

Check if any water exists. Check if any signs of water leak. Check fuel line connections for tightness.

Verify for any fuel leak/odor as well as oil and coolant leaks. Check any loosen parts.

Ensure oil level is appropriate as specified in LIQUIDS section. Check for oil leaks on engine and in

engine compartment.

Ensure coolant tank is full as specified in LIQUIDS section. Check for coolant leaks on engine, in

bilge and from ride plate.

Water or contaminated fuel in carburetor bowl will cause engine suddenly stop when you depress

throttle lever, or you may not be able to start engine. Periodically drain water or contaminated fuel

from the carburetor bowl by loosening the carburetor drain screw. Use a cup to collect the drained

liquids. Ensure the drain screw closed after cleaning.

Should water be present in the bilge, press manual bilge pump switch to start the electric bilge pump.

If some water remains in bilge, tilt the watercraft to the rear and unscrew drain plugs to completely

empty the bilge. Ensure all plugs securely closed before operating your Powerboard.

Ensure the exhaust flush cap (garden hose connector cap) is closed. Running the engine while

leaving the cap open will damage the exhaust system.

Pay attention to battery “+ and “-” signs. Ensure the battery is correctly connected, tighten and

secured.

With the watercraft horizontal, fill the fuel tank. Refer to Liquids section for checking fuel level and

fueling.

•Always close the exhaust flush cap (garden hose connector cap) after flushing the exhaust system.

•Running the engine with the cap open will damage the exhaust system.

•The battery must always be fully charged and in good condition. Loss of battery power may leave

you stranded. Never operate the watercraft if the battery does not have sufficient power or if it shows

any other signs of decreased power.

•Always remove safety lanyard from its post when engine is not running. Leave safety lanyayd on its

post will drain battery dead when engine is not running.

WARNING

WARNING

WARNING

!

!

!

This manual suits for next models

1

Table of contents

Popular Boat manuals by other brands

Jeanneau

Jeanneau SUN ODYSSEY 41 DS owner's manual

Meridian

Meridian 490 Pilothouse owner's manual

Advanced Elements

Advanced Elements AdvancedFrame Expedition AE1009 owner's manual

Robo Marine Indonesia

Robo Marine Indonesia GEOMAR user manual

Swallow Boats

Swallow Boats BayRaider owner's manual

X SHORE

X SHORE EELEX 8000 owner's manual