Thermcraft LBO-24-10-10-1T-J14642/1A User manual

APPRECIATES YOUR BUSINESS

We thank you for purchasing a Thermcraft, Inc. heat treating oven. Since

our establishment in 1971, Thermcraft, Inc. has manufactured reliable, high

quality, electric resistance and gas equipment. Our products are used in a variety

of applications both domestically and around the world.

For over 40 years, Thermcraft, Inc. has manufactured ovens and ovens to

comply with predetermined custom and industrial specifications. This oven has

been completely checked for mechanical and electrical compliance prior to

shipment.

We trust you have received your oven in acceptable condition and that

you will find it meets or exceeds your expectations and requirements.

Prior to installation and operation of your new Thermcraft, Inc. oven, we

strongly urge you to read this manual it its entirety and comply with all

instructions herein.

If you have any questions, feel free to contact us.

Made in the U.S.A

Sincerely,

Thermcraft, Inc.

3950 Overdale Road

Winston-Salem, NC 27117-2037, U.S.A.

Telephone (336) 784-4800

Fax (336) 784-0634

Web: www.thermcraftinc.com

100-340-726 A

THERMCRAFT, INC.

INSTRUCTION MANUAL

CONTENTS

1. Oven Specifications

2. Inspection and Damaged Instructions

3. Accessories

4. Assembly

5. Control Environmental Conditions

6. Installation and Power Connection

7. Operational Safety

8. General Information

9. Preventative Maintenance

10. Thermocouple

11. Enabling Cooling

12. Replacement Parts List

13. Oven Trouble-Shooting

14. MSDS sheet

15. Control System Operation

16. Standard Configuration

17. Over-temperature Controller Operation (if applicable)

18. Oven Assembly Drawing (see included files)

19. Electrical Specifications (see included files)

20. Electrical Wiring Diagram (see included files)

21. Controller Manual (see included files)

1.) OVEN SPECIFICATIONS

Oven Type:

Model #: LBO-24-10-10-1T-J14642/1A

Serial #:

Weight: 350 LBS

Maximum Temperature: -150°C to +350°C

Heater Type: Inconel covered air heaters

Cooling: Liquid Nitrogen

Incoming Power:

Volts 208/230

Amps 20

Watts 3000

Phase 1

Hertz 50/60

Control System:

Model #: 1-1-30-230-E06ST-J5929_7EA

Temperature Controller Type and Model: EUROTHERM 2408/CP/VH/LH/TC

Power Requirement:

Volts: 230

Amps: 30

Plug: INTERPOWER 87520051

Receptacle: INTERPOWER 84232203

Cord: INCLUDED WITH PLUG

Thermocouple Type: T

2.) INSPECTION AND DAMAGED INSTRUCTIONS

INSPECTION

Upon receipt of your new oven, inspect for visible exterior damage. Note

and describe any damage found on the freight bill and file a claim with the carrier.

Once unpacked, carefully inspect for concealed loss or damage on the

unit itself, both the interior and exterior. If necessary, the carrier will arrange for

official inspection to substantiate your claim.

Verify that all of the equipment shown on the packing slip is included with

the unit. Carefully check all packing materials.

RETURN SHIPMENT

Save the shipping box/crate until you are sure all is well. If for any reason

you must return the unit, first contact our Sales Department at 336-784-4800.

Please have the unit’s serial number and model number available when you call

(located on the rating plate). Note: all returns MUST have a Return Authorization

Number.

3.) ACCESSORIES / OPTIONS PURCHASED

_X_ YES ___ NO LOAD PORTS QTY _2_

_X_ YES ___ NO VIEWPORT QTY _1_

_X_ YES ___ NO CRYOGENIC GAS INJECTOR QTY _2_

_X_ YES ___ NO EXHAUST PORT QTY _1_

_X_ YES ___ NO DOOR INTERLOCK SAFETY

___ YES _X_ NO HAND PORT

___ YES _X_ NO PORTABLE OVEN DOLLY

_X_ YES ___ NO OVER-TEMP. CONTROL SYSTEM

___ YES _X_ NO TEMPERATURE RECORDER

4.) ASSEMBLY

The oven will arrive pre-assembled; however, some assembly may be

required prior to start-up.

NOTE: These ovens are heavy and care should be taken to use lifting

devices which are sufficiently rated for these loads. Doors, handles and knobs

are not adequate for lifting or stabilization. The unit should be completely

restrained to prevent tipping during lifting and transport.

For larger ovens some parts such as doors, door tracks, car bottom

tracks, elevator lifts, blower motors, and conveyors may have been disassembled

from the oven to accommodate shipping. Before proceeding with installation,

review all of drawings and diagrams included in this manual.

1. Refer to designs, making sure all oven stands, control boxes,

terminal boxes, doors, etc., are in place and secure. If not, locate

the appropriate parts that are included in the shipment and follow

the oven design drawings in order to complete the assembly.

2. Locate the thermocouple hole and carefully pull out the alignment

pin. Carefully slide thermocouple into the hole, do not force.

If any questions arise concerning assembly of the oven, please contact

Thermcraft, Inc. at 336-784-4800.

5.) CONTROL ENVIRONMENTAL CONDITIONS

Normal Operating Conditions

1. Ambient temperature: 0 – 50°C

2. Rate of change in temperature: 10°C/h or less

3. Ambient humidity: 20-90% RH (no condensation allowed)

4. Altitude: 2000m or less above sea level

Maximum Effects from Operating Conditions

1) Temperature effects

1.1. Thermocouple, DC mV and DC V input: +/- 2u V/°C or +/-0.02% of

F.S/°C, whichever is the larger

1.2. Resistance temperature detector: +/-0.05°C/°C

2) Effect from fluctuation of power supply voltage (within rated voltage range)

2.1. Analog input: +/- 0.2u V/V or +/-0.002% of F.S/V, whichever is the

larger

Transportation and Storage Conditions

1) Temperature: -25 to 70°C

2) Humidity: 5 to 95% RH (no condensation allowed)

6.) INSTALLATION AND POWER CONNECTION

After the above assembly procedures have been completed, the oven is

ready for connection to incoming power as follows:

1. Open the oven and remove the protective packing covering the

heating elements.

2. Consult an electrical professional and the NEC (National Electric

Code) specifications to select wire size to adequately carry the line

amperage shown in section 1.) Oven Specifications: Connect

electrical service to a fused power source disconnect. Such

disconnect device shall be marked as a disconnect device for the

oven.

3. For overcurrent protection device selection, please refer to

amperage shown on the oven rating plate.

NOTE: Be sure to check all external strain relief fittings for tightness. See

Torque Recommendation for Strain Relief Fittings chart below:

TORQUE RECOMMENDATIONS FOR STR

A

IN RELIEF FITTINGS

Torque in Inch Pounds - in lb (Newton Meters - Nm)

METAL STRAIN RELIEF FITTINGS PLASTIC STRAIN RELIEF FITTINGS

DOME NUTS THREAD AND LOCK

NUTS DOME NUTS THREAD AND LOCK

NUTS

PG 7, M12x1.5 36.9 (4.17) 55.3 (6.25) 14.4 (1.62) 22.1 (2.50)

PG 9, PG 11, M16, PG 13.5, 3/8" NPT, 1/2"

NPT, M16x1.5, M20x1.5 36.9 (4.17) 55.3 (6.25) 22.1 (2.50) 33.2 (3.75)

PG 16, 1/2"NPT-E 44.2 (5.00) 66.4 (7.50) 29.5 (3.33) 44.2 (5.00)

PG 21, PG 29, PG 36, PG 42, PG 48,

3/4"NPT, 1"NPT, 1-1/4"NPT, 1-1/2"NPT,

M25x1.5, M32x1.5, M40x1.5, M50x1.5,

M63x1.5

59.0 (6.67) 88.5 (10.00) 44.2 (5.00) 66.4 (7.50)

Note: The values shown above are for reference only.

Note: Nylon strain relief fittings installed in a threaded connection and exposed to elevated temperature

should be retained with a sealant such as Locktite® to avoid a loose connection when temperature

fluctuates.

7.) OPERATIONAL SAFETY

.

Safe operation of your new oven is mandatory. As manufacturer of your oven, we at Thermcraft,

Inc. have adhered to all known safety standards and strongly suggest you install your oven in

accordance with national electric and fire protection codes. Do not exceed the electrical and

temperature rating printed on the oven rating plate.

It is important to pay particular attention to those regulations that are applicable to the

specific governing operations entities including, but not limited to legislated and accredited

national and local industry standards and the type of facility in which the oven will be employed,

including zoning requirements, local building codes, and local electrical codes.

SYMBOLS USED ON THE EQUIPMENT

Caution: risk of electric shock. Caution: hot surface.

Caution: refer to accompanying documents.

The potential for electric shock is always present when electrically operated equipment is

in use. The following suggestions are recommended for your protection:

1. Before beginning service / maintenance procedures on your oven, the power source must

be locked out and tagged out per Occupational Safety and Health Administration (OSHA)

regulations.

2. Insure the oven is properly grounded and electrically protected. Grounding lugs and

ground wires have been installed prior to shipment. The ground wire will terminate within

the external terminal box and is visible to the installer / operator. If unsure of the

grounding status of the equipment, consult the NEC (National Electric Code) or a

licensed professional.

3. If electrically conductive material is to be heat treated, the operator must be protected

from becoming a conductor to the ground. To avoid electric shock observe the following

operating practices:

a. Wear insulated gloves specific to the task that guard against electric shock if the

operator will be in contact with an electric current.

b. When using any metallic instrument to introduce items into the oven, insure the

handle is properly insulated and the instrument is adequately grounded.

c. Install rubber mats in front of and behind the equipment to protect the operator.

CAUTION: If this equipment is used in a manner other than described in this

manual, protection provided by the equipment may be compromised or impaired.

To preclude hazard and minimize risk, follow all instructions and operate within

the design limits noted on the rating plate.

Do not use components or materials not specifically designed for this equipment.

Failure to comply with this precaution could result in damage to the equipment

used or the oven and may create an overheat situation. Also, do not use anything

other than OEM exact replacement parts. Not using OEM replacement parts

could cause faulty instrumentation readings, inoperative equipment, or a

temperature overshoot.

Avoid combustible product which generate toxic or hazardous vapor or fumes.

Work should be done in a properly vented environment.

Observe the following precautions:

* Never stand in front of an open hot oven.

* Wear protective eyewear.

* Wear protective gloves.

WARNING: Do not use combustible gases directly in this oven. Process

gasses must always be contained in a separate tube.

Modification of equipment for use other than that for which it is explicitly designed

for could cause severe injury or death. Any customer after market retrofit violates

the warranty.

Do not modify or disconnect any safety features provided. Disconnection of the

units safety features could allow the unit to become overheated and start on fire,

causing personal injury or death, product and property damage.

Periodically disconnect power from the equipment and allow it to cool completely. Once

cool, inspect for loose or broken heaters and for worn wire coils on the inside of the heated

chamber. Heaters may have to be replaced if damage is severe. Avoid contact with any

exposed heater coils / elements. Do not touch elements with bare hands or oily gloves. Contact

Thermcraft, Inc. if unsure of the safety of the heating elements in the conditions you have

observed.

Only qualified electrical professionals should remove the upper and lower terminal covers

of the terminal boxes. Keep all guards (guide-tabs, backstops, upper and lower terminal covers)

provided with the equipment in place while the oven is in operation. Observe all safety labels.

If questions arise concerning the operation of your oven, contact Thermcraft, Inc. at (336) 784-

8.) GENERAL INFORMATION FOR TEST FRAME OVENS

CAUTION! Failure to check thermocouple wiring and connection before

initial start up could result in damage to the oven.

INSPECTION

Carefully inspect the oven upon its arrival for possible damage incurred during shipment.

If damage is evident, immediately notify the carrier and file a claim.

Do not discard any shipping packages until you are sure all components are accounted

for.

Most options will be attached to or are part of the oven itself. The solenoid valves are

located within the rear cover. The main items not attached to the oven are the port plugs

and mounting shaft collars, if purchased.

DESCRIPTION

The oven's function is to heat and/or cool samples. Please review the Oven-Test

Chamber Specifications page for your oven's limitations.

HEATING

Heat is provided by tubular heating elements located at the rear of the plenum. Air is

recirculated over the elements to generate heat.

COOLING

Cooling is provided by injecting liquid N2 or C02 thru the rear of the oven. (See the

Oven - Test Chamber Specifications page to see which specific option is being used.)

The cold gas is mixed with the recirculating air.

POWER REQUIREMENTS

Refer to the Oven - Test Chamber Specifications page for details.

SENSOR

A thermocouple sensor has been provided with the oven. The final positioning is

covered further in this section under Control Thermocouple Positioning. Other

thermocouple types are also available and can be easily installed.

INSTALLATION

After completing any minor assembly procedures, the oven is ready for connection to

your services. Install as follows:

1. Remove any packing from the interior of the oven.

2. NOTE: The oven has already gone through a partial bake out procedure required

for the mineral wool insulation. This partial bake out is done during quality

control testing and causes discoloration of the inside liner. The discoloration

does not affect the oven's performance. Some smoke or moisture may be

emitted by the oven during the initial burn in. Please ensure that ventilation is

provided to prevent excessive build-up in the test area.

MOUNTING

All ovens are supplied with slide mounting brackets. Before moving the oven, make

sure the locking pins are engaged to prevent the slides from moving.

The oven should only be moved via an overhead crane or fork truck using the supplied

eyebolts on the top of the oven. Position the oven between the slide mounting brackets

and align the front two holes in the slide assembly over the tapped holes in the test

frame.

CAUTION: Do not block the perforated areas on the rear cover. Cooling is required for

the electronics and the blower motor.

ELECTRICAL WIRING CONNECTIONS

The control system has been connected to the chamber before shipment. A conduit

feed through has been provided on the lower feed through panel to allow the wiring to

remain in place when removing the rear cover. The feed through panel can be removed

if necessary. Any conduit provided shall be permanently secured / mounted during

installation. Please make sure that any additional wiring meets all local electrical codes.

NOTE: The control system is supplied with a power cord and plug. Refer to the Oven-

Test Chamber Specifications page for a description of the cord and plug. Ovens shipping

to Europe will also include a matching IEC receptacle.

NOTE: The oven door has a safety interlock switch. The door must be closed for the

oven to operate. This feature was designed to protect the operator from hot or cold air

blowing directly on them while accessing the oven.

THERMOCOUPLE

The thermocouple measures the voltage that is generated as the temperature increases.

A current will flow providing an input signal for the control system to monitor and provide

operational control.

The tip of the thermocouple must be in the heated chamber and not covered or shielded

to the point where it cannot sense the actual temperature.

If the temperature controller displays the message "S.br" (sensor break), the

thermocouple circuit is faulty. A loose connection, broken wire or burned out

thermocouple could be the

cause.

When replacing thermocouples, remember to use the same type thermocouple.

Extension wires and connectors must also be compatible with the thermocouple and

controller. Be sure to observe correct polarity of thermocouple extension wire. Red leg

is always negative for thermocouples.

NOTE: The thermocouple has not been calibrated unless specifically ordered as such.

Upon request, calibration will be preformed on the thermocouple and a calibration report

will be enclosed in the appendix.

OPERATION

The conduit is permanently secured and the rear cover installed, apply power to the

control system to test the oven's components. Then run the oven up to 200F to verify

proper operation.

CAUTION: Do not run up to maximum operating temperature until the control

thermocouple has been positioned properly. Its current location may allow the oven to

exceed operating range and cause damage to the elements, the load train and/or your

specimen.

OPERATING CONTROLS

1. The main circuit breaker is located at the rear of the control cabinet. When the

circuit breaker is in the off position, all power is removed from the oven. The

control cabinet should not be positioned such that it is difficult to operate the

disconnecting device.

2. The control power switch is located on the front of the control cabinet. This

switch must be in the on position for the oven to operate.

3. The light switch is located on the front of the control cabinet and is used to

control the interior light.

4. The reset switch is located on the front of the control cabinet. It is used to reset

the high limit controller should the chamber temperature exceed the limit setting.

5. The high limit controller is located on the front of the control cabinet and is used

to protect the chamber from excess temperature. The high limit backs up the

main temperature controller. If the set point is exceeded, an alarm message will

be flashed on the display. After the temperature has returned to normal, push

the reset switch.

CONTROL THERMOCOUPLE POSITIONING

The final position of the control thermocouple is determined by your requirements. This

may be determined by a trial and error process. It is recommended to have an

additional thermocouple and recorder for the test. A flexible thermocouple has been

provided for the control sensor.

1. Position the monitoring thermocouple on the specimen or in the air near the

specimen. Thermocouple response time is dependent on the location and load.

2. Position the control thermocouple in the air exhaust, mark this location A. This

will provide the slowest response in the system and the specimen may never see

the control temperature. This initial test will ensure that the exhaust temperature

will never be above the maximum for the oven.

3. If the specimen does not reach operating temperature, save the information.

Now reposition the control thermocouple between the exhaust and inlet, mark

this one B.

4. Conduct the test again and compare the results with the first run. If the specimen

reached temperature and the tuning for the controller is satisfactory, you may

either stop or reposition the thermocouple at another location of your choice to

see if any further improvement can be made.

You may have to repeat the test several times before the results meet your

specifications. It is difficult to position the control thermocouple at the factory due to the

limited information on the exact load being used.

AIR FLOW PATTERN

An Oven Air Flow Pattern drawing for this oven is included in this manual. The exhaust

is top and bottom with the inlet in the middle. The main plenum protects the working

chamber from direct radiation from the heating elements. The secondary plenum adds

turbulence and prevents the air from directly recirculating. The secondary plenum also

protects the operator from coming in direct contact with the blower wheel.

Air uniformity will be affected by large specimens and/or load trains. The amount of air

reaching the front of the oven will be reduced by larger specimens. CAUTION: Do not

block the air flow inlet or exhaust. This will restrict air flow and affect the uniformity of

the oven and may damage the elements.

COOLING OPTION

1. C02 systems have a single injector assembly. An extra injector assembly will be

present at the bottom if conversion to LN2 medium is required. The solenoid

valve provided will be set up for either 300 or 1000 psi service per your order. A

1/4" compression fitting is provided for your connection. This can be found on

the rear feed through panel.

2. LN2 systems have dual injectors plumbed from one solenoid valve. The dual

injectors allow the lower pressured LN2 to be distributed evenly. Normal supply

pressure from a 160 liter liquid exceller tank is approximately 25 psi.

VENTILATION

It is IMPORTANT to have adequate ventilation when using C02 or LN2.

A vent hood may be necessary.

SHUT DOWN PROCEDURES FOR OVENS WITH COOL DOWN BLOWERS:

CAUTION! Do not shut the blower off until the oven has cooled down.

Change to the controller set point down to 100° F. Allow the oven to cool down to

100° F then switch the power button to the off position.

For conducting service work, follow your companies log out/ tag out procedure.

AIR BAFFLE

CHANNELS AIR FLOW

REAR COVER

AREA

INJECTOR

HEATER

ELEMENT

BLOWER

MOTOR

BLOWER

WHEEL

FEED THROUGH

LIGHT

(IF REQUIRED)

ALL PLUMBING & ELECTRICAL

ENTER @ FEED THROUGH NOTE: AIR FLOW FOR

CONVENTIONAL OVEN IN

TYPICAL MOUNTING POSITION

OVEN

PORT (ON CENTER LINE)

DOOR SEAL

FLOW LINES

FLOW LINES

C

E

N

T

E

R

L

I

N

E

9.) PREVENTIVE MAINTENANCE

CAUTION: Maintenance should only be performed by trained personnel.

WARNING: Prior to performing maintenance to the oven or the controls,

the main power must be disconnected. Prior to maintaining this

equipment, read the applicable MSDS at the back of the manual.

General Oven Maintenance LIGHT

1. Inspect and verify all electrical connections for tightness. Due to thermal

expansion during the heat- up/cool-down cycles electrical connection may

become loosened.

2. Inspect the heating elements. Do not allow build up of foreign material on

the element. Oil should be cleaned off of any part of the oven prior to

heating. Use caution not to displace the heating elements as the wire may

be brittle and break easily.

3. If oven has a door, verify that the door safety switch is operating and

cutting the power to the heaters once the door is opened.

4. Check all hardware fasteners to ensure that they are tight.

5. Inspect the tip of the thermocouple for excessive heat deterioration.

General Control Cabinet Maintenance

1. Verify that all electrical connections are tight.

2. If applicable, clean the cabinet cooling fan filter.

3. Check all cabinet to oven interconnection wiring.

4. If applicable, check to ensure that all signal lamps light.

REPLACEMENT PARTS

It is recommended that you obtain replacement parts from Thermcraft Inc. to insure that

system safeguards are not compromised. Variations in component specifications could

cause the equipment to be unsafe.

ELEMENTS HEATING

The elements should last more than three (3) years unless overheated due to restricted

air flow or a malfunction of the control system. No other maintenance is required.

FUSE REPLACEMENT

Replace fuses with the same size and type as supplied.

1FU - Bussmann FNQ-R-3Y> (3.5 A, 600 V Dual element time delay fuse)

2FU, 3FU - Bussmann FNQ-R-1 (1 A, 600 V Dual element time delay fuse)

4FU - Bussmann FNM-1 Y. (1.25 A, 250 V Dual element time delay fuse)

PORT PLUG MACHINING OPTION

Port plugs can be purchased with or without a bore. If purchased without a bore, the

following steps may help you with machining them to fit your needs:

1. Plugs will be sent whole and cut to specified holes, solid plugs with have a ¼”

hole for custom drilling. Make sure you use a wood backing to drill into as this will

prevent breakage of the plug. For smaller holes, use a regular drill bit. It may dull

faster if you are drilling multiple holes. For large holes, purchase a hole saw with

the correct size for your requirements.

2. With the correct size hole saw, place the port plug in a drill press or drill. Drill into

the plug keeping a vacuum sweeper handy to collect the dust and pieces. A

normal hole saw does not have the depth required for a 2" thick piece. It may

require you to flip the piece over and continue drilling. Discard center pieces and

check for fit.

INTERNAL OVEN CHAMBER LIGHT (OPTIONAL)

The current light cannot be operated above 600 Deg. F (315 Deg. C). If you are

planning to conduct testing above 600 Deg. F, you must remove the light bulb and

replace it with the insulation plug provided. If your oven was not rated for operation

above 600 Deg. F, then no insulation plug was provided. Operation above 600 Deg. F

with the light bulb in place will cause early failure of the bulb and perhaps cause the bulb

to explode.

SLIDE ASSEMBLY MOUNTING BRACKETS OPTION

This option allows the oven to slide backwards out of the test frame. This exposes the

oven's working area for ambient testing when needed. The locking pins on the side hold

the oven in the forward position.

10.) THERMOCOUPLE

A thermocouple is used to measure the voltage that is generated as the

temperature increases. It provides an input signal for the control system that

monitors the temperature of the heated chamber.

At high temperatures, the elements within the thermocouple may undergo

some oxidation or corrosion causing the signals to be read incorrectly by the

control system.

If possible, the tip of the thermocouple must be at least 1/8 deep. Also, the

thermocouple tip must not contact items being heat treated.

If the control system indicates that a thermocouple is no longer

functioning, it is important to replace the malfunctioning thermocouple with the

same type model thermocouple that was originally provided with the oven.

Replacement extension wires and connectors must also be compatible with the

thermocouple and the controller. If your system has a Eurotherm controller a

failed thermocouple will be indicated by SBR on the display and for a Yokogawa

controller it will indicate B.OUT. Refer to the replacement parts list to determine

the type of thermocouple required.

NOTE: Polarity of the thermocouple extension wires is the

OPPOSITE of the polarity of typical electrical wiring. The red leg is always

negative for thermocouples while the black leg is always positive.

11.) ENABLING THE COOLING FUNCTION

Thermcraft, Inc. does not enable the cooling function of your oven prior to

shipment.

Following are instructions to do so.

To enable output 2A, access the configuration mode.

Put in code, if any. Default is 2.

Using the page down button, select parameter 2A.

Make the following selections:

10 :SSR

Func: Cool

Val-I: 0

Val-h: 100

Out-I: 0

Out-h: 100

Return to the main menu

Using the page button, select Access

Select Full

Using Page Button, select OP

Set Output low = -100

Set Output high = +100

SPL(-328)

12.) REPLACEMENT PARTS LIST

Description Item # Quantity Included

HEATER ELEMENT A-7506 4

THERMOCOUPLE A-7502 1

FAN MOTOR FUSE F1 1

CONTROL TRANS

PRIMARY FUSE F2 – 3 2

CONTROL TRANS

SECONDARY FUSE F4 1

LN2 CONNECTION 850635K459 1

Table of contents

Popular Oven manuals by other brands

Wood Stone

Wood Stone 4048 Installation and operation manual

montpellier

montpellier MON-SFO59LED Installation and operating instructions

Asko

Asko OT8687S Instructions for use

Euro Appliances

Euro Appliances MILAN EMEO60SX manual

Progress

Progress PBN3325X user manual

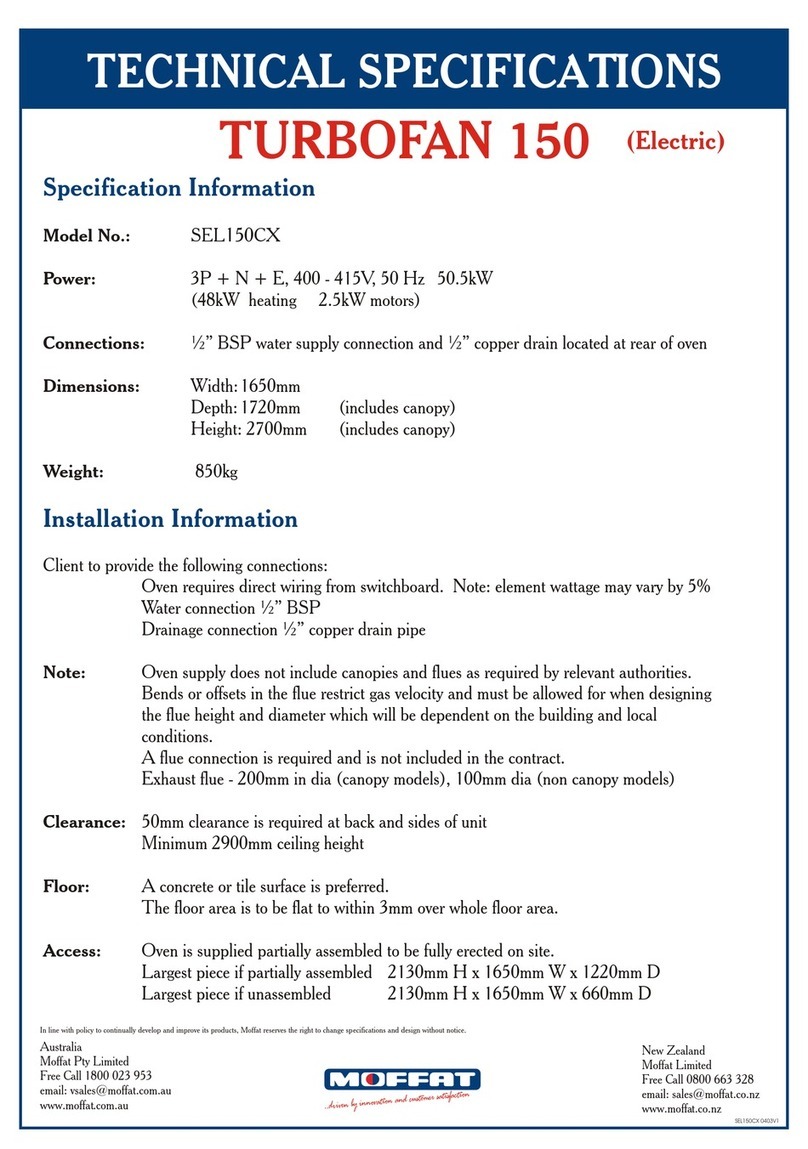

Moffat

Moffat Turbofan SEL150CX Technical specifications