WWW.THERMAFLEX.COM

Thermaflex International Holding b.v

Veerweg 1, 5145 NS Waalwijk

The Netherlands

05.

Clean the fitting by making circular

movements over the entire internal

welding surface of the fitting.

06.

Slide the fitting over the service pipe

on the “fixed” side of the clamping set

and position it right against the

welding clamp.

Important: Don’t use bolts on the

fitting!

07.

Join the service pipes by turning the

handwheel on the clamping set. Make

sure that the other service pipe slides

into the fitting smoothly. Check that

the correct insertion depth has been

reached.

08.

Connect the welding machine to

power supply and the welding cables

to the fitting - the corresponding

"ready" indicator lights up.

09.

Press “Start” to begin the warming up

process. The "Welding" indicator lights

up.

10.

After the warming up process has

been completed there will be a sound

signal and the "end" indicator lights

up.Now, the welding cables can be

removed carefully from the fitting.

11.

After a cooling time of at least 15 min

(20 min for fittings with OD110mm)

clamping set can be removed.

12.

Check if the welding process was

successful: the welding indicators

came up, the insertion depth markings

are visible directly next to the fitting

and there are no visible damages or

irregularities.

Note: After the last welded connection

is established and cooled down, wait

at least 2 hours before starting the

pressure testing procedure.

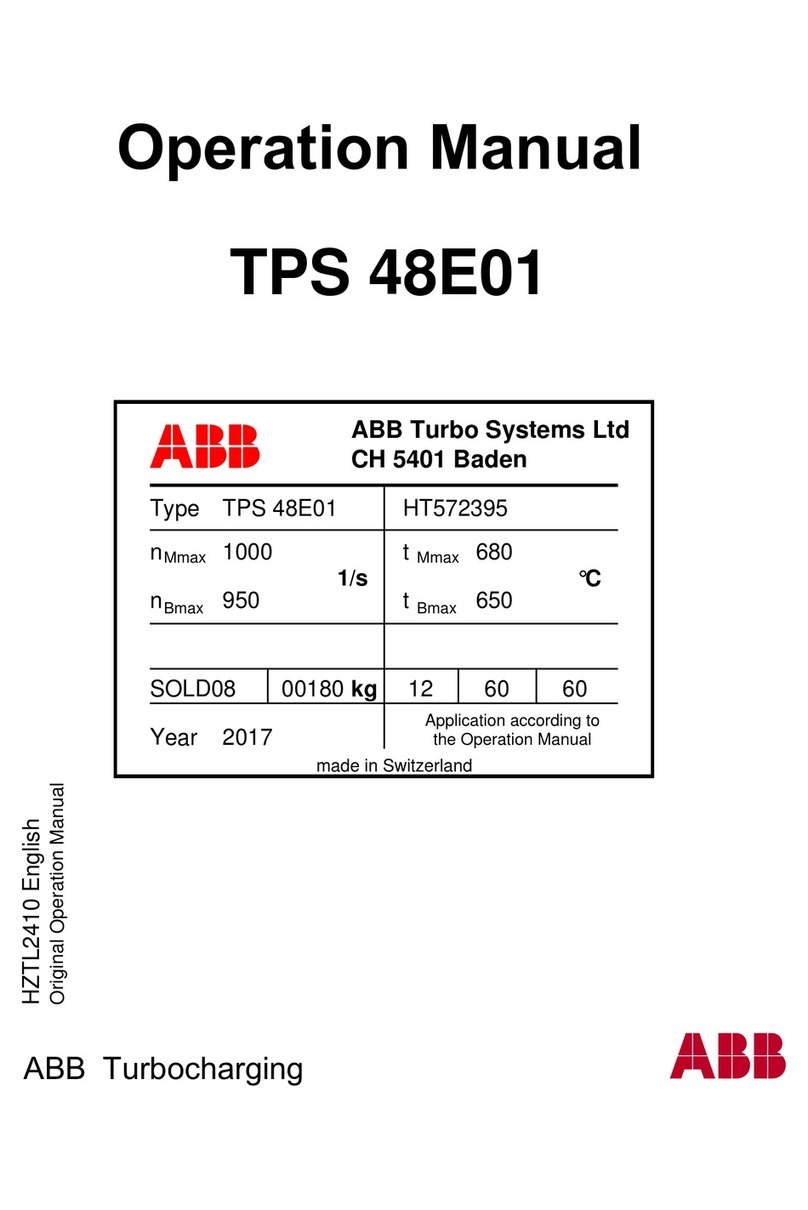

Fitting dimension

OD [mm]