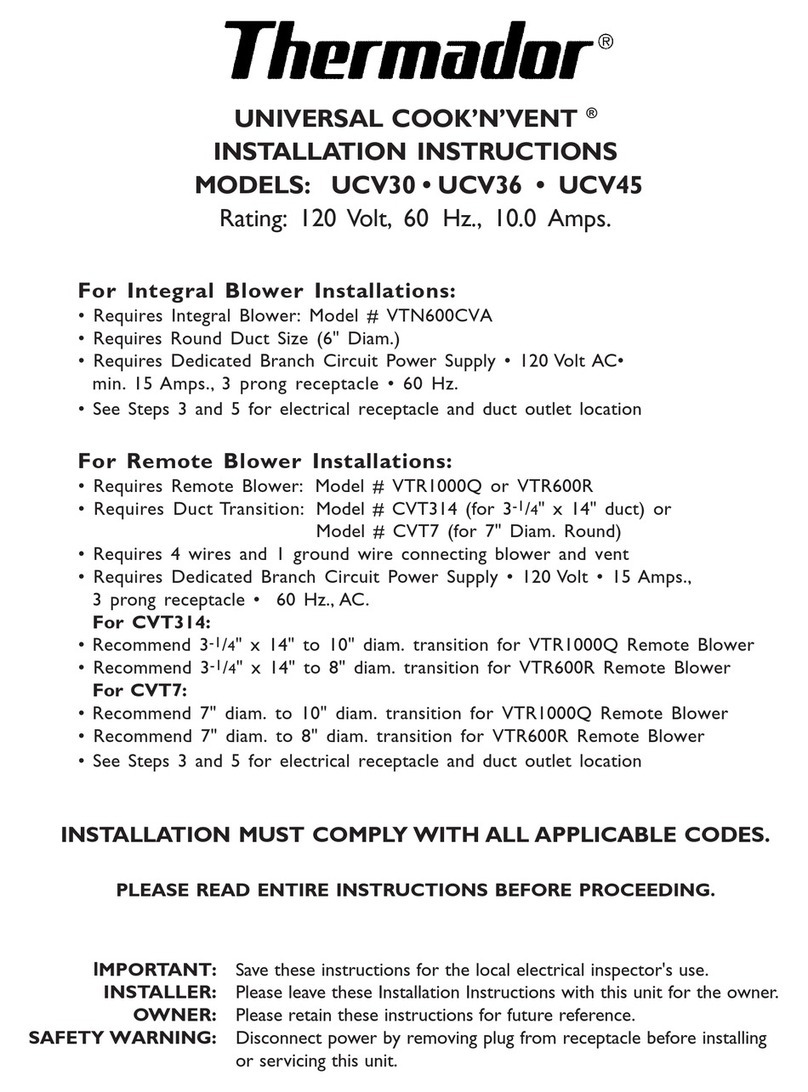

Check the Local Codes:

Work with a qualified service technician, installer or

ventilation engineer to insure that all local installation,

electrical and grounding codes are satisfied.Always

refer to the specific installation instructions for your

ventilation product.

Minimize duct runs and limit the number

of transitions:

The inclusion of elbows and transitions; as well as

long duct runs can have a significant effect on the

ventilation performance and maximum duct run.

Do not use metal flex duct:

Metal flex duct is not recommended for use by

The National Uniform Mechanical Code standards.

Extreme weather conditions:

Cold weather installations require an additional back-

draft damper installed to minimize backward cold

air flow. In addition, a non-metallic thermal break

is needed to minimize conduction of cold air flow

through the ductwork.The damper should be on the

cold air side of the thermal break. The break should

be as close as possible to where the ducting enters

the heated por tion of the house.

Don’t place elbows and transitions back-to-back:

A gradually tapered transition is required between

different sizes of ducting. Placing two elbows or

transitions next to each other can cause a significant

reduction in performance. Include a 15-inch straight

section between transitions whenever possible.

High altitudes effect performance:

Ventilation systems are less effective at higher altitudes

(above 5,000 feet). When configuring your system,

estimate a 20% reduction in CFM performance. If this

is not possible, you can increase your duct size, or

CFM to enhance your performance.

Make-up Air may be required:

Newly built homes have tightly sealed doors and

windows, which can make your ventilation system less

effective. Some heating and air conditioning systems

make allowances for additional make-up air. At the

very least, some replacement air can be introduced

by simply opening a window or door. Please coordi-

nate with your local heating and ventilation exper t.

Do not use ducting smaller than 6":

Ducting smaller than 6," 4" dryer vent pipe or wall

caps are not recommended, because they severely

impair ventilation performance.

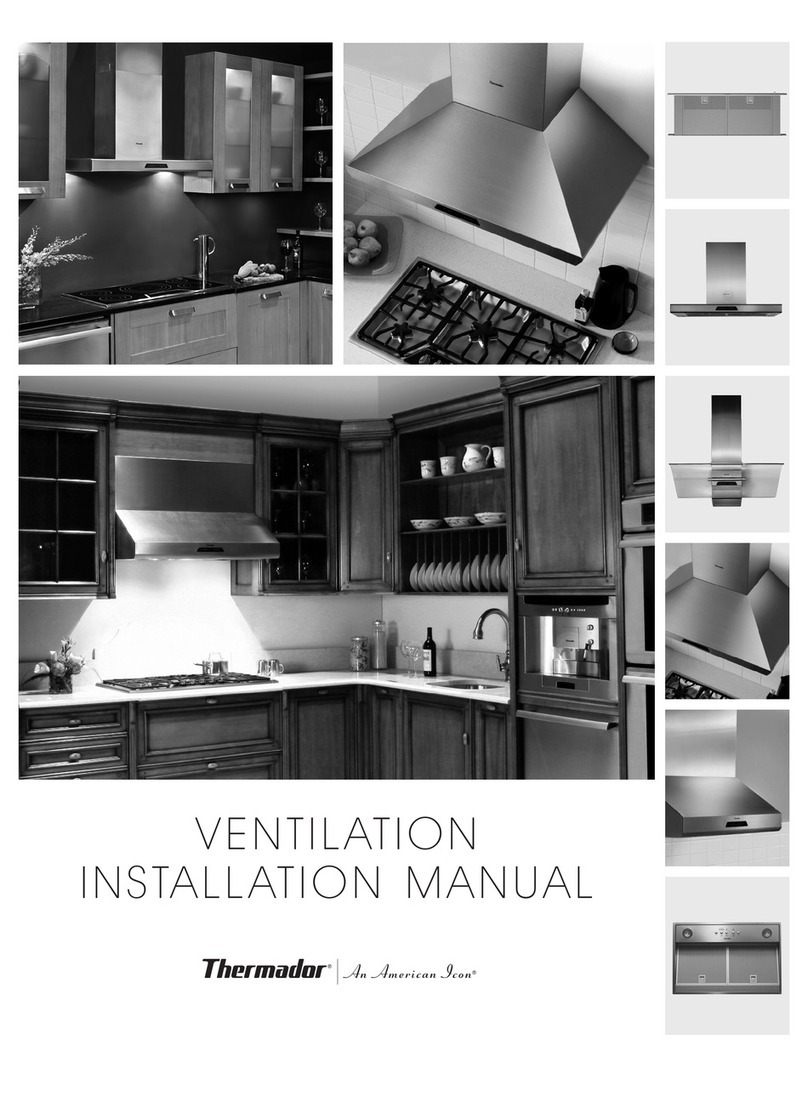

Recirculating vs. Ducted Hoods:

Recirculating hoods recycle the air through a filter

and return it to the kitchen.These hoods will not

remove heat, moisture or combustion gases from the

air. They will also be less effective in reducing odors

and smoke. All of Thermador’s hoods are ducted.

Don’t use butt joints:

Try to use male/female connections with the male

end pointing in the direction of the flow.Tightly tape

joints to prevent vapors from escaping the duct.

Ducting must be vented to the outside:

For safety reasons, never terminate ducting into an

attic, into the garage,underneath the house or into

any enclosed space.

For best air flow, use recommended duct size:

Thermador recommends the following in order

of size:

1st 10" round duct

2nd 8" round duct

3rd 7" round duct

4th 31/4" x 10" duct

5th 6" round duct is the minimum acceptable

(See Thermador ventilator performance charts on

pages 3.4, 3.5 and 5.2)

Base performance calculations on smallest duct size:

For maximum performance, do not use a smaller duct

size than the recommended transition size from the

hood. If you do transition down in size, your perfor-

mance calculations are based on this smaller opening

for the entire duct run.

Calculating Cubic Feet Per Minute (CFM):

Determine the equivalent duct length for your instal-

lation using the equivalent duct lengths for commonly

used transitions shown (on the next page).The

equivalent duct length is computed as follows:

1. Compute equivalent duct length of all transitions:

Transition Equivalent Feet

6" Wall Cap 2'

31/4" x 10" to 6" dia. 90º elbow 10'

Sub-total: 12'

2. Compute the equivalent length of all straight ducts:

Duct Segment Equivalent Feet

4' of 3 1/4" x 10" 4'

2' of 6" diameter duct 2'

Sub-total: 6'

3. Sum Equivalent Lengths for transitions and straight

duct sections:

Transitions 12'

Straight Duct Lengths 6'

Total Equivalent Length: 18'

4. Compute CFM using the performance charts

shown on pages 3.4 and 3.5 and the equivalent

length computed in step 3. Base the equivalent

length on the smallest diameter ducting used in

the system. For this example, you would determine

the CFM for 18' of 6" diameter duct.

Ducting Considerations