The Armstrong Monitoring Corporation AMC-400 Series User manual

AMC-400

Series

Digital Transmitter

with Smart Sensor

2

USER MANUAL

IMPORTANT:

Please read the installation and operating instructions completely and

carefully before starting.

Filename: 3476405D.doc Revised June 12,2017

Copyright ©,Aug 31 2016, AMC

The Armstrong Monitoring Corporation

215 Colonnade Road South, Ottawa, Ontario, Canada K2E 7K3

Tel: (613) 225-9531 • Fax: (613) 225-6965 • Canada & U.S. Toll Free: 1-800-465-5777

AMC-400 Series Digital Transmitter with Smart Sensor 2

ii

.

AMC-400 Series Digital Transmitter with Smart Sensor 2

iii

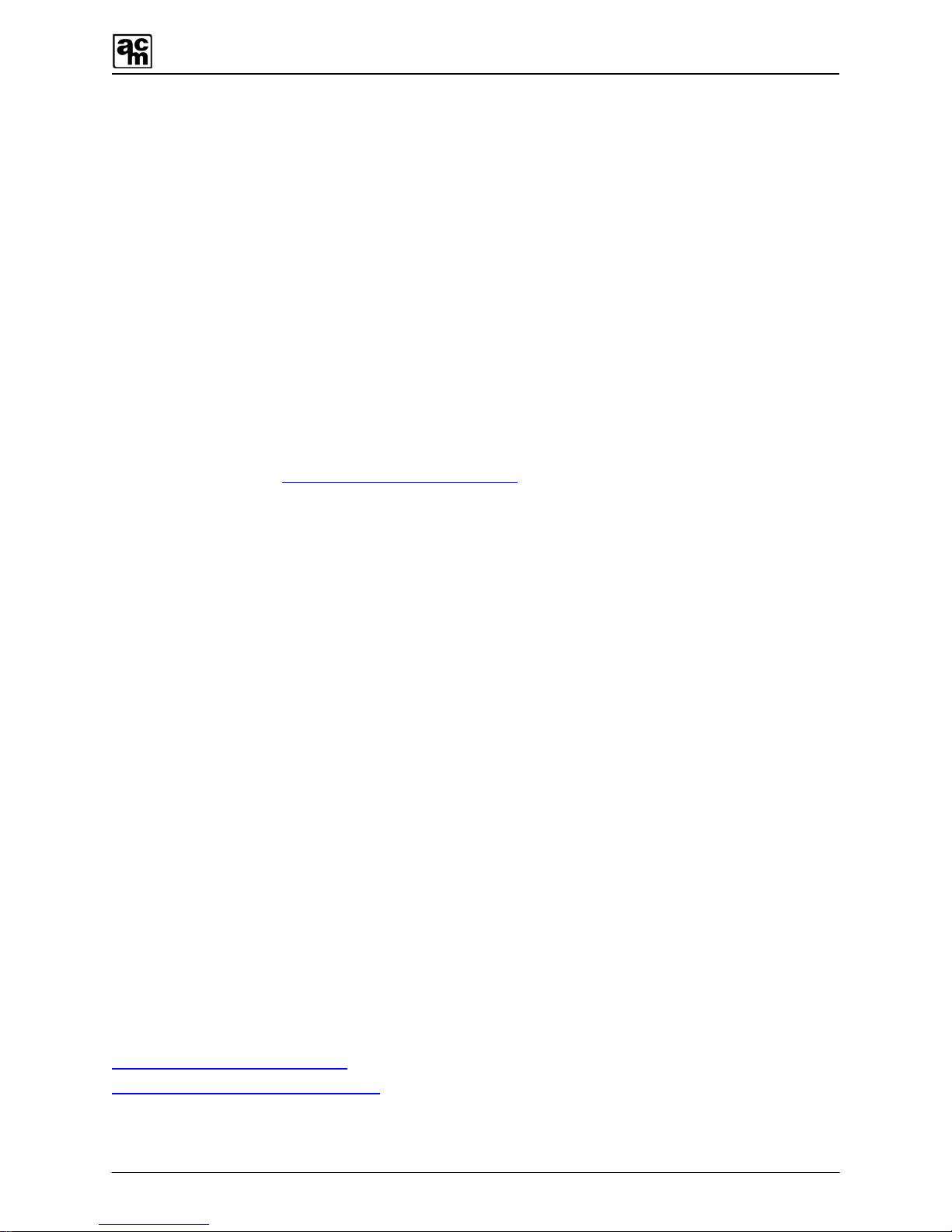

TABLE OF CONTENTS

Section Title Page

1GENERAL INFORMATION......................................................................................1

1.1WARRANTY.......................................................................................................1

1.2LIABILITY...........................................................................................................1

1.3PRODUCT RETURN .........................................................................................1

1.4CONTACT INFORMATION................................................................................1

1.5MODIFICATIONS AND SUBSTITUTIONS.........................................................2

1.6GLOSSARY .......................................................................................................3

2PRODUCT INFORMATION......................................................................................5

2.1.1AMC-400 DIGITAL TRANSMITTER SPECIFICATION...........................................5

2.1.2SMART SENSOR 2 MODULE(S) SPECIFICATION...............................................6

3PRODUCT DESCRIPTION ......................................................................................9

3.1OVERVIEW........................................................................................................9

3.2FRONT LID OVERVIEW..................................................................................10

3.3REAR LID OVERVIEW ....................................................................................11

3.4SMART SENSOR 2 MODULE WITH ELECTROCHEMICAL SENSOR

OVERVIEW................................................................................................................13

3.5SMART SENSOR 2 MODULE WITH CATALYTIC SENSOR OVERVIEW......14

3.6CATALYTIC SENSOR CHARACTERISTICS...................................................15

3.6.1CONTAMINANTS..................................................................................................15

3.6.2CROSS SENSITIVITY...........................................................................................15

3.6.3MAXIMUM RANGE...............................................................................................16

3.6.4ALARM RECOMMENDATIONS............................................................................16

4INSTALLATION .....................................................................................................17

4.1LOCATION AND MOUNTING..........................................................................17

4.1.1ENCLOSURE MOUNTING AND ORIENTATION .................................................18

4.2WIRING............................................................................................................18

4.2.1.1AMC-1DBx Digital Monitor Wiring Details......................................................21

4.2.1.2POWER SUPPLY ..........................................................................................22

4.2.1.3COMMUNICATION........................................................................................24

5OPERATION AND CALIBRATION........................................................................25

5.1OPERATION....................................................................................................25

5.1.1TRANSMITTER JUMPER.....................................................................................25

5.1.2TRANSMITTER AND SMART SENSOR 2............................................................25

5.1.3TRANSMITTER STATUS LED..............................................................................28

5.1.4TROUBLESHOOTING MODBUS USING THE TRANSMITTER STATUS LED...29

5.1.5SENSOR STATUS LED........................................................................................30

5.2INITIAL CONFIGURATION..............................................................................31

5.3CALIBRATION.................................................................................................32

5.3.1REQUIRED EQUIPMENT; EXCHANGE PROGRAM ...........................................34

5.3.2REQUIRED EQUIPMENT; ON-SITE CALIBRATION............................................34

5.3.3CALIBRATION PROCEDURE ..............................................................................34

5.3.4GAS TEST AND SERVICE MODES.....................................................................36

5.4SPECIAL CONFIGURATION FOR SERVICE..................................................37

6MAINTENANCE.....................................................................................................39

AMC-400 Series Digital Transmitter with Smart Sensor 2

iv

6.1GENERAL........................................................................................................39

6.2SCHEDULED CALIBRATION..........................................................................39

6.3SMART SENSOR 2 MODULE REPLACEMENT .............................................39

6.4VERIFICATION OF OPERATION....................................................................39

7APPENDIX: DIGITAL TRANSMITTER CONFIGURATION MENU FLOW............40

8APPENDIX: DIGITAL TRANSMITTER CALIBRATION MENU FLOW..................41

9APPENDIX: USER SUPPORTED MENU GUIDE..................................................42

10APPENDIX: MODBUS REGISTER MAP............................................................48

LIST OF FIGURES

Figure Title Page

Figure 3-1 Front Lid View............................................................................................................10

Figure 3-2 Rear Lid View............................................................................................................11

Figure 3-3 Smart Sensor 2 Module with Electrochemical Sensor View......................................13

Figure 3-4 Smart Sensor 2 Module with Catalytic Sensor View..................................................14

Figure 4-1 Enclosure Mounting and Orientation.........................................................................18

Figure 4-2 Example of Electrical Wiring of Digital Transmitter(s) ...............................................19

Figure 4-3 Example of connections to a 120VAC AMC-1DB1-1XXXXX Digital Monitor.............20

Figure 4-4 5 Example of connections to a 24VDC AMC-1DB1-2XXXXX configuration..............23

Figure 5-1 Front Panel User Interface ........................................................................................27

LIST OF TABLES

Table 3-1 Cross Sensitivity.........................................................................................................16

Table 4-1 Maximum number of sensor on a string limited by drop out voltage...........................22

AMC-400 Series Digital Transmitter with Smart Sensor 2

1

1GENERAL INFORMATION

1.1 WARRANTY

The AMC-400 Digital Transmitter is warranted against defects in material and workmanship for

a period of two years from date of delivery. Maintenance items are not warranted. During the

warranty period, The Armstrong Monitoring Corporation will repair or replace components that

prove to be defective in the opinion of AMC. Any equipment deemed to be defective by the user

should be returned to The Armstrong Monitoring Corporation for evaluation (see product return

below). Site visits by Armstrong personnel, to evaluate/repair equipment, are not covered by

this warranty unless covered under site contract. AMC is not liable for auxiliary interfaced

equipment, nor for consequential damage. This warranty shall not apply to any product, which

has been modified in any way, which has been repaired by any other party other than a qualified

technician or authorized AMC representative, or when failure is due to misuse or conditions of

use.

Note: extended warranty mail in calibration programs are available (please call 1-800-465-5777)

or through contacts at www.armstrongmonitoring.com

1.2 LIABILITY

All AMC products must be installed and maintained according to instructions. Only qualified

personnel should install and maintain the equipment. The AMC-400 Digital Transmitter must not

be located in hazardous locations where combustible gases could exceed 100% LEL.

AMC shall have no liability arising from auxiliary interfaced equipment, for consequential

damage, or the installation and operation of this equipment. AMC shall have no liability for labor

or freight costs, or any other costs or charges in excess of the amount of the invoice for the

products.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

AND SPECIFICALLY THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE

DESCRIPTION ON THE FACE THEREOF.

1.3 PRODUCT RETURN

All products returned for warranty or service should be shipped by prepaid freight and will be

accepted only with RMA or repair number issued by AMC. All products returned to the client will

be shipped by freight collect.

1.4 CONTACT INFORMATION

For information please call 1-800-465-5777 or through contacts at

www.armstrongmonitoring.com or through email directly at

AMC-400 Series Digital Transmitter with Smart Sensor 2

2

1.5 MODIFICATIONS AND SUBSTITUTIONS

Due to an ongoing development program, AMC reserves the right to substitute components and

change specifications at any time without incurring any obligations.

AMC-400 Series Digital Transmitter with Smart Sensor 2

3

1.6 GLOSSARY

Alarm Alarm is an audible, visual, or physical

presentation designed to warn the instrument user

that a specific level of a dangerous gas/vapor

concentration has been reached or exceeded.

Calibration Calibration is the procedure used to adjust the

instrument for proper response.

Calibration Gas Calibration Gas is a gas of known

concentration(s) used to set the instrument span.

Catalytic needs air for calibration.

DT Digital Transmitter

Gas Concentration Gas Concentration is measured in:

PPM

%LEL (Lower Explosive Limit)

LEL Lower explosive limit is the lowest concentration

(percentage) of a gas or a vapor in air capable of

combusting in the presence of an ignition source

(arc, flame, heat).

PPM Parts Per Million (1% volume = 10,000PPM)

Percent by volume Concentration of gas in a mixture expressed as a

percentage of total volume.

RS-485 Superseded with EIA-485 or TIA-485. This

standard defines the electrical characteristics of

drivers and receivers for use in balanced digital

multipoint systems.

Span Full range of a sensor i.e. a CO sensor with a full

range of 0-100 PPM has a 100 PPM span.

T90 Response Time in seconds to achieve 90% gas

concentration reading. This a typical calibration

point that allows for sensor aging, but tends to be

less accurate than a T99 calibration,

T99 Response Time in seconds to achieve 99% gas

concentration reading. This is a more accurate

calibration point.

Zero Buffering Zero buffering is transmitter function which

forces the gas concentration reading to zero when

sensor is exposed to low concentration of a gas.

The zero buffer is indicated in the sensor

specification.

Zero Gas Zero gas is gas in which the target gas is not

present. The presence of oxygen is required.

Clean air is an excellent source for zero

calibration. A known gas concentration can be

entered during zero calibration.

AMC-400 Series Digital Transmitter with Smart Sensor 2

4

AMC-400 Digital Transmitter This refers to a complete AMC-400 unit

including the Smart Sensor 2 module

Smart Sensor 2 Module (SS2) This refers to a Smart Sensor 2 Card with one of

the following sensor mounted: CO, NO2, CH4,

C3H8, H2

AMC-1DA-RPT4 and AMC-1DA-RPT 4 Port and 1 port Repeaters used to expand

system and provide extra device distance.

AMC-400 Series Digital Transmitter with Smart Sensor 2

5

2PRODUCT INFORMATION

The AMC-400 Series Digital Transmitter with Smart Sensor 2 consists of 2 circuit card

assemblies which are the Transmitter card and the Smart Sensor 2 card. Both cards have

Microcontroller (MCUs) to manage and communicate the information in a digital format. The

Transmitter communicates with a monitor (i.e. AMC-1DBx) and carries the Smart Sensor 2

module. The monitor and transmitter communicate to each other over RS-485 using

MODBUS/RTU. The Smart Sensor 2 module acquires data from either an electrochemical gas

sensor or a catalytic sensor and communicates its gas concentration to the transmitter. The

Smart Sensor 2 module consists of the Smart Sensor 2 card and a sensor and is replaced as a

unit. This module is designed for EZ-CAL calibration exchange program.

Note:

All Armstrong Monitoring systems must be installed and maintained according to

instructions to assure proper operation. Only qualified personnel should install and

maintain the equipment. For exchange, re-calibration or extended warranty programs

information please call 1-800-465-5777 or through contacts at

www.armstrongmonitoring.com

2.1.1 AMC-400 DIGITAL TRANSMITTER SPECIFICATION

AMC-400 Digital Transmitter Order Number... AMC-400-CO,

AMC-400-NO2, AMC-400-CH4,

AMC-400-C3H8, AMC-400-H2

Power Supply Requirement…Electrochemical

Catalytic 12-24 VDC 50mA

12-24 VDC 55-90mA

Warranty…………………………………………. 2 Years

Operating Temperature ………Electrochemical

Catalytic -20° to 40° C

Operating Pressure …………………………… 0.9 to 1.1 atm

Relative Humidity ……………………………… 15 to 90% RH, non-condensing

Signaling………………………………………… MODBUS RTU over RS-485

9600 Baud, 8bit Even Parity.

*Note 1:

To ensure proper operation of the AMC-400 Digital Transmitter, the voltage at the V+

test point shown in Fig 3-2 must be between 9.8 and 42 Volts for electrochemical

sensors and 10.5 to 42 Volts for Catalytic Sensors. This V+ Test Point is to be used by

service technicians only. Typical Power Supply recommended is 24V DC. Since

Catalytic sensors draw higher currents with lower operating voltage to improve system

performance place catalytic sensors as close to the power supply as possible.

AMC-400 Series Digital Transmitter with Smart Sensor 2

6

2.1.2 SMART SENSOR 2 MODULE(S) SPECIFICATION

Gas Type………………………………….….….. CARBON MONOXIDE (CO)

Smart Sensor 2 Module Order Number….…… AMC-91JGF

Operating Temperature ……………………… -20° to 40° C

Sensor Height Above Finished Floor (as part

of AMC-400 Digital Transmitter) 4-6 Feet (1.22-1.52m)

Sensor Life…….………………………………… Greater than 6 Years

Sensor Warranty……………………………….. 3 Years

Range …………………………...…………… 0-100ppm

Zero Buffering of Display…………………….. <5ppm

Calibration Kit Part Number………………….. AMC-C1-FK1 (See note)

Default Calibration Gas………………………. 100ppm CO

Gas Flow Rate………………………………….. .5L/min.

Gas Type………………………………….….….. CARBON MONOXIDE (CO) HC

Smart Sensor 2 Module Order Number….…… AMC-91JGG

Operating Temperature ……………………… -20° to 40° C

Sensor Height Above Finished Floor (as part

of AMC-400 Digital Transmitter) 4-6 Feet (1.22-1.52m)

Sensor Life…….………………………………… Greater than 6 Years

Sensor Warranty……………………………….. 3 Years

Range …………………………...…………… 0-200ppm

Zero Buffering of Display…………………….. <5ppm

Calibration Kit Part Number………………….. AMC-C1-FK1 (See note)

Default Calibration Gas………………………. 100ppm CO

Gas Flow Rate………………………………….. .5L/min.

AMC-400 Series Digital Transmitter with Smart Sensor 2

7

Gas Type………………………………….….….. NITROGEN DIOXIDE (NO2)

Smart Sensor 2 Module Order Number……… AMC-98JCC

Operating Temperature ………………………. -20° to 40° C

Sensor Height Above Finished Floor(as part of

AMC-400 Digital Transmitter) 4-6 Feet (1.22-1.52m)

Sensor Life…….………………………………… Greater than 2 Years

Sensor Warranty……………………………….. 1 Years

Range ………………………………………… 0-10ppm

Zero Buffering of Display…………………….. <0.8ppm

Calibration Kit Part Number…………… AMC-C1-FK2 (See note)

Default Calibration Gas………………………. 3 ppm NO2

Gas Flow Rate………………………………….. .5L/min.

Gas Type………………………………….….….. Methane(CH4)

Smart Sensor 2 Module Order Number……… AMC-60JAF

Operating Temperature ………………………. -20° to 40° C

Sensor Height Place 18” (20.32 cm) down from the top of

the ceiling

Do not mount directly to ceiling.

Sensor Life…….………………………………… 2 Years

Sensor Warranty……………………………….. 1 Year

Range ………………………...…………… 0 to <100% LEL (<5% vol.)

Zero Buffering of Display…………………….. <5% LEL

Calibration Kit Part Number…………… AMC-C1-FK2 (See note)

Default Calibration Gas………………………. 50% LEL CH4

Gas Flow Rate………………………………….. .5L/min.

AMC-400 Series Digital Transmitter with Smart Sensor 2

8

Gas Type………………………………….….….. Propane(C3H8)

Smart Sensor 2 Module Order Number……… AMC-61JAF

Operating Temperature ………………………. -20° to 40° C

Sensor Height Place 18” (20.32 cm) up from the bottom of

the floor

Do not mount directly to floor.

Sensor Life…….………………………………… 2 Years

Sensor Warranty……………………………….. 1 Year

Range ………………………...…………… 0 to <100% LEL (<2.0% vol.)

Zero Buffering of Display…………………….. <5% LEL

Calibration Kit Part Number…………… AMC-C1-FK2 (See note)

Default Calibration Gas………………………. 50% LEL C3H8

Gas Flow Rate………………………………….. .5L/min.

Gas Type………………………………….….….. Hydrogen(H2)

Smart Sensor 2 Module Order Number……… AMC-62JAF

Operating Temperature ………………………. -20° to 40° C

Sensor Height Place 18” (20.32 cm) down from the top of

the ceiling

Do not mount directly to ceiling.

Sensor Life…….………………………………… 2 Years

Sensor Warranty……………………………….. 1 Year

Range ………………………...…………… 0 to <100% LEL (<4% vol.)

Zero Buffering of Display…………………….. <5% LEL

Calibration Kit Part Number…………… AMC-C1-FK2 (See note)

Default Calibration Gas………………………. 25% LEL H2

Gas Flow Rate………………………………….. .5L/min.

Note:ThecalibrationkitconsistsofaCalKitcase,acalibrationadapter,andaregulator.The

calibrationgasisorderedseparately.

AMC-400 Series Digital Transmitter with Smart Sensor 2

9

3PRODUCT DESCRIPTION

The AMC-400 Digital Transmitter is designed to provide continuous, reliable monitoring of

ambient air for the target gas listed in the SMART SENSOR 2 MODULE(S) SPECIFICATION

(Section 2.1.2). The AMC-400 Digital Transmitter is hot pluggable and is powered by a DC

power source. It provides a digital representation of the gas concentration detected. A digital

representation of the gas concentration is displayed, which may be configured to remain blank.

Each AMC-400 Digital Transmitter is factory calibrated, and is ready for field installation and

operation.

Each AMC-400 Digital Transmitter features alarm indicators and connection terminal blocks, as

listed and described herein.

3.1 OVERVIEW

The AMC-400 Digital Transmitter consists of three main components;

PVC Enclosure,

Lid Assembly,

Smart Sensor 2 Module.

The following three drawings are provided to briefly describe these components.

AMC-400 Series Digital Transmitter with Smart Sensor 2

10

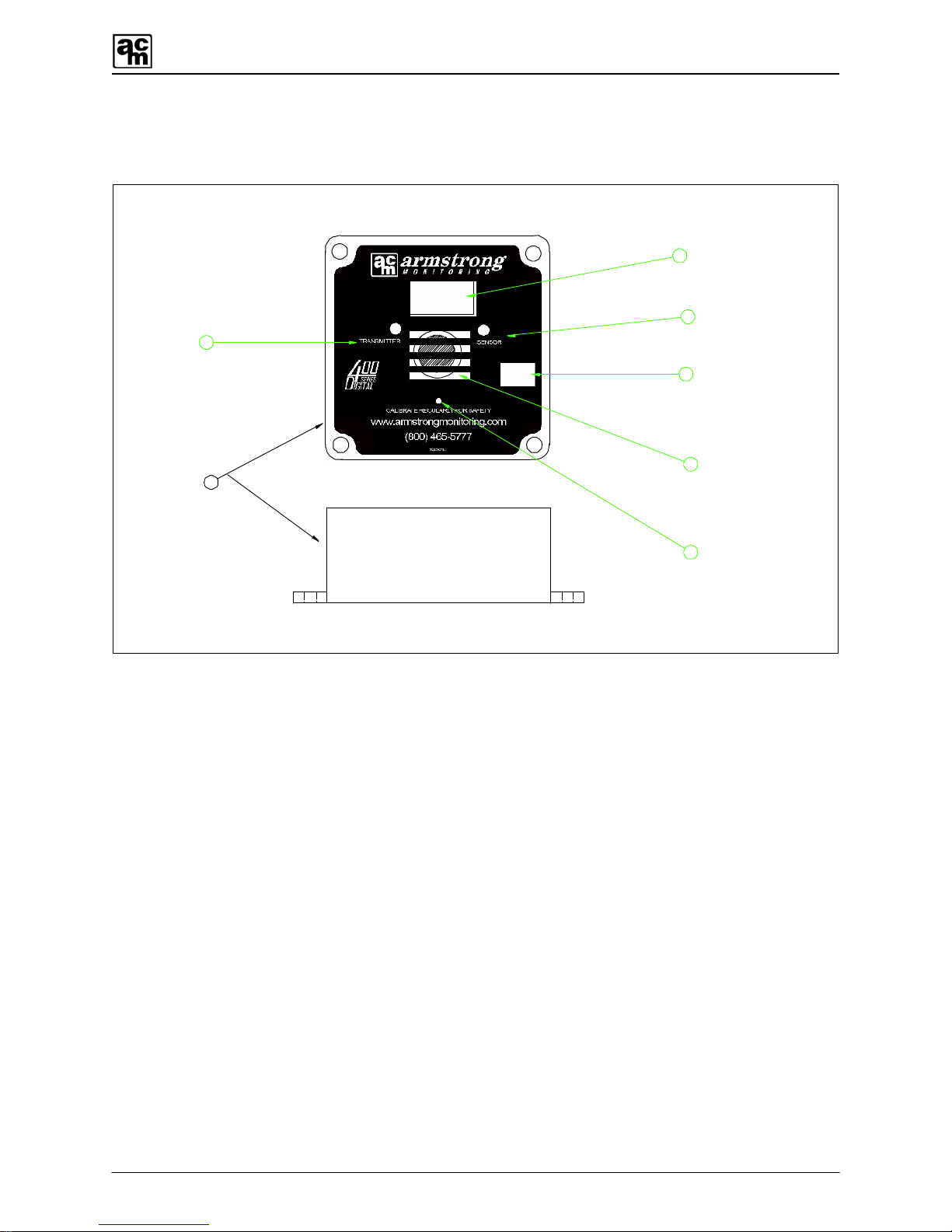

3.2 FRONT LID OVERVIEW

2

3

4

1

5

6

7

Enclosure

Display

Transmitter status

LED

Smart Sensor 2

status LED

Modbus Address

Sensor & Vent

Push button

Figure 3-1 Front Lid View

1. Enclosure: Enclosure and Lid Assembly, PVC 4”x4” Wall mount with

mount points. Enclosure Lid attaches with four screws.

2. Digital Display: Displays gas concentration & Status information, 3 Digit

User Interface for configuration

3. Transmitter Status LED: Red/Green LED

Indicates status of Transmitter.

4. Smart Sensor 2 Status LED: Red/Green LED

Indicates status of integral Smart Sensor 2.

5. MODBUS Address This is a write on area matching the MODBUS device ID

(Address). The indication here may be factory set and can

be changed as needed.

6. Sensor & Vent This vent allows target gas to flow into the sensor. The vent

is also used for gas calibration.

7. Pushbutton: Momentary On/Off Pushbutton

User Interface for Configuration.

AMC-400 Series Digital Transmitter with Smart Sensor 2

11

3.3 REAR LID OVERVIEW

GND VDD V+

8

9

10

11

RS485 A

RS485 B

CGND

SIG GND

+

Power and communication

connector

GND test point

VDD test point

V+ test point

Transmitter female connector

12

13

14

Smart Sensor 2 Termination

Modbus Termination

SS2 Board mounted

15

SS2 mounting hole

Transmitter board

SS2 board

Mounting Standoffs

Sensor

(connects to SS2 male connector)

-

Figure 3-2 Rear Lid View

Note:

When connecting the Smart Sensor 2 module, assure its male header pins are aligned

to mate the receptacle of the Digital transmitter.

Warning:

Care must be taken when connecting services to Power and Communication

Connector. Do not use SIG GND on AMC-400 for powering. Cable shield(s) are to be

connected to CGND. Mixing power and communication connections can cause

permanent damage. Consistent polarity of RS-485 wire is required throughout network

for proper system operation.

AMC-400 Series Digital Transmitter with Smart Sensor 2

12

8. Power and Communication

Connector: This 6 pin male plug connector contains both power and

communication network connection points. The power is

normally 24VDC and the communication network is

MODBUS over RS-485.

9. GND Test Point: This GND Test Point is to be used by service technicians

only with appropriate instrumentation such as a voltmeter. It

is the signal reference point for the digital transmitter control

logic.

10. VDD Test Point: This VDD Test Point is to be used by service technicians

only. It is the digital transmitter control logic supply voltage

and must be 5+/-5% Volts DC.

11. V+ Test Point: This V+ Test Point is to be used by service technicians only.

It is the digital transmitter rectified unregulated power input

and meet the range specified in 2.1.1 AMC-400 DIGITAL

TRANSMITTER SPECIFICATION.

12. SS2 Female Connector: This 7 pin connector mates with the Smart Sensor 2 Module

male connector. This connector carries the power and

communication for Smart Sensor 2.

13. Smart Sensor 2 Termination: Default position: AC Termination (Pins 1-2, bottom). This

termination allows AC or DC Termination for the Smart

Sensor 2 RS-485 signaling.

14. MODBUS Termination: Default position: No Termination (Pin 2) as shown in Figure

3-2. This termination allows AC or DC Termination for the

MODBUS RS-485 signaling. Use AC Termination (Pin 1-2,

bottom) when transmitter is an end point on bus.

15. SS2 Mounting Hole: This mounting hole contains two standoffs to support the

Smart Sensor 2 Module. One standoff is a stud the other is

nylon press-fit.

AMC-400 Series Digital Transmitter with Smart Sensor 2

13

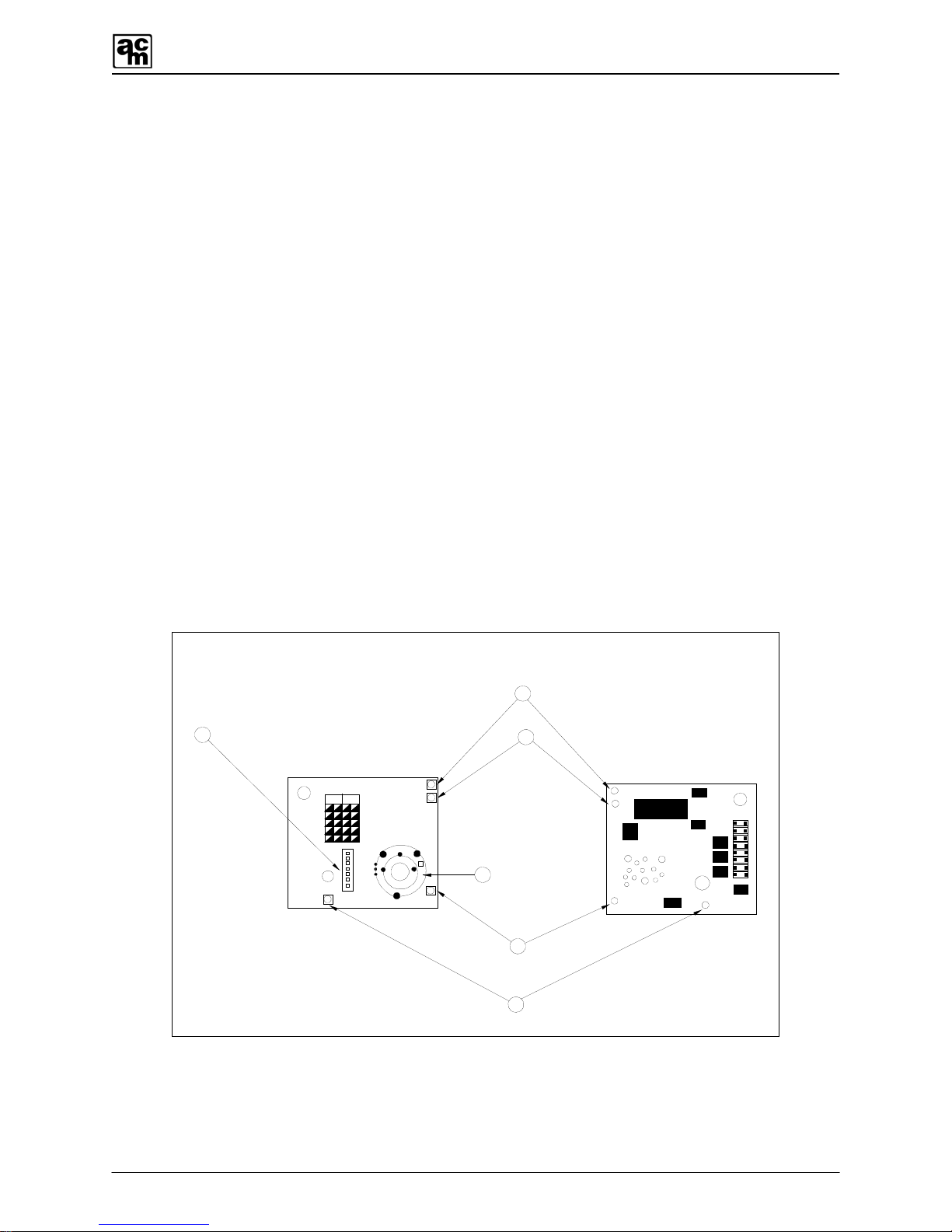

3.4 SMART SENSOR 2 MODULE WITH ELECTROCHEMICAL SENSOR

OVERVIEW

12345

67 89 0

REV

12 3 45

67890

VER

SNS1

SNS4

SNS2

SNS3

Smart Sensor 2 Board

16

SS2 male connector

Sensor Location

GND test point

VDD test point

VREF test point

CTR

SIG

Front Back

19

22

20

21

18

17

VDD

GND

SIG

VREF CTR

Figure 3-3 Smart Sensor 2 Module with Electrochemical Sensor View

16. SS2 Male Connector: This 7 pin connector mates with the Digital Transmitter

female connector. This connector carries the power and

communication.

17. VDD Test Point: This VDD Test Point is to be used by service technicians

only. It is the Smart Sensor 2 control logic supply voltage

and must be 5+/-5% Volts DC.

18. GND Test Point: This GND Test Point is to be used by service technicians

only with appropriate instrumentation such as a voltmeter. It

is the signal reference point for the Smart Sensor 2 control

logic.

AMC-400 Series Digital Transmitter with Smart Sensor 2

14

19. VREF Test Point: This VREF Test Point is to be used by service technicians

only. It is the potentiostat sensor reference and must be 1.8

Volts DC.

20. Sensor: This component may be a variety of 2 or 3 pin

electrochemical sensors. This component is permanently

fastened to the Smart Sensor 2 Module.

21. CTR Test Point: This CTR Test Point is to be used by service technicians

only with appropriate instrumentation such as a voltmeter. It

is the potentiostat counter output used by a 3 pin

electrochemical sensor. Under ideal operation zero gas

situation it is normally 1.8 Volts DC VREF.

22. SIG Test Point: This Sig Test Point is to be used by service technicians only

with appropriate instrumentation such as a voltmeter. It is

the potentiostat sensor output used. Under normal

operation zero gas situation it tracks the 1.8 Volts DC

VREF. When CO gas is applied this SIG Test Point

increases toward 3.6 Volts DC. When NO2 gas is applied

this SIG Test Point decreases towards 0 Volts DC.

3.5 SMART SENSOR 2 MODULE WITH CATALYTIC SENSOR

OVERVIEW

GND

VDD

VREF

SNS2

SNS3SNS1

Smart Sensor 2 Module with Catalytic Sensor

16

20

SS2 male connector

Sensor Location

GND test point

VDD test point

VREF

SIG

Front Back

REV

VER

1

23

45

67

89

01

23

45

67

89

0

SIG

SNS4

SNS5

SNS6 SNS7

TP3

TP1

TP2

TP4

19

test point

18

17

21

Figure 3-4 Smart Sensor 2 Module with Catalytic Sensor View

AMC-400 Series Digital Transmitter with Smart Sensor 2

15

16.SS2 Male Connector: This 7 pin connector mates with the Digital Transmitter

female connector. This connector carries the power and

communication.

17.VDD Test Point: This VDD Test Point is to be used by service technicians

only. It is the Smart Sensor 2 control logic supply voltage

and must be 3.45+/-5% Volts DC.

18.GND Test Point: This GND Test Point is to be used by service technicians

only with appropriate instrumentation such as a voltmeter. It

is the signal reference point for the Smart Sensor 2 control

logic.

19.VREF Test Point: This VREF Test Point is to be used by service technicians

only. It must be 1.8 Volts DC.

20.Sensor: This component is a 3 pin Catalytic sensor. This component

is permanently fastened to the Smart Sensor 2 Module.

21.SIG Test Point: This Sig Test Point is to be used by service technicians only

with appropriate instrumentation such as a voltmeter. It is

the amplified sensor output as seen by the analog to digital

converter. Under normal operation zero gas situation it

tracks the 1.8 +/- 0.4 Volts DC VREF. When a combustible

gas is applied this SIG Test Point increases toward 3.45

Volts DC.

3.6 CATALYTIC SENSOR CHARACTERISTICS

3.6.1 CONTAMINANTS

The performance of the catalytic combustion type gas sensors may be affected by exposure to

substances known as poisons and inhibitors. Inhibitors are present in volatile substances

containing halogens or sulphur compounds. Sensors may recover their sensitivity

characteristics after exposure to inhibitors has ceased. Some substances produce a permanent

poisoning effect on the catalyst. These poisons include silicone oils, greases and petroleum

additives such as tetraethyl lead and phosphate esters. Always be cautious of by products that

may evolve from the thermal decomposition of materials such as plastics.

3.6.2 CROSS SENSITIVITY

The catalytic sensor is also sensitive to other combustible gases. See Table 3-1. As a result the

sensor will provide protection for some of these gases as well.

AMC-400 Series Digital Transmitter with Smart Sensor 2

16

Gas Relative Sensitivity LEL (%vol)

Methane 100 5

Hydrogen 97 4

Ethylene 83 3

Propane 80 2

Butane 83 1.5

n-Pentane 71 1.5

Hexanes 63 1.2

Table 3-1 Cross Sensitivity

3.6.3 MAXIMUM RANGE

Although the sensor output is linear to 100%LEL, the use of catalytic sensors is not

recommended over that range. Above the LEL value there may be insufficient oxygen to

catalyze all of the combustible gas: the output may decrease and indicate a concentration of

less than 100% LEL, causing an ambiguity in the instrument reading.

3.6.4 ALARM RECOMMENDATIONS

The 400 Digital Transmitter equipped with a combustible catalytic sensor is designed for non

hazardous location with the primary purpose of initiating ventilation when low concentration of

combustible gases are detected (20-40%LEL). However, due to the dangers associated with

combustible gases we recommend setting an ‘ultra high’ latching alarm at level approaching the

LEL ie. 80% LEL.

Table of contents