Zakład Wytwórczy Aparatów Elektrycznych Sp. z o.o.

3

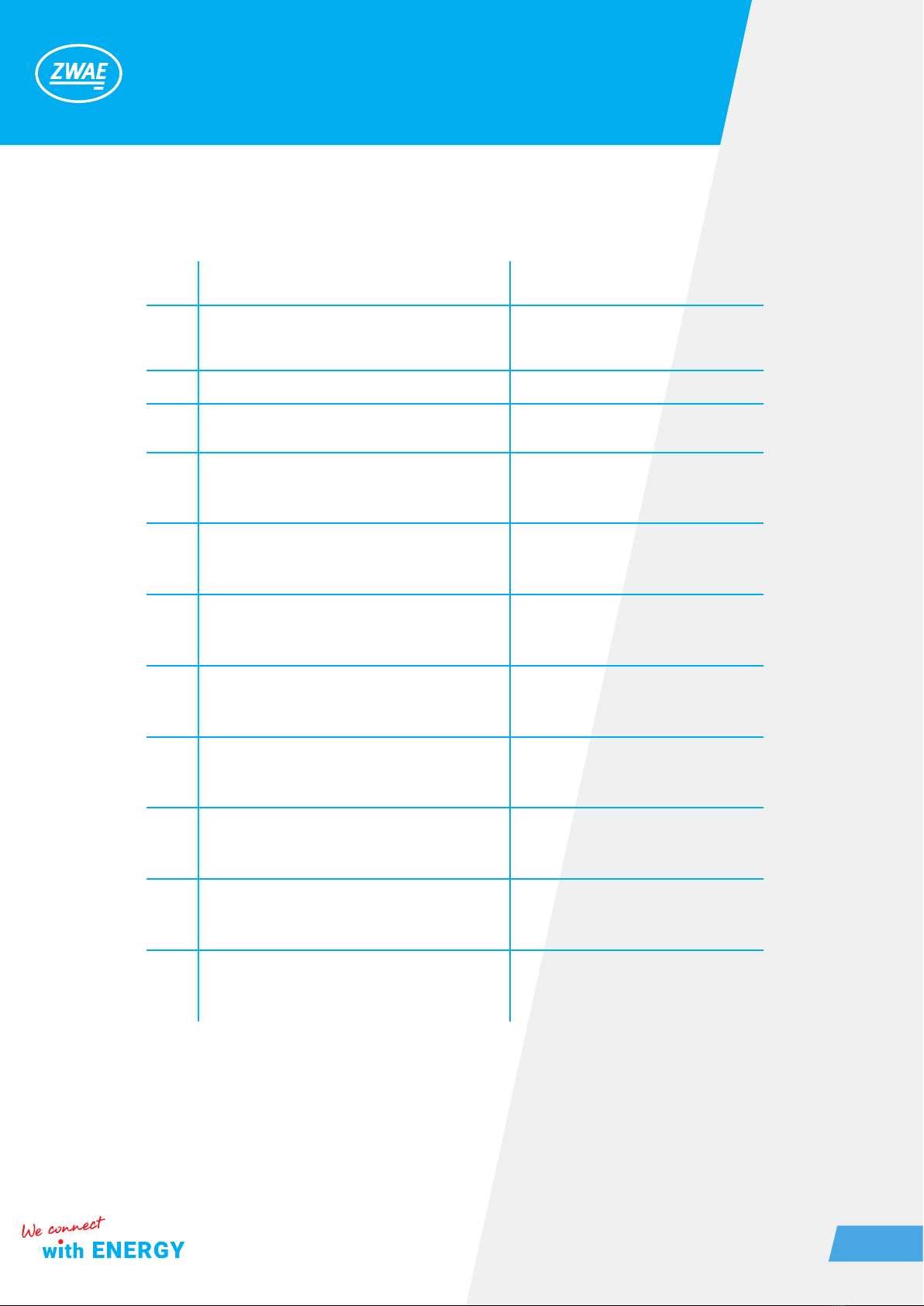

Table of contents

1. TRANSPORT ........................................ 4

1.1. Unpacking and inspection .............................. 4

1.2. Storage and transport.................................. 5

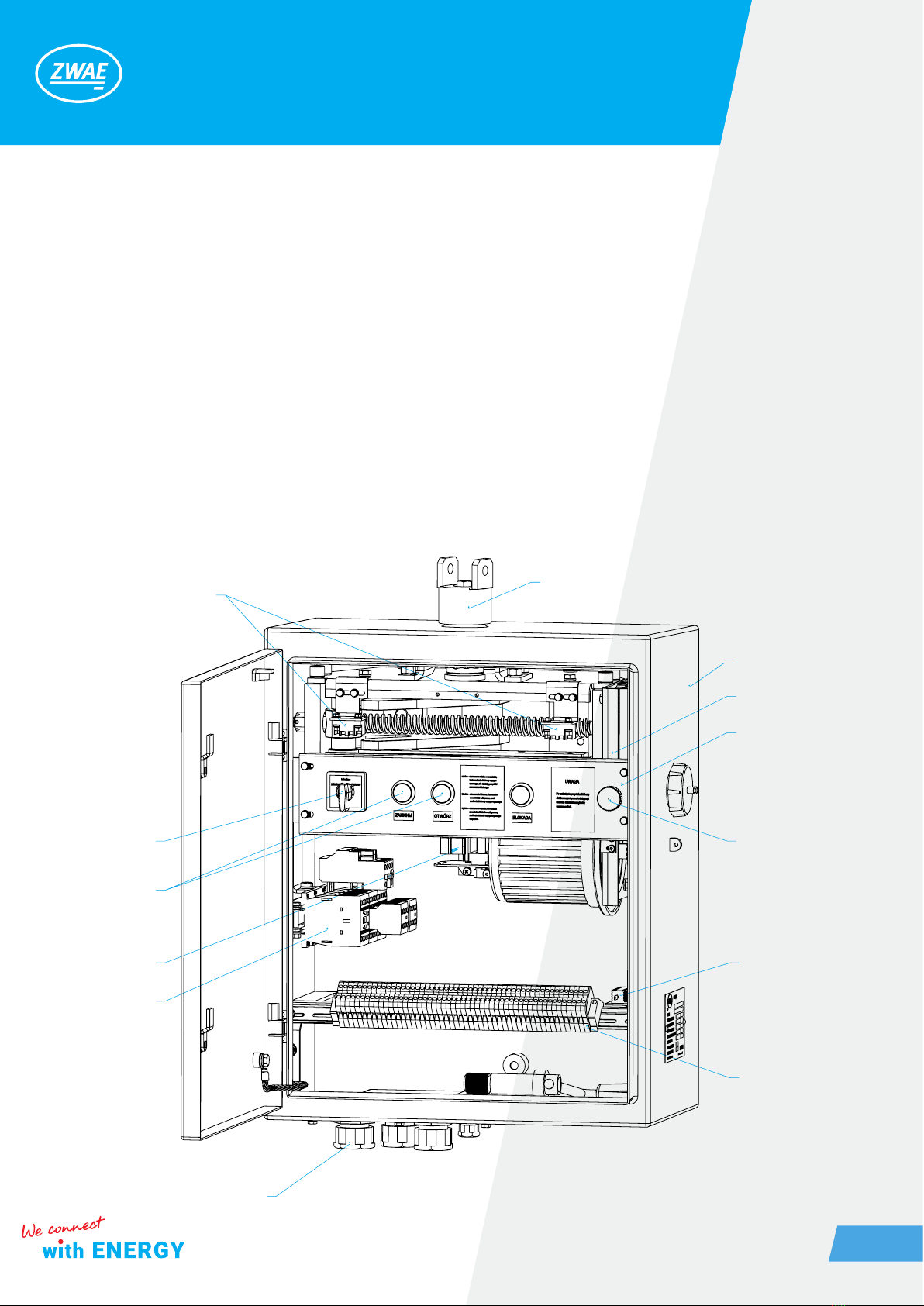

2. DESCRIPTION ........................................ 5

2.1. Construction and principle of operation . .................. 6

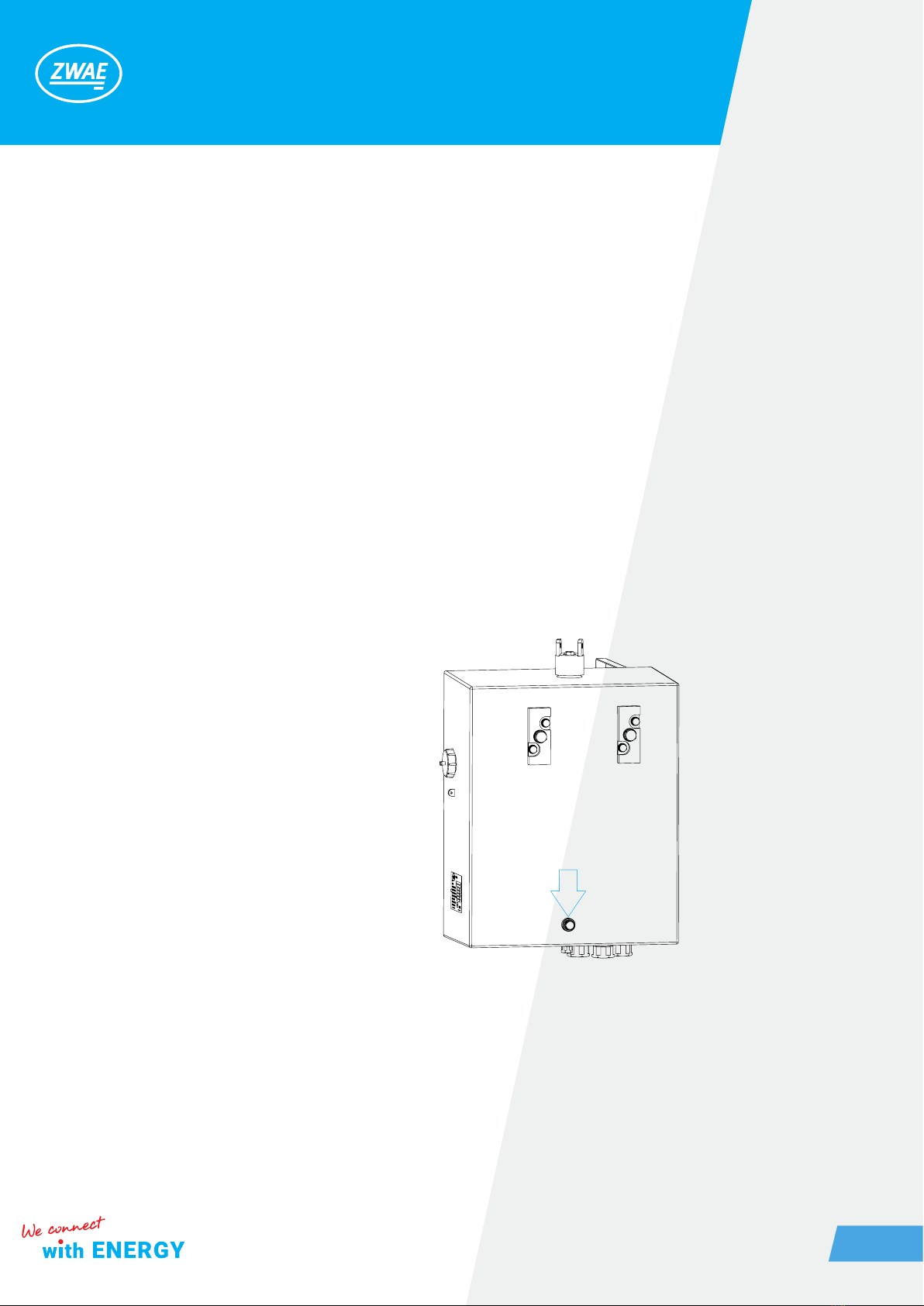

2.2. Housing.............................................. 7

2.3. Driving mechanism .................................... 7

2.4. Climatic conditions .................................... 7

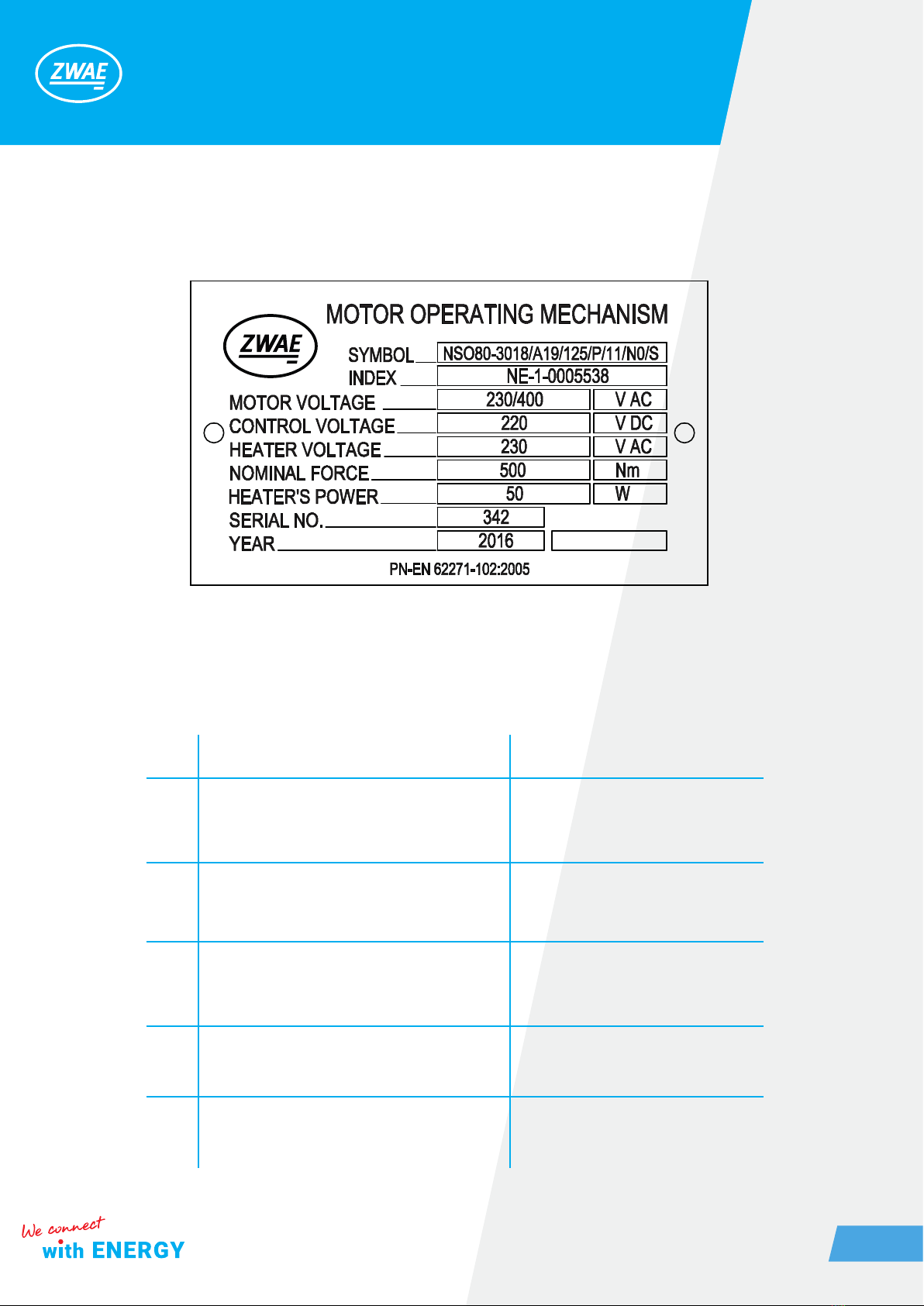

2.5. Nameplate ........................................... 8

2.6. Basic technical parameters ............................. 8

3. INSTALLATION AND ADJUSTMENT ...................... 10

3.1. Coupling with disconnectors ONIII 110 and 220kV ......... 10

3.2. Protective earthing connection.. . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3. Connection of control and auxiliary circuits .. . . . . . . . . . . . . . . 10

3.4. Tests before rst run ................................... 11

4. OPERATING MANUAL ................................. 11

4.1. Manual maneuvring ................................... 11

4.2. Local maneuvring ..................................... 11

4.3. Remote maneuvring ................................... 11

5. INSPECTION AND MAINTENANCE ....................... 12

5.1. Visual inspection ...................................... 12

5.2. Spare parts and recommended maintenance materials ..... 12

5.3. Periodic inspections ................................... 12

6. DIMENSIONAL DRAWING (STANDARD VERSION - 192°) ..... 13

7. UTILIZATION ......................................... 14