Thermics LUNA 2T User manual

LUNALUNA

User terminal manual

Reversible heat pump with inverter technology

Translation of the Original Instructions Rev. 2.0

EN-GB

LUNA 2T

Dear Customer,

Thank you for choosing a Thermics energie machine, an innovative, modern and quality product that

will ensure your well-being, silence operation and safety for a long time.

This instruction manual contains important indications and suggestions that must be observed in order

to make the installation and use of the machine as easy as possible.

Thank you again.

Thermics energie

4

LUNA 2T | USE

1 Use

1.1 Control panel

The control panel consists of a display and programming keys.

1 Alarms It illuminates in the presence of alarm states.

Press the button to display the type of alarm or to reset it.

2 Programming Allows you to access the programming pages or read the

parameters.

3 ESC Allows you to exit the programming pages.

4 Up arrow Moves the blinking cursor to the previous page or increases the value

to be changed.

5 ENTER To conrm and enter the parameter to be modied.

6 Down arrow Moves the blinking cursor to the next page or decreases the value to

be changed.

7 Display Information display.

41

2

3

5

6

7

5

LUNA 2T | USE

1.2 Display

Display Description

1Operating information

2

Shortcut menu

ON-OFF unit menu.

Setpoint setting and setpoint 2 activation menu.

Operating mode change menu: heating, cooling and domestic hot water only.

Unit information display.

3

Reference temperature (DHW or system water inlet).

Standard display: the standard setpoint is active.

Negative display: setpoint 2 is active.

4Date and time.

5Active compressor with speed bar.

6DHW circulator with speed bar.

7System circulator with speed bar.

8Fan(s) with speed bar.

9

Setpoint 2 activation and/or Boost coil.

SET 2 Setpoint 2 is active and the reference temperature numbers are negative.

The DHW coil is active.

The DHW coil and setpoint 2 are active.

ii / ii / ii

ii : ii

SET2 -28.9°C

OFFbyALRM

1 2

3

4

5 12678

9

10

11

6

LUNA 2T | USE

Display Description

10

Operating modes (heating, cooling and DHW).

Operation in DHW production mode.

Operation in system heating mode.

Operation in system cooling mode.

Operation in DHW priority in heating mode.

Operation in DHW priority in cooling mode.

Defrost function active.

Drip function active.

Hot gas defrost valve open.

11 Program active.

1.2.1 Operating information

Function Description

STAND-BY All setpoints are satised, units on hold.

OFFbyALRM Unit OFF due to an active alarm.

OFFbyBMS Unit OFF from Modbus connection.

OFFbyDI Unit OFF by remote contact.

OFFbyKEYB Unit OFF from control panel.

OFFbyChgOvr Unit OFF for operating mode change.

SEASON CHG. Season change active.

PLANT REG. Unit active on system regulation

DEFROST Defrost status active.

SHUT DOWN Shut down procedure active.

CYCL. INV. Cycle inversion after defrosting.

AFREEZE ADV Advanced antifreeze mode active.

ALARMS Alarms present with unit ON.

DHW REG. Unit active on DHW regulation.

7

LUNA 2T | USE

1.3 Access levels

It has 3 consultation and programming levels:

access levels

Without password

To start/stop the unit, program the setpoints,

activate/deactivate the most common functions,

change the season and refer to the active

setpoints and the main temperatures detected.

With User password (Default: “2345”)

To check the unit's programming, change

date and time, activate a time, daily, annual

programming and make some simple settings.

With Maintainer password To read and program the setpoints and check

the machine parameters.

With Manufacturer password To read, program and edit software settings.

8

LUNA 2T | USE

1.4 Procedures

1.4.1 Machine start-up

The machine must be started up for the rst time by personnel authorised by the manufacturer.

1. Set the QF main differential switch located outside the machine to the OFF position.

2. Set any remote ON/OFF switch to OFF.

3. Remove the front panel rst, then the electrical panel.

4. Lift the lever of the compressor's thermal-magnetic circuit breaker.

5. Close the cover of the electrical panel.

6. Place the thermal-magnetic circuit breaker in the electrical panel to ON.

7. Set the QF main differential switch to ON.

8. At this point the control panel will turn on to indicate that the machine is powered.

9. To allow the oil inside the compressor to warm up, select the "OFF" operation on the control

panel and wait at least two hours before activating the unit.

1.4.2 Control panel settings

1. Enter your Service password.

2. Set the language of the control panel.

3. Set date and time.

4. Activate the remote contact (if provided) or alternatively select the function of the

multifunction input F3.

5. Modify the setpoints according to the type of system.

6. If required, set the parameters of the heating or cooling curve related to the dynamic

setpoint (not provided for the DHW setpoint).

7. Select the operating season.

8. Check the correct reading of the BT6 DHW cylinder probe (if present).

1.4.3 Entering the password

To enter the password:

1. Use the and keys to select the rst number.

2. Press the key to conrm the selected number and move on to the next number.

3. Select the next password numbers using the and keys and conrm by pressing .

9

LUNA 2T | USE

1.4.4 Starting

1. Press the and keys to select the ON/OFF menu.

2. Press the key to select ON (1).

3. Press the key to return to the main page.

4. Press the key to move to the "operating mode" menu.

5. Use the and keys to select the desired operating mode: summer, winter and DHW

only.

6. Conrm by pressing .

1.4.5 Changing the season

1. Press the and keys to select the "operation mode" menu.

2. Press the key.

3. Press the key again and select the desired operating mode: summer, winter and DHW

only (2).

Unit On/O Qa001

ON

Mode Qb005

Summer / Winter / DHW:

Summer

1

2

10

LUNA 2T | USE

1.4.6 Switching off

1. Press the and keys to select the ON/OFF menu.

2. Press the key.

3. Press the and keys to move to OFF.

4. Press to conrm.

1.4.7 Setting the setpoints

1. Press the and keys to select the "setpoint settings" menu.

2. Press to conrm.

3. The "Qb01"(3) screen displays the winter setpoints "Set" and "Set 2" (the latter is only

active if the "Set 2" mode is activated).

4. Press the key to move the cursor to the rst setpoint ("Set").

5. Press the and keys to select the desired temperature.

6. Press the key again to change the "Set 2" setpoint

7. Press the key again to move the cursor to the screen header line.

8. Press the and keys to access pages "Qb02" (domestic hot water), "Qb03" (cooling)

and "Qb04" (Set 2 setting).

9. To modify the setpoints of pages Qb02 and Qb03, repeat the operations listed above from

point 4 to 8.

10. On page "Qb04" ("Set 2" setting) it is possible to activate/deactivate the "Set 2" mode:

moving to the ON/OFF menu, press the and keys.

Heating Qb01

Set

30. 0°C

Set2: 35. 0°C

3

11

LUNA 2T | USE

1.4.8 Boost coil activation (optional)

1. Press the and keys to select the "coil" menu (4).

2. Press the key.

3. Press the key to select ON.

1.4.9 Boost coil deactivation (optional)

1. Press the and keys to select the "coil" menu.

2. Press the key.

3. Press the key to select ON.

1.4.10 Information menu display

1. Press the and keys to select the "coil" menu.

2. Press the key.

1.4.11 Setting current date and time

1. Press the key.

2. Enter the user password (see paragraph “1.4.3 Entering the password”).

3. Press the key to enter the "programming" menu.

4. Press the and keys to select "a. Date and Time".

5. Press the key to enter the "Ha001" menu.

6. Press the key again to move the cursor to the "date" eld display mode.

7. The and keys can be used to change the parameter if necessary.

8. Move the cursor back to the "date" eld by pressing .

9. Press the and keys to change the numerical value of the day.

21/08/19

10:28

28.9°C

OFFbyKEYB

4

12

LUNA 2T | USE

10. Press the key to change the month and then the year.

11. Move the cursor back to the "time" eld by pressing .

12. Press the and keys to change the hour.

13. Press the key to change the "minutes" eld.

14. Press the key again to move the cursor to the screen header line where you can select

other items from the "programming" menu.

1.4.12 Setting the language

1. Press the key.

2. Enter the user password (see paragraph “1.4.3 Entering the password”).

3. Press the key to enter the "programming" menu.

4. Press the and keys to select "H. Settings".

5. Press to conrm.

6. Press the and keys to select "c. Language".

7. Press the key to enter the "Language" menu.

8. Press the key again to move the cursor to the language selection eld.

9. Press the and keys to change the parameter if necessary.

10. Press the key to return to the Home screen.

1.4.13 Alarms

In the event of a malfunction, the alarm indication appears on the main screen:

1. Press the key to display the alarm.

2. Press the key to not reset the alarm.

3. Press the key to reset the alarm.

13

LUNA 2T | USE

1.4.14 Program activation

System program:

1. Press the key.

2. Enter the user password (see paragraph “1.4.3 Entering the password”).

3. Press the key to enter the "programming" menu.

4. Press the and keys to select "I. Time Program”

Menu "Fc001":

1. Press the key to enter the "Fc001" menu.

2. Press the key again to move the cursor to the time program enable parameter for the

"Heating/Cooling" circuit.

3. Press the and keys to change to "YES": Time, day of the week and date will be

displayed. In addition, information about the active time band and the currently active

operating mode will be displayed.

4. Press the key again to move the cursor to the screen header line.

5. Press the and keys to continue programming.

Menu "Fc002":

1. Press the key to enter the "Fc002" menu.

2. Press the key again to set the daily operation to four different time bands by moving the

cursor over the various elds.

3. In the last eld of the page it is possible to save the time program: press the key and

change the eld entry to "YES" with the and keys.

Once you have saved your selection, you can copy the settings to other days of the week:

1. Press the key to move with the cursor over the indicated eld.

2. Press the and keys to change the item by selecting the day of the week on which to

copy the daily program.

3. Once the program for the "Heating/Cooling" circuit has been completed, move the cursor

to the "Header" eld.

4. Press the key and change page with the and keys.

Menu "Fc003":

1. On page "Fc003" you can set the special operation to 3 different periods in the year using

the as described in the previous points.

Menu "Fc004":

1. On page "Fc004" you can set the special daily operation on 6 different days of the year by

moving the cursor over the various elds using the key.

IMPORTANT

You can set the DHW program (from menu "Fc005" to menu "Fc008") by following

the procedures of the system program (menu "Fc001" corresponds to menu "Fc005",

"Fc002" to "Fc006", etc.).

14

LUNA 2T | USE

1.4.15 Enabling the Supplementary Source

On the control panel:

1. The “PROGRAMMING” button can be used to access the programming menu after entering

the Service password.

2. Buttons and can be used to select the rst number of the password, after conrming

by pressing the button, you can move to the second number and so on until reaching the

fourth.

3. After selecting the fourth number and pressing , if the password is correct, you can access

the programming menu.

4. Press the and buttons, select the "D. Heater” option and press .

5. You will access menu D0001. Pressing the button will move the cursor to the parameter

for enabling the supplementary source on the system side. This will make all subsequent

screens visible for parameterization.

6. In the following screens, the operation can be adjusted by using to move the cursor to

the required eld, and to modify the parameter and by pressing again to conrm

and move the cursor to the next eld. When the cursor is in the upper left corner, you can

change page by using and.

7. Choosing functions:

By enabling the individual items, it will be possible to access the relative submenus to set the trip

thresholds according to the outdoor temperature, set a hysteresis value for the outdoor temperature and

a temperature value as an alarm threshold to activate the boiler.

The following parameters are available:

operating moDe Description

INTEGRATION The supplementary source is activated in addition to the

heat pump to generate heat

SUBSTITUTION The heat pump switches off and the supplementary source

is activated

INTEGRATION BY ALARM The supplementary source takes over from the heat pump

as it was stopped by mistake

S Heater D0003

User Functions

Integration:

Substitution:

Integration

by alarm:

15

LUNA 2T | USE

INTEGRATION

operating moDe Description

THRESH external probe value for boiler switch on

(recommended value 7°C)

DIFF hysteresis threshold between the operation of one generator

and another (recommended value 3.0°C)

DELAY boiler activation delay (recommended value 180s)

IMPORTANT

Page D0005 shows the parameters that can be used to specify when one and the other

source switches on.

These parameters should be modied by qualied technical personnel.

SUBSTITUTION

S Heater D0004

User Integration

Thresh.: 20.0°C

Di.: 2.0°C

Delay: 175s

S Heater D0006

User Substitution

Thresh.: 6.0°C

Di.: 2.0°C

operating moDe Description

THRESH external probe value for switching on (recommended value

5°C)

DIFF hysteresis threshold between switching on and off

(recommended heat 3°C)

IMPORTANT

Page D0007 displays the parameters for managing the circulator and requests.

These parameters should be modied by qualied technical personnel.

16

LUNA 2T | USE

Intervention parameters for distance from the setpoint

Screen for setting the operating mode of the warning due to an excessive divergence from the setpoint

that activates the supplementary source.

operating moDe Description

MNG.TYPE is set as active for outdoor temperature, it can also be set as

always on or always off.

SETPOINT OFFSET permitted divergence from the setpoint temperature before the

count is activated.

STARTUP

waiting time after which the supplementary source is activated,

it is activated when the reference temperature is lower than the

setpoint – offset temperature

RUN system start-up time within which the supplementary source is

not enabled in any way.

8. The conguration of the supplementary source on the DHW side then starts. Pressing

the button on page D0010 will move the cursor to the parameter for enabling the

supplementary source on the system side. This will make all subsequent screens visible for

parameterization.

9. Choosing functions:

S Heater D0012

Heater Functions

Legionella:

Integration:

Substitution:

Int. by alarm:

Int. by boost:

By enabling the individual items, it will be possible to access the relative submenus to set the trip

thresholds according to the outdoor temperature, set a hysteresis value for the outdoor temperature and

a temperature value as an alarm threshold to activate the boiler.

S Heater D0008

Low water temp.alarm

Mng.type:

Ext.Temp.Active

Setpoint oset: 5.0°C

Startup: 30min

Run: 180s

17

LUNA 2T | USE

The following parameters are available:

operating moDe Description

LEGIONELLA The supplementary source is activated to carry out the

disinfection cycle.

INTEGRATION The supplementary source is activated in addition to the heat

pump to produce DHW

SUBSTITUTION The heat pump switches off and the supplementary source is

activated

INTEGRATION BY ALARM The supplementary source takes over from the heat pump as it

was stopped by mistake

INTEGRATION BY BOOST The supplementary source is activated in addition to the heat

pump to produce DHW at a higher setpoint.

IMPORTANT

On pages D0013, D0014 and D0016, you can decide the mode and frequency of the

disinfection cycle.

On page D0016, you can also set an alarm to check how many times the cycle has not

been completed within the set time.

This parameter should be modied by qualied technical personnel.

INTEGRATION

operating moDe Description

THRESH external probe value for boiler switch on

(recommended value 7°C)

DIFF hysteresis threshold between the operation of one generator

and another (recommended value 3.0°C)

DELAY boiler activation delay (recommended value 180s)

S Heater D0017

DHW Integration

Thresh.: -5.0°C

Di.: 4.0°C

Delay: 60s

18

LUNA 2T | USE

SUBSTITUTION

operating moDe Description

THRESH external probe value for switching on (recommended value

5°C)

DIFF hysteresis threshold between switching on and off

(recommended heat 3°C)

IMPORTANT

Pages D0019 and D0020 display the parameters for managing the circulator and

requests. These parameters should be modied by qualied technical personnel.

BOOST

S Heater D0018

DHW Substitution

Thresh.: -15.0°C

Di.: 5.0°C

S Heater D0021

DHW Boost

Oset: 5.0°C

Di.: 2.0°C

Max setpoint: 85.0°C

Min setpoint: 7.0°C

operating moDe Description

OFFSET setpoint temperature increase (recommended value 5°C)

DIFF hysteresis threshold between switching on and off (recommended

heat 2 °C)

MAX SETPOINT maximum allowed resulting setpoint value

MIN SETPOINT minimum allowed resulting setpoint value

19

LUNA 2T | USE

Intervention parameters for distance from the setpoint

On this screen, we can set the operating mode of the warning due to an excessive divergence from

the setpoint that activates the supplementary source, where:

operating moDe Description

MNG.TYPE is set as active for outdoor temperature, it can also be set as

always on or always off.

SETPOINT OFFSET permitted divergence from the setpoint temperature before the

count is activated.

STARTUP

waiting time after which the supplementary source is activated,

it is activated when the reference temperature is lower than the

setpoint – offset temperature

RUN system start-up time within which the supplementary source is

not enabled in any way.

10. Pressing the ESC key repeatedly will take you back to the main screen.

S Heater D0022

Low water temp.alarm

Mng. type:

Ext. Temp. Active

Setpoint oset:

20.0°C

Startup: 45min

Run: 180s

20

LUNA 2T | USE

1.4.16 Enabling the heating or cooling curve

On the control panel:

1. The “PROGRAMMING” button can be used to access the programming menu after entering

the Service password.

2. Buttons and can be used to select the rst number of the password, after conrming

by pressing the button, you can move to the second number and so on until reaching the

fourth.

3. After selecting the fourth number and pressing , if the password is correct, you can

access the programming menu.

4. Press the and buttons, select the "A. Regulation” option and press .

5. Select the submenu “a. Plant” and press .

6. Move through the pages as far as Aa023, pressing the button will move the cursor to

the “Set. Compens. HP” and “Set. Compens. CH” parameters in order to enable the heating

or cooling curves for winter and summer respectively. This will make all subsequent screens

visible for parameterization.

7. In the following screens, the operation can be adjusted by using to move the cursor to

the required eld, and to modify the parameter and by pressing again to conrm

and move the cursor to the next eld. When the cursor is in the upper left corner, you can

change page using and .

8. Enabling heating or cooling curves

In order to provide a more efcient and rational use of energy, which is also aimed at improving the

heat comfort in the environment, temperature adjustment curves for both heating and air conditioning

can be enabled, where:

operating moDe Description

SET.COMPENS.HP enables the heating compensation curves

SET.COMPENS.CH enables the cooling compensation curves

S Plant Aa023

Functions selection

Set. compens .HP:

Set. compens .CH:

Other manuals for LUNA 2T

2

Table of contents

Popular Control Panel manuals by other brands

Carrier

Carrier INFINITY ZONING CONTROL installation instructions

My ADT

My ADT DSC Power PC1864 quick guide

Truma

Truma CP operating instructions

Honeywell

Honeywell ControLinks YP7999A1000 installation instructions

Mircom

Mircom FR-320 Series Installation and operation manual

Coastal Climate Control

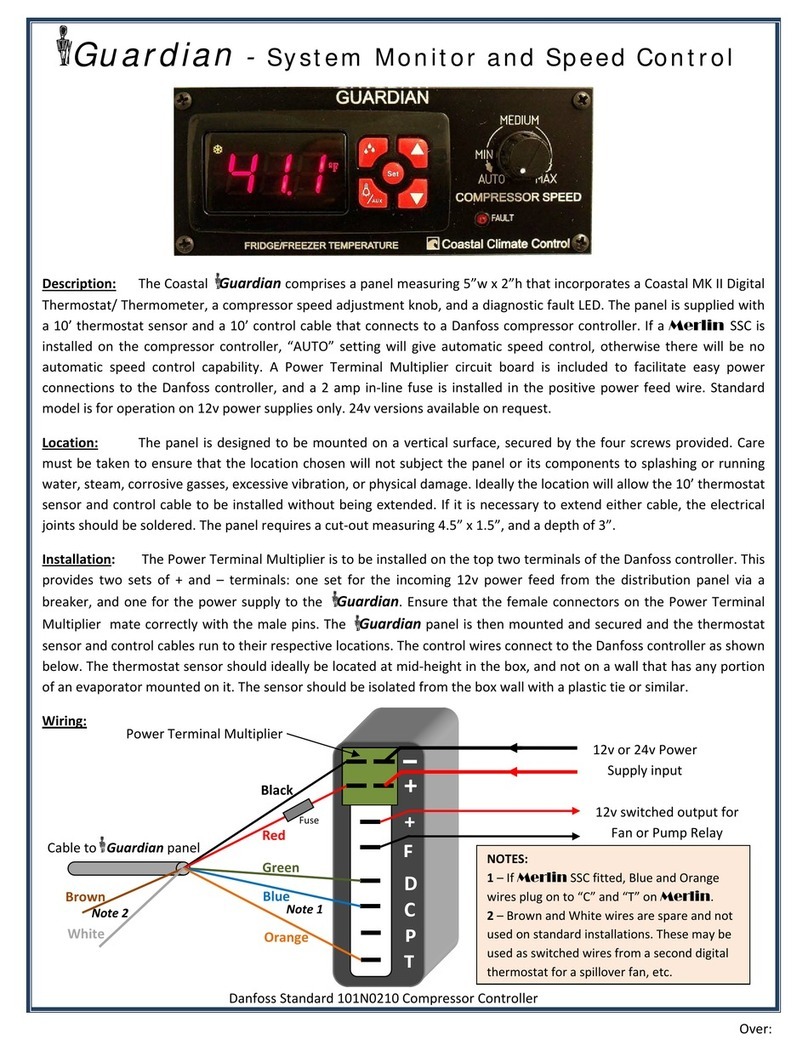

Coastal Climate Control Guardian manual