Thales 82166 Series Manual

86, Bushey Road

Raynes Park, London

SW20 0JW

Tel: +44 (0)20 8946 8011

Fax: +44 (0)20 8946 7530

1

Jul 2008

Revision No. 00

First Issue: Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

INSTALLATION AND MAINTENANCE

MANUAL

Flange Mounted High Power Amplifier

(FMHPA)

82166 Series

Installation Maintenance Manual

FMHPA 82166A30

2

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

THIS PAGE INTENTIONALLY BLANK

Installation Maintenance Manual

FMHPA 82166

i

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

Section 1 INTRODUCTION Page

1.1. Purpose of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2. Scope of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3. Reference documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4. Compliance to Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

A. Federal Communication Commission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

B. European Aviation Safety Agency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Section 2 DESCRIPTION Page

2.1. FMHPA SYSTEM General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

A. Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

(1) RF SRU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

(2) Logic SRU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

B. Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

C. General Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

(1) Functional Modes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

D. HPA Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

E. PSM and CM Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

(1) PSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

(2) CM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

F. Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

(1) Normal operating temperature:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

(2) Cooling:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

(3) Heat dissipation: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

G. Environment Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

H. Weight and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

I. FMHPA Performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.2. Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

A. Aircraft Power Utility Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

B. Communication Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.3. FMHPA Interconnect Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

A. FMHPA Interconnection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

B. FMHPA Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

(1) FMHPA Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

(2) Connector Designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

(3) Connector J1 PIN Out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Section 3 INSTALLATION GUIDELINES Page

3.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2. Interchangeability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3. FMHPA Location and Accessibility Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.4. Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.5. Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.6. Bonding Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Installation Maintenance Manual

FMHPA 82166

ii

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

Section 4 INSPECTION AND SYSTEM CHECKOUT Page

4.1. Inspection/Check Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

A. Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

B. FMHPA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2. System checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

A. Post-Installation Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Section 5 FAULT ISOLATION Page

5.1. Bite Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2. BITE Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

A. Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

B. Health Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3. SDU LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Section 6 MAINTENANCE Practices Page

6.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2. Equipment and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.3. Procedure for the FMHPA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

A. Removal and Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

(1) Remove the FMHPA as follows: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

(2) Install the FMHPA as follows: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

B. Adjustment Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

C. Repair Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

D. Return to Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.4. Cleaning of Mechanical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.5. Periodic Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.6. Cabling and Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.7. Instructions for Continued Airworthiness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Installation Maintenance Manual

FMHPA 82166

iii

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

RECORD OF REVISIONS

Revision

No:

Revision

Date

Date

Inserted

By Revision

No:

Revision

Date

Date

Inserted

By

Installation Maintenance Manual

FMHPA 82166

iv

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

THIS PAGE INTENTIONALLY BLANK

Installation Maintenance Manual

FMHPA 82166

1-1

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

SECTION 1

10000INTRODUCTION

1.1. PURPOSE OF MANUAL

This manual sets forth installation and maintenance guidelines for the THALES

TopFlight Satcom (TFS) Flange-mounted High Power Amplifier (FMHPA). The

FMHPA installation specific and general guidelines contained within this manual are

supported by mechanical and electrical interconnection drawings. Drawings should be

reviewed by the installation organisation, and any requirements specific to a particular

airframe should be assessed before installation is commenced.

The Manual covers the following topics:

a. Title Page.

b. Table of Content.

c. Record of Revisions

d. Introduction.

e. Description.

f. Installation Guidelines.

g. Inspection and System Checkout.

h. Fault Isolation.

i. Maintenance Practices.

NOTE: This manual does not cover aircraft system commissioning test

procedures.

Advisory notes presented within this manual such as: ‘Warnings, Cautions and Notes’

are applicable to the TFS system as follows:

a. A WARNING is used to alert the reader to possible hazard which may

cause loss of life or physical injury.

b. A CAUTION is used to denote the possibility of damage to materiel but

not danger to personnel.

c. A NOTE is used to convey, or draw attention to, information that is

extraneous to the immediate subject of the text.

Installation Maintenance Manual

FMHPA 82166

1-2

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

For any queries related to information contained within this Manual contact the

following:

THALES TFS Project Manager

86 Bushey Road

Raynes Park, London

SW20 0JW, UK

Tel. +44 (0)20 8946 8011

Fax. +44 (0)20 8946 7530

1.2. SCOPE OF MANUAL

The Thales FMHPA comply with the design requirements set forward in the ARINC 781

Characteristic. An ARINC 781 compliant system is intended to support one or more of

the Inmarsat aeronautical services known as ‘Classic-Aero’, ‘Swift 64’, and

‘SwiftBroadband’.

This manual provides information specific for the FMHPA.

1.3. REFERENCE DOCUMENTS

The following publications provide additional useful information:

Table 1.1 Reference Documents

1.4. COMPLIANCE TO REGULATIONS

A. Federal Communication Commission

The FMHPA is designed to be compliant with part 15 and part 87 of the Federal

Communication Commission (FCC) regulations

THALES FMHPA Component Maintenance Manual

THALES SDU Component Maintenance Manual Airbus:44-35-32

Boeing: TBD

EMS AMT-3800 High Gain Antenna Subsystem Installation

Manual

MN-1242-20047

Mark 33 Digital Information Transfer System ARINC 429

Air Transport Avionics Equipment Interfaces ARINC 600

Mark III Aviation Satellite Communication (Satcom) System

Avionics

ARINC 781

Installation Maintenance Manual

FMHPA 82166

1-3

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

B. European Aviation Safety Agency

The installation must be compliant to the following European Aviation Safety Agency

(EASA) regulations:

• EASA/FAR 25.869 Fire protection systems

• EASA 25X0899 Electrical bonding and protection against lightning and

static electricity

• EASA/FAR 25.1301 Equipment, general, function and installation

• EASA/FAR 25.1309 Equipment, systems and installations

• EASA 25X1316 System lightning protection

• EASA/FAR 25.1353 Electrical equipment and installations

• EASA/FAR 25.1357 Circuit protective devices

• EASA 25X1360 Precautions against injury

• EASA/FAR 25.1431 Electronic equipment

• EASA 25.561 Emergency Landing.

Installation Maintenance Manual

FMHPA 82166

1-4

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

THIS PAGE INTENTIONALLY BLANK

Installation Maintenance Manual

FMHPA 82166

2-1

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

SECTION 2

20000DESCRIPTION

2.1. FMHPA SYSTEM GENERAL DESCRIPTION

The FMHPA forms part of the airborne SATCOM system, used in conjunction with a

Satellite Data Unit (SDU), a Diplexer/Low Noise Amplifier (DLNA) and a High Gain

Antenna (HGA) conforming to ARINC 781, with an internal Beam Steering Unit (BSU).

The TopFlight Satcom (TFS) system conforms to the Aeronautical Radio Incorporated

(ARINC) 781 Characteristic, and interfaces with onboard avionics and communication

equipment to provide the aircraft with a range of communication services by

transmitting and receiving L Band signals to and from the fourth generation of

INMARSAT satellites. For this purpose the INMARSAT satellite constellation is

connected to the ground backbone telecommunication network through Satellite Access

Stations (SAS) operated by service providers.

A. Hardware

The FMHPA contains two hardware Shop Replaceable Units (SRU):

• The Radio Frequency (RF) SRU which contains the High Power

Amplifier (HPA) and the RF Filter

• The Logic SRU which contains the Power Supply Module (PSM) and

the Communication Module (CM).

The two SRUs have a heat-skin with cooling fins and a nozzle to dissipate the

temperature.

(1) RF SRU

The RF SRU has two external connectors and two internal connectors:

a. External connectors:

• RF input (J2)

• RF output (J3).

b. Internal connectors, connecting the RF SRU to the Logic SRU:

• Power Supplies

• Communication signal.

Installation Maintenance Manual

FMHPA 82166

2-2

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

(2) Logic SRU

The Logic SRU has one external connector and six internal connectors:

a. External connector:

The external connector (J1) is used to communicate with the SDU and for the power

supplies of the FMHPA.

b. Internal connectors are used to:

• Connect the PSM and the CM

• Connect the RF SRU to the Logic SRU for power supplies and the

communication signal.

• Supply a test connector for testing and downloading.

B. Software

There is no software in the FMHPA.

All FMHPA functions shall be allocated to hardware.

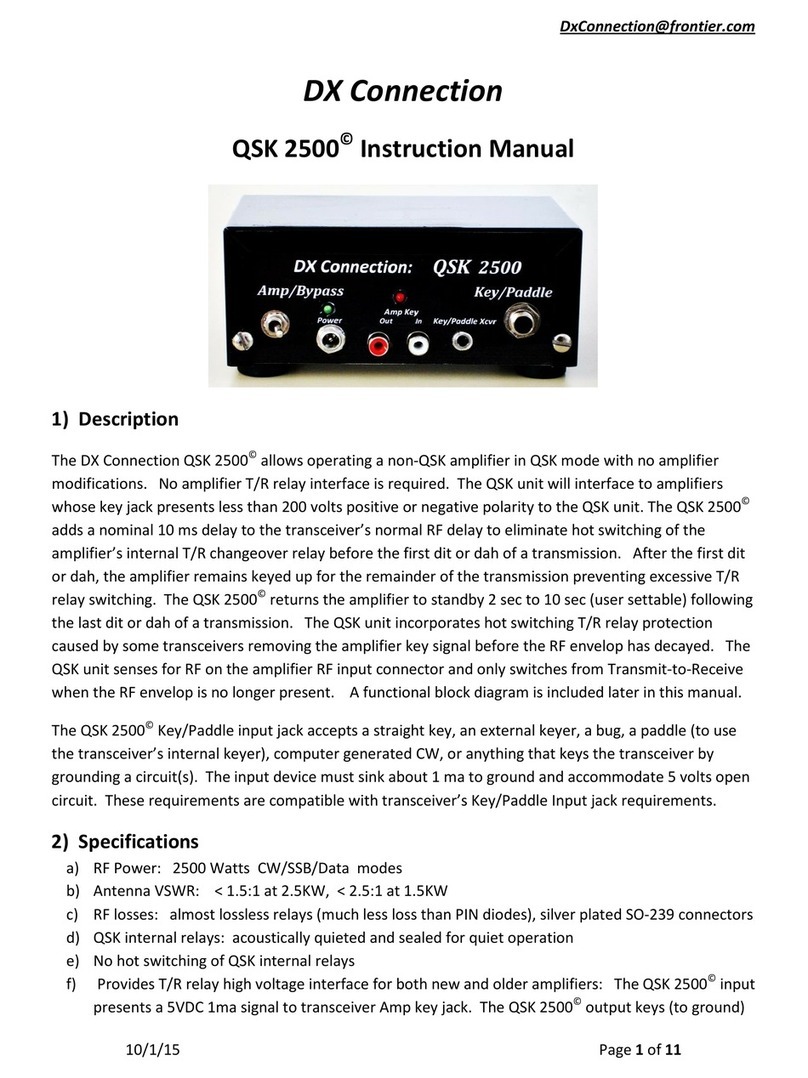

Figure 2.1 FMHPA Internal Organisation.

HPA

Power Supply Converters

Command/

Status

Power

Supplies

Communication Module

PSM

115Vac

ARINC 429 I/O

(J1)

Test and

Maintainability

EMC Filter

RF In (J2)

RF Out (J3)

Airflow

Tav_e_0000761_00

RF

FILTER

SRU1:

HPA+

RF Filter

SRU2:

PSM+

CM

Installation Maintenance Manual

FMHPA 82166

2-3

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

C. General Operation

The FMHPA is a Linear Power Amplifier for embedded communication system (TFS).

FMHPA supplies up to 35W RF power to the Aircraft Satcom antenna when the physical

separation of the SDU and the antenna is such that the RF loss between the SDU and the

antenna will be greater than that allowed in ARINC 781. Alternatively, the FMHPA may

be used in cases where more power is required than would be available from the HPA

within the SDU, to provide the services offered.

Its function is to amplify the modulated signals supplied by the SDU. The number of

signals to be amplified depends on the communication traffic, from a single up to the

maximum capability of the SDU. FMHPA also includes a constant and programmable

RF gain, a high grade of self test (90% of failures are detected) and a high temperature

protection function.

(1) Functional Modes:

The FMHPA operates in the following five modes:

a. Nominal Mode (35W output)

Nominal Mode (NM) is defined as the operating condition when power supplies are

applied. This mode is enabled by default at powerup, the power supply is defined at its

nominal Voltage (around +27V)

b. Low Power mode (9W output)

Low Power Mode is defined as the operating condition which can be enabled by SDU

(or FMHPA in security case) when the temperature is high and in order to reduce the

dissipated power (for example to save the internal temperature when there is a loss of

cooling). For this mode, the power supply is changed from Nominal Voltage (around

+27V) to Low Voltage (around +17V). Cockpit only services available.

With NM and LPM modes, the main characteristic of the modes is to maintain a constant

gain whatever the temperature.

c. Carriers Off/MUTE Mode

This mode switches off the RF gain, and puts the FMHPA in Standby (STBY) mode.

d. STBY / On mode

With Standby mode, the main characteristic of the mode is to have the lowest

consumption.

In this mode, the RF output power equals zero, and the thermal dissipation within the

FMHPA is reduced to the minimum possible to permit temperature monitoring and

Installation Maintenance Manual

FMHPA 82166

2-4

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

communication with the SDU to continue. This STBY mode can be obtained with four

configurations:

• Command configuration: In this case, an input command, Carriers Off/

Mute command from SDU, enable or disable the STBY mode

• Auto-protection configuration: When FMHPA detect an internal failure

(High level) and the SDU doesn’t answer within 2 seconds

• With carriers Off/Mute, the main characteristic of the mode is to have a

high isolation between FMHPA input and FMHPA output

• After HPA Power-On Self Test (POST) or at the end of a self test.

e. BITE Monitoring

A monitoring Mode is defined in order to check if the FMHPA Status is OK or FAIL.

A self test is carried out at Start-up and on request from the SDU.

D. HPA Module

The HPA function is to amplify modulated signals from the SDU, up to 35 W.

The HPA includes an amplification chain, a digital part for control and communication

and a RF filter.

The output RF filter is a mechanical filter, without any electronic component, with a N

connector output.

E. PSM and CM Module

The PSM and CM SRU module contains two modules in the same housing:

• Power Supply Module

• Communication Module.

Installation Maintenance Manual

FMHPA 82166

2-5

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

(1) PSM

(2) CM

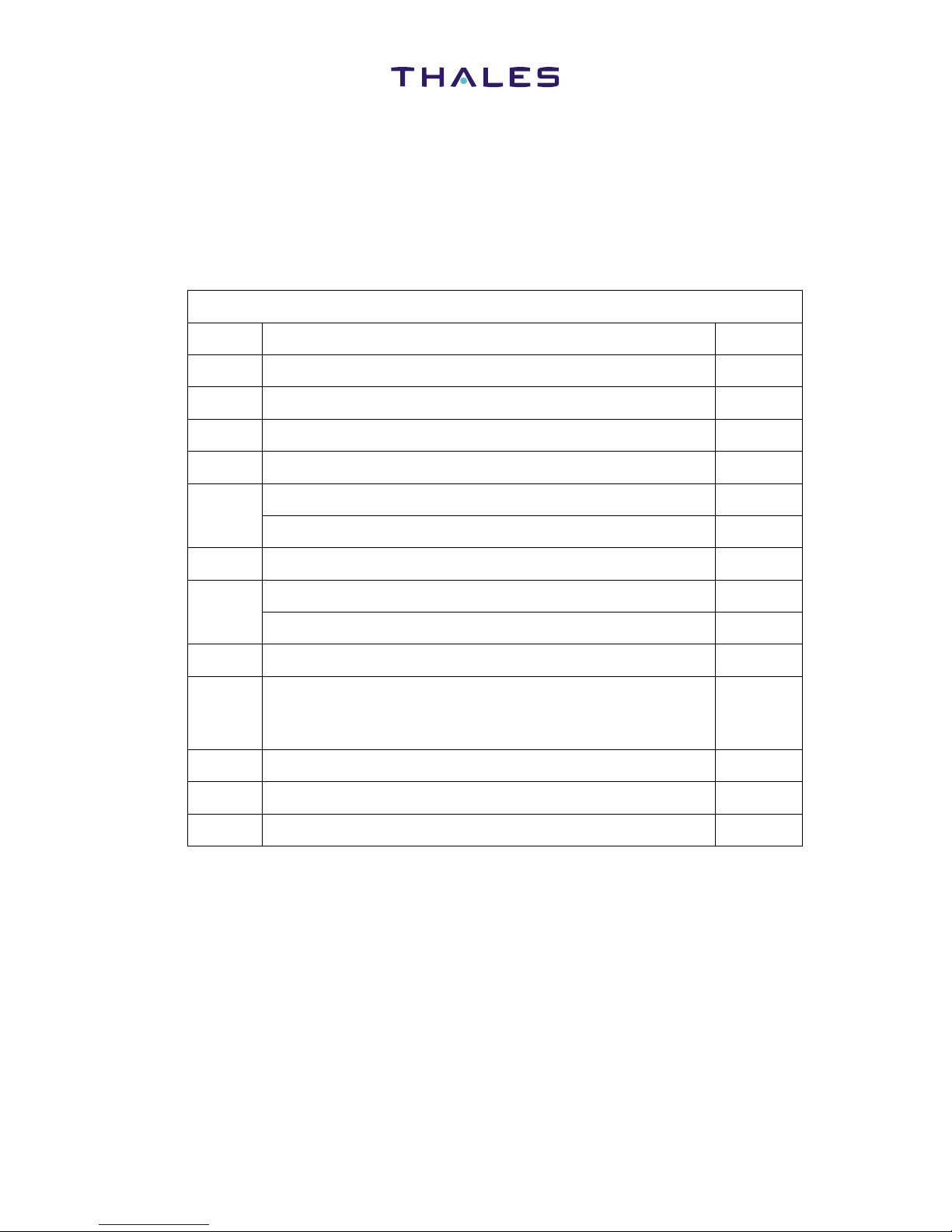

Its function is to manage the interface with the ARINC 429, to send control signals to the

HPA and the PSM and report FMHPA status.

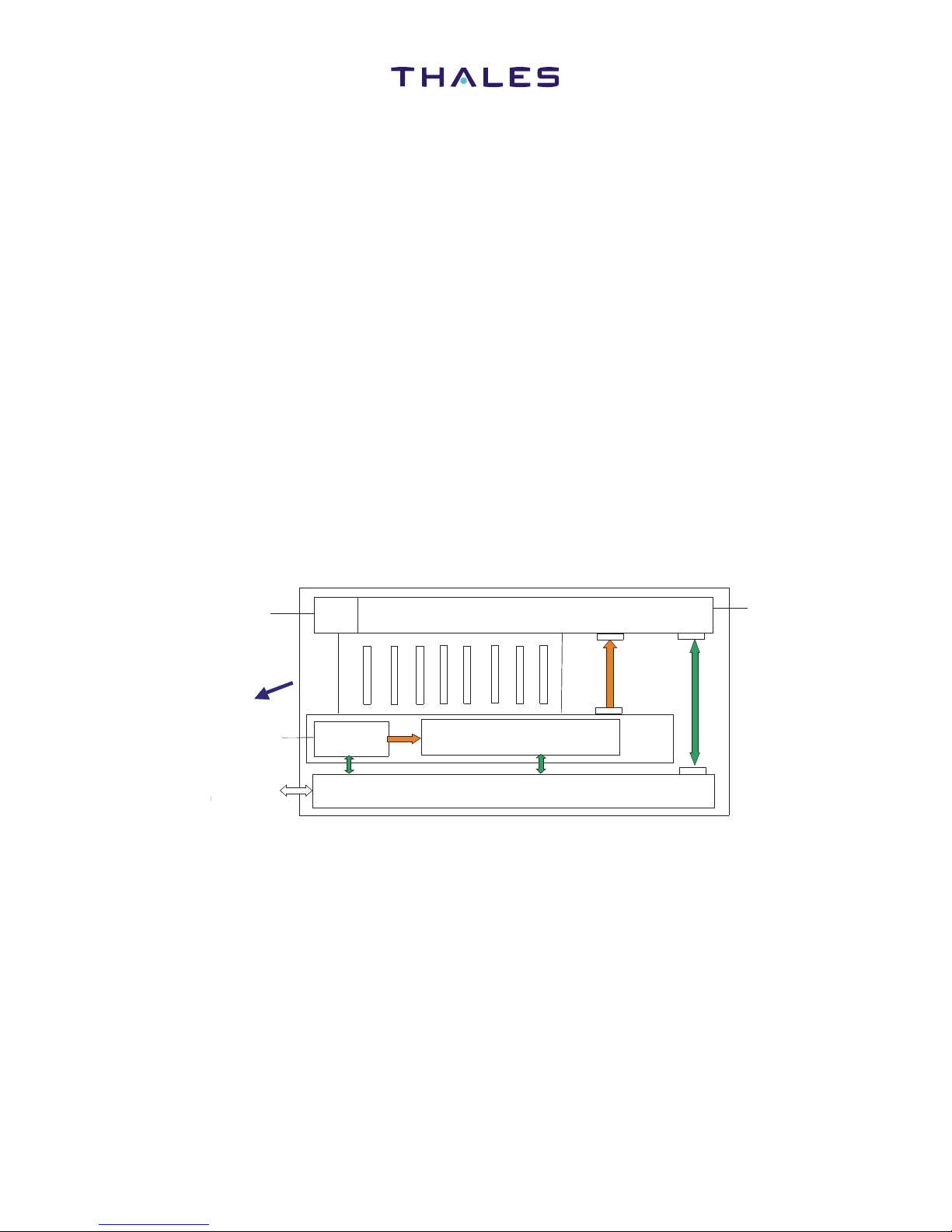

Figure 2.2 Power Supply Module

J1

Lightening/

EMC

protection

Isolated AC/DC

350W PFC

Hold up

capacitors

200ms for

Digital part

DC/DC HPA

HL/LV voltage

300W

DC/DC

+5,1V - 30W

HPA

CM

J9

J5

DC/DC

-15V - 1.5W

+15V - 1.5W

+5V - 0.1W

+5.1V - 2.5W

Temperature

sensors

Voltage

supervision

Power cut

management

Output

discrets Control

signals

Nominal/Low

Voltage

selection

PSM

P115VAC

N115VAC

ARINC 429

In

ARINC 429

Out

33V

DC

J6

J8

J7

Tav_e_0000767_00

Installation Maintenance Manual

FMHPA 82166

2-6

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

F. Operating Environment

(1) Normal operating temperature:

Between -15oC (5oF) and +70oC (158oF)

(2) Cooling:

Forced air type requiring Normal airflow rate of 2.6 lb/min (72 kg/hr). Nominal Mode

(NM) inlet temperature +60oC (140o F) and Low Power Mode (LPM) inlet temperature

of +70oC (158oF).

(3) Heat dissipation:

265 W (assuming 100% duty cycles with HPA operating at 35 W output).

Figure 2.3 Communiction Module

Input LRU

Connector

Communication

Module

HPA

PSM

Test Connector

Tav_e_0000768_00

A429 High

speed

A429 Low

speed

Installation Maintenance Manual

FMHPA 82166

2-7

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

G. Environment Conditions

The FMHPA complies with the RTCA/DO-160. The environmental qualifications

categories complied with, are as per listed refer (Table 2.1).

Table 2.1 Environmental Test categories for SDU and SCM

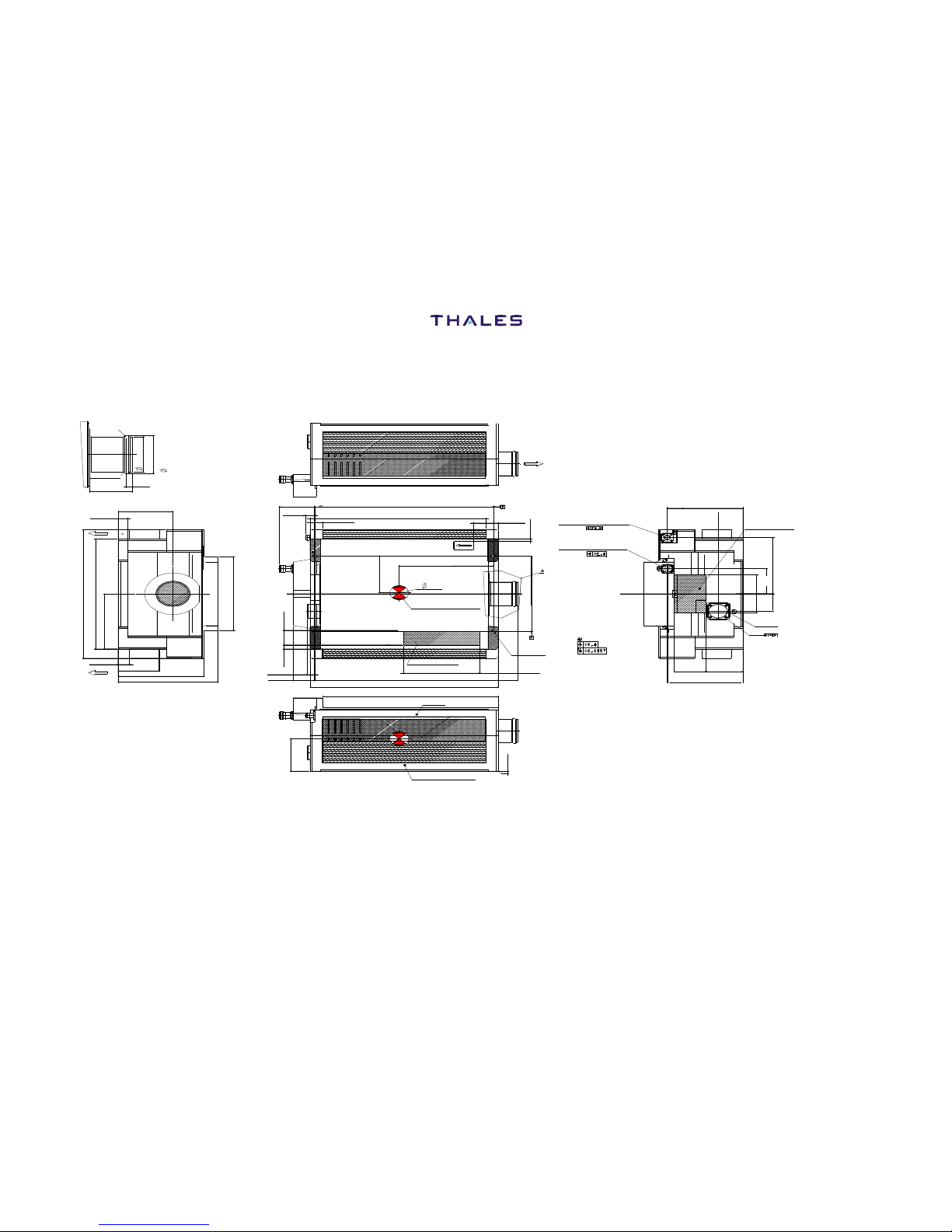

H. Weight and Dimensions

Weight and dimensions of the FMHPA are as follows:

NOTE: Weights and measurements in this manual use both U.S (inches) and S.I.

(metric: mm) values.

Maximum Weight: 8.9 kg (19.8 lb)

RTCA DO-160 Environmental Categories

Section Condition Category

4.0 Temperature/Altitude A2

5.0 Temp Var B

6.0 Humidity A

7.0 Shock/Crash E

8.0 Vibration R

Vibration Curve C or C1

15.0 Magnetic Effect A

16.0 Power Input A

Harmonics H

17.0 Voltage Spike A

18.0 Conducted Audio Susceptibility K(CF),

K(NF),

K(WF)

19.0 Induced Signal Susceptibility CC

20.0 RF Susceptibility T

21.0 RF Emissions T

Installation Maintenance Manual

FMHPA 82166

2-8

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

THIS PAGE INTENTIONALLY BLANK

Installation Maintenance Manual

FMHPA 82166

2-9

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

Figure 2.1 FMHPA Overall Dimensions

R3.27 MAXI

(0.13”)

50.9MAXI

(2”)

54.61MAXI

(2.15”)

R1.87 MAXI

(0.07”)

45.8 +/- 0.4

(1.8)

6.35

(0.25”)

14 +/-0.5

(0.551” +/-0.2”)

85.4 +/-2

(3.362” +/-0.079”)

277MAXI

(10.906”)

237MAXI

(9.331”)

TOP

118.5+/-2

(4.665”+/-0/079”)

18 MINI

(0.709”) 65 MAXI

(2.559”)

136.5 MAXI

(5.374”)

158 MAXI

(6.22”)

BOTTOM

159MAXI

(6.26”)

Drawn Air Flow

284.2

(11.189”)

279.5 MAXI

(11.004”)

19.5 MINI

(0.768”)

59 MAXI

(2.323”)

16 MAXI

(0.63”)

79

(3.11”)

150

(5.91”)

30

(1.18”)

CENTER OF GRAVITY

30MAXI

(1.181”)

8MINI

(0.315”)

13.5 MAXI

(0.531”) 36 MAXI

(1.417”)

INTERFACE PC BOARD

120 MAXI

(4.724”)

328.5 MAXI

(12.933”)

299 MAXI

(11.772”) 279 MINI

(10.984”)

HPA

POWER SUPPLY

70

(2.76”)

0.5MINI

(0.0197”)

6.75+/-).1

(0.266”+/-0.004”)

30 MINI

(1.181”)

162.58

(6.4”)

39+/-10

(1.54”+/-0.39”)

5+/-10

(0.2”+/-0.39”)

J2

RF IN (50 ohms)

INTERFACE SERIES TNC SOCKET

CONTACT

J3

RF OUT (50 ohms)

INTERFACE SERIES N SOCKET

CONTACT

116.8

(4.598”)

39.5

(1.56”) DRAWN AIR FLOW

AREA

121.3

(4.776”)

54.25

(2.136”)

80MAXI

(3.15”)

37.5

(1.476”)

MAJOR KEY

J1

55 MAXI

(2.165”)

56 MINI

(2.2”)

160

(4.59”)

NOTE: MAXIMUM PERMISSIBLE TIGHTENING TORQUE OF ATTACHMENT SCREWS = 5.3 N.m (3.9 lbf.ft)

Installation Maintenance Manual

FMHPA 82166

2-10

Jul 2008

© THALES AVIONICS Ltd. This document and any

information included are the property of Thales Avionics.

They cannot be reproduced, disclosed or utilized without the

company’s prior written approval

THIS PAGE INTENTIONALLY BLANK

Table of contents