en-us Before you begin

8

Before you begin

2 Before you begin

Before you begin

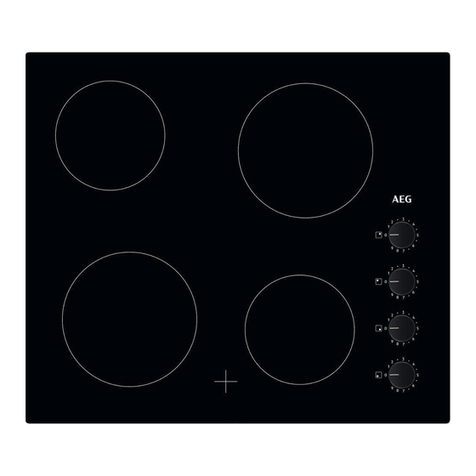

This Installation Guide covers several models. All graphics

are representative. Your appliance may vary in appear-

ance and features.

2.1 Parts included

After unpacking all the parts, check for any damage in

transit and for completeness of delivery.

¡Rangetop

¡STAR® burner caps (1 per burner)

¡Burner grates (2 or 3, depending on model)

2.2 Tools and parts needed

Prepare these tools and accessories before you start to in-

stall your appliance.

Tools

¡Pencil

¡Measuring tape

¡Level

¡Safety gloves

¡T20 star bit screwdriver

¡⁷⁄₁₆" (11mm) box end wrench or ratchet and socket

¡12" (305mm) adjustable wrench

Additional parts needed

¡Pipe compound/tape

¡¾" (19mm) Flex line

NOTICE:

There is a possibility to discolor the back wall under cer-

tain cooking conditions.

2.3 Power requirements and grounding

The outlet must be properly grounded in accordance with

all applicable codes.

2.4 Ventilation requirements

WARNING

The appliance should not be installed with a ventilation

system that blows air downward toward the burners. This

type of ventilation system may cause ignition and combus-

tion problems with the gas cooking appliance resulting in

personal injury or unintended operation.

¡Refer to the “Ventilation Planning Guide” for approved

ventilation combinations.

¡It is strongly recommended that this appliance be in-

stalled in conjunction with a Thermador vent hood. Due

to the high heat capability of this appliance, particular

attention should be paid to the hood and duct work in-

stallation to assure it meets local building codes.

¡Ventilation hoods and blowers are designed for use with

single wall ducting. However, some local building codes

or inspectors may require double wall ducting. Consult

local building codes and/or local agencies before start-

ing to assure that hood and duct installation will meet lo-

cal requirements.

NOTICE:

Most range hoods contain combustible components which

must be considered when planning the installation.

Preparing for the ventilation

1. Select hood and blower models.

– For wall installations, the hood width must, at a mini-

mum, equal the width of the range/rangetop. Where

space permits, a hood larger in width than the range/

rangetop may be desirable for improved ventilation

performance.

– For island installations, the hood width should over-

hang the width of the range/rangetop by a minimum

of 3'' (76 mm) on each side.

2. Consider hood placement.

– For best smoke elimination, the lower edge of the

hood should be installed 30" (762 mm) above the

range cooking surface.

– If the hood contains any combustible materials (i.e. a

wood covering), it must be installed a minimum of 36"

(914 mm) above the cooking surface.

3. Consider make-up air.

– Due to the high volume of ventilation air, a source of

outside replacement air is recommended. This is par-

ticularly important for tightly sealed and insulated

homes.

– A qualified heating and ventilating contractor should

be consulted.

Installation requirements

3 Installation requirements

Installation requirements

Read these instructions to prepare the installation space

for your appliance.

3.1 Location requirements

Ensure your installation location fulfills the following re-

quirements before you begin with the installation proce-

dure.

CAUTION

To prevent possible damage to cabinets and cabinet fin-

ishes:

▶Use only materials and finishes that will not discolor or

divide into layers.

▶Materials should be able to withstand temperatures up

to 194°F (90°C).

▶Heat and moisture resistant adhesive must be used if

the product is to be installed in laminated cabinetry.

▶Check with the product manufacturer to ensure materi-

als meet these requirements.

Specifications:

¡To ensure professional results, the cabinet and counter-

top openings should be prepared by a qualified cabinet

worker.

¡The gas and electrical supply must be located in an

area that is accessible without requiring removal of the

rangetop.

¡The same clearances apply to island installations, ex-

cept for the overhead cabinets, which must have a

space wide enough to accept the island hood.

¡See the Ventilation Planning Guide for recommended

hood options. Due to the high heat of the burners, in-

stalling a microwave oven with a ventilation system over

the appliance is not recommended on anything other

than the 30'' 5–burner model. Refer to the OTR manu-

facturer’s installation manual for clearances.