The Loudspeaker Kit M4S User manual

Assembly manual M4S Kit

2

You will need:

•Phillips head screwdriver

•Woodworking glue

•Damp cloth

•Good quality masking tape

•Ratchet tie down strap (optional)

•Brick or other weight (optional)

Preparation

Lay the contents of the box out and check you have everything you need to complete the kit

(see parts list on back page). Find a suitable work surface and make sure it won’t be ruined if

you spill some glue. If covering the work surface, avoid using newspaper as newsprint may rub

off onto your kit. Baking paper is a good choice.

Easier assembly with mitres

LSK kits now employ mitre construction, which offers greater ease of assembly with much less

sanding. Butt joints are eliminated, avoiding visible hairline cracks that often appear after

painting. Mitre construction puts the join right on the edge where it is less visible. Most

constructors avoid using mitres due to the difficulty in getting the angles correct. Our

manufacturing process provides a level of accuracy that is very difficult to achieve in a home

workshop.

Assembly manual M4S Kit

3

Masking tape

We recommend avoiding cheap masking tape, which tends to break when applied under

tension. If you aren’t using the weight and ratchet strap, you are relying on the masking tape

along to apply pressure to the join as the glue sets.

Lay out the rear, side, top and bottom panels as shown with mitres facing the work surface.

Align carefully and arrange so that all panels are touching at the edges, with no gaps.

Tape all four joints where the rear panel meets the side and top panels. It’s a good idea to

avoid covering the corners so that you can ensure all panels remain aligned during taping.

Lift the panels using the hole for the terminals, turning them over to the other.

Assembly manual M4S Kit

4

Tip: placing masking tape as shown assists with folding up the panels.

Apply a bead of wood working glue to the bottom of the mitre join. Then apply a second bead.

Since the glue will tend to run down towards the bottom, it’s a good idea to apply the glue

above half way up to ensure even coverage.

Assembly manual M4S Kit

5

Confirm the amount of glue applied by folding up the first panel. The glue should cover the

entire surface in contact. It’s preferable to see the glue ooze beyond the join slightly. This

provides visual feedback on whether the glue has set. Once set, PVA glue becomes

transparent.

Assembly manual M4S Kit

6

Apply a single thick bead for the top and side panels. Test the first pair of mitres to confirm

glue coverage, then glue and fold up all the other panels. It is best to fold up and then tape one

join at a time. Ensure the glue covers the join before moving on to the next step.

Assembly manual M4S Kit

7

Ensure the front baffle has the correct orientation. The port on the front and terminals on the

back should be oriented so they are both on the bottom. In the picture above they are both on

the right as the speaker is placed on its side.

Apply a thick glue bead around the internal surfaces of the mitres. You may prefer a zig zag

pattern with a thinner bead. It’s a good idea to remove the panel and confirm even coverage.

Assembly manual M4S Kit

8

Once you have confirmed adequate glue coverage, press the baffle into place and wipe off all

excess glue with a damp cloth. Secure panels firmly with masking tape. Apply pressure when

pressing the tape into position. The tape holds the panels together as the glue sets.

Cover all joins with tape, as shown below. An optional step for improved clamping pressure is

securing top, bottom and side panels together with a tie down ratchet strap. Avoid damage to

the surface of the MDF by placing cardboard strips under the straps at all four corners. Be

careful to avoid applying too much force, which can damage the corners of the MDF.

Assembly manual M4S Kit

9

Place a cardboard protector on top of the baffle then a brick on top to apply pressure.

We don’t recommend using F clamps due to the risk of forcing panels apart. The advantage of

using a brick is that this avoids the temptation to use excessive force.

Drying time

Typical wood glues can achieve moderate strength in as little as 30 minutes. If you are using

PVA glue then a good indicator that it has set is the transparency. PVA becomes transparent

once set. Ideally it’s best to leave the enclosure clamped over night before moving on to

assembly or finishing.

Grille assembly

This kit uses a clever neo magnet attachment system that avoids the use of traditional grille

clips. Flat packs contain neo magnets which have been concealed in the front baffle and grille.

Sequence tip

Final assembly should be done after you have applied

your chosen finish. Otherwise, drivers and terminals

will get damaged and the internal lining will be

covered in MDF dust.

Assembly manual M4S Kit

10

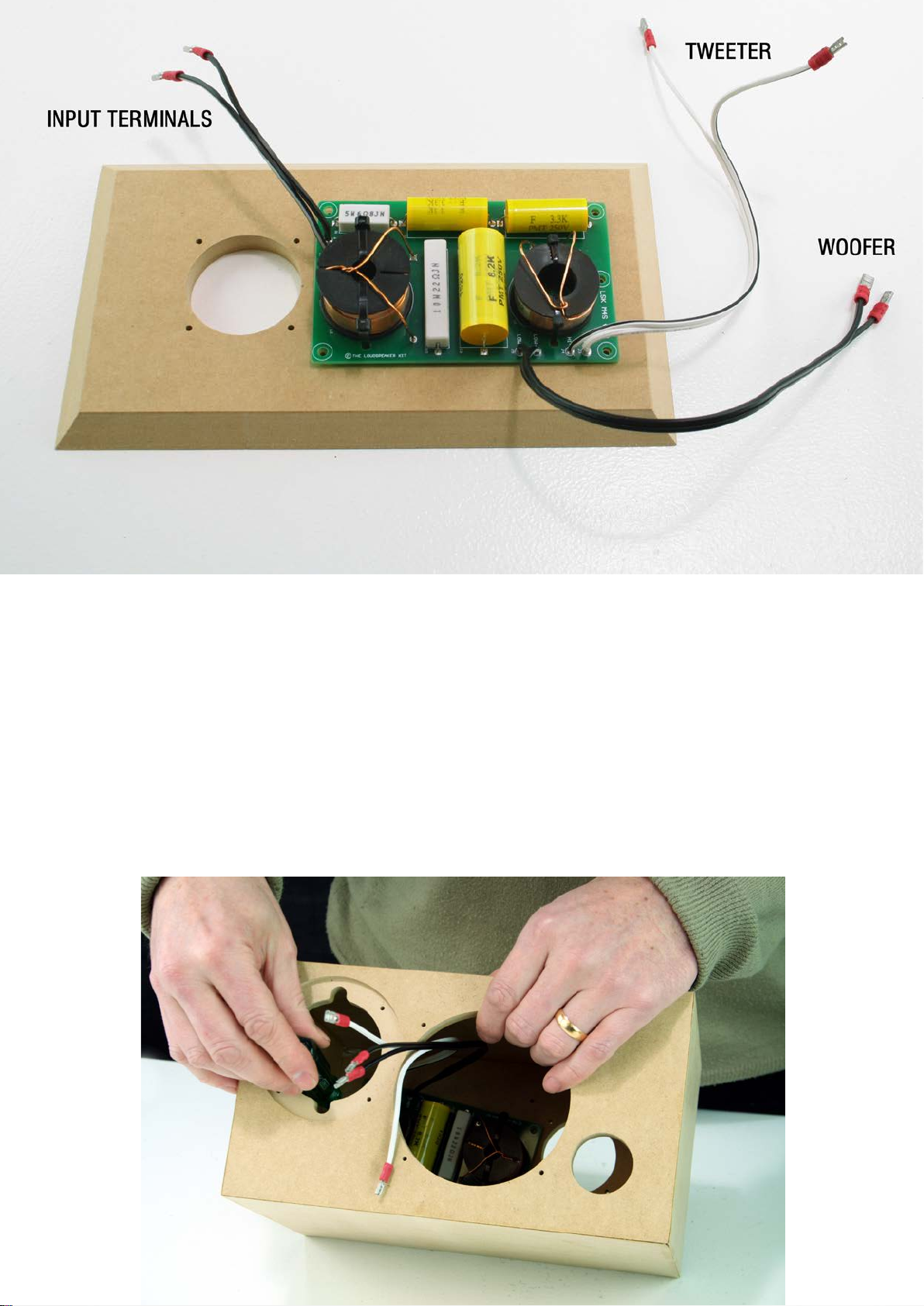

Installing the crossover board

There are three sets of cables:

•Input terminals: located near the larger inductor on the end of the board.

•Tweeter output: easily identified by the white cable

•Woofer output: black cable next to the tweeter outputs

The board is fixed in place with 5 short button head self tapping screws. It’s best to screw them

in place with a screwdriver by hand. Driver cutouts allow access as shown below.

Sequence tip: Normally this step would follow finishing the speaker. Otherwise sanding will

get MDF dust over the crossover.

Assembly manual M4S Kit

11

With the passive crossover in place, find the input terminals and feed them out through the rear

opening. insert the black acoustic lining, which covers the rear, top and bottom internal faces of

the enclosure. Check that it does not block the internal opening of the port. Glue is not

necessary.

Installing terminals

Tip: It’s often necessary to open out the connector slightly with a flat head screwdriver, since

the fit is quite tight.

Note: The cable with the white strip

goes to the negative terminal

-

+

Assembly manual M4S Kit

12

We recommend using a Phillips head screwdriver, as some powered drivers are more likely to

cause damage if the head slips off the screw head. Impact drivers should be avoided. If using

a powered driver, it’s best to use one which has a clutch, so that once the screws are

adequately tightened, the driver will not over-tighten. This avoids stripping the MDF pre drilled

holes or damage to the screw heads. If using a screwdriver, your left hand can hold the shaft to

avoid slipping.

Installing drivers

Find the white wire loom for the tweeter and push the connectors onto the driver tabs.

The connectors are designed to prevent mixing up positive and negative terminals. Avoid

excessive force, which can damage terminals. Lower the tweeter into its recess, aligning the

terminals with the cutout slots. Then secure in place with the provided screws.

The remaining black wire loom is for the woofer. Press the connectors into place and screw the

woofer in place.

Assembly manual M4S Kit

13

Grille assembly

Lightly sand the grille frame so that the edges are slightly rounded over. This provides a more

appealing effect when the grille fabric is in place. Shown below is the original grille prior to

sanding and then the grille after sanding.

Painting

Although the grille frame will be covered with black cloth, it’s best to paint it black to ensure the

lighter colour of the raw MDF won’t be seen. You can use any paint that is suitable for MDF. In

this manual we show the use of a very handy paint which many DIYers use as a finish for their

speaker boxes as well. It is a textured paint which can be applied direct without any priming. It

can be brushed, rolled or sprayed. It’s also a very fast drying paint, which allows you to move

on to gluing the cloth to the frame much quicker than other options.

If you prefer to use a spray can, don’t skip priming as most spray paints won’t provide a very

good finish when applied to raw MDF. For best results with a spray can, we suggest two prime

coats and then two top coats, being careful to observe the recommended time between coatss.

Typically spray painting will take longer than 4 hours. By contrast, the texture paint we use

allows you to start gluing on cloth in as little as 30 minutes. This can vary depending on

climate.

Pre-installed neo

magnets allow the grille

to snap into place

Assembly manual M4S Kit

14

Lay out the grille on a suitable covering to protect your work surface. It’s a good idea to use

disposable gloves for rolling the grille. The paint we use here is Acry-tech DuraTex which can

be purchased through Cannon the Australian Distributor. The ideal roller has a 5mm short nap

– and is small to avoid soaking up too much paint into the roller. Here we’re using a sample

roller. Although you can purchase a texture roller designed for Duratex, we don’t recommend it

for grilles as the texture is quite coarse.

Handy tip: Avoid extra clean up and paint waste by dipping the roller directly into the paint tub.

You can use a scrap of cardboard as shown above to ensure the paint is even spread around

the roller.

A few points to note:

•If you are painting a number of grilles at a time, start with one side for all of them. By

the time you have done one side for all of them, you may be able to progress to the

underside.

•Avoid applying the paint too thick – thinner application with a low nap roller provides a

smoother finished result

•Texture can be improved by rolling over previously applied paint that has not yet dried

– as the paint starts to become tacky the texture can be better controlled

•Two coatss are ideal for grilles

•The second coat can be applied when the first is touch dry. If the first coat is thin, often

the first grille will be ready for the second coat as soon as you have painted the other.

Assembly manual M4S Kit

15

Masking

On the backside of the grille, you will notice a trench inset from the edges. This is the cut line

and defines the area where the cloth will be glued to the frame. The area inside this line needs

to be masked. This allows you to use spray contact adhesive, which provides flat and even

coverage in addition to a fast application. You can measure and cut your own masking or

download the PDF template file (print 100% scale on an A4 sheet). Or you may prefer to

simply use masking tape.

A few features of our mask:

•Masking tape tabs to lift the mask after glue application

•Sticky tabs where the masking tape holds down the mask to the frame

Assembly manual M4S Kit

16

Spray contact adhesive is the simplest and quickest to use and it goes on evenly. Be sure to

carefully follow the instructions on the can as each one is slightly different.

Glue is only required on the back surface as shown here – no glue is required to the sides.

Allow a suitable setting time for the glue. This is different for each product. If you attempt to

attach the cloth too soon, the results may be less than ideal.

At this point, the advantage of using the mask becomes clear. You can quickly remove it with

the masking tape tabs and move on to the next step, without excess glue causing problems.

Now press the cloth onto the glue on the back of the frame. Start with one side and then follow

with the opposing side, stretching the cloth so that wrinkles are seen. These will be removed

when the other pair of sides are glued in place.

Avoid contact of the cloth around the corners. It’s important that these are done last.

Assembly manual M4S Kit

17

Repeat with the other pair of sides. When the final end is pressed into place, all wrinkles

should be removed.

Wrinkle free corners

The biggest challenge in assembling a grille is the corners. If not done correctly, these will

bunch up with many wrinkles. The secret is to stretch the fabric into place.

Hold the cloth with both hands, then pull it back over the frame. Stretch it firmly, pulling back

into the correct position. After stretching it into place, press down to the glue area.

If you find that you have wrinkles on first attempt, you can remove it and try again. It’s

important to work without interruption at this stage, as there is a limited work time involved with

the adhesive.

Assembly manual M4S Kit

18

Now you can use your thumbnail to find the cut line. Pressing your nail into the trench, score all

the way around. Then with a sharp blade, slowly and carefully cut away the grille cloth, using

the trench as a guide.

Tips for a better cut:

•Cut with multiple passes – avoid the temptation to try to cut all the way through in one

pass

•Cut slowly and carefully, ensuring the the blade stays on track

•Cut with a shallow vertical angle – this avoids any tearing you can get if the blade is

too vertical

Assembly manual M4S Kit

19

Parts List:

•2 x 4½” Woofers

•2 x Tweeters

•2 x Crossover Networks

•2 x Round input Terminals

•12 x Panels of CNC machined MDF featuring our unique panel locking system

•2 x CNC machined MDF grille frame with grille cloth

•34 x Self tapping Screws

•2 x 25mm Tuning Ports

•2 x Pieces of Acoustic Lining

•Grille cloth

SPECIFICATIONS:

Woofer Size: 4½”

Woofer Cone: Paper

Tweeter: Soft dome

Frequency Response: 65Hz (-3dB) to 20Khz, +/- 2dB

Recommended Amplifier: 50-100W RMS

Crossover: 1st order @ 2.7Khz

Sensitivity: 86 dB

Power Handling: 50W RMS, 100W peak

Impedance: Nominal 8 ohm (minimum 6.6 ohm)

Dimensions: 260mm high x 145mm wide x 180mm deep

Other manuals for M4S

1

Table of contents

Other The Loudspeaker Kit Speakers manuals