The Bradley Collection GLIDERPOLE User manual

GLIDERPOLE®

THE BRADLEY

COLLECTION

INSTALLATION

INSTRUCTIONS

www.bradleycollection.com

thebradleycollection

Specialised fixings for mounting brackets will be required in certain situations and are not provided as standard.

Steel items are not recommended for damp conditions such as shower rooms.

Crystal finials and acrylic poles should not be positioned in direct sunlight, and are not suitable for use in conservatories.

Fluid Metal items are supplied unlacquered and will tarnish over time.

The Bradley Collection reserves the right to modify design and materials without prior notice as part of a process of continual product

improvement.

Products are protected by Design Rights, under provisions of Copyright, Designs & Patents Act 1988.

Bradley®, The Bradley Collection®and Logo are registered Community trademarks of The Bradley Collection Ltd. in Europe and

registered trademarks of the Bradley Collection, Inc. in the USA.

The Bradley Collection Ltd Lion Barn • Maitland Road • Needham Market • Suffolk • IP6 8NS • UK

UK & REST OF THE WORLD

+44 (0)1449 722 724

USA & CANADA

+1 (310) 815 8255

info.us@bradleycollection.com

CONTACT

Published: 1021 • Copyright © The Bradley Collection Ltd. 2022

2

Please do not use any solvent or chlorine based cleaners as this will damage the finish.

FIXINGS

As a courtesy we have supplied a set of fixings for the system.

These screws and wall plugs are designed to be used in wood and brick walls. We understand our sys-

tems may be used on a variety of materials; drywall, aluminim and steel stud, or lath and plaster.

To properly secure a system onto these or other types of surfaces; appropriate fixings must be inde-

pendently obtained.

Assess your own wall construction and source the appropriate screw type.

PLEASE NOTE, that the enclosed fixings may not be suitable for all wall types.

GLIDERPOLE®

INSTALLATION INSTRUCTIONS

THANK YOU FOR YOUR ORDER

Before fitting this product please ensure that you have thoroughly read these instructions.

We have taken every care to design and manufacture a quality system;

incorrect installation could lead to poor performance.

If any queries arise when reviewing these instructions or during installation please feel free to contact

us for assistance. We will be glad to talk you through the process.

Please retain these instructions for future reference.

SHARE YOUR INSTALL ON INSTAGRAM

TAG: @bradleycollection

Introduction Page 2

FIXINGS Page 2

TOOLS Page 2

CARE & MAINTENANCE Page 2

Flat & Round Gliderpoles Page 3-4

Square Gliderpoles Page 5-6

Alternative Brackets Page 7-8

Adding/Removing Gliders & Rollers Page 9

Corded Systems Page 10

TOOLS

For the installation of the system the following items may be required.

CARE & MAINTENANCE

This gliderpole can be cleaned using a soft cloth and furniture polish.

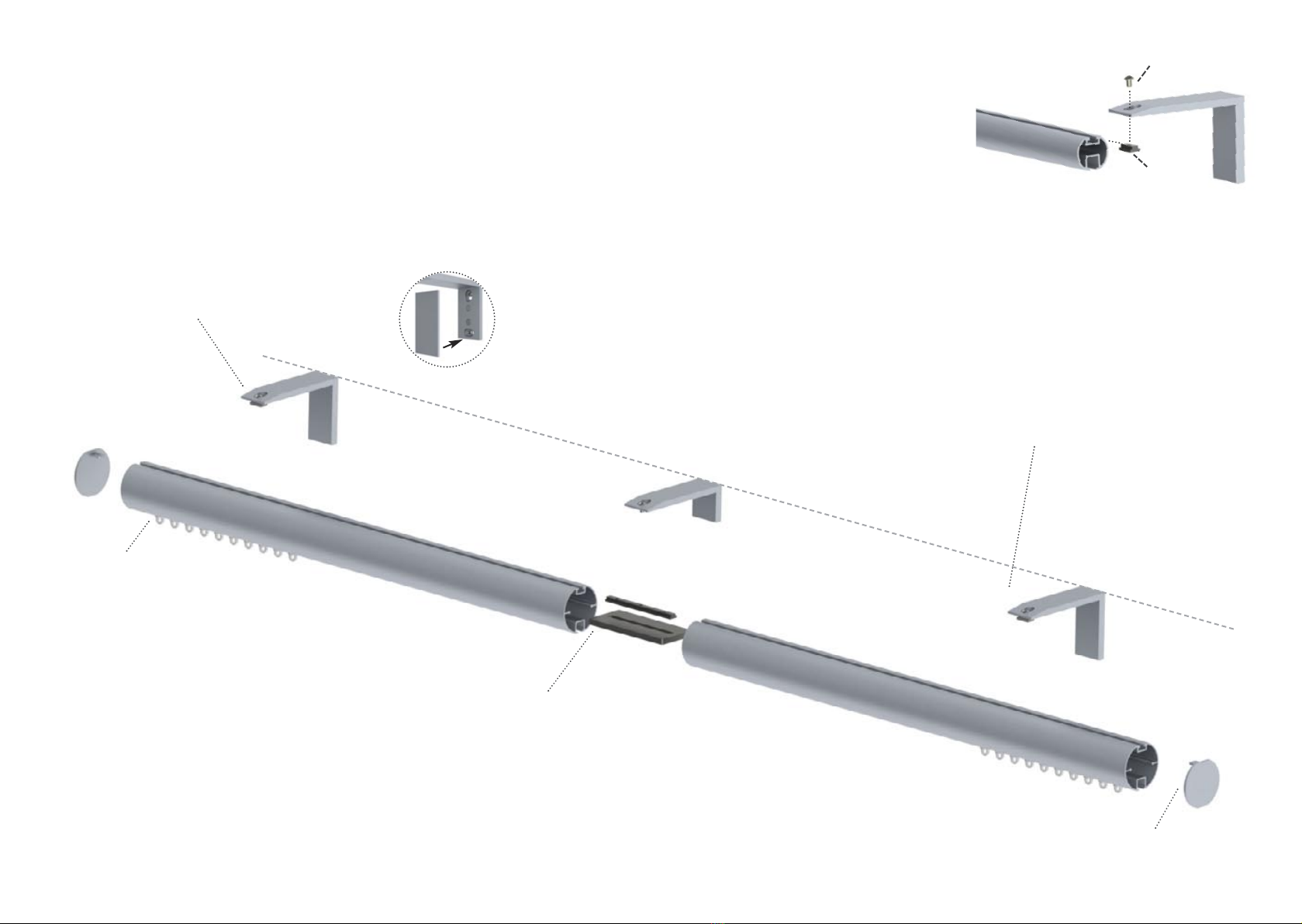

43

FINIALS

Attach the finials by pushing them into position

and tightening the set screws on the finial.

FITTING GLIDERPOLE TO THE BRACKETS

Offer the gliderpole up to the bracket, and tighten

the button head screw into the fixing insert, ensuring

that the pole is fully secured. Making sure that the

overhangs at each end are equal.

If the gliderpole is made of two connected lengths,

the mid bracket should be fitted on the join.

In this instance remove the fixing insert & screw

the button head screw directly into the joiner.

Fixing inserts are pre-installed into the poles.

Spare fixing inserts are supplied with the brackets.

GLIDERPOLE®FLAT POLE - H36mm (17

/

16”) Round pole - Ø30mm (13

/

16”) • 50mm (2”)

POSITIONING & FIXING

SINGLE & DOUBLE BRACKETS FOR ALTERNATIVE BRACKETS TYPES SEE PAGE 7-8

Brackets should be positioned approximately 100mm (4”) from the ends of the pole.

❶Mark the position of the brackets. For longer poles one or more mid bracket are required,

and should be equally spaced along the system.

PLEASE NOTE, Where systems are made in multiple sections.

Joins must be supported by a mid bracket, which must be fitted directly over the join.

To align the brackets, the top of the mid brackets should be fitted in line with the top of the side brackets.

❷Drill holes & use a suitable wall fixing when attaching the plate to the wall.

❸Screw each bracket into position.

Fit the cover plate, the cover is held in place by magnets.

BRACKET ALIGNMENT BRACKET ALIGNMENT

T-Bar

Button Head Screw

JOINING THE GLIDERPOLE

Gliderpoles are supplied pre-cut to your specified lengths, in

some cases the Gliderpole may be made in two or more parts,

joined by a connector.

Push the joiner* into the pole ends and push the gliderpoles

together. Tighten the set screws in the top channel of the profile.

PLEASE NOTE, All joins must be supported by a bracket.

If there is a gap between joins gliders/rollers may

not run efficiently.

* Internal joiner will vary between gliderpole type and diameter.

ADDING AND REMOVING

GLIDERS/ROLLERS

Gliderpoles are supplied with

gliders/rollers pre-installed, in some

instances it may be necessary to

add or remove gliders, to do this

follow the steps on page 9.

CLICK

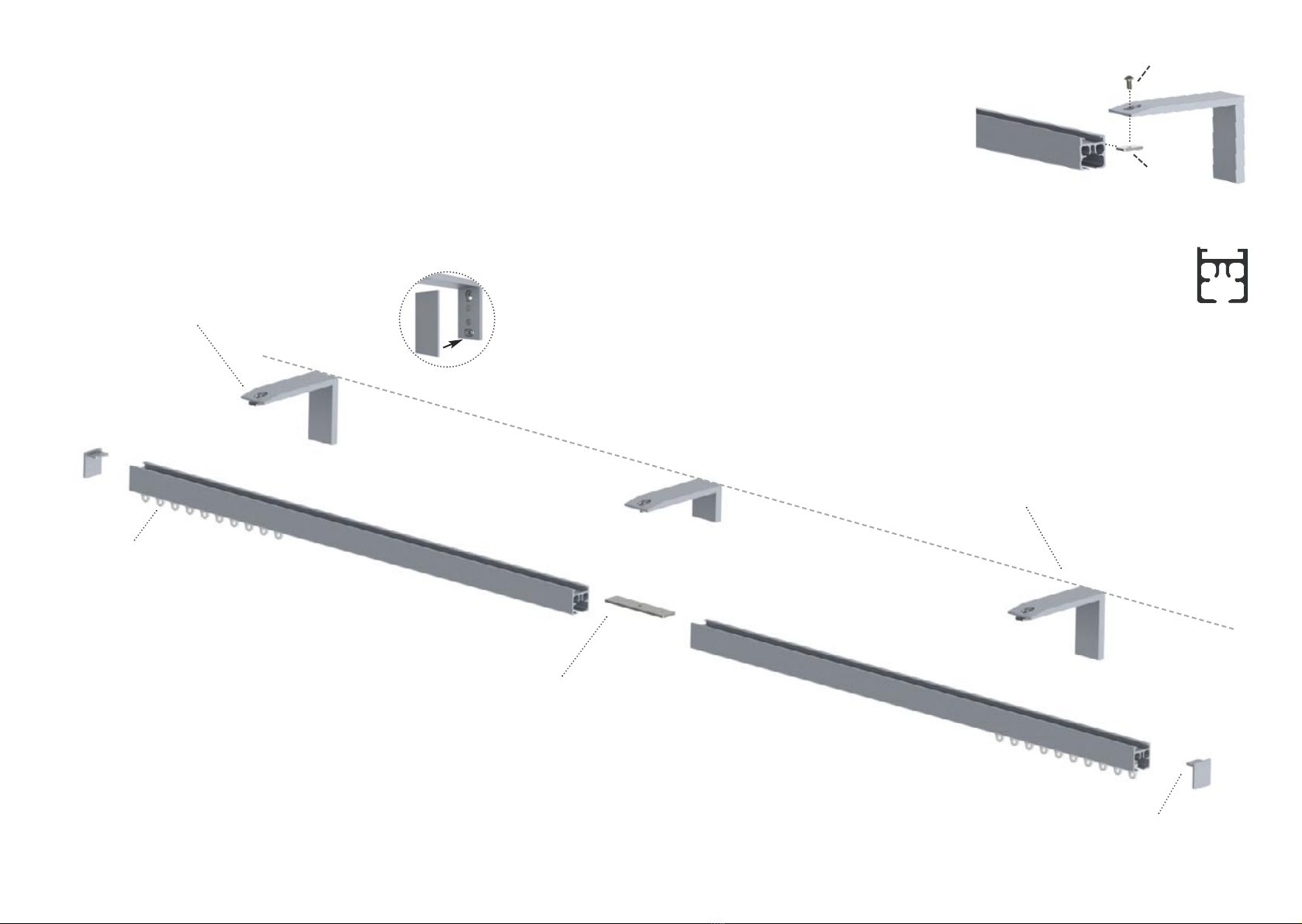

65

GLIDERPOLE®SQUARE POLE - H27mm (11

/

16”)

FINIALS

Attach the finials by pushing them into position

and tightening the set screws on the finial.

FITTING GLIDERPOLE TO THE BRACKETS

When fitting the track ensure the

higher edge of the profile is at

the front.

Offer the gliderpole up to the bracket, and tighten

the button head screw into the fixing insert, ensuring

that the pole is fully secured. Making sure that the

overhangs at each end are equal.

If the gliderpole is made of two connected lengths,

the mid bracket should be fitted on the join.

In this instance remove the fixing insert & screw

the button head screw directly into the joiner.

Fixing inserts are pre-installed into the poles.

Spare fixing inserts are supplied with the brackets.

JOINING THE GLIDERPOLE

Gliderpoles are supplied pre-cut to your specified lengths, in

some cases the Gliderpole may be made in two or more parts,

joined by a connector.

Push the joiner into the pole ends and push the gliderpoles

together. Tighten the set screws in the top channel of the pro-

file.

PLEASE NOTE, All joins must be supported by a bracket.

If there is a gap between joins gliders/rollers may

not run efficiently.

ADDING AND REMOVING

GLIDERS/ROLLERS

Gliderpoles are supplied with

gliders/rollers pre-installed, in some

instances it may be necessary to

add or remove gliders, to do this

follow the steps on page 9.

POSITIONING & FIXING

SINGLE & DOUBLE BRACKETS FOR ALTERNATIVE BRACKETS TYPES SEE PAGE 7-8

Brackets should be positioned approximately 100mm (4”) from the ends of the pole.

❶Mark the position of the brackets. For longer poles one or more mid bracket are required,

and should be equally spaced along the system.

PLEASE NOTE, Where systems are made in multiple sections.

Joins must be supported by a mid bracket, which must be fitted directly over the join.

To align the brackets, the top of the mid brackets should be fitted in line with the top of the side brackets.

❷Drill holes & use a suitable wall fixing when attaching the plate to the wall.

❸Screw each bracket into position.

Fit the cover plate, the cover is held in place by magnets.

BRACKET ALIGNMENT BRACKET ALIGNMENT

Fixing Insert

Button Head Screw

CLICK

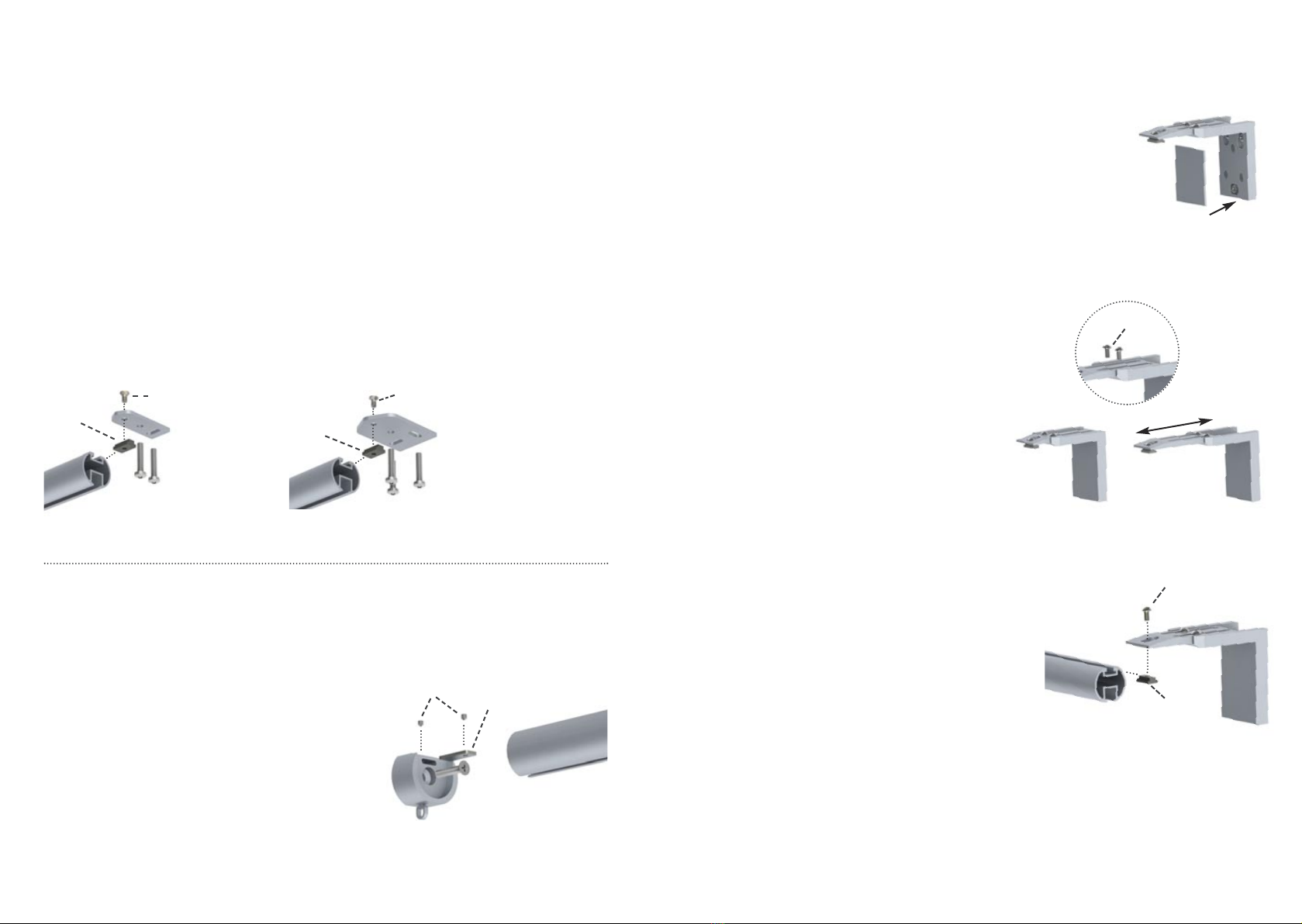

CEILING BRACKETS

Light Duty Ceiling Brackets - Suitable for use with Square • Flat • Round 30mm (13

/

16”) Gliderpoles

Heavy Duty Ceiling Brackets* - Suitable for use with all Gliderpole types

PLEASE NOTE, Bracket must be secured to the Gliderpole before being fitted to the ceiling.

All joins must be supported by a bracket.

Where gliderpoles join, substitute the T-bar/Fixing insert for a joiner.

87

ADJUSTABLE BRACKETS

❶Mark the position of the brackets.

For longer poles a mid bracket is required.

❷Drill holes & use a suitable wall fixing when

attaching the plate to the wall.

❸Screw each bracket into position.

Fit the cover plate, the cover is held in place by

magnets.

❺Screw in the button head screws into the bracket

arm and slide to the desired projection, once the

projection is set tighten the screws to ensure the

bracket arm is firmly secure.

❻Offer the gliderpole up to the bracket, and tighten

the button head screw into the t-bar, ensuring that

the pole is fully secured.

PLEASE NOTE, All joins must be supported by

a bracket. where poles join, substitute the

T-bar/Fixing insert for a joiner.

GLIDERPOLE®ALTERNATIVE BRACKETS

❶Mark the position of the brackets.

❷Drill holes.

❸Locate T-bar/Fixing insert into the top of the pole & tighten the counter sunk screw.

❹Screw each bracket into position, using suitable fixings.

RECESS BRACKETS

PLEASE NOTE, Not suitable for use with ceiling brackets

❶Mark the position of the brackets.

❷Drill holes & use a suitable wall fixing when attaching

the plate to the wall.

❸Screw each bracket into position.

Slide the locking tab inside the top of the pole up

in to the fix plate.

❺Tighten the set screws in both the top of the bracket

and top channel of the pole.

T-Bar/

Fixing Insert

Counter Sunk Screw

T-Bar/

Fixing Insert

Counter

Sunk Screw

Locking Tab

Set Screw

LIGHT DUTY CEILING BRACKET* HEAVY DUTY CEILING BRACKET

* 50mm (2”) Gliderpole not suitable for use with the Light Duty Ceiling Bracket

T-Bar/

Fixing Insert

CLICK

Button Head Screws

Button

Head

Screws

Table of contents

Other The Bradley Collection Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual